- Wireless Door Lock Control System (for Gasoline Model with Smart Key System)

- Smart Key System (for Gasoline Model, Entry Function)

- Smart Key System (for Gasoline Model, Start Function)

- Steering lock function*1

| Last Modified: 01-27-2025 | 6.11:8.1.0 | Doc ID: RM100000002Q1C0 |

| Model Year Start: 2025 | Model: GR Corolla | Prod Date Range: [09/2024 - ] |

| Title: G16E-GTS (ENGINE MECHANICAL): REAR CRANKSHAFT OIL SEAL: REMOVAL; 2025 MY GR Corolla [09/2024 - ] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during rear crankshaft oil seal removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

*1:w/ Steering Lock Function

*2: Not necessary when ECM replaced with new one. *3: If transaxle compensation code read from ECM *4: If transaxle compensation code not read from ECM |

|||

|

Replacement of ECM |

Perform Vehicle Identification Number (VIN) or frame number registration |

MIL illuminates |

|

|

ECU configuration |

- |

||

|

Update ECU security key |

Vehicle Control History (RoB) are stored |

||

|

Heavy Knock History |

- |

||

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

||

|

Code registration (Smart Key System (for Gasoline Model, Start Function)) |

|

||

for UC80F

|

|

||

|

Inspection After Repair |

|

|

|

Automatic transaxle assembly |

|

|

|

|

Automatic transaxle fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly |

|

|

Front wheel alignment adjustment |

|

|

|

|

Tire |

ECU Data Initialization (When performing tire replacement after RoB code X2104 is output) |

Active Torque Split AWD System |

|

NOTICE:

This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

HINT:

When the cable is disconnected / reconnected to the auxiliary battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

-

Learning completes when vehicle is driven

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Front Camera System

Drive the vehicle straight ahead at 35 km/h (22 mph) or more for 5 seconds or more.

-

Learning completes when vehicle is operated normally

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Power door lock control system

- Back door opener

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch.

PROCEDURE

1. REMOVE COVER AND DISC CLUTCH SET (for Manual Transaxle)

2. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY (for Automatic Transaxle)

3. REMOVE FLYWHEEL SUB-ASSEMBLY (for Manual Transaxle)

(a) Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat level surface.

NOTICE:

- Using height adjustment attachments and plate lift attachments, keep the engine assembly level.

- To prevent the oil pan sub-assembly from deforming, do not place any attachments under the oil pan sub-assembly of the engine assembly.

- Using an engine sling device and engine lift, secure the engine assembly before servicing.

|

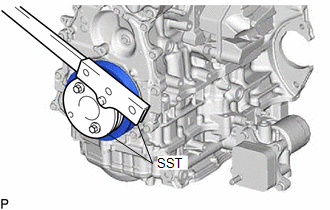

(b) Using SST, hold the crankshaft pulley assembly. SST: 09213-54015 SST: 09330-00021 |

|

|

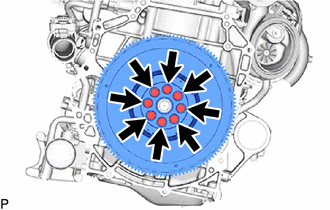

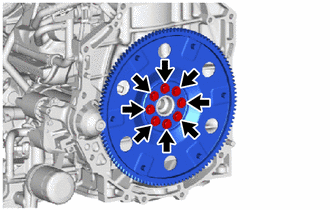

(c) Remove the 8 bolts and flywheel sub-assembly. |

|

4. REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY (for Automatic Transaxle)

(a) Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat level surface.

NOTICE:

- Using height adjustment attachments and plate lift attachments, keep the engine assembly level.

- To prevent the oil pan sub-assembly from deforming, do not place any attachments under the oil pan sub-assembly of the engine assembly.

- Using an engine sling device and engine lift, secure the engine assembly before servicing.

|

(b) Using SST, hold the crankshaft pulley assembly. SST: 09213-54015 SST: 09330-00021 |

|

|

(c) Remove the 8 bolts, drive plate and ring gear sub-assembly and rear drive plate spacer. |

|

5. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE

|

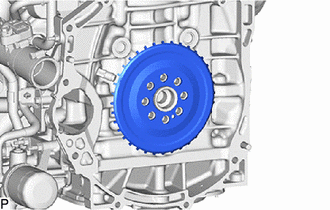

(a) Remove the No. 1 crankshaft position sensor plate. |

|

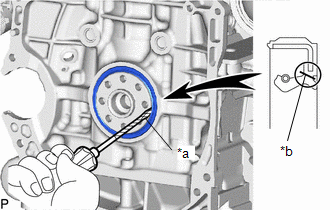

6. REMOVE REAR ENGINE OIL SEAL

|

(a) Using a knife, cut off the lip of the rear engine oil seal. |

|

(b) Using a screwdriver, pry out the rear engine oil seal.

NOTICE:

Do not damage the surface of the rear engine oil seal press fit hole or the crankshaft.

HINT:

Tape the screwdriver tip before use.

|

|

|

![2023 - 2025 MY GR Corolla [09/2022 - ]; G16E-GTS (ENGINE CONTROL): SFI SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)