| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM100000002D0EI |

| Model Year Start: 2024 | Model: GR Corolla | Prod Date Range: [08/2023 - ] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model with Electric Parking Brake System): C051249; Right Rear Wheel Speed Sensor Internal Electronic Failure; 2024 - 2025 MY Corolla Corolla Hatchback GR Corolla [08/2023 - ] | ||

|

DTC |

C051249 |

Right Rear Wheel Speed Sensor Internal Electronic Failure |

DESCRIPTION

When the system is starting up and the skid control ECU (brake actuator assembly) detects a speed sensor circuit malfunction via the speed sensor circuit self-diagnosis function, this DTC is stored.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Note |

|---|---|---|---|---|---|

|

C051249 |

Right Rear Wheel Speed Sensor Internal Electronic Failure |

A circuit malfunction in the speed sensor is detected during the self test. |

|

Comes on |

SAE Code: C0512 |

MONITOR DESCRIPTION

The skid control ECU (brake actuator assembly) has a speed sensor circuit self-diagnosis function.

When the self-diagnosis function that is performed during startup detects a speed sensor circuit malfunction, the skid control ECU (brake actuator assembly) illuminates the MIL and stores this DTC.

MONITOR STRATEGY

|

Related DTCs |

C0512: Wheel speed sensor start up test for RR |

|

Required Sensors/Components(Main) |

Skid control ECU (brake actuator assembly) |

|

Required Sensors/Components(Related) |

Skid control ECU (brake actuator assembly) |

|

Frequency of Operation |

During initial checking |

|

Duration |

- |

|

MIL Operation |

Immediately |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

Monitor runs whenever the following DTCs are not stored |

TMC's intellectual property |

|

Other conditions belong to TMC's intellectual property |

- |

TYPICAL MALFUNCTION THRESHOLDS

|

TMC's intellectual property |

- |

COMPONENT OPERATING RANGE

|

TMC's intellectual property |

- |

CONFIRMATION DRIVING PATTERN

NOTICE:

When performing the normal judgment procedure, make sure that the driver door is closed and is not opened at any time during the procedure.

HINT:

- After repair has been completed, clear the DTC and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

- When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON and turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off.

- Turn the ignition switch to ON and turn the GTS on.

-

Wait for 1 second or more. [*]

HINT:

[*]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

-

Enter the following menus: Chassis / Brake/EPB* / Utility / All Readiness.

*: Electric Parking Brake System

-

Check the DTC judgment result.

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE, perform driving pattern again.

WIRING DIAGRAM

Refer to DTC C051212.

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (SENSOR CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

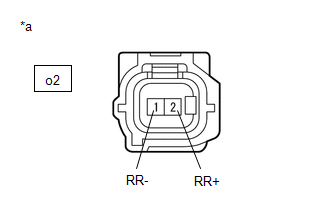

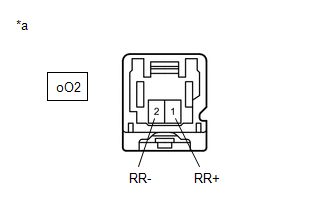

(b) Disconnect the o2 rear speed sensor RH (rear axle hub and bearing assembly RH) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the ignition switch to ON.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

o2-2 (RR+) - o2-1 (RR-) |

Ignition switch ON |

11 to 14 V |

| NG |

|

|

|

2. |

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

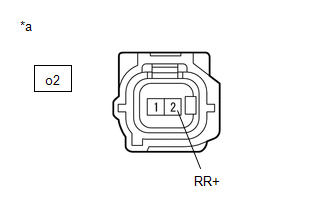

(b) Disconnect the o2 rear speed sensor RH (rear axle hub and bearing assembly RH) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

o2-2 (RR+) - Body ground |

Ignition switch off |

Below 1.5 V |

| NG |

|

|

|

3. |

INSPECT NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

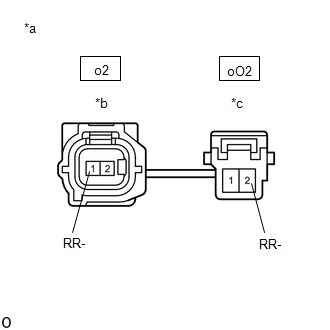

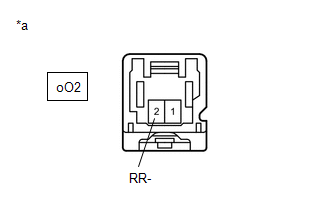

(b) Disconnect the o2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

o2-1 (RR-) or oO2-2 (RR-) - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG |

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

|

4. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-2 (RR-) or A51-37 (RR-) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

REPLACE REAR AXLE HUB AND BEARING ASSEMBLY RH |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

5. |

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

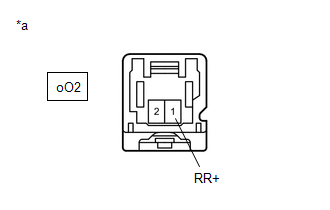

|

(b) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-1 (RR+) - Body ground |

Ignition switch off |

Below 1.5 V |

| OK |

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

|

6. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-1 (RR+) - Body ground |

Always |

Below 1.5 V |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

7. |

CHECK HARNESS AND CONNECTOR (SENSOR CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the ignition switch to ON.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-1 (RR+) - oO2-2 (RR-) |

Ignition switch ON |

11 to 14 V |

| OK |

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

|

8. |

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the ignition switch to ON.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-1 (RR+) - Body ground |

Ignition switch ON |

11 to 14 V |

| NG |

|

|

|

9. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-2 (RR-) - Body ground |

Always |

Below 1.5 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

10. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-2 (RR-) - A51-37 (RR-) |

Always |

Below 1 Ω |

|

oO2-1 (RR+) or A51-22 (RR+) - oO2-2 (RR-) or A51-37 (RR-) |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

11. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-1 (RR+) - A51-22 (RR+) |

Always |

Below 1 Ω |

|

oO2-1 (RR+) or A51-22 (RR+) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2024 - 2025 MY Corolla Corolla Hatchback GR Corolla [08/2023 - ]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model with Electric Parking Brake System): C051212; Right Rear Wheel Speed Sensor Circuit Short to Battery](/t3Portal/stylegraphics/info.gif)