| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM100000002D0DS |

| Model Year Start: 2024 | Model: GR Corolla | Prod Date Range: [08/2023 - ] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model with Electric Parking Brake System): C050612; Right Front Wheel Speed Sensor Circuit Short to Battery; 2024 - 2025 MY Corolla Corolla Hatchback GR Corolla [08/2023 - ] | ||

|

DTC |

C050612 |

Right Front Wheel Speed Sensor Circuit Short to Battery |

DESCRIPTION

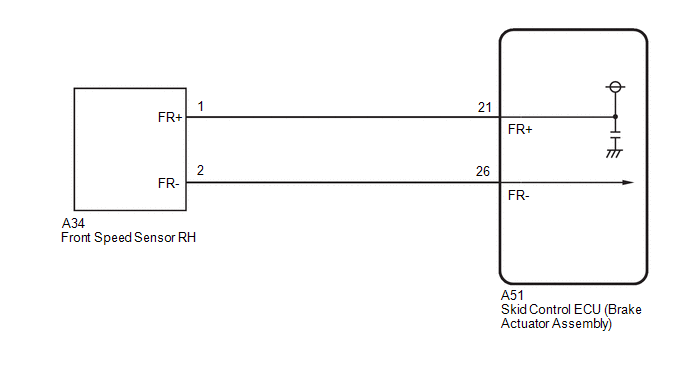

Each speed sensor detects wheel speed and sends signals to the skid control ECU (brake actuator assembly). These signals are used by the ABS control.

The speed sensor detects the magnetic fields of the speed sensor rotor as it rotates and outputs a pulse signal.

The frequency of the pulse varies in accordance with the rotational speed of the speed sensor rotor and the system uses this to determine the wheel speed.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Note |

|---|---|---|---|---|---|

|

C050612 |

Right Front Wheel Speed Sensor Circuit Short to Battery |

A short to +B in the speed sensor signal circuit is detected for 0.12 seconds or more. |

|

Comes on |

SAE Code: C0509 |

MONITOR DESCRIPTION

The skid control ECU (brake actuator assembly) has a speed sensor circuit self-diagnosis function.

When the self-diagnosis function that is performed during startup detects that the current of the speed sensor circuit exceeds a certain value, the skid control ECU (brake actuator assembly) illuminates the MIL and stores this DTC.

MONITOR STRATEGY

|

Related DTCs |

C0509: Wheel speed sensor line monitoring for FR (signal line short to BATT) |

|

Required Sensors/Components(Main) |

Skid control ECU (brake actuator assembly) |

|

Required Sensors/Components(Related) |

Skid control ECU (brake actuator assembly) |

|

Frequency of Operation |

Continuous |

|

Duration |

0.12 seconds |

|

MIL Operation |

2 driving cycles |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

Monitor runs whenever the following DTCs are not stored |

TMC's intellectual property |

|

Other conditions belong to TMC's intellectual property |

- |

TYPICAL MALFUNCTION THRESHOLDS

|

TMC's intellectual property |

- |

COMPONENT OPERATING RANGE

|

TMC's intellectual property |

- |

CONFIRMATION DRIVING PATTERN

NOTICE:

When performing the normal judgment procedure, make sure that the driver door is closed and is not opened at any time during the procedure.

HINT:

- After repair has been completed, clear the DTC and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

- When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON and turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off.

- Turn the ignition switch to ON and turn the GTS on.

-

Wait for 1 second or more. [*]

HINT:

[*]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

-

Enter the following menus: Chassis / Brake/EPB* / Utility / All Readiness.

*: Electric Parking Brake System

-

Check the DTC judgment result.

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE, perform driving pattern again.

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (SENSOR GROUND CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

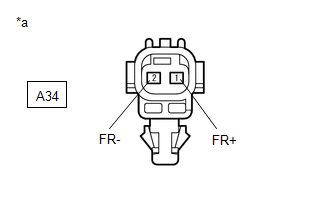

(b) Disconnect the A34 front speed sensor RH connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the ignition switch to ON.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A34-1 (FR+) - A34-2 (FR-) |

Ignition switch ON |

11 to 14 V |

| OK |

|

|

|

2. |

CHECK HARNESS AND CONNECTOR (FRONT SPEED SENSOR RH - BRAKE ACTUATOR ASSEMBLY) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

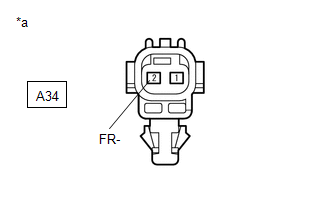

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the A34 front speed sensor RH connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A34-2 (FR-) - Body ground |

Always |

Below 1.5 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK HARNESS AND CONNECTOR (FRONT SPEED SENSOR RH - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the A34 front speed sensor RH connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A34-1 (FR+) or A51-21 (FR+) - A34-2 (FR-) or A51-26 (FR-) |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|