|

Last Modified: 05-13-2024 |

6.11:8.1.0 |

Doc ID: RM100000002BA0B |

|

Model Year Start: 2023 |

Model: Corolla Hatchback |

Prod Date Range: [03/2023 -

] |

|

Title: M20A-FKS (ENGINE MECHANICAL): CYLINDER HEAD GASKET: REMOVAL; 2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ] |

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during cylinder head gasket removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure

|

Necessary Procedure

|

Effect/Inoperative Function when Necessary Procedure not Performed

|

Link

|

|

Replacement of ECM

|

Vehicle Identification Number (VIN) registration

|

MIL comes on

|

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE CONTROL): SFI SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

|

|

-

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - ]; SETUP: WHEN REPLACING OR REMOVING/INSTALLING PARTS: ECU CONFIGURATION](/t3Portal/stylegraphics/info.gif)

|

|

Update ECU security key

|

Vehicle Control History (RoB) are stored

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - ]; SETUP: WHEN REPLACING OR REMOVING/INSTALLING PARTS: UPDATE ECU SECURITY KEY](/t3Portal/stylegraphics/info.gif)

|

|

ECU communication ID registration (Immobiliser system)

|

Engine start function

|

![2023 - 2025 MY Corolla Corolla Hatchback GR Corolla [11/2022 - ]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

|

Replacement of ECM*3

|

Code registration (Smart Key System (for Gasoline Model, Start Function))

|

-

Wireless Door Lock Control System (for Gasoline Model with Smart Key System)

-

Smart Key System (for Gasoline Model, Entry Function)

-

Smart Key System (for Gasoline Model, Start Function)

-

Steering lock function*1

|

![2023 - 2025 MY Corolla Corolla Hatchback GR Corolla [11/2022 - ]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

|

Replacement of ECM*2

|

Code registration (Immobiliser system)

|

-

Engine start

-

Telematics System

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [11/2022 - ]; THEFT DETERRENT / KEYLESS ENTRY: IMMOBILISER SYSTEM (w/o Smart Key System): REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

-

Gas leak from exhaust system is repaired

-

Replacement of throttle body with motor assembly

-

Replacement of cam timing control motor with EDU assembly

-

Removal and installation of a cam timing control motor with EDU assembly

-

Replacement of camshaft timing gear assembly

-

Removal and installation of a camshaft timing gear assembly

-

Replacement of cylinder head sub-assembly

-

Replacement of camshaft (for intake or exhaust camshaft)

-

Replacement of camshaft timing exhaust gear assembly

-

Replacement of port fuel injector assembly

-

Replacement of direct fuel injector assembly

-

Replacement of fuel pump assembly (for high pressure side)

-

Replacement of spark plug

-

Replacement of ignition coil assembly

-

Replacement of EGR valve assembly

-

Replacement of knock control sensor

-

Replacement of air fuel ratio sensor (sensor 2)

|

Inspection After Repair

|

-

Poor idle, etc.

-

Engine start function, etc.

|

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (ENGINE CONTROL): SFI SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Replacement of continuously variable transaxle assembly

|

for K120

-

Input transaxle compensation code into TCM

-

Perform reset memory

-

CVT oil pressure calibration

-

Perform road test to allow TCM to learn

|

-

Large shift shock

-

Deterioration of fuel efficiency

|

Initialization:

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; K120 / K121 (CVT): K120 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

Registration:

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; K120 / K121 (CVT): K120 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

for K121

-

Input transaxle compensation code into ECM

-

Perform reset memory

-

CVT oil pressure calibration

-

Perform road test to allow ECM to learn

|

-

Large shift shock

-

Deterioration of fuel efficiency

|

Initialization:

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

Registration:

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

|

Replacement of ECM

|

for K120

-

Perform reset memory

-

CVT oil pressure calibration

-

Perform road test to allow TCM to learn

|

-

Large shift shock

-

Deterioration of fuel efficiency

|

Initialization:

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; K120 / K121 (CVT): K120 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

Registration:

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; K120 / K121 (CVT): K120 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

for K121

-

Transfer transaxle compensation code*5

-

Reset transaxle compensation code*6

-

CVT oil pressure calibration

-

Perform road test to allow ECM to learn

|

-

Large shift shock

-

Deterioration of fuel efficiency

|

Initialization:

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

Registration:

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

|

Front wheel alignment adjustment

|

-

Perform "Reset Memory"

-

Perform "Calibration"

|

-

VSC is disabled or malfunctions

-

DTCs are output

-

Slip indicator light illuminates

-

ABS warning light illuminates

|

w/ Electric Parking Brake System:

![2023 - 2025 MY Corolla Corolla Hatchback GR Corolla [11/2022 - ]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model with Electric Parking Brake System): UTILITY](/t3Portal/stylegraphics/info.gif)

w/o Electric Parking Brake System:

![2023 - 2025 MY Corolla Corolla Hatchback GR Corolla [09/2022 - ]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model without Electric Parking Brake System TMC Made): UTILITY](/t3Portal/stylegraphics/info.gif)

|

|

CVT fluid

|

ATF thermal degradation estimate reset

|

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly

|

for K120:

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; K120 / K121 (CVT): K120 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

for K121:

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

-

Steering gear assembly*4

-

No. 2 steering intermediate shaft assembly*4

|

for TMC Made

-

End position initial setting

|

-

|

![2023 - 2025 MY Corolla Corolla Hatchback GR Corolla [09/2022 - ]; POWER ASSIST SYSTEMS: POWER STEERING SYSTEM (for Gasoline Model): CALIBRATION](/t3Portal/stylegraphics/info.gif)

|

NOTICE:

This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here

![2019 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [06/2018 - ]; INTRODUCTION: REPAIR INSTRUCTION: PRECAUTION](/t3Portal/stylegraphics/info.gif)

HINT:

When the cable is disconnected / reconnected to the battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

Learning completes when vehicle is driven

|

Effect/Inoperative Function when Necessary Procedure not Performed

|

Necessary Procedure

|

Link

|

|

Front Camera System

|

Drive the vehicle straight ahead at 15 km/h (9 mph) or more for 1 second or more.

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [11/2022 - ]; ADVANCED DRIVER ASSISTANCE SYSTEM: FRONT CAMERA SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

Learning completes when vehicle is operated normally

|

Effect/Inoperative Function when Necessary Procedure not Performed

|

Necessary Procedure

|

Link

|

|

Power Door Lock Control System

|

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch.

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [11/2022 - ]; DOOR LOCK: POWER DOOR LOCK CONTROL SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

PROCEDURE

1. INSTALL ENGINE ASSEMBLY TO ENGINE STAND

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE ASSEMBLY: REMOVAL](/t3Portal/stylegraphics/info.gif)

2. REMOVE ENGINE HANGER

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE ASSEMBLY: REMOVAL+](/t3Portal/stylegraphics/info.gif)

3. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: REMOVAL+](/t3Portal/stylegraphics/info.gif)

4. REMOVE NO. 2 WATER BY-PASS PIPE SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: REMOVAL+](/t3Portal/stylegraphics/info.gif)

5. REMOVE FLOW SHUTTING VALVE (WATER BY-PASS HOSE ASSEMBLY)

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: REMOVAL+](/t3Portal/stylegraphics/info.gif)

6. REMOVE NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

for Double Wishbone Type Suspension: Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (INTAKE / EXHAUST): EXHAUST MANIFOLD (for Double Wishbone Type Suspension): REMOVAL+](/t3Portal/stylegraphics/info.gif)

for Torsion Beam Type Suspension: Click here

![2023 - 2025 MY Corolla Corolla Hatchback [09/2022 - ]; M20A-FKS (INTAKE / EXHAUST): EXHAUST MANIFOLD (for Torsion Beam Type Suspension): REMOVAL+](/t3Portal/stylegraphics/info.gif)

7. REMOVE EXHAUST MANIFOLD (TWC: Front Catalyst)

for Double Wishbone Type Suspension: Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (INTAKE / EXHAUST): EXHAUST MANIFOLD (for Double Wishbone Type Suspension): REMOVAL+](/t3Portal/stylegraphics/info.gif)

for Torsion Beam Type Suspension: Click here

![2023 - 2025 MY Corolla Corolla Hatchback [09/2022 - ]; M20A-FKS (INTAKE / EXHAUST): EXHAUST MANIFOLD (for Torsion Beam Type Suspension): REMOVAL+](/t3Portal/stylegraphics/info.gif)

8. REMOVE THROTTLE BODY WITH MOTOR ASSEMBLY

Click here

![2020 - 2025 MY Corolla Corolla Hatchback [09/2019 - ]; M20A-FKS (ENGINE CONTROL): THROTTLE BODY: REMOVAL+](/t3Portal/stylegraphics/info.gif)

9. REMOVE THROTTLE BODY GASKET

Click here

![2020 - 2025 MY Corolla Corolla Hatchback [09/2019 - ]; M20A-FKS (ENGINE CONTROL): THROTTLE BODY: REMOVAL+](/t3Portal/stylegraphics/info.gif)

10. REMOVE EGR COOLER ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (EMISSION CONTROL): EGR COOLER: REMOVAL+](/t3Portal/stylegraphics/info.gif)

11. REMOVE NO. 1 EGR PIPE SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [09/2022 - ]; M20A-FKS (EMISSION CONTROL): EGR VALVE: REMOVAL+](/t3Portal/stylegraphics/info.gif)

12. REMOVE EGR VALVE ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [09/2022 - ]; M20A-FKS (EMISSION CONTROL): EGR VALVE: REMOVAL+](/t3Portal/stylegraphics/info.gif)

13. REMOVE NO. 3 WATER BY-PASS PIPE

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: REMOVAL+](/t3Portal/stylegraphics/info.gif)

14. REMOVE INTAKE MANIFOLD STAY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (INTAKE / EXHAUST): INTAKE MANIFOLD: REMOVAL+](/t3Portal/stylegraphics/info.gif)

15. DISCONNECT NO. 1 FUEL VAPOR FEED HOSE

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (INTAKE / EXHAUST): INTAKE MANIFOLD: REMOVAL+](/t3Portal/stylegraphics/info.gif)

16. REMOVE INTAKE MANIFOLD

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (INTAKE / EXHAUST): INTAKE MANIFOLD: REMOVAL+](/t3Portal/stylegraphics/info.gif)

17. REMOVE NO. 1 INTAKE MANIFOLD TO HEAD GASKET

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (INTAKE / EXHAUST): INTAKE MANIFOLD: REMOVAL+](/t3Portal/stylegraphics/info.gif)

18. DISCONNECT FUEL TUBE SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: REMOVAL+](/t3Portal/stylegraphics/info.gif)

19. REMOVE NO. 1 FUEL PIPE SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: REMOVAL+](/t3Portal/stylegraphics/info.gif)

20. REMOVE FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure)

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (FUEL): FUEL PUMP (for High Pressure): REMOVAL+](/t3Portal/stylegraphics/info.gif)

21. REMOVE NO. 1 WATER BY-PASS HOSE ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: REMOVAL+](/t3Portal/stylegraphics/info.gif)

22. REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (FUEL): FUEL INJECTOR (for Port Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

23. REMOVE FUEL DELIVERY SPACER

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (FUEL): FUEL INJECTOR (for Port Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

24. REMOVE INJECTOR VIBRATION INSULATOR

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (FUEL): FUEL INJECTOR (for Port Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

25. REMOVE NO. 5 ENGINE WIRE

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (FUEL): FUEL INJECTOR (for Port Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

26. REMOVE PORT FUEL INJECTOR ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (FUEL): FUEL INJECTOR (for Port Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

27. REMOVE FUEL DELIVERY PIPE

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (FUEL): FUEL INJECTOR (for Direct Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

28. REMOVE DIRECT FUEL INJECTOR ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (FUEL): FUEL INJECTOR (for Direct Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

29. REMOVE FUEL INJECTOR SEAL

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (FUEL): FUEL INJECTOR (for Direct Injection): REMOVAL+](/t3Portal/stylegraphics/info.gif)

30. REMOVE IGNITION COIL ASSEMBLY

Click here

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE CONTROL): IGNITION COIL AND SPARK PLUG: REMOVAL+](/t3Portal/stylegraphics/info.gif)

31. REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: REMOVAL+](/t3Portal/stylegraphics/info.gif)

32. REMOVE VACUUM SURGE TANK

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: REMOVAL+](/t3Portal/stylegraphics/info.gif)

33. REMOVE OIL PRESSURE CONTROL VALVE ASSEMBLY

Click here

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (LUBRICATION): OIL PRESSURE SWITCHING VALVE: REMOVAL+](/t3Portal/stylegraphics/info.gif)

34. REMOVE CAMSHAFT POSITION SENSOR (for Intake Side)

Click here

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE CONTROL): CAMSHAFT POSITION SENSOR: REMOVAL+](/t3Portal/stylegraphics/info.gif)

35. REMOVE CAMSHAFT POSITION SENSOR (for Exhaust Side)

Click here

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE CONTROL): CAMSHAFT POSITION SENSOR: REMOVAL+](/t3Portal/stylegraphics/info.gif)

36. REMOVE CAM TIMING OIL CONTROL SOLENOID ASSEMBLY

Click here

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE CONTROL): CAMSHAFT OIL CONTROL SOLENOID: REMOVAL+](/t3Portal/stylegraphics/info.gif)

37. REMOVE CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE CONTROL): CAMSHAFT TIMING CONTROL MOTOR: REMOVAL+](/t3Portal/stylegraphics/info.gif)

38. REMOVE CAM TIMING CONTROL MOTOR O-RING

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE CONTROL): CAMSHAFT TIMING CONTROL MOTOR: REMOVAL+](/t3Portal/stylegraphics/info.gif)

39. REMOVE VACUUM PUMP ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; BRAKE SYSTEM (OTHER): VACUUM PUMP (for M20A-FKS): REMOVAL+](/t3Portal/stylegraphics/info.gif)

40. REMOVE CRANKSHAFT PULLEY ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

41. REMOVE WATER OUTLET

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

42. REMOVE WATER BY-PASS OUTLET SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

43. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

44. REMOVE SPARK PLUG TUBE GASKET

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

45. REMOVE ENGINE MOUNTING BRACKET RH

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

46. REMOVE NO. 2 TIMING CHAIN COVER ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

47. REMOVE TIMING CHAIN COVER OIL SEAL

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

48. SET NO. 1 CYLINDER TO TDC (COMPRESSION)

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

49. REMOVE OIL PUMP DRIVE CHAIN SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

50. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

51. REMOVE CHAIN SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

52. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

53. REMOVE CHAIN TENSIONER SLIPPER

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

54. REMOVE NO. 1 CHAIN VIBRATION DAMPER

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

55. REMOVE CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

56. REMOVE TIMING CHAIN COVER ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

57. REMOVE FUEL PUMP LIFTER GUIDE

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

58. REMOVE CAMSHAFT HOUSING SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

59. REMOVE CAMSHAFT BEARING CAP

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

60. REMOVE INTAKE CAMSHAFT SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

61. REMOVE EXHAUST CAMSHAFT SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

62. REMOVE NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

63. REMOVE VALVE LASH ADJUSTER ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

64. REMOVE CYLINDER HEAD SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

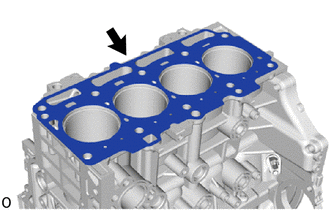

65. REMOVE CYLINDER HEAD GASKET

(a) Remove the cylinder head gasket from the cylinder block sub-assembly.

66. INSPECT CYLINDER HEAD SET BOLT

Click here

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: INSPECTION+](/t3Portal/stylegraphics/info.gif)

67. INSPECT CYLINDER HEAD SUB-ASSEMBLY

Click here

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE MECHANICAL): CYLINDER HEAD: INSPECTION+](/t3Portal/stylegraphics/info.gif)

|