|

Last Modified: 05-13-2024 |

6.11:8.1.0 |

Doc ID: RM100000002BA09 |

|

Model Year Start: 2023 |

Model: Corolla Hatchback |

Prod Date Range: [03/2023 -

] |

|

Title: M20A-FKS (ENGINE MECHANICAL): CAMSHAFT: REMOVAL; 2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ] |

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during camshaft removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure

|

Necessary Procedure

|

Effect/Inoperative Function when Necessary Procedure not Performed

|

Link

|

|

Replacement of ECM

|

Vehicle Identification Number (VIN) registration

|

MIL comes on

|

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE CONTROL): SFI SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

|

|

-

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - ]; SETUP: WHEN REPLACING OR REMOVING/INSTALLING PARTS: ECU CONFIGURATION](/t3Portal/stylegraphics/info.gif)

|

|

Update ECU security key

|

Vehicle Control History (RoB) are stored

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - ]; SETUP: WHEN REPLACING OR REMOVING/INSTALLING PARTS: UPDATE ECU SECURITY KEY](/t3Portal/stylegraphics/info.gif)

|

|

ECU communication ID registration (Immobiliser system)

|

Engine start function

|

![2023 - 2025 MY Corolla Corolla Hatchback GR Corolla [11/2022 - ]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

|

Replacement of ECM*3

|

Code registration (Smart Key System (for Gasoline Model, Start Function))

|

-

Wireless Door Lock Control System (for Gasoline Model with Smart Key System)

-

Smart Key System (for Gasoline Model, Entry Function)

-

Smart Key System (for Gasoline Model, Start Function)

-

Steering lock function*1

|

![2023 - 2025 MY Corolla Corolla Hatchback GR Corolla [11/2022 - ]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

|

Replacement of ECM*2

|

Code registration (Immobiliser system)

|

-

Engine start

-

Telematics System

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [11/2022 - ]; THEFT DETERRENT / KEYLESS ENTRY: IMMOBILISER SYSTEM (w/o Smart Key System): REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

-

Gas leak from exhaust system is repaired

-

Replacement of cam timing control motor with EDU assembly

-

Removal and installation of a cam timing control motor with EDU assembly

-

Replacement of camshaft timing gear assembly

-

Removal and installation of a camshaft timing gear assembly

-

Replacement of camshaft (for intake or exhaust camshaft)

-

Replacement of camshaft timing exhaust gear assembly

-

Replacement of fuel pump assembly (for high pressure side)

-

Replacement of ignition coil assembly

-

Replacement of air fuel ratio sensor (sensor 2)

|

Inspection After Repair

|

-

Poor idle, etc.

-

Engine start function, etc.

|

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (ENGINE CONTROL): SFI SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Replacement of ECM

|

for K120

-

Perform reset memory

-

CVT oil pressure calibration

-

Perform road test to allow TCM to learn

|

-

Large shift shock

-

Deterioration of fuel efficiency

|

Initialization:

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; K120 / K121 (CVT): K120 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

Registration:

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; K120 / K121 (CVT): K120 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

for K121

-

Transfer transaxle compensation code*4

-

Reset transaxle compensation code*5

-

CVT oil pressure calibration

-

Perform road test to allow ECM to learn

|

-

Large shift shock

-

Deterioration of fuel efficiency

|

Initialization:

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

Registration:

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

|

NOTICE:

This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here

![2019 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [06/2018 - ]; INTRODUCTION: REPAIR INSTRUCTION: PRECAUTION](/t3Portal/stylegraphics/info.gif)

HINT:

When the cable is disconnected / reconnected to the battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

Learning completes when vehicle is driven

|

Effect/Inoperative Function when Necessary Procedure not Performed

|

Necessary Procedure

|

Link

|

|

Front Camera System

|

Drive the vehicle straight ahead at 15 km/h (9 mph) or more for 1 second or more.

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [11/2022 - ]; ADVANCED DRIVER ASSISTANCE SYSTEM: FRONT CAMERA SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

Learning completes when vehicle is operated normally

|

Effect/Inoperative Function when Necessary Procedure not Performed

|

Necessary Procedure

|

Link

|

|

Power Door Lock Control System

|

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch.

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [11/2022 - ]; DOOR LOCK: POWER DOOR LOCK CONTROL SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

PROCEDURE

1. INSTALL ENGINE SUPPORT BRIDGE

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE CONTROL): CAMSHAFT TIMING CONTROL MOTOR: REMOVAL](/t3Portal/stylegraphics/info.gif)

2. REMOVE ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE CONTROL): CAMSHAFT TIMING CONTROL MOTOR: REMOVAL+](/t3Portal/stylegraphics/info.gif)

3. REMOVE FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure)

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (FUEL): FUEL PUMP (for High Pressure): REMOVAL](/t3Portal/stylegraphics/info.gif)

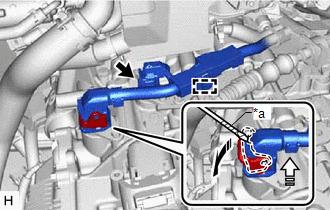

4. DISCONNECT NO. 1 VACUUM HOSE CONNECTOR

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; BRAKE SYSTEM (OTHER): VACUUM PUMP (for M20A-FKS): REMOVAL+](/t3Portal/stylegraphics/info.gif)

5. SEPARATE ENGINE WIRE

|

(a) Disconnect the connector and disengage the clamp.

|

|

(b) Remove the bolt, 2 nuts and separate the engine wire.

|

(c) Disconnect the connector.

|

|

|

(d) Disconnect the 6 connectors and disengage the 3 clamps.

|

|

(e) Release the lock lever and disconnect the connector.

|

*a

|

Protective Tape

|

|

Release the lock lever

|

|

Disconnect the connector

|

(f) Disconnect the connector and disengage the clamp.

|

(g) Disconnect the connector.

|

|

|

(h) Remove the bolt and separate the vacuum surge tank.

|

|

|

(i) Disengage the 3 clamps and separate the 3 hoses.

|

|

(j) Remove the bolt and No. 3 water hose clamp bracket.

6. REMOVE VACUUM PUMP ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; BRAKE SYSTEM (OTHER): VACUUM PUMP (for M20A-FKS): REMOVAL+](/t3Portal/stylegraphics/info.gif)

7. REMOVE IGNITION COIL ASSEMBLY

Click here

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE CONTROL): IGNITION COIL AND SPARK PLUG: REMOVAL+](/t3Portal/stylegraphics/info.gif)

8. REMOVE CAMSHAFT POSITION SENSOR (for Intake Side)

Click here

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE CONTROL): CAMSHAFT POSITION SENSOR: REMOVAL+](/t3Portal/stylegraphics/info.gif)

9. REMOVE CAMSHAFT POSITION SENSOR (for Exhaust Side)

Click here

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE CONTROL): CAMSHAFT POSITION SENSOR: REMOVAL+](/t3Portal/stylegraphics/info.gif)

10. REMOVE CAM TIMING OIL CONTROL SOLENOID ASSEMBLY

Click here

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE CONTROL): CAMSHAFT OIL CONTROL SOLENOID: REMOVAL+](/t3Portal/stylegraphics/info.gif)

11. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (EXHAUST CAMSHAFT TIMING GEAR BOLT ASSEMBLY)

Click here

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE CONTROL): CAMSHAFT OIL CONTROL VALVE: REMOVAL+](/t3Portal/stylegraphics/info.gif)

12. REMOVE CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE CONTROL): CAMSHAFT TIMING CONTROL MOTOR: REMOVAL+](/t3Portal/stylegraphics/info.gif)

13. REMOVE CAM TIMING CONTROL MOTOR O-RING

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE CONTROL): CAMSHAFT TIMING CONTROL MOTOR: REMOVAL+](/t3Portal/stylegraphics/info.gif)

14. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

15. REMOVE SPARK PLUG TUBE GASKET

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

16. REMOVE FUEL PUMP LIFTER GUIDE

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

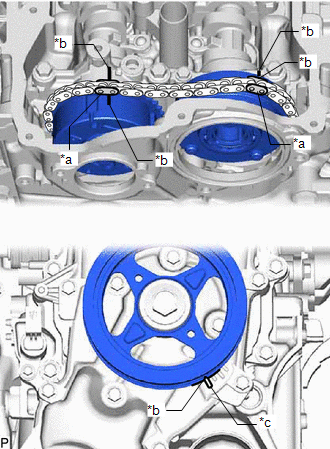

17. SET NO. 1 CYLINDER TO TDC (COMPRESSION)

|

(a) Turn the crankshaft clockwise to align the timing mark (cutout) on the crankshaft pulley assembly with the "0" timing mark on the No. 2 timing chain cover assembly.

|

|

|

*a

|

Paint Mark

|

|

*b

|

Timing Mark

|

|

*c

|

"0" Timing Mark

|

|

|

(b) Check that the timing marks are positioned as shown in the illustration.

HINT:

If the timing marks are not positioned as shown in the illustration, turn the crankshaft clockwise and then align them again.

(c) Place paint marks on the chain sub-assembly at points aligned with the timing marks on the camshaft timing gear assembly and camshaft timing exhaust gear assembly.

18. REMOVE STRAIGHT SCREW PLUG

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY+](/t3Portal/stylegraphics/info.gif)

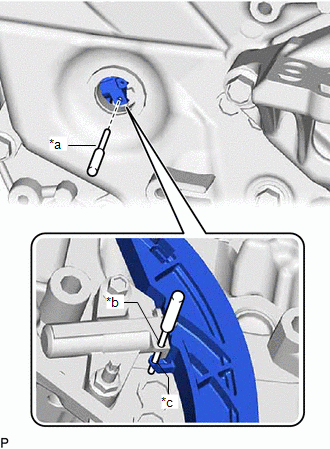

19. REMOVE CAMSHAFT

|

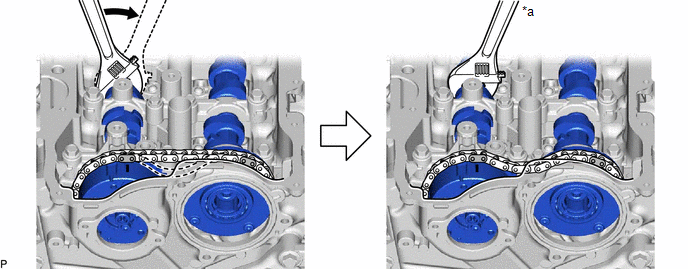

(a) Rotate the crankshaft approximately 15° clockwise.

|

|

|

(b) Rotate the crankshaft approximately 15° counterclockwise.

|

|

|

(c) Align the pin hole of the No. 1 chain tensioner assembly with the pin hole of the chain tensioner slipper, and then insert the pin.

|

|

|

*a

|

Pin

|

|

*b

|

Pin Hole (No. 1 Chain Tensioner Assembly Side)

|

|

*c

|

Pin Hole (Chain Tensioner Slipper Side)

|

|

|

(d) Type A:

|

(1) Using the hexagonal portion of the exhaust camshaft sub-assembly, secure the exhaust camshaft sub-assembly.

NOTICE:

Do not damage the camshaft housing sub-assembly, cylinder head sub-assembly and spark plug tube.

|

|

(2) Using a 5 mm hexagon wrench, remove the 2 bolts from the camshaft timing exhaust gear assembly.

(e) Type B:

|

(1) Using the hexagonal portion of the exhaust camshaft sub-assembly, secure the exhaust camshaft sub-assembly.

NOTICE:

Do not damage the camshaft housing sub-assembly, cylinder head sub-assembly and spark plug tube.

|

|

(2) Using a 5 mm hexagon wrench, remove the 2 bolts from the camshaft timing exhaust gear assembly.

(f) Using the hexagonal portion of the intake camshaft sub-assembly, secure the intake camshaft sub-assembly.

|

*a

|

Hold

|

|

Turn

|

NOTICE:

-

Do not damage the camshaft housing sub-assembly, cylinder head sub-assembly and spark plug tube.

-

Do not disassemble the camshaft timing gear assembly.

(g) Using a 10 mm bi-hexagon socket wrench, remove the bolt from the camshaft timing gear assembly.

(h) Using the hexagonal portion of the exhaust camshaft sub-assembly, loosen and hold the chain sub-assembly while moving the exhaust camshaft sub-assembly in the direction shown in the illustration.

|

*a

|

Hold

|

-

|

-

|

|

Turn

|

-

|

-

|

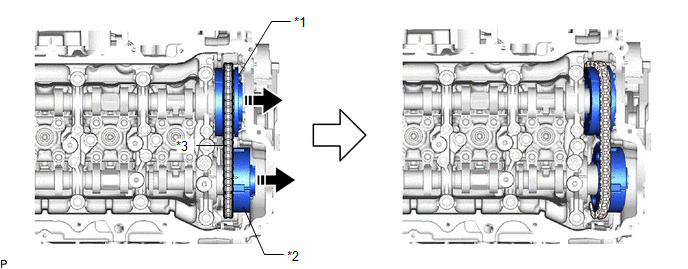

(i) Move the camshaft timing gear assembly together with the camshaft timing exhaust gear assembly and chain sub-assembly toward the No. 2 timing chain cover assembly as shown in the illustration.

|

*1

|

Camshaft Timing Gear Assembly

|

*2

|

Camshaft Timing Exhaust Gear Assembly

|

|

*3

|

Chain Sub-assembly

|

-

|

-

|

|

Remove in this Direction

|

-

|

-

|

(j) Remove the camshaft timing exhaust gear assembly from the chain sub-assembly.

(k) Remove the camshaft timing gear assembly from the chain sub-assembly.

|

(l) Secure the chain sub-assembly to the vehicle using rope, etc.

NOTICE:

Do not drop the chain sub-assembly into the timing chain cover assembly.

|

|

|

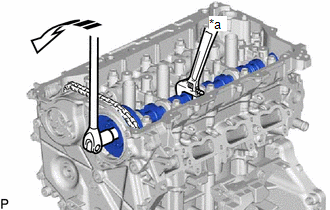

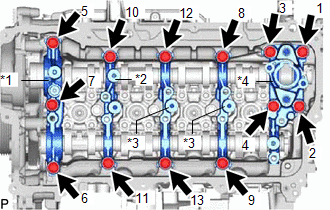

(m) Uniformly loosen and remove the 9 bolts in the order shown in the illustration.

|

|

|

(n) Uniformly loosen and remove the 13 bolts in the order shown in the illustration.

NOTICE:

Uniformly loosen the bolts while holding the camshaft horizontally.

|

|

|

*1

|

No. 1 Camshaft Bearing Cap

|

|

*2

|

No. 2 Camshaft Bearing Cap

|

|

*3

|

No. 3 Camshaft Bearing Cap

|

|

*4

|

No. 4 Camshaft Bearing Cap

|

|

|

(o) Remove the No. 1 camshaft bearing cap, No. 2 camshaft bearing cap, 2 No. 3 camshaft bearing caps and No. 4 camshaft bearing cap.

HINT:

Arrange the removed parts so that they can be reinstalled in their original locations.

|

(p) Remove the intake camshaft sub-assembly from the camshaft housing sub-assembly.

|

|

|

(q) Remove the exhaust camshaft sub-assembly from the camshaft housing sub-assembly.

|

|

|