- Transfer transaxle compensation code*4

- Reset transaxle compensation code*5

- CVT oil pressure calibration

- Perform road test to allow ECM to learn

| Last Modified: 01-27-2025 | 6.11:8.1.0 | Doc ID: RM100000002B8P0 |

| Model Year Start: 2023 | Model: Corolla Hatchback | Prod Date Range: [03/2023 - ] |

| Title: K120 / K121 (CVT): K121 SHIFT LEVER POSITION SENSOR: ADJUSTMENT; 2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ] | ||

ADJUSTMENT

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed, installed, or replaced during shift lever position sensor adjustment are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced

|

Replacement Part or Procedure |

Necessary Procedure |

Effect/Inoperative when not Performed |

Link |

|---|---|---|---|

|

*1: w/o Smart Key System

*2: w/ Smart Key System *3: w/ Steering Lock Function *4: If transaxle compensation code read from ECM *5: If transaxle compensation code not read from ECM |

|||

|

Replacement of ECM |

Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU configuration |

- |

||

|

Update ECU security key |

Vehicle Control History (RoB) are stored |

||

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

||

|

|

|

||

|

Replacement of ECM*2 |

Code registration (Smart Key System (for Gasoline Model, Start Function)) |

|

|

|

Replacement of ECM*1 |

Code registration (Immobiliser system) |

|

|

HINT:

When the cable is disconnected / reconnected to the battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

Learning completes when vehicle is driven

|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

|

Front Camera System |

Drive the vehicle straight ahead at 15 km/h (10 mph) or more for 1 second or more. |

Learning completes when vehicle is operated normally

|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

| *1: for Hatchback | ||

|

Power Door Lock Control System

|

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch. |

|

PROCEDURE

1. SECURE VEHICLE

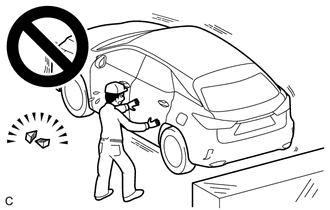

(a) Fully apply the parking brake and chock a wheel.

CAUTION:

- Make sure to apply the parking brake and chock a wheel before performing this procedure.

- If the vehicle is not secure and the shift lever is moved to N, the vehicle may suddenly move, possibly resulting in an accident or serious injury.

2. INSPECT SHIFT LEVER POSITION SENSOR POSITION

(a) Start the engine.

(b) Move the shift lever to D and release the brake pedal.

CAUTION:

Be sure to apply the parking brake and chock all 4 wheels to secure the vehicle.

|

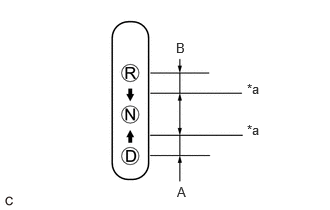

(c) Slowly move the shift lever to N and measure the moving distance (A) of the shift lever from the original point to the gear disengagement point. NOTICE: Be sure to move the shift lever slowly. |

|

(d) Move the shift lever to R and release the brake pedal.

CAUTION:

Be sure to apply the parking brake and chock all 4 wheels to secure the vehicle.

(e) Slowly move the shift lever to N and measure the moving distance (B) of the shift lever from the original point to the gear disengagement point.

NOTICE:

Be sure to move the shift lever slowly.

(f) Check that the moving distances (A) and (B) shown in the illustration are almost the same.

HINT:

- If the moving distances (A) and (B) are almost the same, adjustment of the shift lever position sensor position is not necessary.

- If the moving distance (A) is shorter than (B), perform step [#1] of adjust shift lever position sensor position.

- If the moving distance (B) is shorter than (A), perform step [#2] of adjust shift lever position sensor position.

3. ADJUST SHIFT LEVER POSITION SENSOR POSITION

(a) Remove the battery.

(b) Remove the ECM.

(c) Remove the battery clamp sub-assembly.

(d) If the moving distance (A) is shorter than (B). [#1]

HINT:

If the shift lever is moved from R to N, the moving distance of the shift lever from the original point to the gear disengagement point becomes longer.

(1) Move the shift lever to N.

|

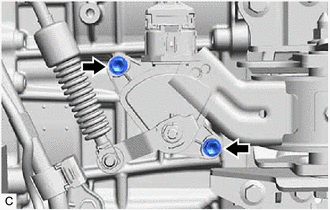

(2) Loosen the 2 bolts. |

|

|

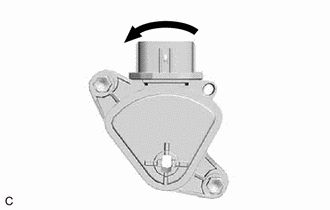

(3) Slightly turn the shift lever position sensor counterclockwise. |

|

|

(4) Tighten the 2 bolts. Torque: 5.4 N·m {55 kgf·cm, 48 in·lbf} |

|

(5) Check the shift lever position sensor position.

(e) If the moving distance (B) is shorter than (A). [#2]

HINT:

If the shift lever is moved from D to N, the moving distance of the shift lever from the original point to the gear disengagement point becomes longer.

(1) Move the shift lever to N.

|

(2) Loosen the 2 bolts. |

|

|

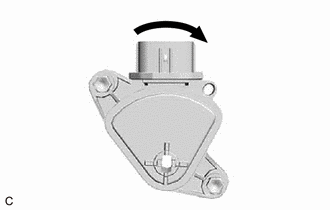

(3) Slightly turn the shift lever position sensor clockwise. |

|

|

(4) Tighten the 2 bolts. Torque: 5.4 N·m {55 kgf·cm, 48 in·lbf} |

|

(5) Check the shift lever position sensor position.

|

|

|

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE CONTROL): SFI SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)