|

Last Modified: 05-13-2024 |

6.11:8.1.0 |

Doc ID: RM100000002B36B |

|

Model Year Start: 2023 |

Model: Corolla Hatchback |

Prod Date Range: [03/2023 -

] |

|

Title: K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: P07457E,P08CC7E,P09149E; Pressure Control Solenoid "A" Actuator Stuck On; 2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ] |

|

DTC

|

P07457E

|

Pressure Control Solenoid "A" Actuator Stuck On

|

|

DTC

|

P08CC7E

|

Shift Solenoid "J" Control Actuator Stuck On

|

|

DTC

|

P09149E

|

Gear Shift Position Circuit "A" Range/Performance Stuck On

|

DESCRIPTION

Using the current from the ECM, the shift solenoid valve SL1 controls the C1 clutch pressure and S1 synchronizer in accordance with the requested shift mode.

By controlling the current, the ECM controls the shift solenoid valve SC2 and switches the shift solenoid valve SL1 between the role of controlling the C1 clutch pressure and controlling the S1 synchronizer.

When the ECM requests the shift mode to be changed to gear mode, the S1 synchronizer is engaged and input torque is transferred to the 1st gear.

The shift stroke sensor detects the S1 synchronizer position using the magnet on the shift fork, and sends signals to the ECM.

|

DTC No.

|

Detection Item

|

DTC Detection Condition

|

Trouble Area

|

MIL

|

DTC Output from

|

Priority

|

Note

|

|

P07457E

|

Pressure Control Solenoid "A" Actuator Stuck On

|

Any of the following conditions are met (2-trip detection logic):

-

When the ECM commands the S1 synchronizer to be released, the shift stroke sensor output value is 9.205 mm (0.362 in.) or more for 3 seconds or more.

-

When the ECM commands the S1 synchronizer to be released, the shift stroke sensor output value is 1.498 mm (0.0590 in.) or more for 8 seconds or more.

|

-

Shift stroke sensor

-

Transmission valve body assembly (shift solenoid valve SL1 or SC2)

-

Continuously variable transaxle assembly

|

Comes on

|

Engine

|

B

|

SAE Code:

P0747

|

|

P08CC7E

|

Shift Solenoid "J" Control Actuator Stuck On

|

Any of the following conditions are met (2-trip detection logic):

-

When the ECM commands the S1 synchronizer to be released, the shift stroke sensor output value is 9.205 mm (0.362 in.) or more for 3 seconds or more.

-

When the ECM commands the S1 synchronizer to be released, the shift stroke sensor output value is 1.498 mm (0.0590 in.) or more for 8 seconds or more.

|

-

Shift stroke sensor

-

Transmission valve body assembly (shift solenoid valve SL1 or SC2)

-

Continuously variable transaxle assembly

|

Comes on

|

Engine

|

B

|

SAE Code:

P08CE

|

|

P09149E

|

Gear Shift Position Circuit "A" Range/Performance Stuck On

|

Any of the following conditions are met (2-trip detection logic):

-

When the ECM commands the S1 synchronizer to be released, the shift stroke sensor output value is 9.205 mm (0.362 in.) or more for 3 seconds or more.

-

When the ECM commands the S1 synchronizer to be released, the shift stroke sensor output value is 1.498 mm (0.0590 in.) or more for 8 seconds or more.

|

-

Shift stroke sensor

-

Transmission valve body assembly (shift solenoid valve SL1 or SC2)

-

Continuously variable transaxle assembly

|

Comes on

|

Engine

|

B

|

SAE Code:

P0915

|

MONITOR DESCRIPTION

When the shift solenoid valve SC2 turns ON, the shift solenoid valve SL1 controls the S1 synchronizer and moves it to the requested position according to the requested shift mode.

When the ECM detects that the S1 synchronizer is not in the appropriate position, it determines that the shift solenoid valve SL1, SC2 or shift stroke sensor is malfunctioning, illuminates the MIL and stores a DTC.

MONITOR STRATEGY

|

Related DTCs

|

P0747: Pressure control solenoid "A" (Shift solenoid valve SL1)/Functional check

P08CE: Shift Solenoid "J" (Shift solenoid valve SC2)/Functional check

P0915 (ON malfunction): Gear shift position (SFV)/Rationality fault diagnostics

|

|

Required sensors/Components

|

Crankshaft position sensor

Transmission revolution sensor (NT)

Transmission revolution sensor (NC1)

Transmission revolution sensor (NSS)

Gear shift position sensor

CVT fluid temperature sensor

Engine coolant temperature sensor

Oil pressure sensor

Shift solenoid valve SL1

Shift solenoid valve SL2

Shift solenoid valve SLP

Shift solenoid valve SLS

Shift solenoid valve SC1

Shift solenoid valve SC2

Shift solenoid valve SC3

|

|

Frequency of operation

|

Continuous

|

|

Duration

|

P0747:

-

Condition (A): 3 sec.

Condition (B): 8 sec.*

P08CE:

-

Condition (A): 3 sec.

Condition (B): 8 sec.*

P0915 (ON malfunction):

-

Condition (A): 3 sec.

Condition (B): 3 sec.

Condition (C): 8 sec.*

|

|

MIL operation

|

2 driving cycles

|

|

Sequence of operation

|

None

|

TYPICAL ENABLING CONDITIONS

All

|

ETC system

(Electronic throttle control system)

|

Not system down

(MIL illuminated by following codes: P0121, P0122, P0123, P0222, P0223, P0604, P0606, P0607, P060D, P060E, P0657, P0658, P1607, P16B0, P2102, P2103, P2111, P2112, P2119, P2135)

|

|

KCS sensor circuit

(Knock sensor)

|

Not circuit malfunction

(MIL illuminated by following codes: P0327, P0328)

|

|

ECT sensor circuit

(Engine coolant temperature sensor)

|

Not circuit malfunction

(MIL illuminated by following codes: P0117, P0118)

|

|

IAT sensor circuit

(Intake air temperature sensor)

|

Not circuit malfunction

(MIL illuminated by following codes: P0112, P0113)

|

|

Crankshaft position sensor "A" circuit

(Crankshaft position sensor)

|

Not circuit malfunction

(MIL illuminated by following codes: P0335, P0337, P0338)

|

|

Low voltage flag

|

OFF

|

|

Transmission fluid temperature sensor "A" circuit

(CVT fluid temperature sensor)

|

Not circuit malfunction

(MIL illuminated by following codes: P0712, P0713)

|

|

Turbine speed sensor "A" circuit

(Transmission revolution sensor (NT))

|

Not circuit malfunction

(MIL illuminated by following codes: P0717, P07BF, P07C0)

|

|

Intermediate shaft speed sensor "C" circuit

(Transmission revolution sensor (NSS))

|

Not circuit malfunction

(MIL illuminated by following codes: P07C9, P07CA, P2751)

|

|

Gear shift position circuit

|

Not circuit malfunction

(MIL illuminated by following codes: P0916, P0917)

|

|

Output speed sensor circuit

(Transmission revolution sensor (NOUT))

|

Not circuit malfunction

(MIL illuminated by following codes: P0722, P077C, P077D)

|

|

Intermediate shaft speed sensor "B" circuit

(Transmission revolution sensor (NC1))

|

Not circuit malfunction

(MIL illuminated by following codes: P07C7, P07C8, P2747)

|

|

Shift solenoid "H" circuit

(Shift solenoid valve SC1)

|

Not circuit malfunction

(MIL illuminated by following codes: P099E, P099F)

|

|

Shift solenoid "J" circuit

(Shift solenoid valve SC2)

|

Not circuit malfunction

(MIL illuminated by following codes: P08D2, P08D3)

|

|

Shift solenoid "K" circuit

(Shift solenoid valve SC3)

|

Not circuit malfunction

(MIL illuminated by following codes: P08DB, P08DC)

|

|

Shift position

|

"N" or "P" or "D" or "B"

|

|

Gear mode clutch

|

Released

|

|

Reverse clutch

|

Released

|

|

Shift solenoid valve SLP

|

Operating shift control by ECM command

|

|

Engine speed

|

500 rpm or more

|

|

Any of the following conditions are met: (a) or (b)

|

-

|

|

(a) Gear mode clutch speed

|

Less than 4500 rpm

|

|

(b) Time after following condition is met

at CVT fluid temperature 80°C (176°F)

(Conditions vary with CVT fluid temperature)

|

60 sec. or more

|

|

- Engine speed

|

400 rpm or more

|

P0747:

-

All

|

Pressure control solenoid "J" circuit

(Shift solenoid valve SLP)

|

Not circuit malfunction

(MIL illuminated by following codes: P2826, P2827)

|

|

Pressure control solenoid "K" circuit

(Shift solenoid valve SLS)

|

Not circuit malfunction

(MIL illuminated by following codes: P282F, P2830)

|

|

Pressure control solenoid "A" circuit

(Shift solenoid valve SL1)

|

Not circuit malfunction

(MIL illuminated by following codes: P0962, P0963)

|

|

Pressure control solenoid "B" circuit

(Shift solenoid valve SL2)

|

Not circuit malfunction

(MIL illuminated by following codes: P0966, P0967)

|

P08CE:

-

All

|

Pressure control solenoid "K" circuit

(Shift solenoid valve SLS)

|

Not circuit malfunction

(MIL illuminated by following codes: P282F, P2830)

|

|

Pressure control solenoid "A" circuit

(Shift solenoid valve SL1)

|

Not circuit malfunction

(MIL illuminated by following codes: P0962, P0963)

|

|

Pressure control solenoid "B" circuit

(Shift solenoid valve SL2)

|

Not circuit malfunction

(MIL illuminated by following codes: P0966, P0967)

|

TYPICAL MALFUNCTION THRESHOLDS

P0747 and P08CE:

-

Any of the following conditions are met: Condition (A) or (B)

Condition (A)

|

ECM indicate synchronizer

|

Release

|

|

Synchronizer

|

Engaged

|

Condition (B)

|

ECM indicate synchronizer

|

Release

|

|

Synchronizer

|

Not released

|

P0915 (ON malfunction):

-

Condition (A) and (B) are met or condition (C) is met

Condition (A)

|

ECM indicate synchronizer

|

Release

|

|

Synchronizer

|

Engaged

|

Condition (B) (after condition (A) is met)

|

Synchronizer input speed - Synchronizer output speed

|

300 rpm or more

|

Condition (C)

|

ECM indicate synchronizer

|

Release

|

|

Synchronizer

|

Not released

|

CONFIRMATION DRIVING PATTERN

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

-

After repairs have been completed, clear the DTCs and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

-

When clearing the permanent DTCs, refer to the Clear Permanent DTC procedure.

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)

-

Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

-

Turn the ignition switch off and wait for 2 minutes or more.

-

Perform the D Position Shift Test inspection in Road Test. [*1]

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: ROAD TEST](/t3Portal/stylegraphics/info.gif)

HINT:

[*1]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

-

Stop the vehicle.

-

Enter the following menus: Powertrain / Engine / Utility / All Readiness.

-

Input the DTC: P07457E, P08CC7E or P09149E.

-

Check the DTC judgment result.

|

GTS Display

|

Description

|

|

NORMAL

|

-

DTC judgment completed

-

System normal

|

|

ABNORMAL

|

-

DTC judgment completed

-

System abnormal

|

|

INCOMPLETE

|

-

DTC judgment not completed

-

Perform driving pattern after confirming DTC enabling conditions

|

|

N/A

|

-

Unable to perform DTC judgment

-

Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

|

HINT:

-

If the judgment result shows NORMAL, the system is normal.

-

If the judgment result shows ABNORMAL, the system has a malfunction.

-

If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

CAUTION / NOTICE / HINT

NOTICE:

-

Perform the universal trip to clear permanent DTCs.

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)

-

Perform registration and/or initialization when parts related to the continuously variable transaxle system are replaced.

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: PRECAUTION](/t3Portal/stylegraphics/info.gif)

-

Check that no DTCs are stored after performing initialization.

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)

HINT:

If any DTCs other than P07457E, P08CC7E or P09149E are output, perform troubleshooting for those DTCs first.

PROCEDURE

(a) Read the DTCs using the GTS.

Powertrain > Engine > Trouble Codes

|

Result

|

Proceed to

|

|

Only DTCs in the following table are output

|

A

|

|

DTCs other than the DTCs in the table below are output

|

B

|

|

Relevant DTC

|

|

P07457E

|

Pressure Control Solenoid "A" Actuator Stuck On

|

|

P08CC7E

|

Shift Solenoid "J" Control Actuator Stuck On

|

|

P09149E

|

Gear Shift Position Circuit "A" Range/Performance Stuck On

|

| B |

|

GO TO DTC CHART

|

|

A

|

|

|

|

2.

|

INSPECT SHIFT STROKE SENSOR

|

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [09/2022 - ]; K120 / K121 (CVT): SHIFT STROKE SENSOR: INSPECTION](/t3Portal/stylegraphics/info.gif)

|

OK

|

|

|

|

3.

|

INSPECT TRANSMISSION VALVE BODY ASSEMBLY (SHIFT SOLENOID VALVE SL1 and SC2)

|

Pre-procedure1

(a) Disconnect the transmission wire connector from the shift solenoid valves SL1 and SC2.

HINT:

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 VALVE BODY ASSEMBLY: REMOVAL](/t3Portal/stylegraphics/info.gif)

Procedure1

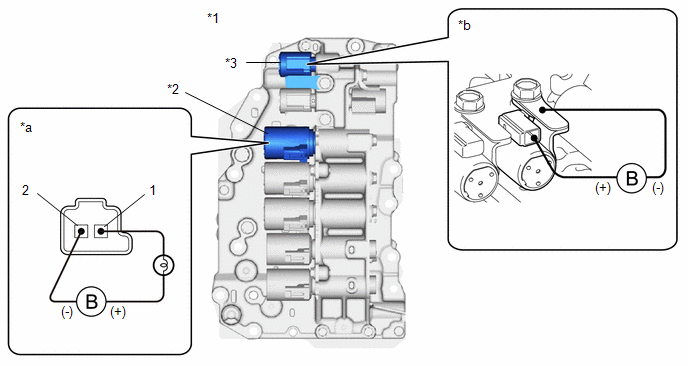

(b) Connect a positive (+) lead from the battery with a 21 W bulb to terminal 1 and a negative (-) lead to terminal 2 of the shift solenoid valve SL1 connector. Check that the valve moves and makes an operating sound.

|

*1

|

Transmission Valve Body Assembly

|

*2

|

Shift Solenoid Valve SL1

|

|

*3

|

Shift Solenoid Valve SC2

|

-

|

-

|

|

*a

|

Component without harness connected

(Shift Solenoid Valve SL1)

|

*b

|

Component without harness connected

(Shift Solenoid Valve SC2)

|

OK:

Valve moves and makes an operating sound.

(c) Connect a positive (+) lead from the battery to the terminal of the shift solenoid valve SC2 connector and a negative (-) lead to the shift solenoid valve SC2 body. Check that the valve moves and makes an operating sound.

OK:

Valve moves and makes an operating sound.

Post-procedure1

(d) None

|

OK

|

|

|

|

4.

|

REPLACE CONTINUOUSLY VARIABLE TRANSAXLE ASSEMBLY

|

HINT:

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): CONTINUOUSLY VARIABLE TRANSAXLE ASSEMBLY: REMOVAL](/t3Portal/stylegraphics/info.gif)

| NEXT |

|

PERFORM REGISTRATION AND INITIALIZATION

for Registration: Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

for Initialization: Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

5.

|

REPLACE TRANSMISSION VALVE BODY ASSEMBLY

|

HINT:

Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 VALVE BODY ASSEMBLY: REMOVAL](/t3Portal/stylegraphics/info.gif)

| NEXT |

|

PERFORM REGISTRATION AND INITIALIZATION

for Registration: Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)

for Initialization: Click here

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|