- DTC judgment completed

- System normal

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000002B367 |

| Model Year Start: 2023 | Model: Corolla Hatchback | Prod Date Range: [03/2023 - ] |

| Title: K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: P172A7E; Starter Enable Relay Actuator Stuck On; 2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ] | ||

|

DTC |

P172A7E |

Starter Enable Relay Actuator Stuck On |

DESCRIPTION

w/o Smart Key System

-

When the shift lever is in P or N, the ECM turns on the N/ST relay (No. 2 starter relay).

The starter assembly can be operated by the ignition switch only when the N/ST relay (No. 2 starter relay) is on.

w/ Smart Key System

-

When the shift lever is in P or N, the ECM sends the shift state signal to the certification ECU (smart key ECU assembly).

Certification ECU (smart key ECU assembly) operates the starter assembly only when the shift lever is in P or N.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

DTC Output from |

Priority |

Note |

|---|---|---|---|---|---|---|---|

|

P172A7E |

Starter Enable Relay Actuator Stuck On |

All of the following conditions are met for 0.3 seconds or more (1-trip detection logic):

|

w/o Smart Key System

w/ Smart Key System

|

Does not come on |

Engine |

B |

SAE Code: P172B |

MONITOR DESCRIPTION

When the ECM has not given permission for starter operation and a starter signal is received, the ECM detects the malfunction and stores this DTC.

CONFIRMATION DRIVING PATTERN

NOTICE:

Perform the confirmation driving pattern with the AUTO function (shift-linked function) of the electric parking brake system off.

HINT:

After repairs have been completed, clear the DTCs and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for 2 minutes or more.

-

Fully apply the parking brake and chock all 4 wheels.

HINT:

When the parking brake indicator (red) is illuminated after the electric parking brake switch (electric parking brake switch assembly) has been pulled to the lock side, the maximum amount of braking force is applied if the electric parking brake switch (electric parking brake switch assembly) is pulled to the lock side one more time.

- Depress the brake pedal and move the shift lever to R.

-

w/o Smart Key System:

Turn the ignition switch START.

-

w/ Smart Key System:

Turn the ignition switch on (Start).

- Depress the brake pedal and move the shift lever to D.

-

w/o Smart Key System:

Turn the ignition switch START.

-

w/ Smart Key System:

Turn the ignition switch on (Start).

-

w/o Sequential Shift:

Depress the brake pedal and move the shift lever to B.

-

w/o Smart Key System:

Turn the ignition switch START.

-

w/ Smart Key System:

Turn the ignition switch on (Start).

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P172A7E.

-

Check the DTC judgment result.

GTS Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the Confirmation Driving Pattern and check the DTC judgment result again.

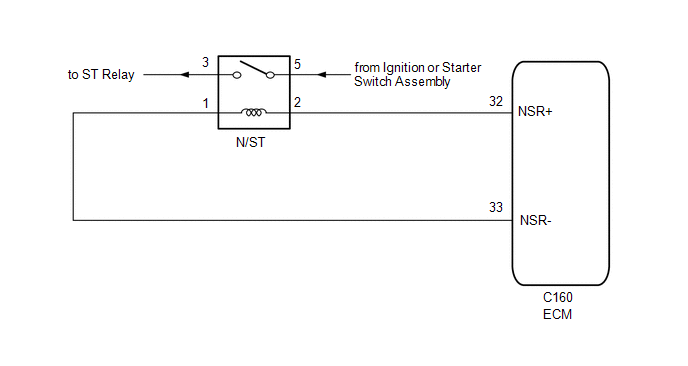

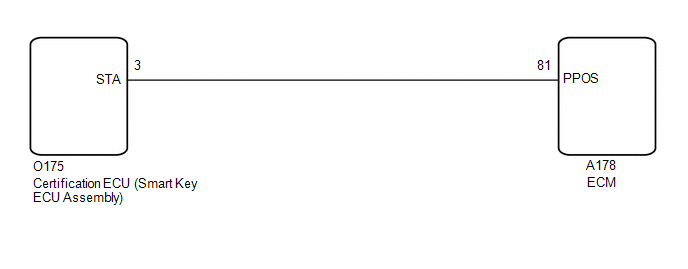

WIRING DIAGRAM

w/o Smart Key System

w/ Smart Key System

CAUTION / NOTICE / HINT

NOTICE:

HINT:

If any DTCs other than P172A7E are output, perform troubleshooting for those DTCs first.

PROCEDURE

|

1. |

CHECK VEHICLE CONDITION |

(a) Choose the model to be inspected.

|

Result |

Proceed to |

|---|---|

|

w/o Smart Key System |

A |

|

w/ Smart Key System |

B |

| B |

|

|

|

2. |

CHECK DTC OUTPUT (DTC P172A7E) |

(a) Read the DTCs.

Powertrain > Engine > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

Only P172A7E is output |

A |

|

P172A7E and other DTCs are output |

B |

| B |

|

GO TO DTC CHART |

|

|

3. |

INSPECT RELAY (N/ST RELAY (NO. 2 STARTER RELAY)) |

| NG |

|

REPLACE RELAY (N/ST RELAY (NO. 2 STARTER RELAY)) |

|

|

4. |

CHECK HARNESS AND CONNECTOR (N/ST RELAY (NO. 2 STARTER RELAY) - ECM) |

Pre-procedure1

(a) Remove the N/ST relay (No. 2 starter relay) from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Disconnect the C160 ECM connector.

Procedure1

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (N/ST relay) or C160-33 (NSR-) - Other terminals |

Always |

10 kΩ or higher |

|

2 (N/ST relay) or C160-32 (NSR+) - Other terminals |

Always |

10 kΩ or higher |

Post-procedure1

(d) Connect the C160 ECM connector.

(e) Install the N/ST relay (No. 2 starter relay).

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

REPLACE ECM |

HINT:

| NEXT |

|

PERFORM REGISTRATION AND INITIALIZATION |

|

6. |

CHECK DTC OUTPUT (HEALTH CHECK) |

(a) Using the GTS, perform a Health Check.

|

Result |

Proceed to |

|---|---|

|

Only P172A7E is output |

A |

|

P172A7E and other DTCs are output |

B |

| B |

|

GO TO DTC CHART |

|

|

7. |

INSPECT ECM (PPOS VOLTAGE) |

Pre-procedure1

(a) Disconnect the O175 smart key ECU assembly connector.

(b) Turn the ignition switch to ON.

Procedure1

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

O175-3 (STA) - Body ground |

Ignition switch ON, shift lever in P or N |

11 to 14 V |

|

O175-3 (STA) - Body ground |

Ignition switch ON, shift lever not in P or N |

Below 1 V |

Post-procedure1

(d) Turn the ignition switch off.

(e) Connect the O175 smart key ECU assembly connector.

| OK |

|

|

|

8. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU) - ECM) |

Pre-procedure1

(a) Disconnect the O175 smart key ECU assembly connector.

(b) Disconnect the A178 ECM connector.

Procedure1

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

O175-3 (STA) or A178-81 (PPOS) - Other terminals |

Always |

10 kΩ or higher |

Post-procedure1

(d) Connect the A178 ECM connector.

(e) Connect the O175 smart key ECU assembly connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

9. |

REPLACE ECM |

HINT:

| NEXT |

|

PERFORM REGISTRATION AND INITIALIZATION |

|

|

|

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: PRECAUTION](/t3Portal/stylegraphics/info.gif)