- DTC judgment completed

- System normal

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000002B35W |

| Model Year Start: 2023 | Model: Corolla Hatchback | Prod Date Range: [03/2023 - ] |

| Title: K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: P096412; Pressure Control Solenoid "B" Control Circuit Short to Battery; 2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ] | ||

|

DTC |

P096412 |

Pressure Control Solenoid "B" Control Circuit Short to Battery |

DESCRIPTION

Using the current from the ECM, the shift solenoid valve SL2 controls the C2 clutch pressure in accordance with the requested shift mode.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

DTC Output from |

Priority |

Note |

|---|---|---|---|---|---|---|---|

|

P096412 |

Pressure Control Solenoid "B" Control Circuit Short to Battery |

A short to +B is detected in the shift solenoid valve SL2 circuit for 1 second or more (1-trip detection logic). |

|

Comes on |

Engine |

A |

SAE Code: P0967 |

MONITOR DESCRIPTION

This DTC indicates a short to +B in the shift solenoid valve SL2 circuit. If there is a short to +B in the shift solenoid valve SL2 circuit, the ECM detects the malfunction, illuminates the MIL and stores this DTC.

MONITOR STRATEGY

|

Related DTCs |

P0967: Pressure control solenoid "B" (Shift solenoid valve SL2)/Range check (High current) P0967: Pressure control solenoid "B" (Shift solenoid valve SL2)/Range check (High voltage) |

|

Required sensors/Components |

Shift solenoid valve SL2 |

|

Frequency of operation |

Continuous |

|

Duration |

High current: 1 sec. High voltage: 1.3 sec. |

|

MIL operation |

Immediate |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

All

|

The monitor will run whenever the following DTCs are not stored |

None |

|

Solenoid current cut status |

Not cut |

|

Ignition switch |

ON |

|

Starter |

OFF |

High current (A)

|

Battery voltage |

8 V or more and 12.499 V or less |

|

Target current (0.1 sec. or more) |

0.8 A or less |

High current (B)

|

Battery voltage |

12.5 V or more and less than 16 V |

|

Target current (0 sec. or more) |

1 A or less |

High voltage

|

Battery voltage |

10.5 V or more |

|

Target current |

0.2 A or more |

|

Output duty cycle |

10% or more and 90% or less |

TYPICAL MALFUNCTION THRESHOLDS

High current:

-

Any of the following conditions are met: High current (A) or (B)

High current (A)

Battery voltage

8 V or more and 12.499 V or less

Solenoid current

More than 0.92 A

High current (B)

Battery voltage

12.5 V or more and less than 16 V

Solenoid current

More than 1.1 A

High voltage

|

Solenoid voltage monitor |

No signal |

COMPONENT OPERATING RANGE

High current

|

Both of the following conditions are met |

(a) or (b) |

|

(a) Battery voltage |

8 V or more and 12.499 V or less |

|

Solenoid current |

0.92 A or less |

|

(b) Battery voltage |

12.5 V or more and less than 16 V |

|

Solenoid current |

1.1 A or less |

High voltage

|

Solenoid voltage monitor |

Signal input |

CONFIRMATION DRIVING PATTERN

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for 2 minutes or more.

-

Perform the D Position Shift Test inspection in Road Test. [*1]

HINT:

[*1]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Stop the vehicle.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P096412.

-

Check the DTC judgment result.

GTS Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

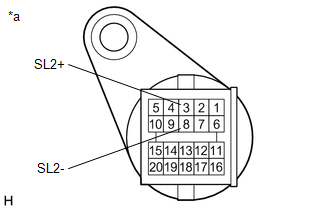

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

PROCEDURE

|

1. |

INSPECT TRANSMISSION WIRE (SHIFT SOLENOID VALVE SL2) |

Pre-procedure1

(a) Disconnect the C61 transmission wire connector.

Procedure1

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

Result:

|

|

Post-procedure1

(c) Connect the C61 transmission wire connector.

| NG |

|

|

|

2. |

CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM) |

Pre-procedure1

(a) Disconnect the C160 ECM connector.

Procedure1

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C160-7 (SL2+) - Other terminals |

Always |

10 kΩ or higher |

|

C160-6 (SL2-) - Other terminals |

Always |

10 kΩ or higher |

Post-procedure1

(c) Connect the C160 ECM connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (TRANSMISSION WIRE - ECM) |

|

|

3. |

REPLACE ECM |

HINT:

| NEXT |

|

PERFORM REGISTRATION AND INITIALIZATION |

|

4. |

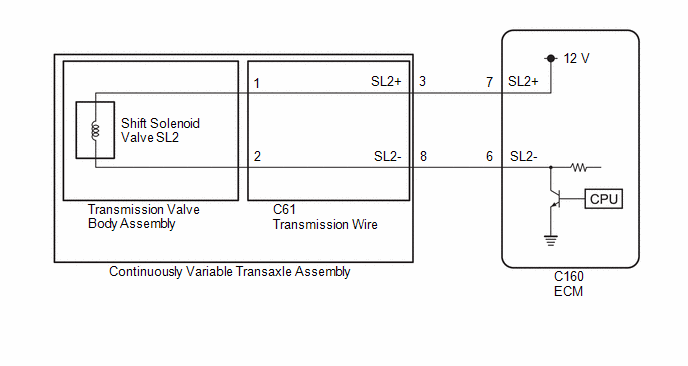

INSPECT TRANSMISSION WIRE |

Pre-procedure1

(a) Disconnect the C61 transmission wire connector.

(b) Disconnect the transmission wire connector from the shift solenoid valve SL2.

HINT:

Procedure1

(c) Measure the resistance according to the value(s) in the table below.

|

*1 |

Transmission Valve Body Assembly |

*2 |

Shift Solenoid Valve SL2 |

|

*3 |

Transmission Wire |

- |

- |

|

*a |

Shift Solenoid Valve Side |

*b |

Wire Harness Connector Side |

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (shift solenoid valve side) or 3 (SL2+) (wire harness connector side) - All other terminals |

Always |

10 kΩ or higher |

|

2 (shift solenoid valve side) or 8 (SL2-) (wire harness connector side) - All other terminals |

Always |

10 kΩ or higher |

Post-procedure1

(d) None

| NG |

|

|

|

5. |

REPLACE TRANSMISSION VALVE BODY ASSEMBLY |

HINT:

| NEXT |

|

PERFORM REGISTRATION AND INITIALIZATION |

|

|

|

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)