- DTC judgment completed

- System normal

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000002B35G |

| Model Year Start: 2023 | Model: Corolla Hatchback | Prod Date Range: [03/2023 - ] |

| Title: K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: P070562; Transmission Range Sensor "A" Signal Compare Failure; 2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ] | ||

|

DTC |

P070562 |

Transmission Range Sensor "A" Signal Compare Failure |

DESCRIPTION

The shift lever position sensor and transmission control switch (shift lock control unit assembly) detect the shift lever position and send signals to the ECM.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

DTC Output from |

Priority |

Note |

|---|---|---|---|---|---|---|---|

|

P070562 |

Transmission Range Sensor "A" Signal Compare Failure |

Any of the following conditions are met for 2 seconds or more (1-trip detection logic). w/ Sequential Shift:

w/o Sequential Shift:

|

|

Comes on |

Engine |

A |

SAE Code: P0705 |

MONITOR DESCRIPTION

This DTC indicates a problem with the shift lever position sensor, transmission control switch*1 or wire harness of their circuits.

The shift lever position sensor sends a signal to the ECM according to the shift lever position (P, R, N, D or B*2).

If the ECM detects a malfunction in the signal of the shift position sensor, it is suspected that a sensor or related component is malfunctioning. The ECM will then illuminate the MIL and store a DTC.

*1: w/ Sequential Shift

*2: w/o Sequential Shift

MONITOR STRATEGY

|

Related DTCs |

P0705: Transmission range switch/Verify switch input |

|

Required sensors/Components |

Shift lever position sensor Transmission control switch |

|

Frequency of operation |

Continuous |

|

Duration |

2 sec. |

|

MIL operation |

Immediate |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

All

|

Ignition switch |

ON |

|

Battery voltage |

8 V or more |

|

Starter |

OFF |

Condition (B)

|

S range position switch monitor condition |

Met |

TYPICAL MALFUNCTION THRESHOLDS

Any of the following conditions are met: Condition (A) or (B)

Condition (A)

|

Transmission range switch input pattern monitor error |

Occurred |

Condition (B)

|

S position switch |

ON |

CONFIRMATION DRIVING PATTERN

HINT:

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for 2 minutes or more.

-

w/ Sequential Shift:

- Wait with the shift lever in each position (P, R, N or D) for 2 seconds or more each with the ignition switch ON. [*1]

-

Wait for 2 seconds or more with the shift lever in M. [*2]

HINT:

[*1] and [*2]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

-

w/o Sequential Shift:

-

Wait with the shift lever in each position (P, R, N, D or B) for 2 seconds or more each with the ignition switch ON. [*1]

HINT:

[*1] : Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

-

Wait with the shift lever in each position (P, R, N, D or B) for 2 seconds or more each with the ignition switch ON. [*1]

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P070562.

-

Check the DTC judgment result.

GTS Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

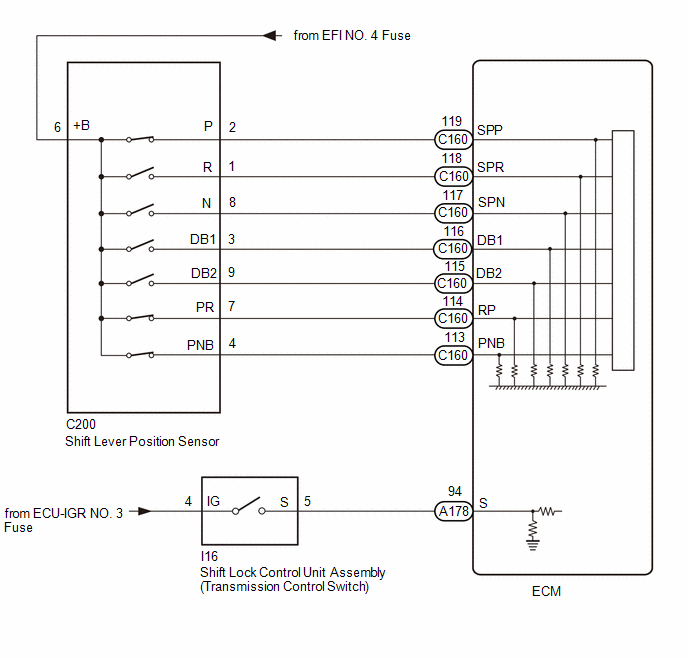

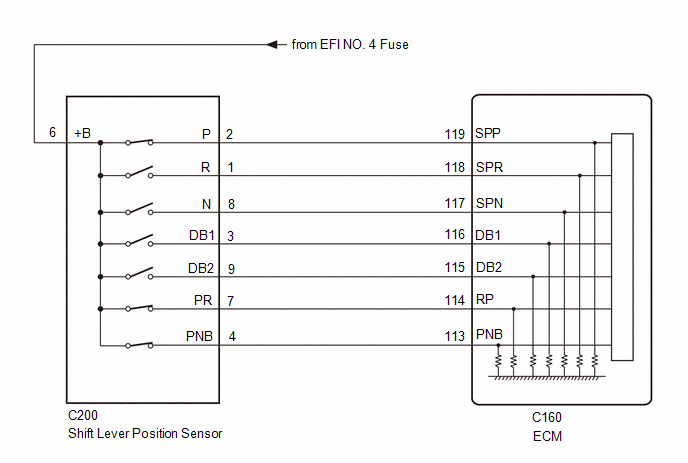

WIRING DIAGRAM

w/ Sequential Shift

w/o Sequential Shift

CAUTION / NOTICE / HINT

NOTICE:

- Perform the universal trip to clear permanent DTCs.

- Perform registration and/or initialization when parts related to the continuously variable transaxle system are replaced.

- Check that no DTCs are stored after performing initialization.

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK VEHICLE CONDITION |

(a) Choose the model to be inspected.

|

Result |

Proceed to |

|---|---|

|

w/ Sequential Shift |

A |

|

w/o Sequential Shift |

B |

| B |

|

|

|

2. |

READ VALUE USING GTS (SHIFT LEVER POSITION SENSOR) |

(a) According to the display on the GTS, read the Data List.

Powertrain > Engine > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Shift Sensor Switch DB1 |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

|

Shift Sensor Switch DB2 |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

|

Shift Sensor Switch SPN |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

|

Shift Sensor Switch SPR |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

|

Shift Sensor Switch SPP |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

|

Shift Sensor Switch PNB |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

|

Shift Sensor Switch RP |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Shift Sensor Switch DB1 |

|

Shift Sensor Switch DB2 |

|

Shift Sensor Switch SPN |

|

Shift Sensor Switch SPR |

|

Shift Sensor Switch SPP |

|

Shift Sensor Switch PNB |

|

Shift Sensor Switch RP |

Standard:

|

Data List |

Shift Position |

|||

|

P |

R |

N |

D |

|

|

Shift Sensor Switch (DB1) |

OFF |

OFF |

OFF |

ON |

|

Shift Sensor Switch (DB2) |

OFF |

OFF |

OFF |

ON |

|

Shift Sensor Switch (SPN) |

OFF |

OFF |

ON |

OFF |

|

Shift Sensor Switch (SPR) |

OFF |

ON |

OFF |

OFF |

|

Shift Sensor Switch (SPP) |

ON |

OFF |

OFF |

OFF |

|

Shift Sensor Switch (PNB) |

ON |

OFF |

ON |

OFF |

|

Shift Sensor Switch (RP) |

ON |

ON |

OFF |

OFF |

| NG |

|

|

|

3. |

READ VALUE USING GTS (SHIFT SW STATUS (S RANGE)) |

(a) According to the display on the GTS, read the Data List.

Powertrain > Engine > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Shift SW Status (S Range) |

Transmission control switch status |

OFF or ON |

OFF: Shift lever not in M, "+" or "-" |

- |

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Shift SW Status (S Range) |

|

Result |

Proceed to |

|---|---|

|

The value of Shift SW Status (S Range) is OFF |

A |

|

The value of Shift SW Status (S Range) is not OFF |

B |

| A |

|

|

|

4. |

CHECK HARNESS AND CONNECTOR (SHIFT LOCK CONTROL UNIT ASSEMBLY (POWER SOURCE)) |

Pre-procedure1

(a) Disconnect the I16 shift lock control unit assembly connector.

Procedure1

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I16-4 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

|

I16-4 (IG) - Body ground |

Ignition switch off |

Below 1 V |

Post-procedure1

(c) Connect the I16 shift lock control unit assembly connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (SHIFT LOCK CONTROL UNIT ASSEMBLY (POWER SOURCE)) |

|

|

5. |

INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY (TRANSMISSION CONTROL SWITCH) |

| NG |

|

|

|

6. |

CHECK HARNESS AND CONNECTOR (SHIFT LOCK CONTROL UNIT ASSEMBLY - ECM) |

Pre-procedure1

(a) Disconnect the I16 shift lock control unit assembly connector.

(b) Disconnect the A178 ECM connector.

Procedure1

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I16-5 (S) - A178-94 (S) |

Always |

Below 1 Ω |

|

I16-5 (S) or A178-94 (S) - Body ground |

Always |

10 kΩ or higher |

Post-procedure1

(d) Connect the A178 ECM connector.

(e) Connect the I16 shift lock control unit assembly connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (SHIFT LOCK CONTROL UNIT ASSEMBLY - ECM) |

|

|

7. |

REPLACE ECM |

HINT:

| NEXT |

|

PERFORM REGISTRATION AND INITIALIZATION |

|

8. |

CHECK HARNESS AND CONNECTOR (BATTERY - SHIFT LEVER POSITION SENSOR) |

Pre-procedure1

(a) Disconnect the C200 shift lever position sensor connector.

Procedure1

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C200-6 (+B) - Body ground |

Ignition switch ON |

11 to 14 V |

|

C200-6 (+B) - Body ground |

Ignition switch off |

Below 1 V |

Post-procedure1

(c) Connect the C200 shift lever position sensor connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - SHIFT LEVER POSITION SENSOR) |

|

|

9. |

INSPECT SHIFT LEVER POSITION SENSOR |

| NG |

|

|

|

10. |

CHECK HARNESS AND CONNECTOR (SHIFT LEVER POSITION SENSOR - ECM) |

Pre-procedure1

(a) Disconnect the C200 shift lever position sensor connector.

(b) Disconnect the C160 ECM connector.

Procedure1

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C200-2 (P) - C160-119 (SPP) |

Always |

Below 1 Ω |

|

C200-1 (R) - C160-118 (SPR) |

Always |

Below 1 Ω |

|

C200-8 (N) - C160-117 (SPN) |

Always |

Below 1 Ω |

|

C200-3 (DB1) - C160-116 (DB1) |

Always |

Below 1 Ω |

|

C200-9 (DB2) - C160-115 (DB2) |

Always |

Below 1 Ω |

|

C200-7 (PR) - C160-114 (RP) |

Always |

Below 1 Ω |

|

C200-4 (PNB) - C160-113 (PNB) |

Always |

Below 1 Ω |

|

C200-2 (P) or C160-119 (SPP) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C200-1 (R) or C160-118 (SPR) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C200-8 (N) or C160-117 (SPN) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C200-3 (DB1) or C160-116 (DB1) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C200-9 (DB2) or C160-115 (DB2) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C200-7 (PR) or C160-114 (RP) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C200-4 (PNB) or C160-113 (PNB) - Body ground and other terminals |

Always |

10 kΩ or higher |

Post-procedure1

(d) Connect the C160 ECM connector.

(e) Connect the C200 shift lever position sensor connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (SHIFT LEVER POSITION SENSOR - ECM) |

|

|

11. |

REPLACE ECM |

HINT:

| NEXT |

|

PERFORM REGISTRATION AND INITIALIZATION |

|

12. |

READ VALUE USING GTS (SHIFT LEVER POSITION SENSOR) |

(a) According to the display on the GTS, read the Data List.

Powertrain > Engine > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Shift Sensor Switch DB1 |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

|

Shift Sensor Switch DB2 |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

|

Shift Sensor Switch SPN |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

|

Shift Sensor Switch SPR |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

|

Shift Sensor Switch SPP |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

|

Shift Sensor Switch PNB |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

|

Shift Sensor Switch RP |

Shift lever position sensor status |

OFF or ON |

|

When the shift lever position displayed on the GTS differs from the actual position, the adjustment of the shift lever position sensor or shift cable may be incorrect. |

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Shift Sensor Switch DB1 |

|

Shift Sensor Switch DB2 |

|

Shift Sensor Switch SPN |

|

Shift Sensor Switch SPR |

|

Shift Sensor Switch SPP |

|

Shift Sensor Switch PNB |

|

Shift Sensor Switch RP |

Standard:

|

Data List |

Shift Position |

||||

|

P |

R |

N |

D |

B |

|

|

Shift Sensor Switch (DB1) |

OFF |

OFF |

OFF |

ON |

ON |

|

Shift Sensor Switch (DB2) |

OFF |

OFF |

OFF |

ON |

ON |

|

Shift Sensor Switch (SPN) |

OFF |

OFF |

ON |

OFF |

OFF |

|

Shift Sensor Switch (SPR) |

OFF |

ON |

OFF |

OFF |

OFF |

|

Shift Sensor Switch (SPP) |

ON |

OFF |

OFF |

OFF |

OFF |

|

Shift Sensor Switch (PNB) |

ON |

OFF |

ON |

OFF |

ON |

|

Shift Sensor Switch (RP) |

ON |

ON |

OFF |

OFF |

OFF |

| OK |

|

| NG |

|

|

|

|

![2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ]; K120 / K121 (CVT): K121 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)