| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000002AU7I |

| Model Year Start: 2023 | Model: Corolla Hatchback | Prod Date Range: [03/2023 - ] |

| Title: M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: REASSEMBLY; 2023 - 2025 MY Corolla Corolla Hatchback [03/2023 - ] | ||

REASSEMBLY

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

PROCEDURE

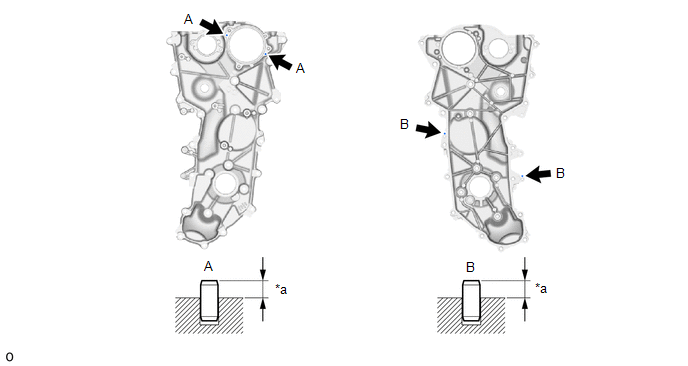

1. INSTALL STRAIGHT PIN

NOTICE:

It is not necessary to remove the straight pins unless they are being replaced.

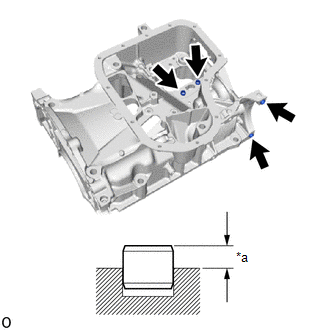

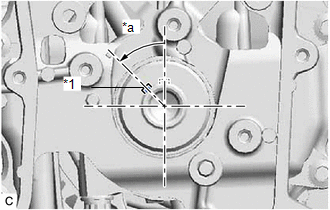

(a) Using a plastic hammer, tap in 4 new straight pins to the No. 2 timing chain cover assembly.

|

*a |

Protrusion Height |

- |

- |

Standard Protrusion Height:

Straight Pin (A)

3.0 to 5.0 mm (0.118 to 0.197 in.)

Straight Pin (B)

5.0 to 7.0 mm (0.197 to 0.276 in.)

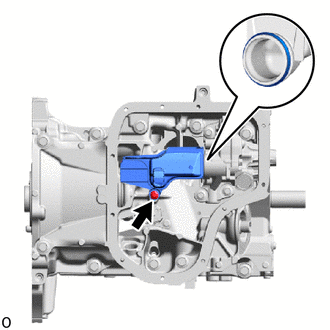

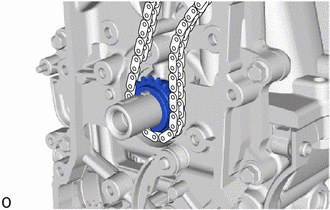

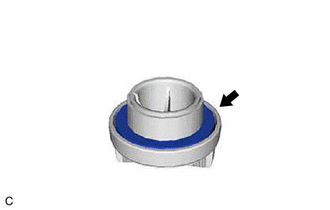

2. INSTALL RING PIN

NOTICE:

It is not necessary to remove the ring pins unless they are being replaced.

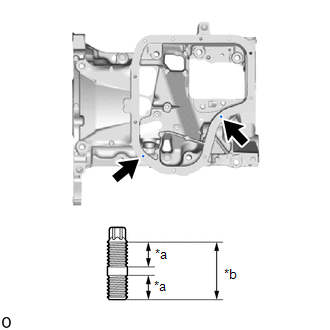

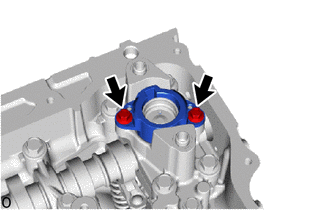

|

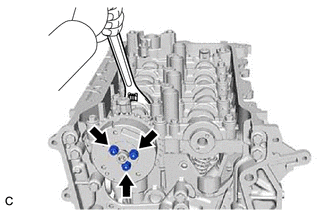

(a) Using a plastic hammer, tap in 4 new ring pins to the stiffening crankcase assembly. Standard Protrusion Height: 3.5 to 4.5 mm (0.138 to 0.177 in.) |

|

3. INSTALL STUD BOLT

NOTICE:

If a stud bolt is deformed or its threads are damaged, replace it.

|

(a) Using an E6 "TORX" socket wrench, install the 2 stud bolts to the stiffening crankcase assembly. Torque: 4.0 N·m {41 kgf·cm, 35 in·lbf} |

|

|

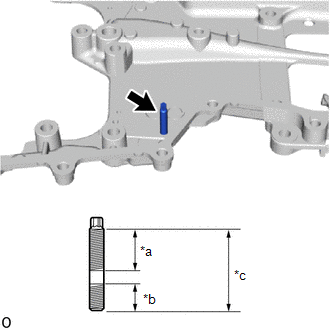

(b) Using an E6 "TORX" socket wrench, install the stud bolt to the timing chain cover assembly. Torque: 4.0 N·m {41 kgf·cm, 35 in·lbf} |

|

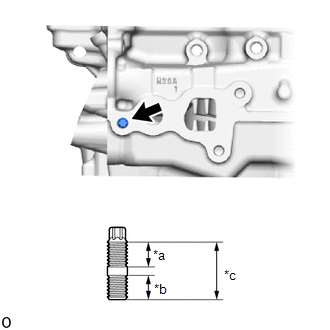

(c) w/ Stud Bolt:

|

(1) Using an E8 "TORX" socket wrench, install the stud bolt to the cylinder head sub-assembly. Torque: 6.5 N·m {66 kgf·cm, 58 in·lbf} |

|

4. INSTALL WIRE HARNESS CLAMP BRACKET

(a) Install the wire harness clamp bracket to the stiffening crankcase assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

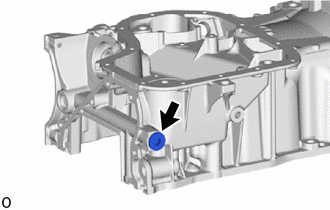

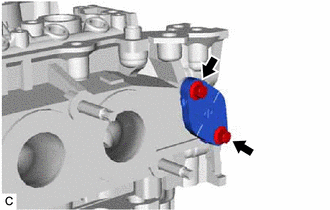

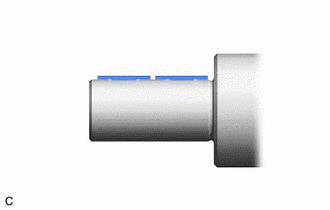

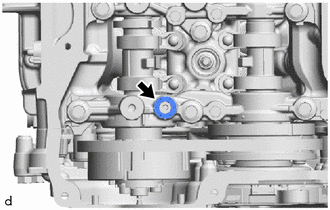

5. INSTALL STRAIGHT SCREW PLUG

|

(a) Using a 10 mm hexagon socket wrench, install the straight screw plug and a new gasket to the stiffening crankcase assembly. Torque: 44 N·m {449 kgf·cm, 32 ft·lbf} |

|

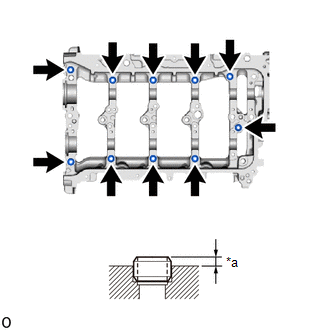

6. INSTALL STIFFENING CRANKCASE ASSEMBLY

|

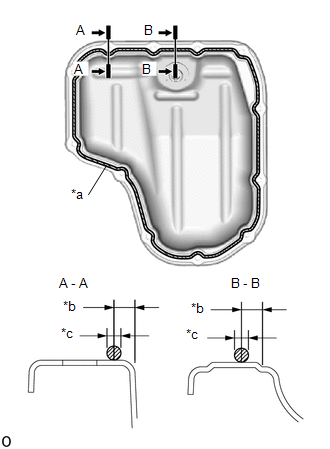

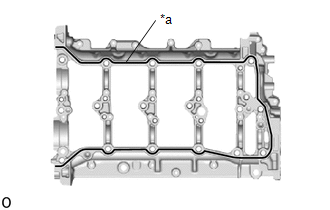

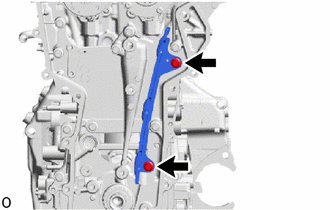

(a) Apply seal packing in a continuous line as shown in the illustration. Seal Packing: Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Standard Seal Packing Dimension:

NOTICE:

|

|

|

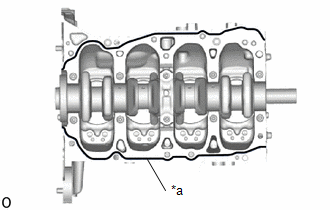

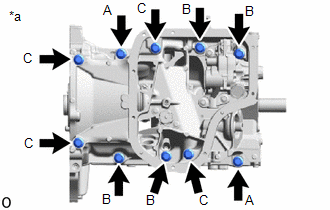

(b) Temporarily install the stiffening crankcase assembly with the 10 bolts. Bolt Length :

|

|

|

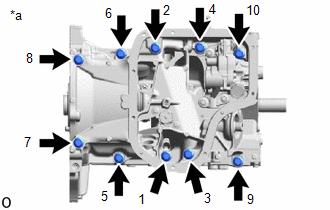

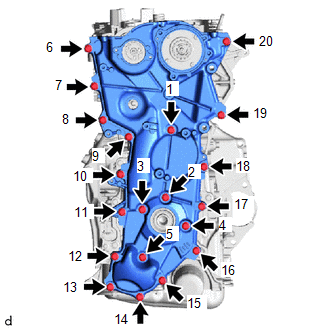

(c) Tighten the 10 bolts in the order shown in the illustration to install the stiffening crankcase assembly. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} |

|

7. INSTALL OIL PUMP ASSEMBLY

8. INSTALL ENGINE OIL LEVEL SENSOR (w/ Engine Oil Level Sensor)

9. INSTALL CRANKCASE CAP ASSEMBLY (w/o Engine Oil Level Sensor)

(a) Install the crankcase cap assembly to the stiffening crankcase assembly.

(b) Install a new clip to the crankcase cap assembly.

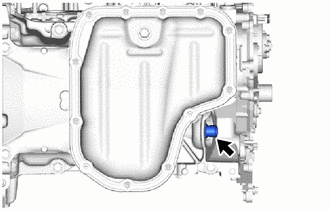

10. INSTALL OIL STRAINER SUB-ASSEMBLY

(a) Apply a light coat of engine oil to a new oil strainer gasket.

|

(b) Using an 8 mm socket wrench, install the oil strainer sub-assembly and oil strainer gasket with the bolt. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

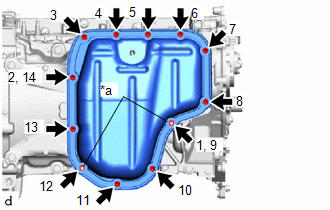

11. INSTALL OIL PAN SUB-ASSEMBLY

|

(a) Apply seal packing in a continuous line as shown in the illustration. Seal Packing: Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Standard Seal Packing Diameter: 2.5 to 3.5 mm (0.0984 to 0.138 in.) NOTICE:

|

|

|

(b) Install the oil pan sub-assembly with the 10 bolts and 2 nuts in several steps in the order shown in the illustration. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

12. INSTALL OIL PAN DRAIN PLUG

(a) Install a new gasket and the oil pan drain plug to the oil pan sub-assembly.

Torque:

40 N·m {408 kgf·cm, 30 ft·lbf}

13. INSTALL OIL FILTER UNION

|

(a) Using a 12 mm hexagon socket wrench, install the oil filter union to the stiffening crankcase assembly. Torque: 29.5 N·m {301 kgf·cm, 22 ft·lbf} |

|

14. INSTALL OIL FILTER SUB-ASSEMBLY

15. INSTALL REAR ENGINE OIL SEAL

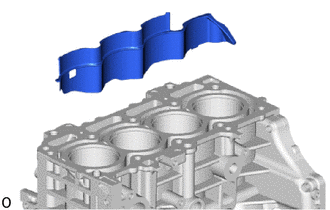

16. INSTALL CYLINDER BLOCK WATER JACKET SPACER

|

(a) Install the cylinder block water jacket spacer to the exhaust side of the cylinder block sub-assembly. |

|

17. INSTALL CYLINDER HEAD GASKET

18. INSTALL CYLINDER HEAD SUB-ASSEMBLY

HINT:

The cylinder head set bolts are tightened in 3 progressive steps.

(a) Place the cylinder head sub-assembly on the cylinder block sub-assembly.

NOTICE:

- Ensure that the contact surface of the cylinder head sub-assembly is free of oil.

- Place the cylinder head sub-assembly on the cylinder block sub-assembly gently in order not to damage the cylinder head gasket with the bottom of the cylinder head sub-assembly.

(b) Install the 6 plate washers to the 10 cylinder head set bolts.

Bolt Length :

|

Item |

Length |

|---|---|

|

Bolt (A) |

129.1 to 130.9 mm (5.08 to 5.15 in.) |

|

Bolt (B) |

139.1 to 140.9 mm (5.48 to 5.55 in.) |

|

*a |

Plate Washer |

|

Front of Engine |

(c) Apply a light coat of engine oil to the threads and under the heads of the cylinder head set bolts.

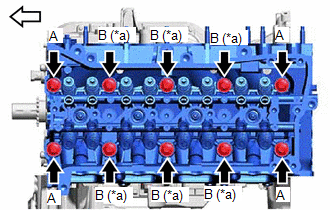

(d) Step 1:

(1) Using a 12 mm socket wrench, install and uniformly tighten the 10 cylinder head set bolts in several steps in the order shown in the illustration.

|

Front of Engine |

Torque:

50 N·m {510 kgf·cm, 37 ft·lbf}

NOTICE:

Be careful not to drop the plate washers into the cylinder head sub-assembly.

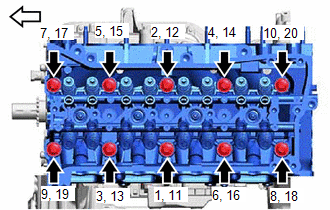

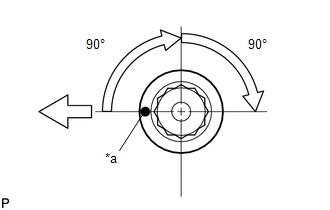

(e) Step 2:

(1) Mark each cylinder head set bolt head with paint as shown in the illustration.

|

*a |

Paint Mark |

|

Front of Engine |

(2) Tighten the cylinder head set bolts 90° in the order shown in step 1.

(f) Step 3:

(1) Tighten the cylinder head set bolts another 90° in the order shown in step 1.

(2) Check that the paint marks are now facing rearward.

HINT:

Perform Inspection After Repair after replacing the cylinder head sub-assembly.

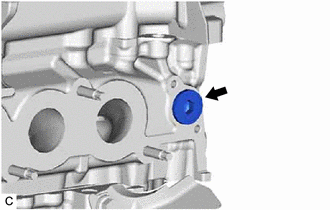

19. INSTALL WATER SEAL PLATE (w/o Straight Screw with Head Plug)

|

(a) Using an 8 mm socket wrench, install the water seal plate and a new gasket to the cylinder head sub-assembly with the 2 bolts. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} NOTICE: Install the water seal plate with the S mark facing the seating surface of the bolts. |

|

20. INSTALL STRAIGHT SCREW WITH HEAD PLUG (w/ Straight Screw with Head Plug)

|

(a) Apply adhesive to the straight screw with head plug. Adhesive: Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent |

|

(b) Using a 10 mm hexagon socket wrench, install the straight screw with head plug to the cylinder head sub-assembly.

Torque:

44 N·m {449 kgf·cm, 32 ft·lbf}

NOTICE:

- Install the straight screw with head plug within 3 minutes of applying adhesive.

- Do not add engine oil for at least 1 hour after installation.

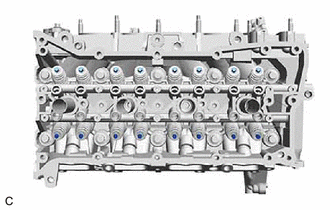

21. INSTALL VALVE STEM CAP

(a) Apply a light coat of engine oil to the valve stem cap ends.

|

(b) Install the 16 valve stem caps to the cylinder head sub-assembly. NOTICE:

|

|

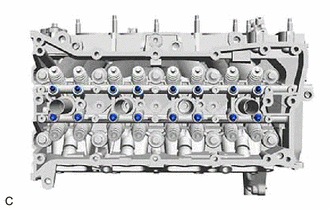

22. INSTALL VALVE LASH ADJUSTER ASSEMBLY

HINT:

If there is tappet noise from the cylinder head sub-assembly after replacing the valve lash adjuster assembly with a new one, idle the engine for 10 minutes or more and check that the tappet noise disappears.

|

(a) Apply engine oil to the outer surface of the valve lash adjuster assembly bodies and the tips of the plungers, and then install the 16 valve lash adjuster assemblies while turning them. NOTICE: Install the same parts in the same combination to their original locations. |

|

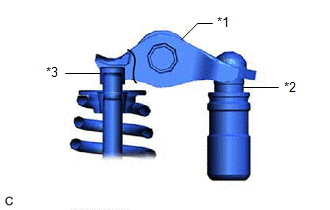

23. INSTALL NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

|

(a) Apply engine oil to the valve lash adjuster assembly tips and valve stem caps. |

|

(b) Install the 16 No. 1 valve rocker arm sub-assemblies as shown in the illustration.

NOTICE:

Install the same parts in the same combination to their original locations.

24. INSTALL CAMSHAFT BEARING CAP SETTING RING PIN

NOTICE:

It is not necessary to remove the camshaft bearing cap setting ring pins unless they are being replaced.

|

(a) Using a plastic hammer, tap in 10 new camshaft bearing cap setting ring pins to the camshaft housing sub-assembly. Standard Protrusion Height: 3.2 to 4.3 mm (0.126 to 0.169 in.) |

|

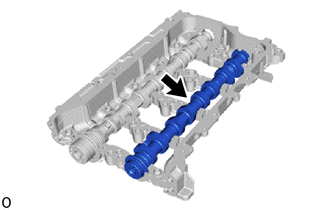

25. INSTALL EXHAUST CAMSHAFT SUB-ASSEMBLY

HINT:

Perform Inspection After Repair after replacing the exhaust camshaft sub-assembly.

(a) Clean the camshaft journals and camshaft housing sub-assembly.

(b) Apply a light coat of engine oil to the camshaft journals and camshaft housing sub-assembly.

|

(c) Install the exhaust camshaft sub-assembly to the camshaft housing sub-assembly. |

|

26. INSTALL INTAKE CAMSHAFT SUB-ASSEMBLY

HINT:

Perform Inspection After Repair after replacing the intake camshaft sub-assembly.

(a) Clean the camshaft journals, camshaft housing sub-assembly and camshaft bearing caps.

(b) Apply a light coat of engine oil to the camshaft journals, camshaft housing sub-assembly and camshaft bearing caps.

|

(c) Install the intake camshaft sub-assembly to the camshaft housing sub-assembly. |

|

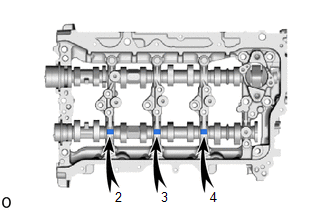

27. INSTALL CAMSHAFT BEARING CAP

|

(a) Place the No. 1 camshaft bearing cap, No. 2 camshaft bearing cap and 2 No. 3 camshaft bearing caps and No. 4 camshaft bearing cap in their correct locations. |

|

|

(b) Uniformly tighten the 9 bolts in the order shown in the illustration. Torque: 16 N·m {163 kgf·cm, 12 ft·lbf} |

|

(c) Check the torque of each bolt again.

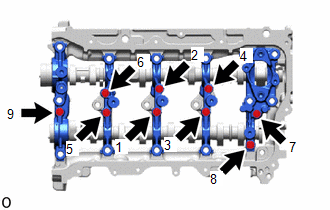

28. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY

|

(a) Check that the No. 1 valve rocker arm sub-assemblies are installed as shown in the illustration. |

|

|

(b) Apply seal packing in a continuous line as shown in the illustration. Seal Packing: Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Standard Seal Packing Diameter: 3.0 to 4.0 mm (0.118 to 0.157 in.) NOTICE:

|

|

|

(c) Position the intake camshaft sub-assembly and exhaust camshaft sub-assembly as shown in the illustration. |

|

|

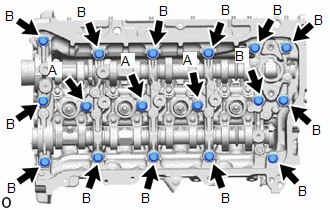

(d) Temporarily install the camshaft housing sub-assembly with the 17 bolts. Bolt Length :

|

|

|

(e) Tighten the 17 bolts in several steps in the order shown in the illustration. Torque: 28.5 N·m {291 kgf·cm, 21 ft·lbf} NOTICE:

|

|

29. INSTALL FUEL PUMP LIFTER GUIDE

|

(a) Using an 8 mm socket wrench, install the fuel pump lifter guide to the No. 4 camshaft bearing cap with the 2 bolts. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

30. INSTALL CRANKSHAFT TIMING GEAR KEY

|

(a) Using a plastic hammer, tap in the 2 crankshaft timing gear keys. HINT: Tap in the crankshaft timing gear keys until they contact the crankshaft as shown in the illustration. |

|

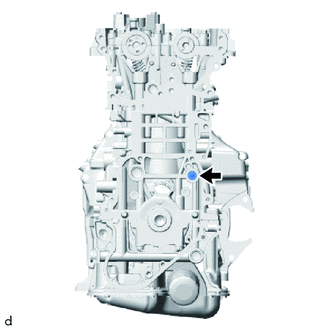

31. INSTALL OIL NOZZLE VALVE SUB-ASSEMBLY

|

(a) Install the oil nozzle valve sub-assembly to the cylinder block sub-assembly. |

|

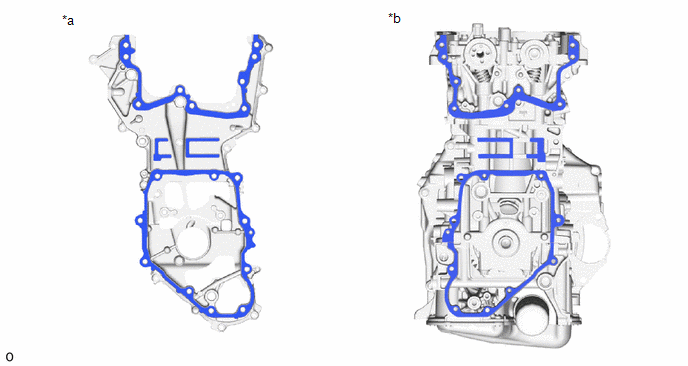

32. INSTALL TIMING CHAIN COVER ASSEMBLY

(a) Clean the contact surfaces of the timing chain cover assembly, cylinder head sub-assembly, camshaft housing sub-assembly, cylinder block sub-assembly and stiffening crankcase assembly, and confirm that no oil, moisture, or other foreign matter is on the surfaces.

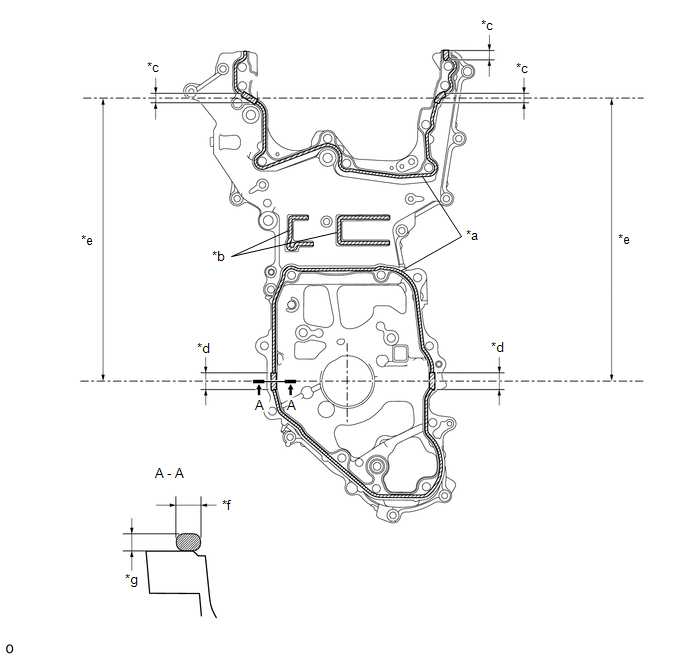

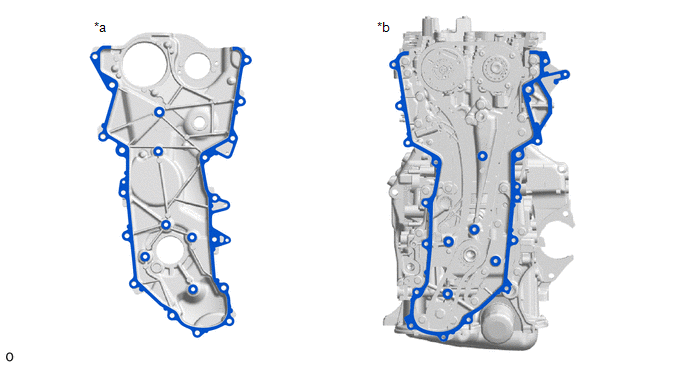

|

*a |

Timing Chain Cover Assembly Side |

*b |

Engine Assembly Side |

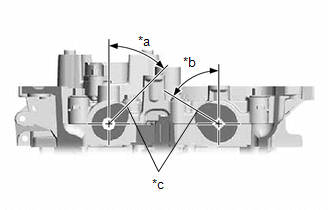

(b) Apply seal packing to the timing chain cover assembly as shown in the illustration.

|

*a |

2.5 to 3.5 mm (0.0984 to 0.138 in.) |

*b |

2.0 to 6.0 mm (0.0787 to 0.236 in.) |

|

*c |

10 mm (0.394 in.) |

*d |

20 mm (0.787 in.) |

|

*e |

344.2 mm (1.13 ft.) |

*f |

4.0 to 6.0 mm (0.157 to 0.236 in.) |

|

*g |

3.0 to 4.0 mm (0.118 to 0.157 in.) |

- |

- |

|

Seal Packing |

- |

- |

Seal Packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

NOTICE:

- Clean the surfaces with non-residue solvent before applying seal packing.

- Install the timing chain cover assembly within 3 minutes and tighten the bolts within 10 minutes of applying seal packing.

- Do not add oil for at least 2 hours after installation.

- Do not start the engine for at least 2 hours after installation.

- Make sure that the diameter at the start and end of each line of seal packing is 5 +/- 2 mm (0.197 +/- 0.0787 in.).

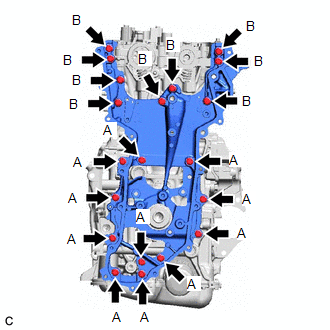

|

(c) Temporarily install the timing chain cover assembly with the 20 bolts. Bolt Length:

NOTICE: Make sure there is no oil on the bolts. If oil is found on any bolt, clean it before installation. |

|

|

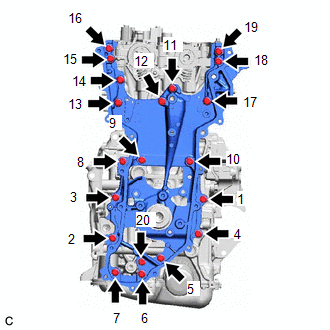

(d) Tighten the 20 bolts in the order shown in the illustration. Torque: 27 N·m {275 kgf·cm, 20 ft·lbf} |

|

33. INSTALL CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY

HINT:

Perform Inspection After Repair after replacing the camshaft timing exhaust gear assembly.

|

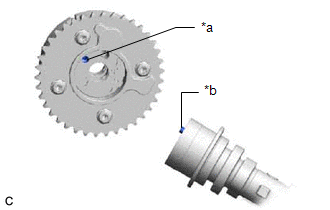

(a) Align and fit the knock pin of the exhaust camshaft sub-assembly to the knock pin hole of the camshaft timing exhaust gear assembly. |

|

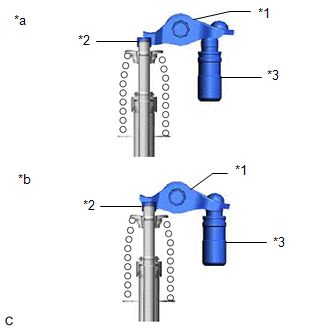

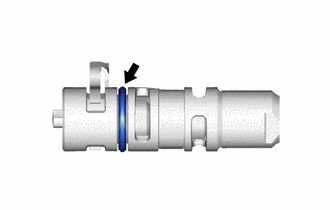

(b) Type A:

|

(1) Apply a light coat of engine oil to the O-ring of the camshaft timing oil control valve assembly (exhaust camshaft timing gear bolt assembly). NOTICE: If reusing the camshaft timing oil control valve assembly (exhaust camshaft timing gear bolt assembly), be sure to inspect the O-ring. |

|

|

(2) Using a wrench, hold the hexagonal portion of the exhaust camshaft sub-assembly. NOTICE: Be careful not to damage the camshaft housing sub-assembly, cylinder head sub-assembly and spark plug tube with the wrench. |

|

(3) Using a 5 mm hexagon socket wrench, install the camshaft timing exhaust gear assembly and camshaft timing oil control valve assembly (exhaust camshaft timing gear bolt assembly) with the 3 bolts.

Torque:

19 N·m {194 kgf·cm, 14 ft·lbf}

(c) Type B:

|

(1) Using a wrench, hold the hexagonal portion of the exhaust camshaft sub-assembly. NOTICE: Be careful not to damage the camshaft housing sub-assembly, cylinder head sub-assembly and spark plug tube with the wrench. |

|

(2) Using a 5 mm hexagon socket wrench, install the camshaft timing exhaust gear assembly and camshaft timing oil control valve assembly (exhaust camshaft timing gear bolt assembly) with the 3 bolts.

Torque:

19 N·m {194 kgf·cm, 14 ft·lbf}

NOTICE:

Make sure to fit the protrusion of the camshaft timing oil control valve assembly (exhaust camshaft timing gear bolt assembly) into the cutout of the camshaft timing exhaust gear assembly.

(3) Pull the camshaft timing oil control valve assembly (exhaust camshaft timing gear bolt assembly) to confirm that is installed securely.

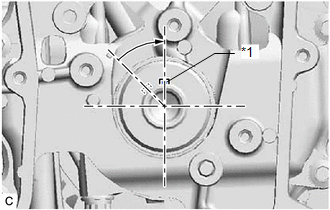

34. SET NO. 1 CYLINDER TO TDC (COMPRESSION)

(a) Temporarily install the crankshaft pulley bolt.

|

(b) Rotate the crankshaft 44.2° counterclockwise to position the crankshaft timing gear key as shown in the illustration. |

|

|

(c) Check that the timing marks of the camshaft timing exhaust gear assembly and knock pin are as shown in the illustration. |

|

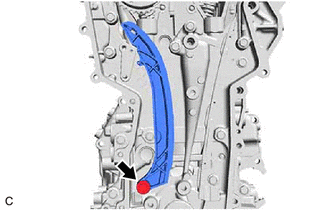

35. INSTALL NO. 1 CHAIN VIBRATION DAMPER

|

(a) Install the No. 1 chain vibration damper with the 2 bolts. Torque: 24 N·m {245 kgf·cm, 18 ft·lbf} |

|

36. INSTALL CHAIN TENSIONER SLIPPER

|

(a) Install the chain tensioner slipper with the bolt. Torque: 24 N·m {245 kgf·cm, 18 ft·lbf} |

|

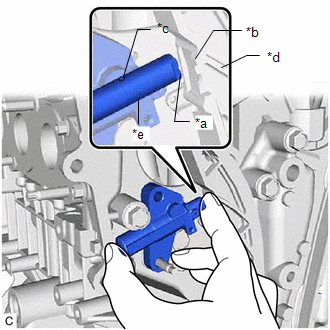

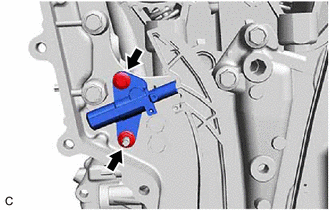

37. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

HINT:

After replacing or removing and installing the No. 1 chain tensioner assembly, an abnormal noise may occur at start up until the oil in the line has had time to replenish.

|

(a) While slightly pushing in the plunger of the No. 1 chain tensioner assembly, install the chain tensioner slipper. HINT:

|

|

|

(b) Using an 8 mm socket wrench, install the bolt. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

(c) Install the No. 1 chain tensioner assembly with the nut.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

38. INSTALL CHAIN SUB-ASSEMBLY

|

(a) Set the crankshaft timing gear key as shown in the illustration. |

|

(b) Remove the crankshaft pulley bolt.

|

(c) Install the crankshaft timing sprocket and chain sub-assembly. |

|

|

(d) Align the paint mark (yellow) of the chain sub-assembly with the timing mark of the crankshaft timing sprocket and install the chain sub-assembly to the crankshaft timing sprocket. |

|

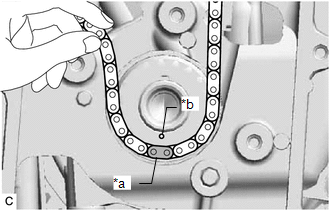

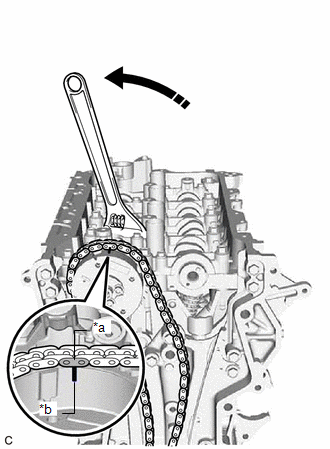

(e) Using the hexagonal portion of the exhaust camshaft sub-assembly, rotate the exhaust camshaft sub-assembly counterclockwise with a wrench, align the timing mark of the camshaft timing exhaust gear assembly with the paint mark (orange) of the chain sub-assembly, and install the chain sub-assembly to the camshaft timing exhaust gear assembly.

|

*a |

Paint Mark (Orange) |

|

*b |

Timing Mark |

|

Turn |

39. INSTALL CAMSHAFT TIMING GEAR ASSEMBLY

HINT:

Perform Inspection After Repair after replacing the camshaft timing gear assembly.

|

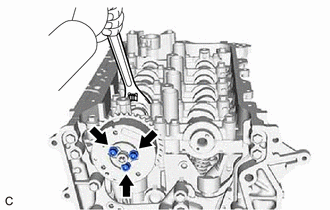

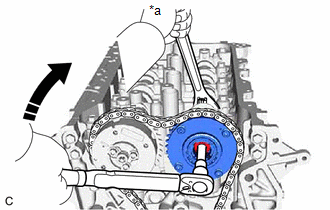

(a) Hold the hexagonal portion of the exhaust camshaft sub-assembly with a wrench and turn the camshaft timing exhaust gear assembly clockwise to loosen the chain sub-assembly between the camshaft timing exhaust gear assembly and crankshaft timing sprocket as shown in the illustration. |

|

|

(b) Align the paint mark (orange) of the chain sub-assembly with the timing mark of the camshaft timing gear assembly and install the chain sub-assembly to the camshaft timing gear assembly. |

|

|

(c) Align and fit the knock pin of the intake camshaft sub-assembly to the knock pin hole of the camshaft timing gear assembly. |

|

(d) Using a wrench, hold the hexagonal portion of the intake camshaft sub-assembly.

|

*a |

Hold |

|

Turn |

NOTICE:

- Be careful not to damage the camshaft housing sub-assembly, cylinder head sub-assembly and spark plug tube with the wrench.

- Do not disassemble the camshaft timing gear assembly.

(e) Using a 10 mm bi-hexagonal wrench, install the camshaft timing gear assembly with the bolt.

Torque:

86 N·m {877 kgf·cm, 63 ft·lbf}

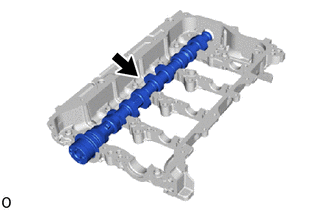

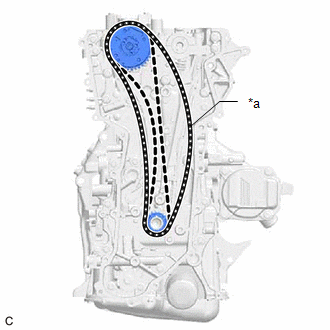

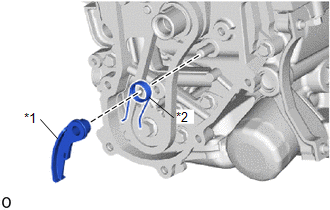

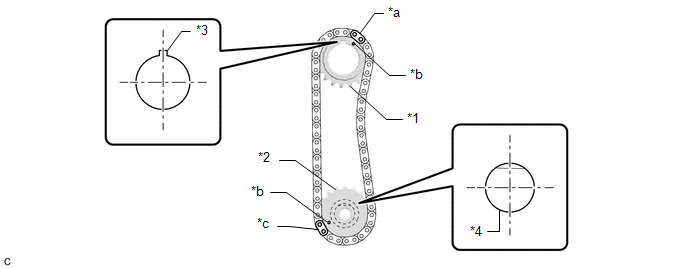

40. INSTALL OIL PUMP DRIVE CHAIN SUB-ASSEMBLY

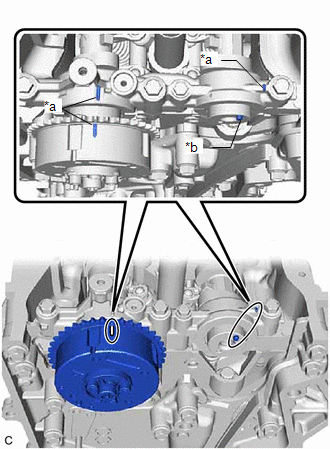

(a) Set the crankshaft timing gear key as shown in the illustration.

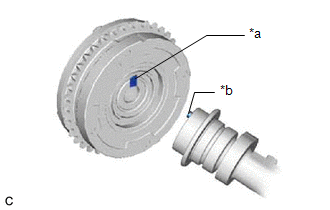

|

*1 |

Oil Pump Drive Sprocket |

*2 |

Oil Pump Drive Shaft Sprocket |

|

*3 |

Crankshaft Timing Gear Key |

*4 |

Oil Pump Sub-assembly |

|

*a |

Mark Plate (Yellow) |

*b |

Timing Mark |

|

*c |

Mark Plate (Orange) |

- |

- |

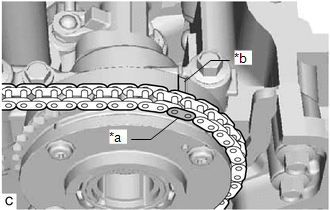

(b) Turn the oil pump drive shaft so that the flat face is facing upward.

(c) Align the mark plates with the timing marks of the oil pump drive sprocket and oil pump drive shaft sprocket as shown in the illustration.

HINT:

Make sure the mark plates of the oil pump drive chain sub-assembly are facing away from the engine assembly.

(d) With the oil pump drive chain sub-assembly placed around the oil pump drive sprocket and oil pump drive shaft sprocket, install the oil pump drive sprocket to the crankshaft and temporarily install the oil pump drive shaft sprocket to the oil pump drive shaft.

|

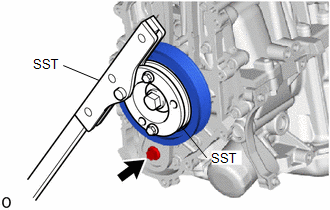

(e) Install the chain damper spring to the chain tensioner plate, and then install the chain tensioner plate. |

|

(f) Temporarily install the crankshaft pulley assembly with the crankshaft pulley bolt.

|

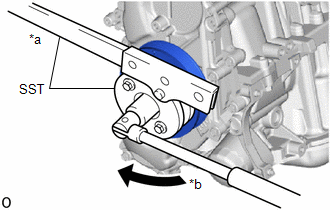

(g) Using SST, hold the crankshaft pulley assembly and tighten the bolt. SST: 09213-54015 SST: 09330-00021 Torque: 50 N·m {510 kgf·cm, 37 ft·lbf} |

|

(h) Remove SST, the crankshaft pulley bolt and crankshaft pulley assembly.

41. SET NO. 1 CYLINDER TO TDC (COMPRESSION)

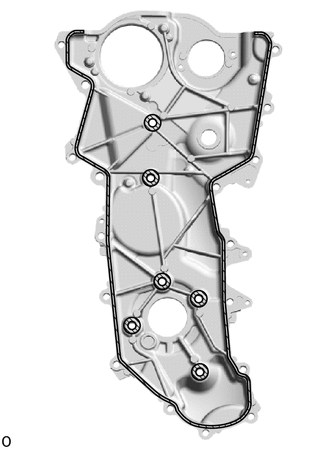

42. INSTALL NO. 2 TIMING CHAIN COVER ASSEMBLY

(a) Clean the contact surfaces of the No. 2 timing chain cover assembly and timing chain cover assembly, and confirm that no oil, moisture, or other foreign matter is on the surfaces.

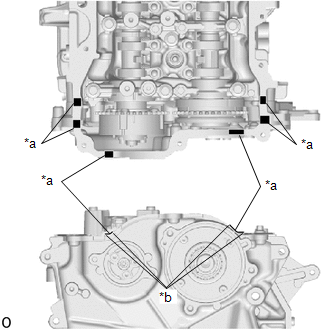

|

*a |

No. 2 Timing Chain Cover Assembly Side |

*b |

Timing Chain Cover Assembly Side |

|

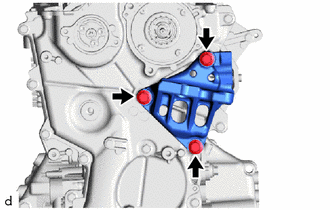

(b) Apply seal packing in a continuous line to the No. 2 timing chain cover assembly as shown in the illustration. Seal Packing: Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Standard Seal Packing Diameter: 2.5 to 3.5 mm (0.0984 to 0.138 in.) NOTICE:

|

|

|

(c) Temporarily install the No. 2 timing chain cover assembly to the timing chain cover assembly with the 20 bolts. NOTICE: Make sure there is no oil on the bolts. If oil is found on any bolt, clean it before installation. |

|

(d) Tighten the 20 bolts in the order shown in the illustration.

Torque:

24 N·m {245 kgf·cm, 18 ft·lbf}

|

(e) Install the engine mounting bracket RH with the 3 bolts. Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} NOTICE: After applying seal packing to the No. 2 timing chain cover assembly, install the engine mounting bracket RH within 10 minutes. |

|

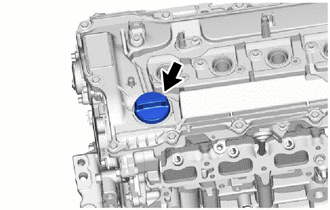

43. INSTALL STRAIGHT SCREW PLUG

(a) Apply adhesive to the straight screw plug.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent

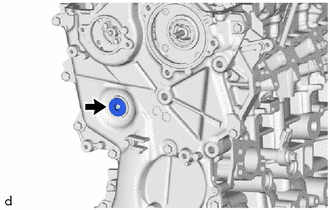

|

(b) Using a 10 mm hexagon wrench, install the straight screw plug. Torque: 40 N·m {408 kgf·cm, 30 ft·lbf} NOTICE:

|

|

44. INSTALL TIMING CHAIN COVER OIL SEAL

45. INSTALL SPARK PLUG TUBE GASKET

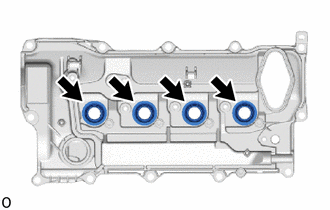

|

(a) Install 4 new spark plug tube gaskets to the cylinder head cover sub-assembly. |

|

46. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

|

(a) Install a new camshaft bearing cap oil hole gasket to the No. 1 camshaft bearing cap. NOTICE: Remove any oil from the contact surfaces. |

|

(b) Install 7 new cylinder head cover gaskets to the cylinder head cover sub-assembly.

NOTICE:

Remove any oil from the contact surfaces.

(c) Apply seal packing as shown in the illustration.

|

*a |

Seal Packing Diameter: 3.0 to 6.0 mm (0.118 to 0.236 in.) |

|

*b |

Mark |

|

Seal Packing |

Seal Packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Standard Seal Packing Diameter:

3.0 to 6.0 mm (0.118 to 0.236 in.)

NOTICE:

- Remove any oil from the contact surfaces.

- Install the cylinder head cover sub-assembly within 3 minutes and tighten the bolts within 15 minutes of applying seal packing.

- Do not start the engine for at least 2 hours after installation.

|

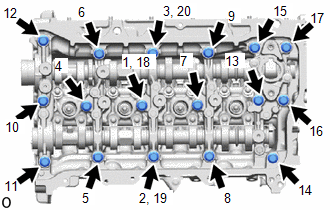

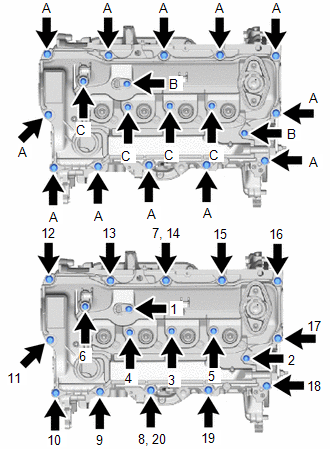

(d) Install the cylinder head cover sub-assembly with the 12 bolts (A) and using an 8 mm socket wrench, install 4 new bolts (C) and the 2 camshaft position sensors (for Exhaust Side and for Intake Side) with 2 new bolts (B) in the order shown in the illustration. Bolt Length:

Torque: 7.5 N·m {76 kgf·cm, 66 in·lbf} NOTICE:

HINT: After tightening all bolts, check the tightening torque of the bolts (7) and (8). Retighten them if necessary. |

|

47. INSTALL WATER BY-PASS OUTLET SUB-ASSEMBLY

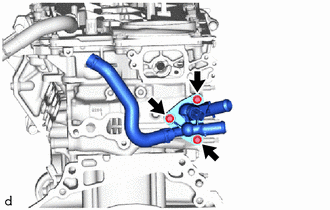

|

(a) Using an 8 mm socket wrench, install the water by-pass outlet sub-assembly and a new water pipe outlet gasket to the cylinder head sub-assembly with the 3 bolts. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

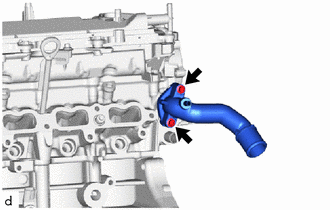

48. INSTALL WATER OUTLET

|

(a) Using an 8 mm socket wrench, install the water outlet and a new water outlet gasket to the cylinder head sub-assembly with the 2 bolts. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

49. INSTALL CRANKSHAFT PULLEY ASSEMBLY

|

(a) Align the crankshaft timing gear key with the key groove of the crankshaft pulley assembly. |

|

(b) Using SST, hold the crankshaft pulley assembly and install the crankshaft pulley bolt.

SST: 09213-54015

SST: 09330-00021

Torque:

260 N·m {2651 kgf·cm, 192 ft·lbf}

50. INSTALL VACUUM PUMP ASSEMBLY

51. INSTALL PCV VALVE (VENTILATION VALVE SUB-ASSEMBLY)

52. INSTALL CRANKSHAFT POSITION SENSOR

53. INSTALL OIL FILLER CAP GASKET

|

(a) Install a new oil filler cap gasket to the oil filler cap assembly. |

|

54. INSTALL OIL FILLER CAP ASSEMBLY

|

(a) Install the oil filler cap assembly to the cylinder head cover sub-assembly. |

|

55. INSTALL CAM TIMING CONTROL MOTOR O-RING

56. INSTALL CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY

57. INSTALL CAM TIMING OIL CONTROL SOLENOID ASSEMBLY

58. INSTALL OIL PRESSURE CONTROL VALVE ASSEMBLY

59. INSTALL OIL PRESSURE AND TEMPERATURE SENSOR

60. INSTALL KNOCK CONTROL SENSOR

61. INSTALL SPARK PLUG

|

|

|

![2019 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [06/2018 - ]; INTRODUCTION: REPAIR INSTRUCTION: PRECAUTION](/t3Portal/stylegraphics/info.gif)