- DTCs are stored

- Slight vibration at a vehicle speed of 5 km/h (3 mph) or less

- Shock or vibration during acceleration

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM1000000028RAE |

| Model Year Start: 2023 | Model: Corolla | Prod Date Range: [11/2022 - ] |

| Title: 2ZR-FXE (ENGINE MECHANICAL): REAR CRANKSHAFT OIL SEAL: REMOVAL; 2023 - 2025 MY Corolla Corolla HV [11/2022 - ] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rear crankshaft oil seal removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Replacement of inverter with converter assembly |

ECU configuration |

- |

|

|

Resolver learning |

|

||

|

Replacement of hybrid vehicle transaxle assembly |

|

||

|

Replacement of ECM |

Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU configuration |

- |

||

|

Update ECU security key |

Vehicle Control History (RoB) are stored |

||

|

Inspection After Repair |

|

|

|

Front wheel alignment adjustment |

|

|

HINT:

When the cable is disconnected / reconnected to the auxiliary battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

Learning completes when vehicle is driven

|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

|

Front Camera System |

Drive the vehicle straight ahead at 15 km/h (9 mph) or more for 1 second or more. |

PROCEDURE

1. REMOVE ENGINE ASSEMBLY

2. REMOVE TRANSMISSION INPUT DAMPER ASSEMBLY

(a) Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat level surface.

NOTICE:

- Using height adjustment attachments and plate lift attachments, keep the engine assembly horizontal.

- To prevent the oil pan sub-assembly from deforming, do not place any attachments under the oil pan sub-assembly of the engine assembly.

- Using an engine sling device and engine lift, secure the engine assembly before servicing.

|

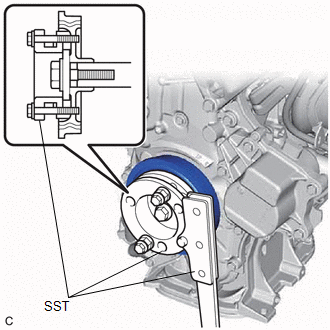

(b) Using SST, hold the crankshaft pulley. SST: 09213-58014 91551-80840 SST: 09330-00021 |

|

|

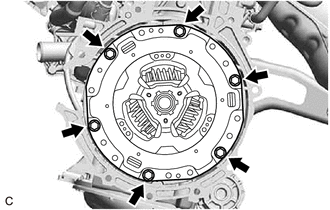

(c) Remove the 6 bolts and transmission input damper assembly from the flywheel sub-assembly. |

|

3. REMOVE FLYWHEEL SUB-ASSEMBLY

|

(a) Using SST, hold the crankshaft pulley. SST: 09213-58014 91551-80840 SST: 09330-00021 |

|

|

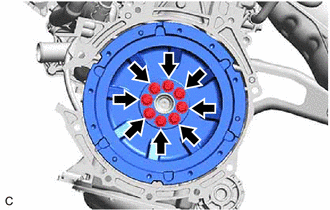

(b) Remove the 8 bolts and flywheel sub-assembly from the crankshaft. |

|

4. REMOVE REAR ENGINE OIL SEAL

|

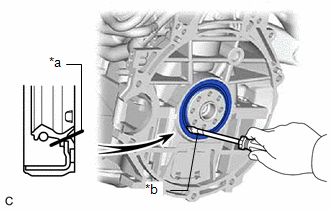

(a) Using a knife, cut through the lip of the rear engine oil seal. |

|

(b) Using a screwdriver with its tip wrapped with protective tape, pry out the rear engine oil seal.

NOTICE:

Be careful not to damage the crankshaft.

|

|

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - ]; SETUP: WHEN REPLACING OR REMOVING/INSTALLING PARTS: ECU CONFIGURATION](/t3Portal/stylegraphics/info.gif)