- If there is a malfunction when the brake signal sent via direct line is on, the engine can be started by pressing the engine switch with the brake pedal released.

-

If there is a malfunction when the brake signal sent via direct line is off, the engine cannot be started by pressing the engine switch with the brake pedal depressed.

- With the electrical key transmitter sub-assembly in the cabin, even if an engine start operation is performed, the engine does not start (the key indicator display is not displayed on the multi-information display). However, the engine can be started by turning the ignition switch to ACC and then pressing and holding it.

| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM1000000028KAA |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [11/2022 - 03/2023] |

| Title: THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): P057162; Brake Switch "A" Signal Compare Failure; 2023 MY Corolla Corolla Hatchback GR Corolla [11/2022 - 03/2023] | ||

|

DTC |

P057162 |

Brake Switch "A" Signal Compare Failure |

DESCRIPTION

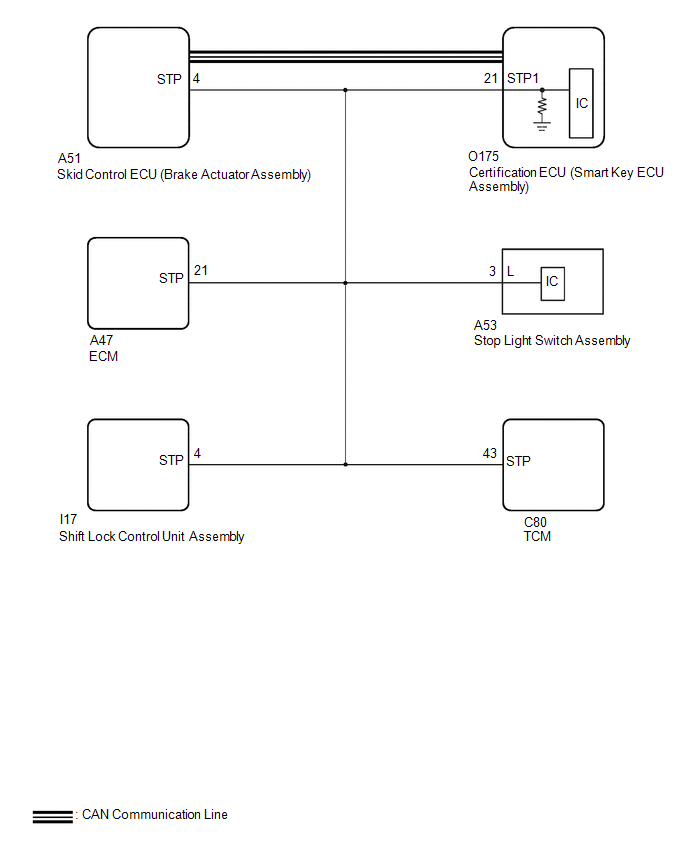

This DTC is stored when the brake signal sent via direct line and the brake signal sent via CAN communication do not match.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

Note |

|---|---|---|---|---|

|

P057162 |

Brake Switch "A" Signal Compare Failure |

The brake signal sent via direct line and the brake signal sent via CAN communication do not match. (1-trip detection logic*) |

|

DTC Output Confirmation Operation:

|

- *: Only detected while a malfunction is present and the ignition switch is ON.

Vehicle Condition and Fail-safe Function when Malfunction Detected

|

Vehicle Condition when Malfunction Detected |

Fail-safe Function when Malfunction Detected |

|---|---|

|

|

- |

Related Data List and Active Test Items

|

DTC No. |

Data List and Active Test |

|---|---|

|

P057162 |

Power Source Control

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

-

When using the GTS with the ignition switch off, connect the GTS to the DLC3 and turn a courtesy light switch on and off at intervals of 1.5 seconds or less until communication between the GTS and the vehicle begins.

Then select Model Code "KEY REGIST" under manual mode and enter the following menus: Body Electrical / Start Key(CAN). While using the GTS, periodically turn a courtesy light switch on and off at intervals of 1.5 seconds or less to maintain communication between the GTS and the vehicle.

- The smart key system (for Start Function) uses the LIN communication system and CAN communication system. Inspect the communication function by following How to Proceed with Troubleshooting. Troubleshoot the smart key system (for Start Function) after confirming that the communication systems are functioning properly.

- When disconnecting the cable from the negative (-) auxiliary battery terminal, some systems need to be initialized after the cable is reconnected.

- Before replacing the certification ECU (smart key ECU assembly), refer to Registration.

- After repair, confirm that no DTCs are output by performing "DTC Output Confirmation Operation".

PROCEDURE

|

1. |

READ VALUE USING GTS (STOP LIGHT SWITCH) |

(a) Read the Data List according to the display on the GTS.

Body Electrical > Power Source Control > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Stop Light Switch |

State of brake pedal |

OFF or ON |

OFF: Brake pedal released |

|

Body Electrical > Power Source Control > Data List

|

Tester Display |

|---|

|

Stop Light Switch |

OK:

The GTS display changes correctly in response to the brake pedal operation.

|

Result |

Proceed to |

|---|---|

|

The value of Stop Light Switch is OFF |

A |

|

The value of Stop Light Switch is not OFF |

B |

| B |

|

|

|

2. |

READ VALUE USING GTS (STOP LIGHT SWITCH) |

(a) Read the Data List according to the display on the GTS.

Body Electrical > Power Source Control > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Stop Light Switch |

State of brake pedal |

OFF or ON |

ON: Brake pedal depressed |

|

Body Electrical > Power Source Control > Data List

|

Tester Display |

|---|

|

Stop Light Switch |

OK:

The GTS display changes correctly in response to the brake pedal operation.

|

Result |

Proceed to |

|---|---|

|

The value of Stop Light Switch is ON |

A |

|

The value of Stop Light Switch is not ON |

B |

| A |

|

GO TO ELECTRONICALLY CONTROLLED BRAKE SYSTEM (HOW TO PROCEED WITH TROUBLESHOOTING) |

|

|

3. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - STOP LIGHT SWITCH ASSEMBLY) |

Pre-procedure1

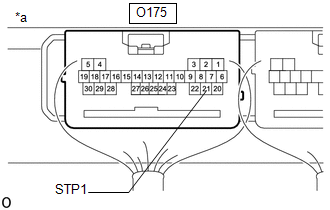

(a) Disconnect the O175 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the A53 stop light switch assembly connector.

(c) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(d) Disconnect the A47 ECM connector.

(e) Disconnect the I17 shift lock control unit assembly connector.

(f) Disconnect the C80 TCM connector.

Procedure1

(g) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

O175-21 (STP1) - A53-3 (L) |

Always |

Below 1 Ω |

Post-procedure1

(h) None

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

Pre-procedure1

(a) Connect the O175 certification ECU (smart key ECU assembly) connector.

(b) Connect the A53 stop light switch assembly connector.

Procedure1

|

(c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

Result:

|

|

Post-procedure1

(d) None

| OK |

|

| NG |

|

|

|

|

![2023 - 2025 MY Corolla Corolla Hatchback GR Corolla [11/2022 - ]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function, Gasoline Model): HOW TO PROCEED WITH TROUBLESHOOTING](/t3Portal/stylegraphics/info.gif)