| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM1000000028I85 |

| Model Year Start: 2023 | Model: Corolla Hatchback | Prod Date Range: [11/2022 - ] |

| Title: M20A-FKS (ENGINE CONTROL): THROTTLE BODY: INSTALLATION; 2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ] | ||

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

PROCEDURE

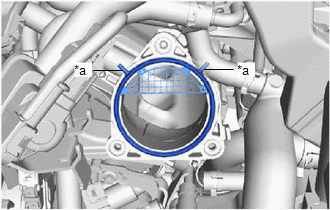

1. INSTALL THROTTLE BODY GASKET

|

(a) Install a new throttle body gasket to the intake manifold with the protrusion of the throttle body gasket oriented as shown in the illustration. |

|

2. INSTALL THROTTLE BODY WITH MOTOR ASSEMBLY

HINT:

Perform "Inspection After Repair" after replacing the throttle body with motor assembly.

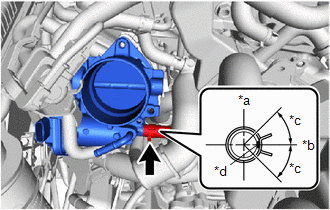

|

(a) Connect the No. 5 water by-pass hose to the throttle body with motor assembly and slide the clip to secure it. NOTICE:

|

|

|

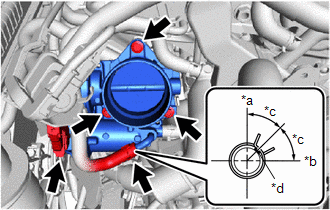

(b) Using an 8 mm socket wrench, install the throttle body with motor assembly to the intake manifold with the 3 bolts. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

(c) Connect the No. 8 water by-pass hose to the throttle body with motor assembly and slide the clip to secure it.

NOTICE:

Make sure to position the clip as shown in the illustration.

(d) Connect the throttle body with motor assembly connector.

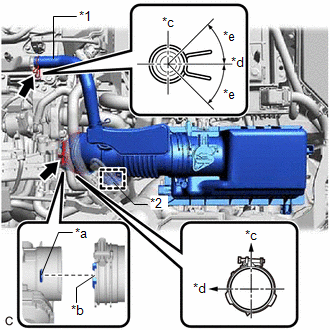

3. INSTALL AIR CLEANER CAP WITH AIR CLEANER HOSE

|

(a) Install the air cleaner cap with air cleaner hose to the throttle body with motor assembly and tighten the hose clamp. Torque: 2.0 N·m {20 kgf·cm, 18 in·lbf} NOTICE: Align the cutout of the air cleaner hose with the protrusion of the throttle body with motor assembly as shown in the illustration. |

|

(b) Connect the No. 2 ventilation hose to the cylinder head cover sub-assembly and slide the clip to secure it.

NOTICE:

Make sure to position the clip as shown in the illustration.

(c) Engage the guide to connect the vacuum switching valve assembly.

(d) Engage the 2 guides and 2 clamps.

(e) Engage the wire harness clamp and connect the mass air flow meter connector.

4. ADD ENGINE COOLANT (for Fully Sealed Type)

5. ADD ENGINE COOLANT (for Non-Fully Sealed Type)

6. INSPECT FOR COOLANT LEAK (for Fully Sealed Type)

7. INSPECT FOR COOLANT LEAK (for Non-Fully Sealed Type)

8. PERFORM INITIALIZATION

NOTICE:

- Be sure to perform this procedure after removing and reinstalling the throttle body with motor assembly or any throttle body with motor assembly components.

- Perform the following procedure after replacing the throttle body with motor assembly or any throttle body with motor assembly components. The following procedure should also be performed if the throttle body with motor assembly is cleaned.

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(e) Perform "Inspection After Repair".

(f) Start the engine and check that the MIL is not illuminated. After the engine is warmed up, check that the idle speed is within the specified range with the A/C switch off.

Standard Idle Speed:

750 to 850 rpm

NOTICE:

- Be sure to perform this step with all accessories off.

- Make sure that the shift lever is in P or N.

(g) Enter the following menus: Powertrain / Engine / Data List / Throttle Position Sensor No.1 Voltage %.

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Throttle Position Sensor No.1 Voltage % |

(h) According to the display on the Techstream, read the Data List while fully depressing the accelerator pedal and check that the value is 60% or higher.

(i) Perform a road test and confirm that there are no abnormalities.

|

|

|

![2019 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [06/2018 - ]; INTRODUCTION: REPAIR INSTRUCTION: PRECAUTION](/t3Portal/stylegraphics/info.gif)