- Replacement of cam timing control motor with EDU assembly

- Removal and installation of a cam timing control motor with EDU assembly

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM1000000028GQZ |

| Model Year Start: 2023 | Model: Corolla Hatchback | Prod Date Range: [11/2022 - 03/2023] |

| Title: M20A-FKS (ENGINE CONTROL): CAMSHAFT TIMING CONTROL MOTOR: REMOVAL; 2023 MY Corolla Corolla Hatchback [11/2022 - 03/2023] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during cam timing control motor with EDU assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

*1: w/ Smart Key System

*2: w/o Smart Key System *3: w/ Steering Lock Function |

|||

|

|

Inspection after repair |

|

|

|

Replacement of ECM |

Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

Update ECU security key |

Vehicle Control History (RoB) are stored |

||

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

||

|

|

||

|

Replacement of ECM*1 |

Code registration (Smart Key System (for Gasoline Model, Start Function)) |

|

|

|

Replacement of ECM*2 |

Code registration (Immobiliser system) |

|

|

NOTICE:

This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

HINT:

When the cable is disconnected / reconnected to the battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

Learning completes when vehicle is driven

|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

|

Front Camera System |

Drive the vehicle straight ahead at 15 km/h (9 mph) or more for 1 second or more. |

Learning completes when vehicle is operated normally

|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

| *1: for Hatchback | ||

|

Power Door Lock Control System

|

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch. |

|

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the engine switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal.

2. REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY

3. REMOVE REAR ENGINE UNDER COVER RH

4. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

5. REMOVE NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

6. REMOVE OUTER COWL TOP PANEL SUB-ASSEMBLY

7. REMOVE ECM

8. REMOVE BATTERY

9. REMOVE BATTERY CLAMP SUB-ASSEMBLY

10. REMOVE FUEL DELIVERY GUARD

11. INSTALL ENGINE HANGER

12. INSTALL ENGINE SUPPORT BRIDGE

13. REMOVE ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH

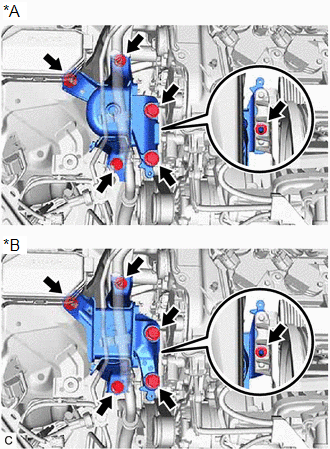

|

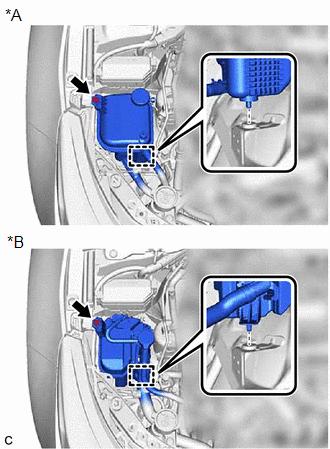

(a) Disconnect the air conditioner pressure sensor connector. |

|

|

(b) Remove the bolt. |

|

(c) Disengage the pin and separate the reserve sealed tank.

|

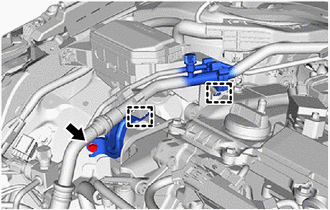

(d) Remove the bolt and disengage the clamp to remove the No. 1 cooler refrigerant hose bracket from the engine mounting insulator sub-assembly RH. |

|

(e) Disengage the clamp to separate the piping clamp.

|

(f) Remove the bolt and separate the No. 2 earth wire from the engine mounting insulator sub-assembly RH. |

|

|

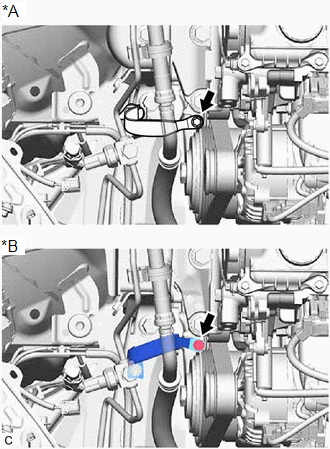

(g) Remove the 4 bolts, 2 nuts and engine mounting insulator sub-assembly RH from the vehicle body and engine mounting bracket RH. HINT: As the engine mounting insulator sub-assembly RH contacts the air conditioning tube assembly and cannot be taken out, move the engine mounting insulator sub-assembly RH to a position where the bolt of the cam timing control motor with EDU assembly can be removed. |

|

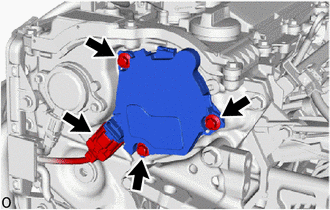

14. REMOVE CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY

|

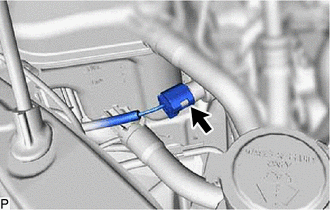

(a) Disconnect the cam timing control motor with EDU assembly connector. |

|

(b) Remove the 3 bolts and cam timing control motor with EDU assembly from the No. 2 timing chain cover assembly.

NOTICE:

If the cam timing control motor with EDU assembly has been struck or dropped, replace it.

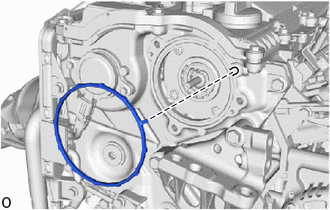

15. REMOVE CAM TIMING CONTROL MOTOR O-RING

|

(a) Remove the cam timing control motor O-ring from the No. 2 timing chain cover assembly. |

|

|

|

|

![2023 - 2025 MY Corolla Corolla Hatchback [11/2022 - ]; M20A-FKS (ENGINE CONTROL): SFI SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)