| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM1000000028D6O |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [11/2022 - 08/2023] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model with Electric Parking Brake System): C050C12; Left Rear Wheel Speed Sensor Circuit Short to Battery; 2023 MY Corolla Corolla Hatchback GR Corolla [11/2022 - 08/2023] | ||

|

DTC |

C050C12 |

Left Rear Wheel Speed Sensor Circuit Short to Battery |

DESCRIPTION

Each speed sensor detects wheel speed and sends signals to the skid control ECU (brake actuator assembly). These signals are used by the ABS control.

The speed sensor detects the magnetic fields of the speed sensor rotor as it rotates and outputs a pulse signal.

The frequency of the pulse varies in accordance with the rotational speed of the speed sensor rotor and the system uses this to determine the wheel speed.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

C050C12 |

Left Rear Wheel Speed Sensor Circuit Short to Battery |

A short to +B in the speed sensor signal circuit is detected for 0.12 seconds or more. |

|

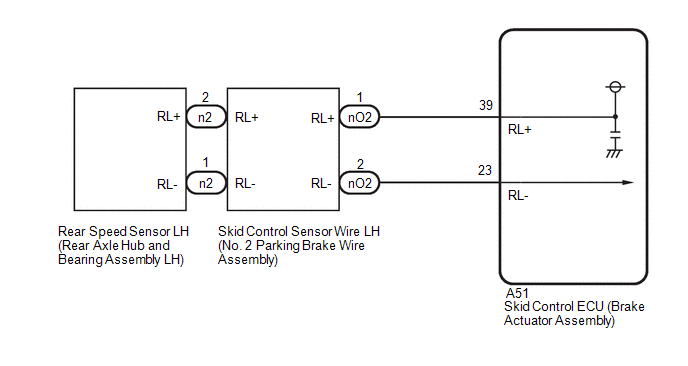

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (SENSOR GROUND CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

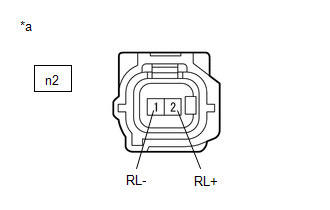

(b) Disconnect the n2 rear speed sensor LH (rear axle hub and bearing assembly LH) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the ignition switch to ON.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

n2-2 (RL+) - n2-1 (RL-) |

Ignition switch ON |

11 to 14 V |

| OK |

|

REPLACE REAR AXLE HUB AND BEARING ASSEMBLY LH |

|

|

2. |

CHECK HARNESS AND CONNECTOR (SENSOR GROUND CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

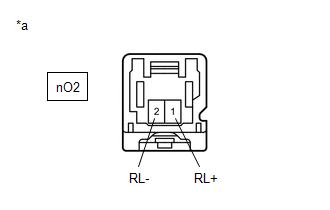

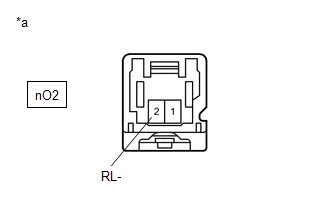

(b) Disconnect the nO2 skid control sensor wire LH (No. 2 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the ignition switch to ON.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

nO2-1 (RL+) - nO2-2 (RL-) |

Ignition switch ON |

11 to 14 V |

| OK |

|

REPLACE NO. 2 PARKING BRAKE WIRE ASSEMBLY |

|

|

3. |

CHECK HARNESS AND CONNECTOR (NO. 2 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the nO2 skid control sensor wire LH (No. 2 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

nO2-2 (RL-) - Body ground |

Always |

Below 1.5 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK HARNESS AND CONNECTOR (NO. 2 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the nO2 skid control sensor wire LH (No. 2 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

nO2-1 (RL+) or A51-39 (RL+) - nO2-2 (RL-) or A51-23 (RL-) |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV [09/2022 - ]; AXLE AND DIFFERENTIAL: REAR AXLE HUB (for Double Wishbone Type Suspension 2WD with Electric Parking Brake): REMOVAL](/t3Portal/stylegraphics/info.gif)