| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM1000000027APQ |

| Model Year Start: 2023 | Model: Corolla | Prod Date Range: [09/2022 - 11/2022] |

| Title: 2ZR-FAE (ENGINE CONTROL): SFI SYSTEM: ECM Power Source Circuit; 2023 MY Corolla [09/2022 - 11/2022] | ||

|

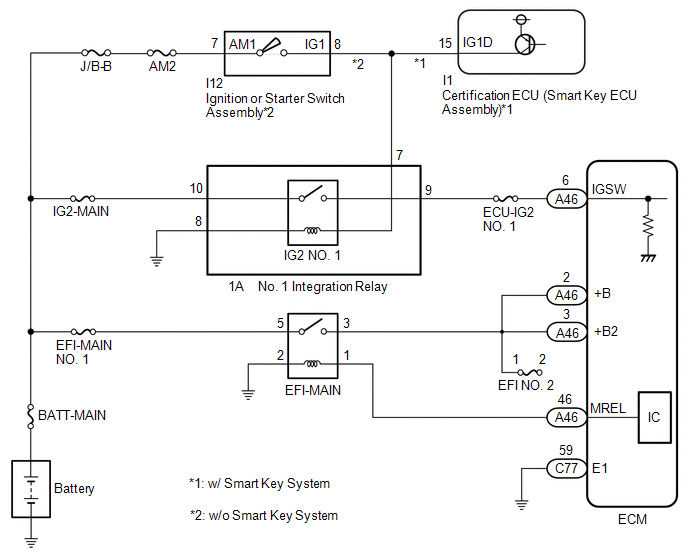

ECM Power Source Circuit |

DESCRIPTION

When the ignition switch is turned to ON, the battery voltage is applied to IGSW of the ECM. The output signal from the MREL terminal of the ECM causes a current to flow to the coil, closing the contacts of the EFI-MAIN relay and supplying power to either terminal +B or +B2 of the ECM.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (ECM - BODY GROUND) |

(a) Disconnect the ECM connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C77-59 (E1) - Body ground |

Always |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

2. |

CHECK TERMINAL VOLTAGE (IGSW TERMINAL VOLTAGE) |

|

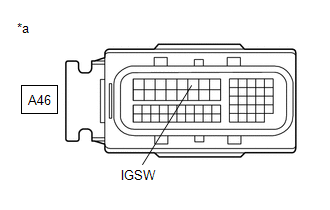

*a |

Front view of wire harness connector (to ECM) |

(a) Disconnect the ECM connector.

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A46-6 (IGSW) - Body ground |

Ignition switch ON |

11 to 14 V |

| NG |

|

|

|

3. |

INSPECT EFI-MAIN RELAY |

(a) Inspect the EFI-MAIN relay.

| NG |

|

REPLACE EFI-MAIN RELAY |

|

|

4. |

CHECK HARNESS AND CONNECTOR (EFI-MAIN RELAY - BODY GROUND) |

(a) Remove the EFI-MAIN relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2 (EFI-MAIN relay) - Body ground |

Always |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

CHECK HARNESS AND CONNECTOR (EFI-MAIN RELAY - ECM) |

(a) Disconnect the ECM connector.

(b) Remove the EFI-MAIN relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (EFI-MAIN relay) - A46-46 (MREL) |

Always |

Below 1 Ω |

|

3 (EFI-MAIN relay) - A46-2 (+B) |

Always |

Below 1 Ω |

|

3 (EFI-MAIN relay) - A46-3 (+B2) |

Always |

Below 1 Ω |

|

1 (EFI-MAIN relay) or A46-46 (MREL) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

3 (EFI-MAIN relay), A46-2 (+B) or A46-3 (+B2) - Body ground and other terminals |

Always |

10 kΩ or higher |

HINT:

If a short is detected in any of the above circuits, there may be a malfunction in the circuit of a connected ECU.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. |

CHECK TERMINAL VOLTAGE (POWER SOURCE OF EFI-MAIN RELAY) |

|

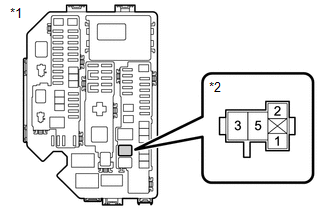

*1 |

NO. 1 Engine Room Relay Block and NO. 1 Junction Block Assembly |

|

*2 |

EFI-MAIN Relay |

(a) Remove the EFI-MAIN relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

5 (EFI-MAIN relay) - Body ground |

Always |

11 to 14 V |

| OK |

|

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - EFI-MAIN RELAY) |

|

7. |

CHECK TERMINAL VOLTAGE (POWER SOURCE OF NO. 1 INTEGRATION RELAY) |

|

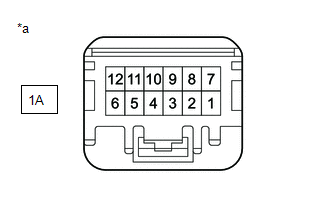

*a |

Front view of wire harness connector (to No. 1 Integration Relay) |

(a) Disconnect the No. 1 integration relay connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1A-10 - Body ground |

Always |

11 to 14 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - NO. 1 INTEGRATION RELAY) |

|

|

8. |

INSPECT NO. 1 INTEGRATION RELAY (IG2 NO. 1 RELAY) |

(a) Inspect the No. 1 integration relay (IG2 NO. 1 relay).

| NG |

|

|

|

9. |

CHECK HARNESS AND CONNECTOR (NO. 1 INTEGRATION RELAY - ECM) |

(a) Disconnect the No. 1 integration relay connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1A-9 - A46-6 (IGSW) |

Always |

Below 1 Ω |

|

1A-9 or A46-6 (IGSW) - Body ground and other terminals |

Always |

10 kΩ or higher |

HINT:

If a short is detected in any of the above circuits, there may be a malfunction in the circuit of a connected ECU.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

10. |

CHECK HARNESS AND CONNECTOR (NO. 1 INTEGRATION RELAY - BODY GROUND) |

(a) Disconnect the No. 1 integration relay connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1A-8 - Body ground |

Always |

Below 1 Ω |

|

Result |

Proceed to |

|---|---|

|

OK (w/ Smart Key System) |

A |

|

OK (w/o Smart Key System) |

B |

|

NG |

C |

| B |

|

| C |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

11. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - NO. 1 INTEGRATION RELAY) |

(a) Disconnect the certification ECU (smart key ECU assembly) connector.

(b) Disconnect the No. 1 integration relay connector.

(c) Disconnect the instrument panel junction block assembly 4F connector.

HINT:

Disconnect the IG1-NO. 1, IG1-NO. 2 and IG2-NO. 2 relays connected between the checked terminals as the coil inside the relay influences the measurement value.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I1-15 (IG1D) - 1A-7 |

Always |

Below 1 Ω |

|

I1-15 (IG1D) or 1A-7 - Body ground and other terminals |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

12. |

INSPECT IGNITION OR STARTER SWITCH ASSEMBLY |

(a) Inspect the ignition or starter switch assembly.

| NG |

|

|

|

13. |

CHECK HARNESS AND CONNECTOR (IGNITION OR STARTER SWITCH ASSEMBLY - NO. 1 INTEGRATION RELAY) |

(a) Disconnect the ignition or starter switch assembly connector.

(b) Disconnect the No. 1 integration relay connector.

(c) Disconnect the instrument panel junction block assembly 4F connector.

HINT:

Disconnect the IG1-NO. 1, IG1-NO. 2 and IG2-NO. 2 relays connected between the checked terminals as the coil inside the relay influences the measurement value.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I12-8 (IG1) - 1A-7 |

Always |

Below 1 Ω |

|

I12-8 (IG1) or 1A-7 - Body ground and other terminals |

Always |

10 kΩ or higher |

| OK |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - IGNITION OR STARTER SWITCH ASSEMBLY) |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2020 - 2023 MY Corolla [01/2019 - 11/2022]; 2ZR-FAE (ENGINE CONTROL): RELAY: ON-VEHICLE INSPECTION+](/t3Portal/stylegraphics/info.gif)