| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM10000000271T8 |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - ] |

| Title: DOOR / HATCH: FUEL LID OPENER SYSTEM: Fuel Lid Opener does not Operate; 2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - ] | ||

|

Fuel Lid Opener does not Operate |

DESCRIPTION

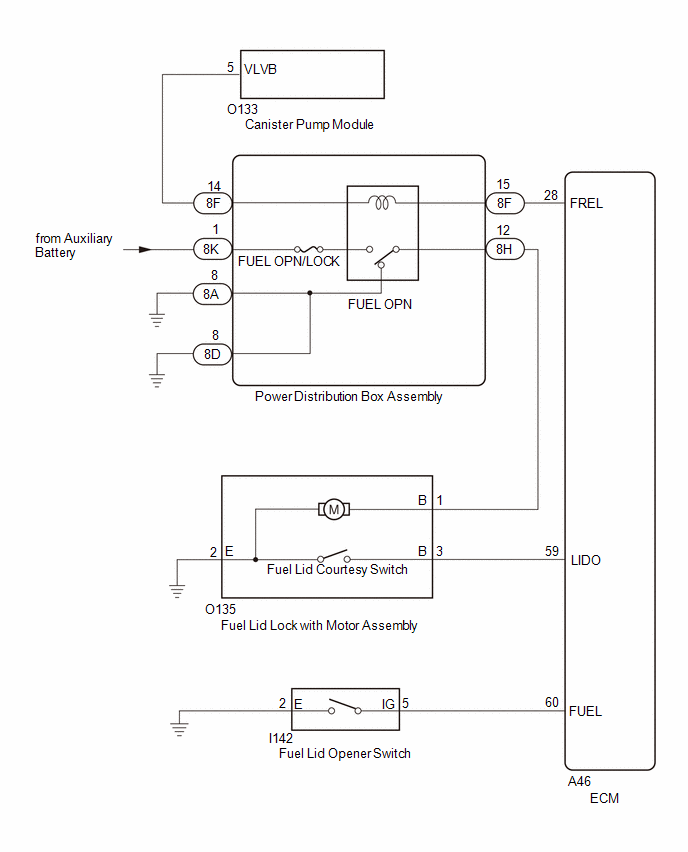

When the fuel lid opener switch is pushed, a fuel lid opener switch signal is sent to the ECM. The ECM turns on the FUEL OPN relay and EFI-MAIN relay, and the fuel lid lock with motor assembly opens the fuel lid. When the fuel lid is open, a fuel lid courtesy switch signal is output from the fuel lid lock with motor assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

|

1. |

CHECK FOR DTCs (HEALTH CHECK) |

(a) Connect the GTS to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the GTS on.

(d) Enter the following menus: System Select / Health Check.

(e) Check DTCs.

|

Result |

Proceed to |

|---|---|

|

No DTCs are output. |

A |

|

DTCs are output. |

B |

| B |

|

GO TO DTC CHART |

|

|

2. |

PERFORM ACTIVE TEST USING GTS (ACTIVATE THE FUEL FILLER OPENER) |

(a) Enter the following menus: Powertrain / Engine / Active Test.

(b) Perform the Active Test according to the display on the GTS.

Powertrain > Engine > Active Test

|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Activate the Fuel Filler Opener |

Fuel lid lock with motor assembly |

OFF/ON |

- |

Powertrain > Engine > Active Test

|

Tester Display |

|---|

|

Activate the Fuel Filler Opener |

OK:

The fuel lid lock with motor assembly operates normally.

| NG |

|

|

|

3. |

READ VALUE USING GTS (Fuel Lid SW) |

(a) Enter the following menus: Powertrain / Engine / Data List.

(b) Read the Data List according to the display on the GTS.

Powertrain > Engine > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Fuel Lid SW |

Fuel lid opener switch status |

Close or Open |

Close: Fuel lid opener switch not pushed Open: Fuel lid opener switch pushed |

- |

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Fuel Lid SW |

OK:

The GTS display changes correctly in response to the operation of the fuel lid opener switch.

| NG |

|

|

|

4. |

READ VALUE USING GTS (FUEL LID SENSOR SW) |

(a) Read the Data List according to the display on the GTS.

Powertrain > Engine > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Fuel Lid Sensor SW |

Fuel lid courtesy switch status |

Close or Open |

Close: Fuel lid closed Open: Fuel lid open |

- |

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Fuel Lid Sensor SW |

OK:

The GTS display changes correctly in response to the operation of the fuel lid courtesy switch (fuel lid lock with motor assembly).

| NG |

|

|

|

5. |

CHECK CLOSE TANK VALVE ASSEMBLY OR FUEL TANK VENT HOSE |

(a) Check the close tank valve assembly or fuel tank vent hose for clogging.

OK:

The close tank valve assembly or fuel tank vent hose is not clogged.

| OK |

|

| NG |

|

REMOVE THE CLOGGING |

|

6. |

INSPECT FUEL LID LOCK WITH MOTOR ASSEMBLY (FUEL LID COURTESY SWITCH) |

(a) Remove the fuel lid lock with motor assembly.

(b) Inspect the fuel lid lock with motor assembly.

| NG |

|

|

|

7. |

CHECK HARNESS AND CONNECTOR (FUEL LID LOCK WITH MOTOR ASSEMBLY - ECM) |

(a) Disconnect the A46 ECM connector.

(b) Disconnect the O135 fuel lid lock with motor assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

O135-3 (B) - A46-59 (LIDO) |

Always |

Below 1 Ω |

|

O135-3 (B) or A46-59 (LIDO) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

8. |

INSPECT FUEL LID OPENER SWITCH |

(a) Remove the fuel lid opener switch.

(b) Inspect the fuel lid opener switch.

| NG |

|

|

|

9. |

CHECK HARNESS AND CONNECTOR (FUEL LID OPENER SWITCH - ECM AND BODY GROUND) |

(a) Disconnect the A46 ECM connector.

(b) Disconnect the I142 fuel lid opener switch connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I142-5 (IG) - A46-60 (FUEL) |

Always |

Below 1 Ω |

|

I142-5 (IG) or A46-60 (FUEL) - Body ground |

Always |

10 kΩ or higher |

|

I142-2 (E) - Body ground |

Always |

Below 1 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

10. |

INSPECT FUEL LID LOCK WITH MOTOR ASSEMBLY (MOTOR OPERATION) |

(a) Remove the fuel lid lock with motor assembly.

(b) Inspect the fuel lid lock with motor assembly.

| NG |

|

|

|

11. |

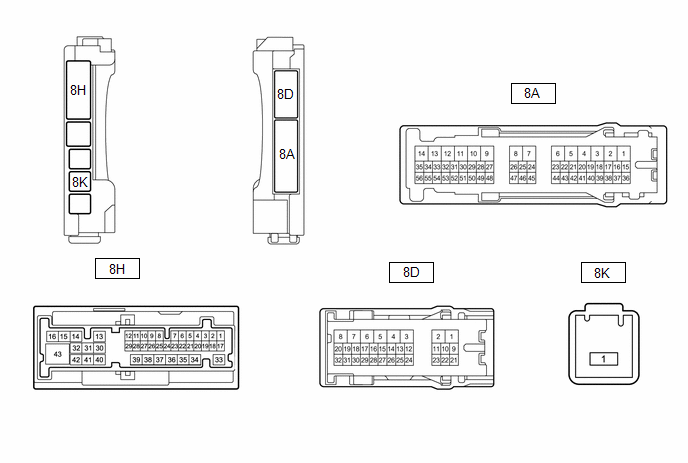

CHECK HARNESS AND CONNECTOR (FUEL LID LOCK WITH MOTOR ASSEMBLY - POWER DISTRIBUTION BOX ASSEMBLY AND BODY GROUND) |

(a) Disconnect the O135 fuel lid lock with motor assembly connector.

(b) Disconnect the 8H power distribution box assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

O135-1 (B) - 8H-12 |

Always |

Below 1 Ω |

|

O135-2 (E) - Body ground |

Always |

Below 1 Ω |

|

O135-1 (B) or 8H-12 - Body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

12. |

CHECK HARNESS AND CONNECTOR (POWER DISTRIBUTION BOX ASSEMBLY - BATTERY) |

(a) Disconnect the 8K, 8A and 8D power distribution box assembly connectors.

(b) Measure the voltage and resistance according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

8K-1 - Body ground |

Ignition switch off |

11 to 14 V |

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

8A-8 - Body ground |

Always |

Below 1 Ω |

|

8D-8 - Body ground |

Always |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

13. |

CHECK HARNESS AND CONNECTOR (POWER DISTRIBUTION BOX ASSEMBLY - ECM) |

(a) Disconnect the 8F power distribution box assembly connector.

(b) Disconnect the A46 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

8F-15 - A46-28 (FREL) |

Always |

Below 1 Ω |

|

8F-15 or A46-28 (FREL) - Body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

14. |

CHECK HARNESS AND CONNECTOR (POWER DISTRIBUTION BOX ASSEMBLY - CANISTER PUMP MODULE) |

(a) Disconnect the 8F power distribution box assembly connector.

(b) Disconnect the O133 canister pump module connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

8F-14 - O133-5 (VLVB) |

Always |

Below 1 Ω |

|

8F-14 or O133-5 (VLVB) - Body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

15. |

INSPECT POWER DISTRIBUTION BOX ASSEMBLY (FUEL OPN RELAY) |

(a) Remove the power distribution box assembly.

(b) Remove the main body ECU (multiplex network body ECU) from the power distribution box assembly.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

8K-1 - 8H-12 |

Voltage applied between terminals 8F-14 and 8F-15 |

Below 1 Ω |

|

8K-1 - 8H-12 |

Voltage not applied between terminals 8F-14 and 8F-15 |

10 kΩ or higher |

|

8A-8 - 8H-12 |

Voltage not applied between terminals 8F-14 and 8F-15 |

Below 1 Ω |

|

8A-8 - 8H-12 |

Voltage applied between terminals 8F-14 and 8F-15 |

10 kΩ or higher |

|

8D-8 - 8H-12 |

Voltage not applied between terminals 8F-14 and 8F-15 |

Below 1 Ω |

|

8D-8 - 8H-12 |

Voltage applied between terminals 8F-14 and 8F-15 |

10 kΩ or higher |

| NG |

|

|

|

16. |

CHECK CANISTER PUMP MODULE (VENT VALVE POWER SOURCE CIRCUIT) |

| OK |

|

| NG |

|

|

|

|

![2023 - 2025 MY Corolla Corolla Hatchback [09/2022 - ]; M20A-FKS (EMISSION CONTROL): EMISSION CONTROL SYSTEM (w/ Canister Pump Module): ON-VEHICLE INSPECTION](/t3Portal/stylegraphics/info.gif)