- Poor idle, etc.

- Engine start function, etc.

| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM100000002714W |

| Model Year Start: 2023 | Model: Corolla Hatchback | Prod Date Range: [09/2022 - 11/2022] |

| Title: EG60 (MANUAL TRANSMISSION / TRANSAXLE): MANUAL TRANSAXLE ASSEMBLY: REMOVAL; 2023 MY Corolla Corolla Hatchback [09/2022 - 11/2022] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during manual transaxle assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

*1: w/ Smart Key System

*2: w/o Smart Key System *3: w/ Steering Lock Function |

|||

|

Replacement of ECM |

Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

||

|

Gas leak from exhaust system is repaired |

Inspection after repair |

|

|

|

Replacement of ECM*1 |

Code registration (Smart Key System (for Gasoline Model, Start Function)) |

|

|

|

Replacement of ECM*2 |

Code registration (Immobiliser system) |

|

|

|

Front wheel alignment adjustment |

|

|

|

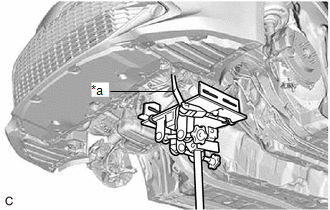

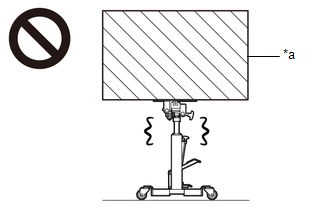

CAUTION:

-

To prevent burns, do not touch the engine, exhaust pipe or other high temperature components while the engine is hot.

-

Because the manual transaxle assembly is extremely heavy, make sure to follow the work procedures described in the repair manual.

*a

Heavy object exceeding the capacity of the transmission jack

- If work is not performed according to the procedures described in the repair manual, there is a danger that the transmission jack could drop and components could fall down.

NOTICE:

When the manual transaxle assembly is removed, be sure to use a new clutch release cylinder with bearing assembly and new installation bolts. Removal of the manual transaxle assembly allows the compressed clutch release cylinder with bearing assembly to return to its original position. Dust from the moving section may damage the seal of the clutch release cylinder with bearing assembly, possibly causing clutch fluid leaks.

HINT:

When the cable is disconnected / reconnected to the battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

Learning completes when vehicle is driven

|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

|

Pre-collision System (for TMMMS Made) |

Drive the vehicle straight ahead at 35 km/h (22 mph) or more for 5 seconds or more. |

|

|

Lane Tracing Assist System (for TMMMS Made) |

||

|

Lane Departure Alert System (for TMMMS Made) |

PROCEDURE

1. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

2. REMOVE FRONT DRIVE SHAFT ASSEMBLY

3. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

4. REMOVE NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

5. REMOVE OUTER COWL TOP PANEL SUB-ASSEMBLY

|

(a) Remove the 9 bolts, 4 nuts and outer cowl top panel sub-assembly. |

|

|

(b) Install the 4 nuts. Torque: 50 N·m {510 kgf·cm, 37 ft·lbf} |

|

6. REMOVE ECM

7. REMOVE BATTERY

8. REMOVE BATTERY CLAMP SUB-ASSEMBLY

9. DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

10. REMOVE FRONT FLOOR COVER LH

11. REMOVE FRONT FLOOR COVER RH

12. REMOVE FRONT FLOOR CENTER BRACE

13. REMOVE FRONT EXHAUST PIPE ASSEMBLY (TWC: Rear Catalyst)

14. DISCONNECT WIRE HARNESS

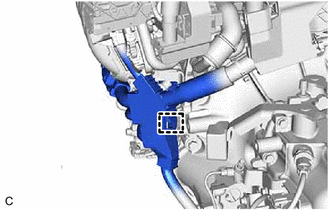

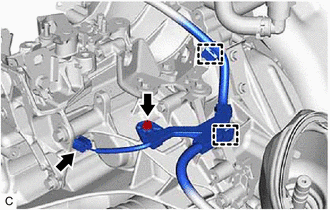

|

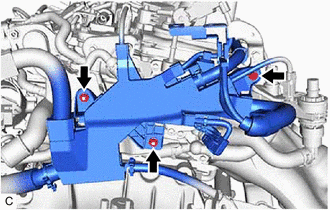

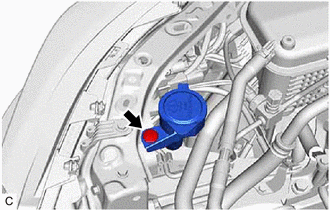

(a) Disconnect the engine coolant temperature sensor connector. |

|

|

(b) Remove the bolt and 2 nuts. |

|

|

(c) Disengage the clamp. |

|

|

(d) Disconnect the back-up light switch assembly connector. |

|

(e) Remove the bolt.

(f) Disengage the 2 clamps.

|

(g) w/ Neutral Position Switch: (1) Disconnect the neutral position switch connector. |

|

(h) Disconnect the transmission revolution sensor connector.

(i) Remove the earth bolt.

(j) Disengage the 2 clamps.

|

(k) Disengage the 3 clamps. |

|

15. REMOVE FUEL DELIVERY GUARD

16. INSTALL ENGINE HANGER

17. REMOVE STARTER ASSEMBLY

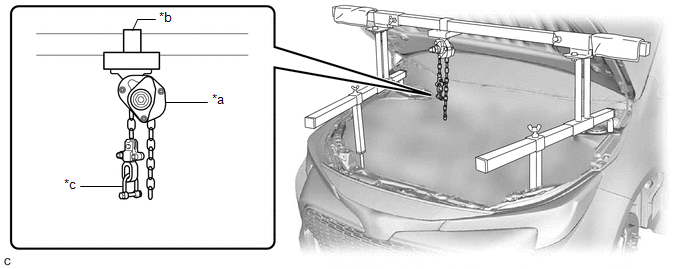

18. INSTALL ENGINE SUPPORT BRIDGE

|

(a) Remove the clip and disconnect the neck from the windshield washer jar assembly. |

|

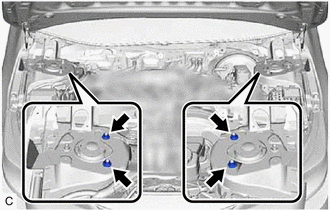

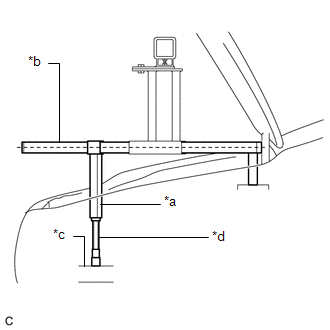

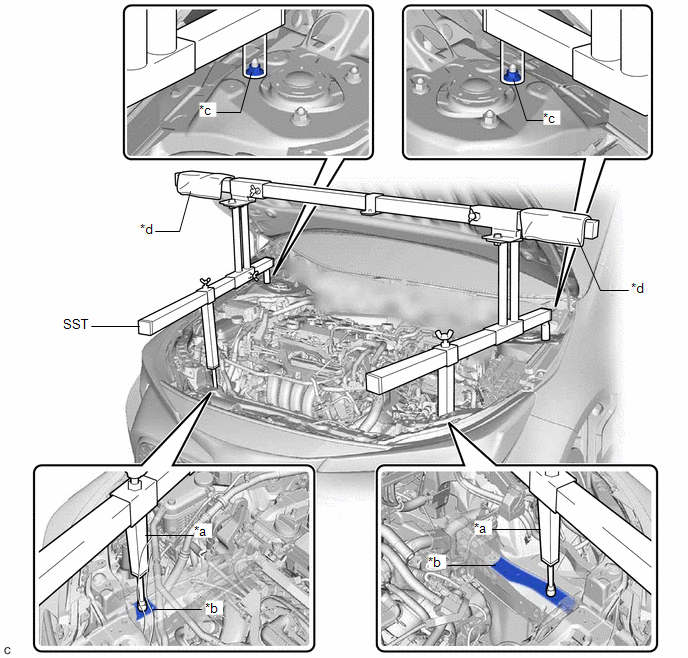

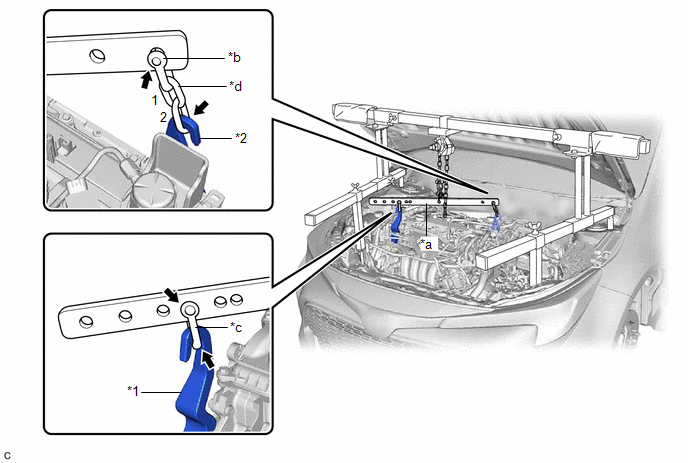

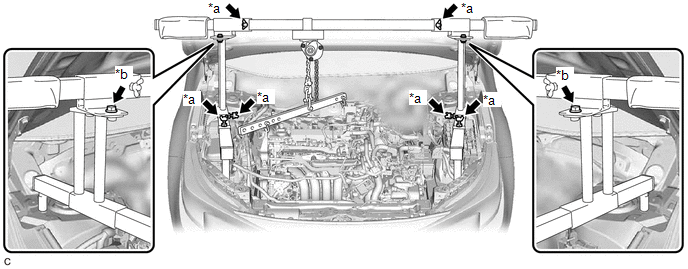

(b) Install SST to the vehicle body as shown in the illustration.

|

*a |

Support Shaft |

*b |

Front Side Member |

|

*c |

Nut |

*d |

Cloth |

SST: 09940-10020

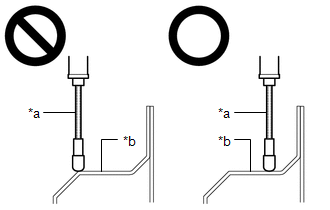

CAUTION:

-

Make sure that no oil or grease is on the front side member, and set the support shaft on the level surface of the front side member.

*a

Support Shaft

*b

Front Side Member

- The engine support bridge may fall off if any oil or grease is still on or it is installed on the unlevel surface.

NOTICE:

- Prevent SST from contacting the vehicle body exterior and windshield glass.

- To prevent damage to the engine hood, place pieces of cloth between the engine hood and SST.

- Lightly shake SST by hand to make sure it is securely installed before performing work.

|

(c) Turn the threaded portion of each support shaft to adjust its height until the sub beams are parallel to the ground. |

|

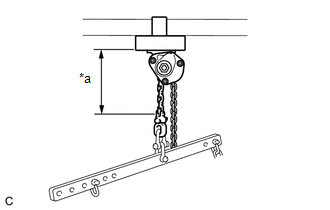

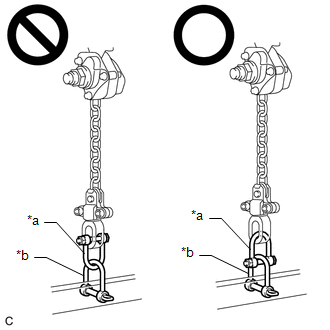

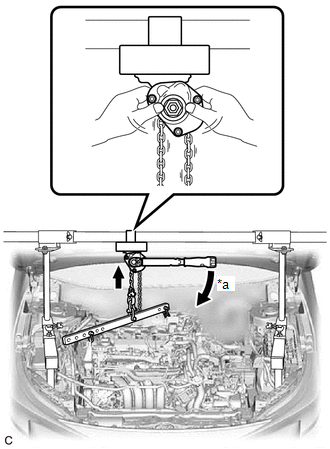

(d) Install the chain block assembly to the sling bracket.

|

*a |

Chain Block Assembly |

*b |

Sling Bracket |

|

*c |

Fuse Shackle |

- |

- |

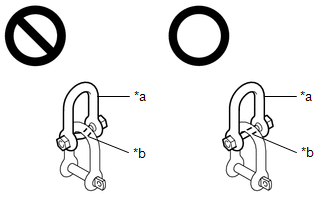

(e) Install the division bar to the chain block assembly with the shackle (A).

CAUTION:

-

Make sure the fuse shackle is on the chain block assembly side and the shackle (A) is on the division bar side as shown in the illustration so that the fuse bolt is visible and can be checked for deformation easily.

*a

Fuse Shackle

*b

Shackle (A)

- If the fuse shackle is installed upside down, deformation of the fuse bolt will not be visible and cannot be used to tell if the load capacity of the engine support bridge has been exceeded. If the load capacity is exceeded, it may cause the engine support bridge to damage the vehicle and the engine assembly with transaxle assembly may fall.

-

Make sure that the fuse bolt of the fuse shackle is free of damage, such as deformation or cracks. If damaged, replace the fuse shackle.

*a

Fuse Shackle

*b

Fuse Bolt

- If a deformed fuse bolt is used, it cannot be used to tell if the load capacity of the engine support bridge has been exceeded. If the load capacity is exceeded, it may cause the engine support bridge to damage the vehicle and the engine assembly with transaxle assembly may fall.

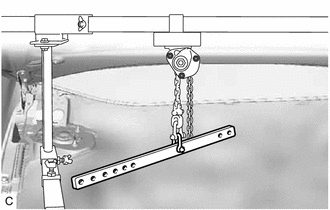

(f) Connect the division bar to the No. 1 engine hanger with the shackle (B).

|

*1 |

No. 1 Engine Hanger |

*2 |

No. 2 Engine Hanger |

|

*a |

Division Bar |

*b |

Shackle (A) |

|

*c |

Shackle (B) |

*d |

Chain |

(g) Connect the division bar to the No. 2 engine hanger with the shackle (A) and chain.

NOTICE:

Connect the 2nd link of the chain to the No. 2 engine hanger.

|

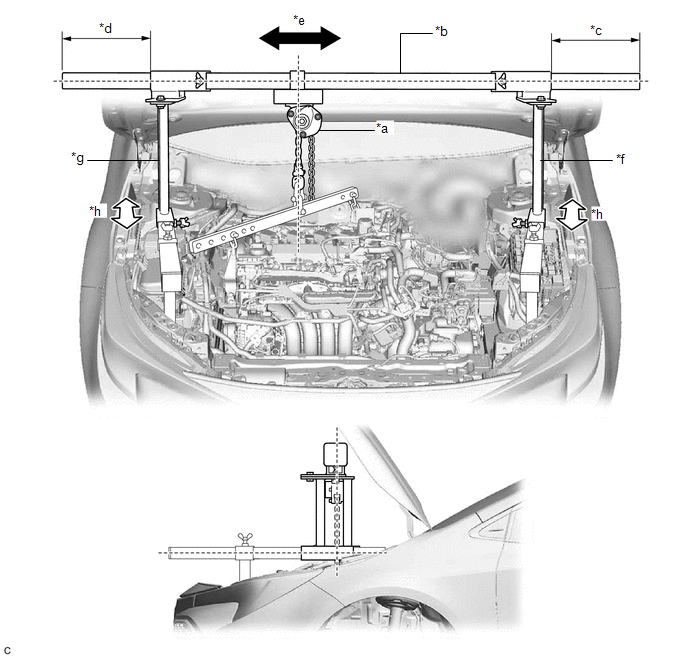

(h) Make sure the distance between the chain block assembly and suspension ring is 120 mm (4.72 in.) or more. HINT: If the suspension height is less than 120 mm (4.72 in.), adjust the links of the chain which connect the division bar and engine hanger. |

|

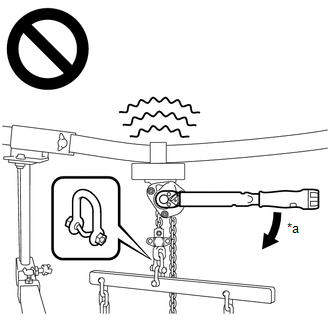

(i) Adjust the positions of the chain block assembly, support brackets and main beam so that the chain of the chain block assembly is perpendicular to the main beam and the length of the main beam on the outer side of the support bracket LH and RH is the same as shown in the illustration.

|

*a |

Chain Block Assembly |

*b |

Main Beam |

|

*c |

Dimension (A) |

*d |

Dimension (B) |

|

*e |

Right to Left Adjustment |

*f |

Support Bracket LH |

|

*g |

Support Bracket RH |

*h |

Front to Rear Adjustment |

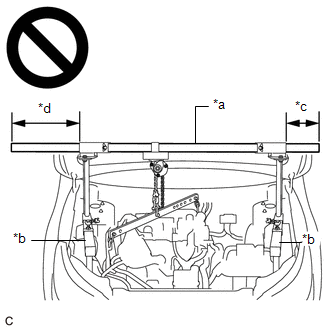

CAUTION:

-

To prevent the engine with transaxle assembly from falling, make sure that the length of dimension (A) and dimension (B) are equal.

*a

Main Beam

*b

Sub Beam

*c

Dimension (A)

*d

Dimension (B)

- Do not perform any procedures if the length of dimension (A) and dimension (B) are not equal.

- Performing any procedure when the length of dimension (A) and dimension (B) are not equal may cause the engine assembly with transaxle assembly and engine support bridge to fall, possibly causing serious injury.

- Do not perform any procedures if the chain of the chain block assembly is not straight.

- When removing the engine mount, if the chain of the chain block assembly is not straight, the engine assembly or transaxle assembly may contact the vehicle body.

(j) Confirm the appropriate installation state of the engine support bridge and tighten the 6 wing bolts and 2 bolts.

|

*a |

Wing Bolt |

*b |

Bolt |

Torque:

Bolt :

30 N·m {306 kgf·cm, 22 ft·lbf}

CAUTION:

-

Do not perform any procedures before tightening the bolts to the specified torque.

- Performing procedures without tightening the bolts to the specified torque, may cause the engine support bridge to fall.

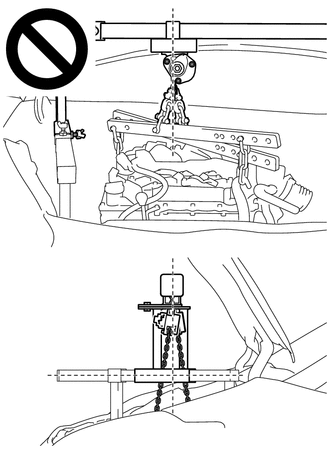

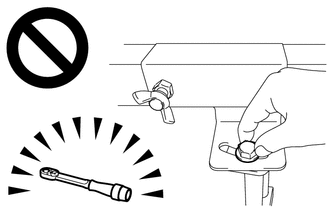

(k) Tighten the chain block assembly until it cannot be moved any further by hand.

|

*a |

Turn |

|

*a |

41 N*m (418 kgf*cm, 30 ft.*lbf) or more |

- When suspending the engine with transaxle assembly, do not tighten the chain block assembly more than 41 N*m (418 kgf*cm, 30 ft.*lbf).

- Tightening the chain block assembly more than 41 N*m (418 kgf*cm, 30 ft.*lbf) will cause the load capacity (400 kg (881.8 lb)) to be exceeded and may cause damage to the engine support bridge and vehicle body.

19. SECURE STEERING WHEEL

20. REMOVE COLUMN HOLE COVER SILENCER SHEET

21. SEPARATE NO. 2 STEERING INTERMEDIATE SHAFT ASSEMBLY

22. SEPARATE NO. 1 STEERING COLUMN HOLE COVER SUB-ASSEMBLY

23. REMOVE REAR SIDE RAIL REINFORCEMENT SUB-ASSEMBLY LH

24. REMOVE REAR SIDE RAIL REINFORCEMENT SUB-ASSEMBLY RH

25. REMOVE FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

|

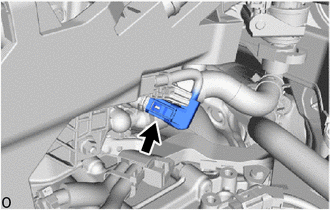

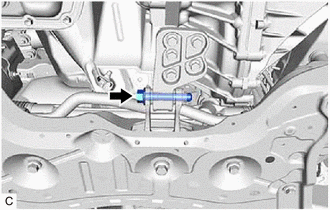

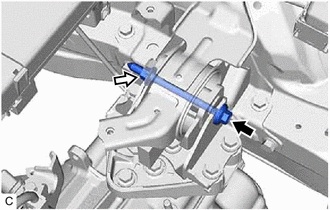

(a) Remove the bolt and separate the engine moving control rod. |

|

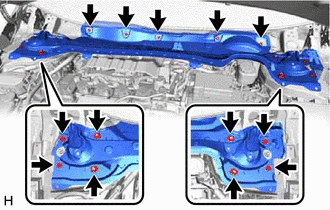

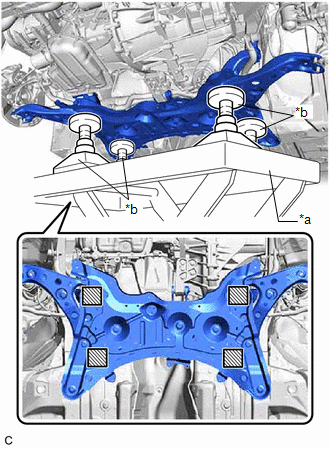

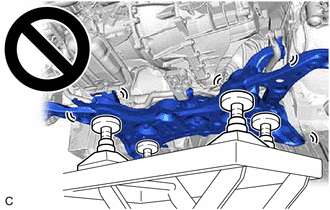

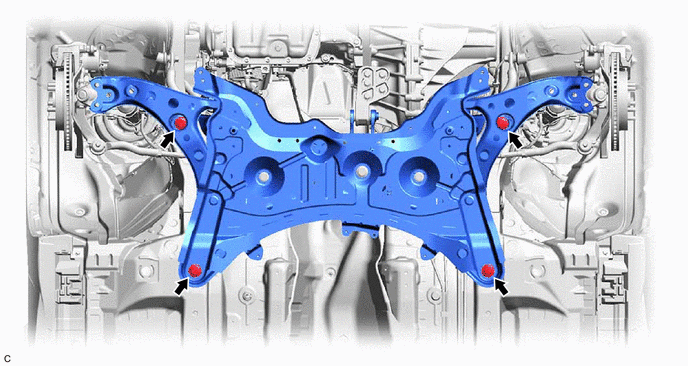

(b) Support the front suspension crossmember sub-assembly with an engine lifter using 4 attachments or equivalent tools as shown in the illustration.

|

*a |

Engine Lifter |

|

*b |

Attachment |

|

Attachment placement location |

CAUTION:

- The front suspension crossmember sub-assembly is a very heavy component. Make sure that it is supported securely.

- If the front suspension crossmember sub-assembly is not securely supported, it may drop, resulting in serious injury.

NOTICE:

Use attachments to keep the front suspension crossmember sub-assembly level.

(c) Remove the 4 bolts and front suspension crossmember sub-assembly from the vehicle body.

(d) Slowly lower the front suspension crossmember sub-assembly.

NOTICE:

When lowering the front suspension crossmember sub-assembly, be careful not to damage the vehicle body or other components installed to the vehicle.

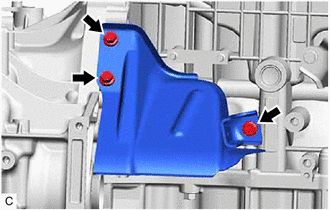

26. REMOVE MANIFOLD STAY

27. REMOVE DRIVE SHAFT HEAT INSULATOR SUB-ASSEMBLY

|

(a) Remove the 3 bolts and drive shaft heat insulator sub-assembly from the cylinder block sub-assembly. |

|

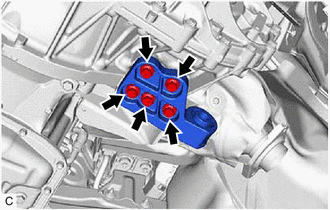

28. REMOVE NO. 2 ENGINE MOVING CONTROL ROD

|

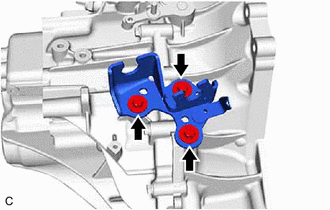

(a) Remove the 5 bolts and No. 2 engine moving control rod from the manual transmission case. |

|

29. SUPPORT MANUAL TRANSAXLE ASSEMBLY

|

(a) Using a transmission jack, support the manual transaxle assembly. NOTICE:

|

|

30. REMOVE ENGINE MOUNTING INSULATOR LH

(a) Remove the bolt and nut.

|

Bolt |

|

Nut |

NOTICE:

While holding the nut in place, loosen the bolt.

|

(b) Remove the 4 bolts, nut and engine mounting insulator LH from the vehicle body. |

|

31. REMOVE ENGINE MOUNTING STAY LH

HINT:

Perform this procedure only when replacement of the engine mounting stay LH is necessary.

|

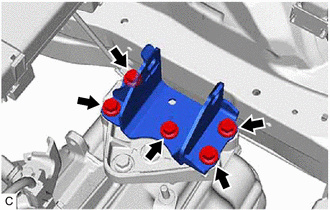

(a) Remove the 5 bolts and engine mounting stay LH from the engine mounting bracket LH. |

|

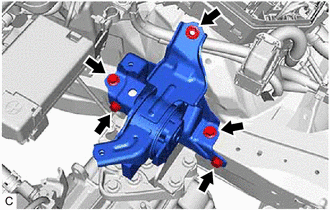

32. REMOVE ENGINE MOUNTING BRACKET LH

|

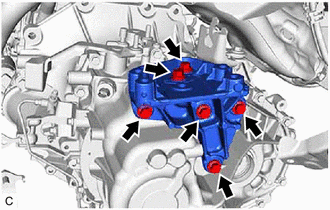

(a) Remove the 6 bolts and engine mounting bracket LH from the manual transmission case. |

|

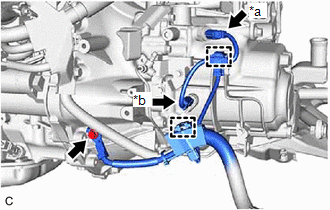

33. DISCONNECT NO. 1 CLUTCH HOSE

34. REMOVE MANUAL TRANSAXLE ASSEMBLY

|

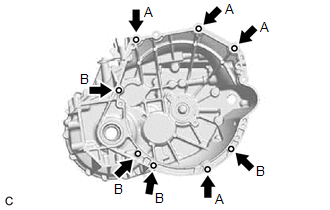

(a) Remove the 8 bolts and manual transaxle assembly from the engine assembly. NOTICE: To prevent damage to the 2 knock pins, do not pry between the manual transaxle assembly and engine assembly. HINT:

|

|

35. REMOVE BLEEDER TO FLEXIBLE HOSE TUBE

36. REMOVE CLUTCH RELEASE CYLINDER WITH BEARING ASSEMBLY

37. REMOVE CLUTCH RELEASE CYLINDER WITH BEARING ASSEMBLY TO BLEEDER TUBE

38. REMOVE CLUTCH RELEASE BLEEDER SUB-ASSEMBLY

39. REMOVE CLUTCH FLEXIBLE HOSE BRACKET

|

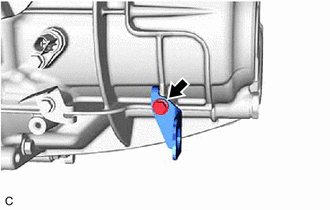

(a) Remove the bolt and clutch flexible hose bracket from the manual transmission case. |

|

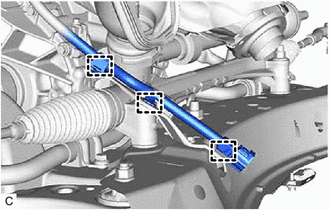

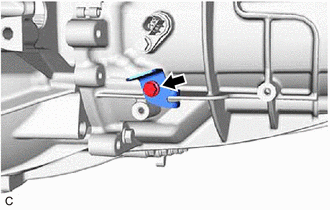

40. REMOVE WIRE HARNESS CLAMP BRACKET

|

(a) Remove the bolt and wire harness clamp bracket from the manual transmission case. |

|

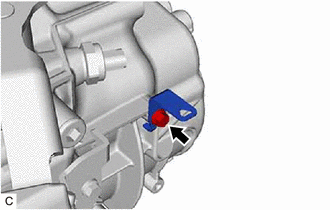

|

(b) Remove the bolt and wire harness clamp bracket from the manual transmission case. |

|

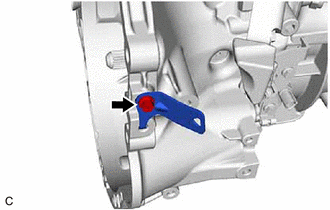

|

(c) Remove the bolt and wire harness clamp bracket from the transaxle(MTM) case sub-assembly. |

|

|

(d) Remove the bolt and wire harness clamp bracket from the transaxle(MTM) case sub-assembly. |

|

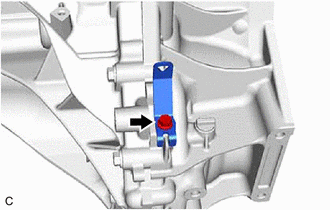

41. REMOVE CONTROL CABLE BRACKET ASSEMBLY

|

(a) Remove the 3 bolts and control cable bracket assembly from the manual transmission case and transaxle(MTM) case sub-assembly. |

|

|

|

|

![2019 - 2025 MY Corolla Corolla Hatchback [06/2018 - ]; M20A-FKS (ENGINE CONTROL): SFI SYSTEM: REGISTRATION](/t3Portal/stylegraphics/info.gif)