| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000002710I |

| Model Year Start: 2023 | Model: Corolla Hatchback | Prod Date Range: [09/2022 - 11/2022] |

| Title: EC65 (MANUAL TRANSMISSION / TRANSAXLE): MANUAL TRANSAXLE ASSEMBLY: INSTALLATION; 2023 MY Corolla Corolla Hatchback [09/2022 - 11/2022] | ||

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

When the manual transaxle assembly is removed, be sure to use a new clutch release with bearing cylinder assembly and new installation bolts. Removal of the manual transaxle assembly allows the compressed clutch release with bearing cylinder assembly to return to its original position. Dust from the moving section may damage the seal of the clutch release with bearing cylinder assembly, possibly causing clutch fluid leaks.

PROCEDURE

1. INSTALL SPEEDOMETER DRIVEN HOLE COVER SUB-ASSEMBLY

(a) Coat a new O-ring with gear oil.

(b) Install the O-ring to the speedometer driven hole cover sub-assembly.

(c) Install the speedometer driven hole cover sub-assembly to the front transaxle (MTM) case with the bolt.

Torque:

11.3 N·m {115 kgf·cm, 8 ft·lbf}

2. INSTALL WIRE HARNESS CLAMP BRACKET

(a) Install the 3 wire harness clamp brackets to the manual transmission case and front transaxle (MTM) case with the 3 bolts.

Torque:

12.5 N·m {127 kgf·cm, 9 ft·lbf}

3. INSTALL CLUTCH RELEASE CYLINDER WITH BEARING ASSEMBLY

4. REMOVE CLUTCH RELEASE BLEEDER SUB-ASSEMBLY

5. INSPECT CLUTCH PIPE LINE

6. INSTALL CLUTCH RELEASE BLEEDER SUB-ASSEMBLY

7. INSTALL CLUTCH FLEXIBLE HOSE BRACKET

(a) Install the clutch flexible hose bracket to the manual transmission case with the bolt.

Torque:

12 N·m {122 kgf·cm, 9 ft·lbf}

8. INSTALL BLEEDER CLUTCH RELEASE TUBE

9. SUPPORT MANUAL TRANSAXLE ASSEMBLY

(a) Using a transmission jack, support the manual transaxle assembly.

NOTICE:

- Adjust the attachment of the transmission jack to securely support the manual transaxle assembly.

- Using a lashing belt or a rope, secure the manual transaxle assembly to the transmission jack.

10. INSTALL MANUAL TRANSAXLE ASSEMBLY

|

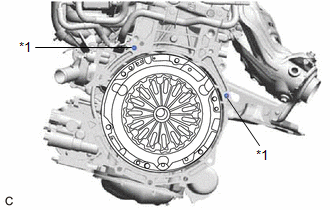

(a) Check that the 2 knock pins are installed on the engine assembly before installing the manual transaxle assembly. |

|

(b) Align the input shaft with the clutch disc and install the engine assembly to the manual transaxle assembly.

|

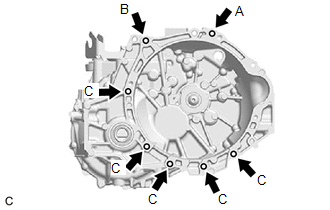

(c) Temporarily install the bolt (A). HINT: Bolt (A): Install from the manual transaxle assembly side. |

|

(d) Install the bolt (B), then fully tighten the bolt (A).

Torque:

33 N·m {337 kgf·cm, 24 ft·lbf}

HINT:

Bolt (B): Install from the manual transaxle assembly side.

(e) Install the 5 bolts (C).

Torque:

33 N·m {337 kgf·cm, 24 ft·lbf}

NOTICE:

- Make sure that the wire harness or similar items are not pinched between the contact surfaces.

- Do not forcibly pry on the manual transaxle assembly when installing it to the engine assembly.

- Do not apply excessive force to the manual transaxle assembly as this will break the input shaft.

- Make sure that the knock pins fit securely into the holes when installing the manual transaxle assembly to the engine assembly.

- Make sure that the contact surfaces of the engine assembly and manual transaxle assembly are flat against each other before tightening the bolts.

HINT:

Bolt (C): Install from the engine assembly side.

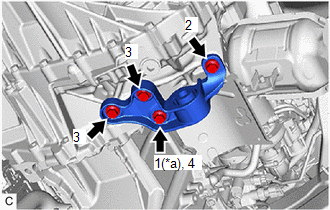

11. INSTALL ENGINE MOUNTING BRACKET LH

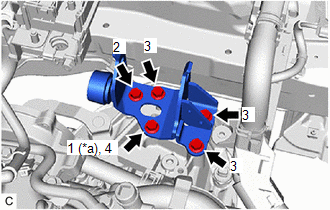

|

(a) Install the engine mounting bracket LH to the manual transmission case with the 5 bolts in the order shown in the illustration. Torque: 41 N·m {418 kgf·cm, 30 ft·lbf} |

|

12. INSTALL ENGINE MOUNTING INSULATOR LH

(a) Temporarily install the engine mounting insulator LH to the vehicle body.

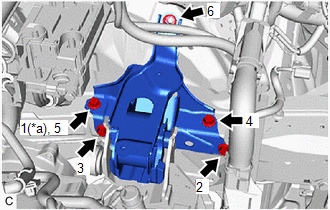

|

(b) Install the 4 bolts and nut in the order shown in the illustration. Torque: 42 N·m {428 kgf·cm, 31 ft·lbf} |

|

(c) Install the engine mounting insulator LH to the engine mounting bracket LH with the bolt and nut.

Torque:

44 N·m {449 kgf·cm, 32 ft·lbf}

NOTICE:

While holding the nut in place, tighten the bolt.

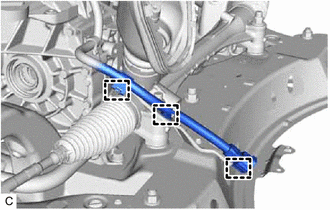

13. INSTALL NO. 2 ENGINE MOVING CONTROL ROD

|

(a) Install the No. 2 engine moving control rod to the manual transmission case with the 4 bolts in the order shown in the illustration. Torque: 44 N·m {449 kgf·cm, 32 ft·lbf} |

|

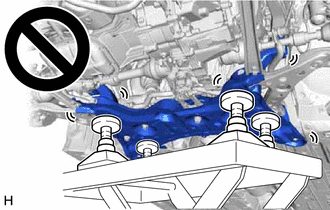

14. INSTALL FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

(a) Slowly jack up the front suspension crossmember sub-assembly with an engine lifter using 4 attachments or equivalent tools.

CAUTION:

- The front suspension crossmember sub-assembly is a very heavy component. Make sure that it is supported securely.

- If the front suspension crossmember sub-assembly is not securely supported, it may drop, resulting in serious injury.

NOTICE:

Use attachments to keep the front suspension crossmember sub-assembly level.

(b) Install the front suspension crossmember sub-assembly to the vehicle body with the 4 bolts.

Torque:

141 N·m {1438 kgf·cm, 104 ft·lbf}

(c) Lower the engine lifter.

(d) Install the engine moving control rod with the bolt.

Torque:

170 N·m {1734 kgf·cm, 125 ft·lbf}

15. INSTALL REAR SIDE RAIL REINFORCEMENT SUB-ASSEMBLY LH

16. INSTALL REAR SIDE RAIL REINFORCEMENT SUB-ASSEMBLY RH

17. CONNECT NO. 1 STEERING COLUMN HOLE COVER SUB-ASSEMBLY

18. CONNECT NO. 2 STEERING INTERMEDIATE SHAFT ASSEMBLY

19. INSTALL COLUMN HOLE COVER SILENCER SHEET

20. REMOVE ENGINE SUPPORT BRIDGE

(a) Remove SST from the vehicle body.

NOTICE:

Prevent SST from contacting the vehicle body or windshield glass.

(b) Install the No. 3 radiator hose to the fan shroud with the 2 bolts.

(c) Connect the inlet hose to the vehicle body with the clip.

21. REMOVE ENGINE HANGERS

22. INSTALL WIRE HARNESS CLAMP BRACKET

23. INSTALL STARTER ASSEMBLY

24. CONNECT NO. 1 CLUTCH HOSE

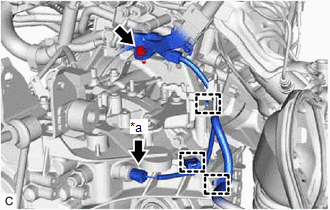

25. CONNECT ENGINE WIRE

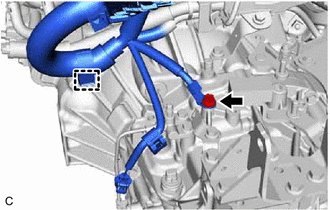

|

(a) Engage the 3 clamps. |

|

|

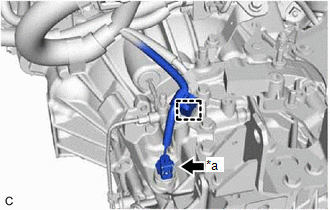

(b) w/ Neutral Position Switch: (1) Install the bolt. Torque: 12.5 N·m {127 kgf·cm, 9 ft·lbf} (2) Engage the 3 clamps. (3) Connect the neutral position switch connector. |

|

|

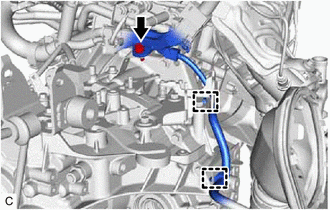

(c) w/o Neutral Position Switch: (1) Install the bolt. Torque: 12.5 N·m {127 kgf·cm, 9 ft·lbf} (2) Engage the 2 clamps. |

|

|

(d) Engage the clamp. |

|

(e) Install the earth bolt.

Torque:

12.5 N·m {127 kgf·cm, 9 ft·lbf}

|

(f) Engage the clamp. |

|

(g) Connect the back-up light switch assembly connector.

26. INSTALL FRONT EXHAUST PIPE ASSEMBLY (TWC: Rear Catalyst)

27. INSTALL FRONT FLOOR CENTER BRACE

28. CONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

29. INSTALL BATTERY CLAMP SUB-ASSEMBLY

30. CONNECT ENGINE WIRE

31. INSTALL BATTERY

32. INSTALL ECM

33. INSTALL AIR CLEANER CASE SUB-ASSEMBLY

34. INSTALL AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

35. INSTALL INLET NO. 1 AIR CLEANER

36. INSTALL RADIATOR SUPPORT OPENING COVER

37. INSTALL AIR CLEANER CAP WITH AIR CLEANER HOSE

38. INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

(a) Remove the 4 nuts.

(b) Install the outer cowl top panel sub-assembly with the 9 bolts and 4 nuts.

Torque:

Bolt :

12 N·m {122 kgf·cm, 9 ft·lbf}

Nut :

50 N·m {510 kgf·cm, 37 ft·lbf}

39. INSTALL NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

40. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

41. INSTALL FRONT DRIVE SHAFT ASSEMBLY

42. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

43. ADJUST TRANSMISSION CONTROL CABLE ASSEMBLY

44. BLEED CLUTCH LINE

45. INSPECT FOR EXHAUST GAS LEAK

46. INITIALIZATION AFTER RECONNECTING BATTERY TERMINAL

HINT:

When disconnecting and reconnecting the battery, there is an automatic learning function that completes learning when the respective system is used.

|

|

|

![2023 MY Corolla Corolla Hatchback [09/2022 - 11/2022]; CLUTCH: CLUTCH UNIT (for EC65): INSTALLATION+](/t3Portal/stylegraphics/info.gif)