- Poor idle, etc.

- Engine start function, etc.

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM1000000026ZXJ |

| Model Year Start: 2023 | Model: Corolla Hatchback | Prod Date Range: [09/2022 - 11/2022] |

| Title: M20A-FKS (FUEL): FUEL PUMP (w/o Canister Pump Module (for Double Wishbone Type Suspension)): REMOVAL; 2023 MY Corolla Corolla Hatchback [09/2022 - 11/2022] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during fuel pump removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Replacement of fuel pump |

Inspection after repair |

|

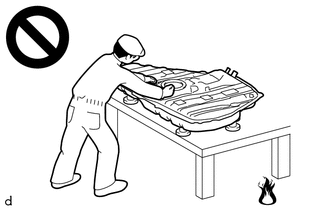

CAUTION:

-

Never perform work on fuel system components near any possible ignition sources.

- Vaporized fuel could ignite, resulting in a serious accident.

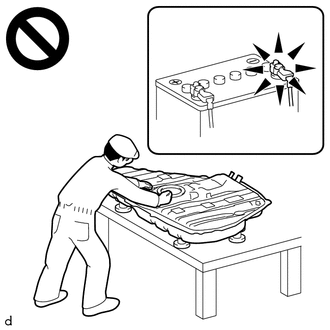

-

Do not perform work on fuel system components without first disconnecting the cable from the negative (-) battery terminal.

- Sparks could cause vaporized fuel to ignite, resulting in a serious accident.

HINT:

- If a malfunction such as pump lock occurs and the fuel pump is damaged, excessive current may be continuously applied to the fuel pump control ECU, damaging its internal parts. Make sure to replace the fuel pump control ECU at the same time when replacing the fuel pump.

- When the cable is disconnected / reconnected to the battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

Learning completes when vehicle is driven

|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

|

Front Camera System (for TMC Made) |

Drive the vehicle straight ahead at 15 km/h (9 mph) or more for 1 second or more. |

|

|

Pre-collision System (for TMMMS Made) |

Drive the vehicle straight ahead at 35 km/h (22 mph) or more for 5 seconds or more. |

|

|

Lane Tracing Assist System (for TMMMS Made) |

||

|

Lane Departure Alert System (for TMMMS Made) |

Learning completes when vehicle is operated normally

|

Effect/Inoperative Function when Necessary Procedure not Performed |

Necessary Procedure |

Link |

|---|---|---|

| *1: for Hatchback | ||

|

Power Door Lock Control System

|

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch. |

|

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the engine switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal.

2. DISCHARGE FUEL SYSTEM PRESSURE

3. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

4. REMOVE REAR SEAT ASSEMBLY

5. REMOVE REAR FLOOR SERVICE HOLE COVER

|

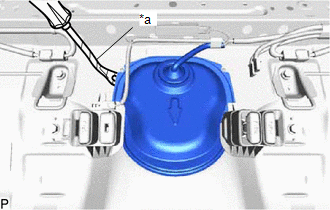

(a) Using a clip remover with its tip wrapped with protective tape, remove the rear floor service hole cover and butyl tape. |

|

|

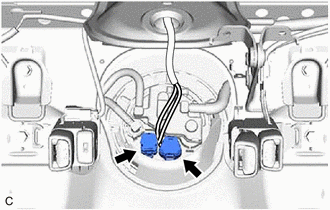

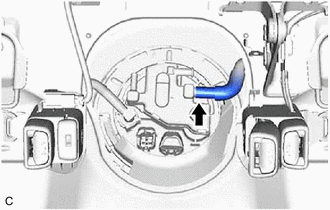

(b) Disconnect the 2 fuel suction tube with pump and gauge assembly connectors. |

|

6. DISCONNECT NO. 1 FUEL EVAPORATION TUBE SUB-ASSEMBLY

|

(a) Disconnect the No. 1 fuel evaporation tube sub-assembly from the fuel suction tube with pump and gauge assembly. |

|

7. DISCONNECT CHARCOAL CANISTER OUTLET HOSE

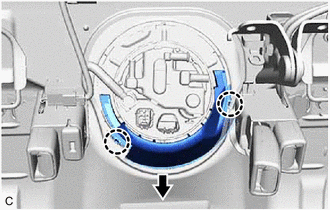

(a) Disconnect the charcoal canister outlet hose from the fuel suction tube with pump and gauge assembly.

8. DISCONNECT FUEL TANK MAIN TUBE SUB-ASSEMBLY

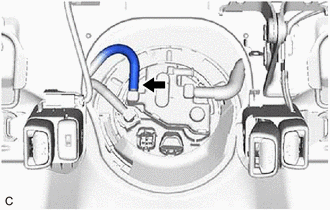

(a) Disengage the 2 claws to remove the No. 1 fuel tube clamp.

|

Front Side |

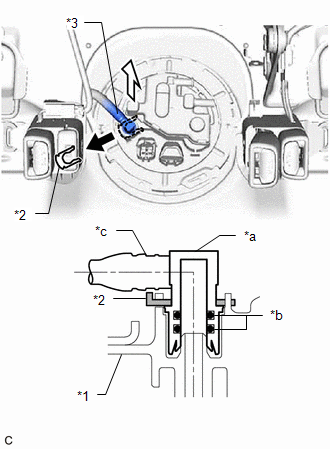

(b) Remove the tube joint clip, and pull off the fuel tube joint of the fuel tank main tube sub-assembly.

NOTICE:

- Remove any foreign matter on the fuel tube joint before performing this work.

- Do not scratch or allow any foreign matter to get on the parts when disconnecting them as the fuel tube connector has O-rings that seal the pipe (fuel pipe).

- Be sure to disconnect the fuel tube joint by hand.

- Do not bend, twist, pinch or kink the nylon tube.

- Cover the disconnected fuel tube joint with a plastic bag to prevent damage and contamination.

- If the fuel tube joint and fuel suction plate sub-assembly are stuck, push and pull to release them.

|

*1 |

Fuel Suction Plate Sub-assembly |

|

*2 |

Tube Joint Clip |

|

*3 |

Fuel Tank Main Tube Sub-assembly |

|

*a |

Fuel Tube Joint |

|

*b |

O-ring |

|

*c |

Nylon Tube |

|

Pull off |

|

Pull off |

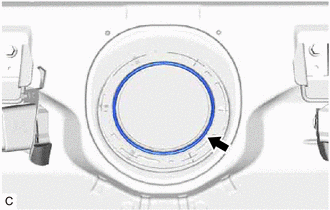

9. REMOVE FUEL PUMP GAUGE RETAINER

(a) Remove the fuel pump gauge retainer.

|

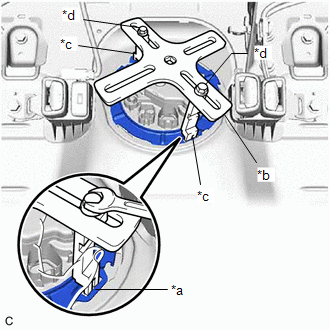

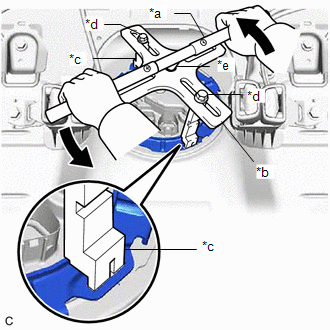

(1) Temporarily install SST (plate) and SST (claw) to the fuel pump gauge retainer. SST: 09808-01071 SST: 09808-14031 09808-01030 09808-01090 HINT: Securely insert the ends of SST (claw) into the insertion points in the fuel pump gauge retainer. |

|

(2) While firmly pressing SST (claw) into the insertion points in the fuel pump gauge retainer, tighten SST (bolt).

|

(3) Install SST (handle) and an extension bar (270 mm) to SST (plate). SST: 09808-01071 SST: 09808-14031 09808-01010 09808-01030 09808-01090 |

|

(4) Lightly press down on SST to prevent it from separating from the fuel pump gauge retainer. While pressing down on SST, rotate SST (handle) slowly to loosen the fuel pump gauge retainer.

NOTICE:

- Do not use any tools other than specified as this may result in damage to the fuel pump gauge retainer or fuel tank assembly.

- Do not press down on SST excessively as this may make the fuel pump gauge retainer hard to rotate, and may damage components.

- Make sure to rotate SST (handle) horizontally. If it is rotated at an angle, SST may come off.

- Do not spin SST too fast or use an impact wrench as this may result in damage to components.

- If SST comes off of the fuel pump gauge retainer, loosen SST (bolt) and reinstall SST.

(5) While pressing down on the fuel suction tube with pump and gauge assembly, remove the fuel pump gauge retainer.

10. REMOVE FUEL SUCTION TUBE WITH PUMP AND GAUGE ASSEMBLY

(a) Remove the fuel suction tube with pump and gauge assembly from the fuel tank assembly.

NOTICE:

Be careful not to bend the arm of the fuel sender gauge assembly.

|

(b) Remove the fuel suction tube set gasket from the fuel tank assembly. |

|

|

|

|

![2021 - 2023 MY Corolla Corolla Hatchback [04/2020 - 11/2022]; M20A-FKS (ENGINE CONTROL): SFI SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)