| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM1000000026WBA |

| Model Year Start: 2023 | Model: Corolla HV | Prod Date Range: [09/2022 - ] |

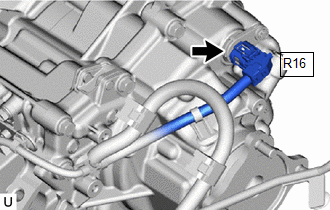

| Title: HYBRID / BATTERY CONTROL: HYBRID CONTROL SYSTEM (for LITHIUM-ION BATTERY with PA10): Rear Motor Resolver Circuit; 2023 - 2025 MY Corolla HV [09/2022 - ] | ||

|

Rear Motor Resolver Circuit |

DESCRIPTION

The cause of this malfunction may be the rear motor resolver.

Check the rear motor resolver internal resistance and the connection condition from the inverter to the resolver.

Related Parts Check

|

Area |

Inspection |

|---|---|

|

Wire harness and connector between the inverter and rear motor resolver |

Check for short circuit between wire harness and +B side. |

|

Resolver, wire harness, connector |

Check the internal resistance of resolver (including wire harness), body ground resistance, and connector connection condition. |

|

Resolver |

Check for open or short circuit of the resolver |

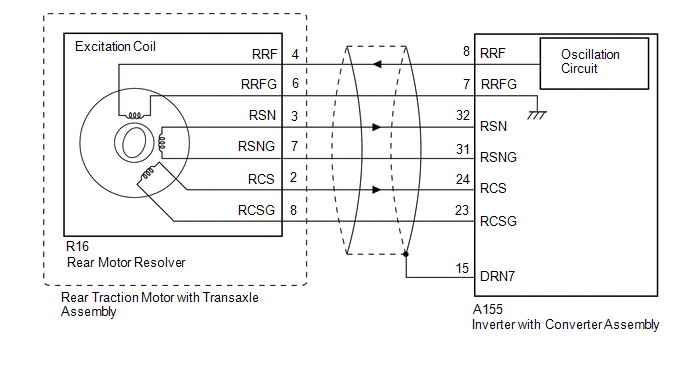

SYSTEM DESCRIPTION

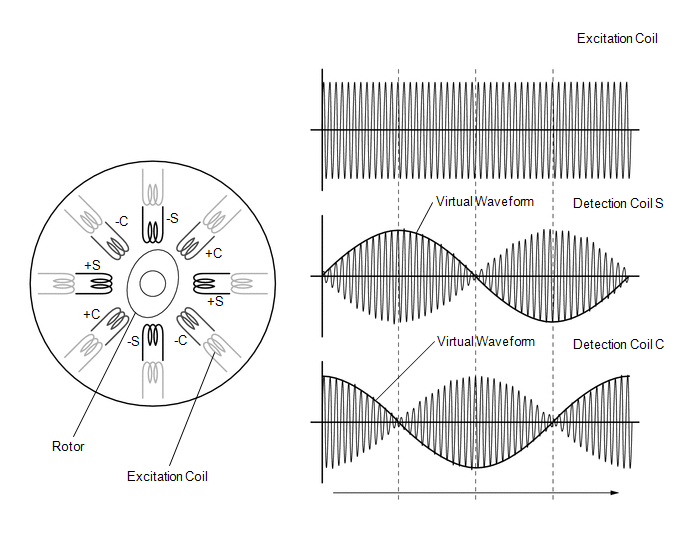

A resolver is a sensor that is used to detect the position of the magnetic poles of the rotor of a motor. Knowing the position of the poles is indispensable for ensuring precise control of the rear motor (MGR).

Each resolver contains a stator that has an excitation coil and 2 detection coils (S, C). The gap between the stator and rotor changes as the rotor turns because the rotor is oval shaped. An alternating current with a predetermined frequency flows through the excitation coil, and detection coils S and C output alternating currents in accordance with the sensor rotor position.

The MG ECU, which is built into the inverter with converter assembly, detects the absolute position of the rotor according to the phases of detection coils S and C and the heights of their waveforms. Furthermore, the CPU calculates the amount of change in the position within a predetermined length of time, in order to use the resolver as a revolution speed sensor.

The MG ECU monitors signals output from the rear motor resolver and detects malfunctions.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

This diagnostic procedure is referenced to in the diagnostic procedure of several DTCs.

If the result of this diagnostic procedure is normal, proceed as directed in the procedure for the DTC.

CAUTION:

Refer to the precautions before inspecting high voltage circuit.

NOTICE:

- After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

-

When disconnecting and reconnecting the auxiliary battery

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

HINT:

- If the problem symptom cannot be reproduced, performing a road test on a road on which the vehicle tends to vibrate will make it easier to reproduce the symptom.

- If the resolver is malfunctioning, the vehicle may not drive smoothly.

- When inspecting the connectors, if it is difficult to judge if a connector was disconnected, deformed or improperly secured, disconnect and reconnect the connector and then check for DTCs again. Check if the same DTC is output. If the same DTC is not output, improper connection of connectors is suspected.

- As a malfunction detection threshold may be exceeded when performing the vibration or heat connector inspections, make sure to perform the following inspection to check that the DTC was not stored due to the malfunction of a part.

PROCEDURE

|

1. |

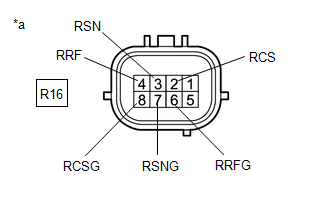

CHECK HARNESS AND CONNECTOR (INVERTER WITH CONVERTER ASSEMBLY - REAR MOTOR RESOLVER) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Disconnect the inverter with converter assembly connector.

(c) Connect the cable to the negative (-) auxiliary battery terminal.

(d) Turn the ignition switch to ON.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A155-8 (RRF) - Body ground |

Ignition switch ON |

Below 1 V |

|

A155-7 (RRFG) - Body ground |

Ignition switch ON |

Below 1 V |

|

A155-32 (RSN) - Body ground |

Ignition switch ON |

Below 1 V |

|

A155-31 (RSNG) - Body ground |

Ignition switch ON |

Below 1 V |

|

A155-24 (RCS) - Body ground |

Ignition switch ON |

Below 1 V |

|

A155-23 (RCSG) - Body ground |

Ignition switch ON |

Below 1 V |

NOTICE:

Turning the ignition switch to ON with the inverter with converter assembly disconnected causes other DTCs to be stored. Clear the DTCs after performing this inspection.

(f) Turn the ignition switch off.

(g) Disconnect the cable from the negative (-) auxiliary battery terminal and wait for 2 minutes or more.

(h) Reconnect the inverter with converter assembly connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

2. |

CHECK REAR MOTOR RESOLVER |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Disconnect the inverter with converter assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A155-8 (RRF) - A155-7 (RRFG) |

Ignition switch off |

8.9 to 14.9 Ω |

|

A155-32 (RSN) - A155-31 (RSNG) |

Ignition switch off |

16.2 to 28.2 Ω |

|

A155-24 (RCS) - A155-23 (RCSG) |

Ignition switch off |

18.1 to 30.1 Ω |

HINT:

To correct the variation of the measured resistance due to temperature, use the following formula to calculate the resistance at 20°C (68°F).

R20 = Rt / {1 + 0.00393 X (T - 20)}

The calculation is based on the following:

R20: Resistance at 20°C (68°F) (mΩ)

Rt: Measured resistance (mΩ)

T: Temperature when the resistance is measured (°C (°F).)

Standard Resistance (Check for Short):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A155-8 (RRF) or A155-7 (RRFG) - Body ground and other terminals |

Ignition switch off |

1 MΩ or higher |

|

A155-32 (RSN) or A155-31 (RSNG) - Body ground and other terminals |

Ignition switch off |

1 MΩ or higher |

|

A155-24 (RCS) or A155-23 (RCSG) - Body ground and other terminals |

Ignition switch off |

1 MΩ or higher |

|

A151-15 (DRN7) - Other terminals |

Ignition switch off |

1 MΩ or higher |

(d) Reconnect the inverter with converter assembly connector.

| OK |

|

REAR MOTOR RESOLVER CIRCUIT NORMAL (PERFORM NEXT STEP FOR REFERENCED DTC) |

|

|

3. |

CHECK CONNECTOR CONNECTION CONDITION (REAR MOTOR RESOLVER CONNECTOR) |

|

(a) Check the connection condition of the rear motor resolver connector and the contact pressure of each terminal. Check the terminals for deformation, and check the connector for water ingress and foreign matter. OK: - The connector is connected securely. - The terminals are not deformed and are connected securely. - No water or foreign matter in the connector. |

|

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (The connector is not connected securely.) |

B |

|

NG (The terminals are not making secure contact or are deformed, or water or foreign matter exists in the connector.) |

C |

| B |

|

CONNECT SECURELY |

| C |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

INSPECT REAR TRACTION MOTOR WITH TRANSAXLE ASSEMBLY (REAR MOTOR RESOLVER) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Disconnect the resolver connector.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

HINT: To correct the variation of the measured resistance due to temperature, use the following formula to calculate the resistance at 20°C (68°F). R20 = Rt / {1 + 0.00393 X (T - 20)} The calculation is based on the following: R20: Resistance at 20°C (68°F) (mΩ) Rt: Measured resistance (mΩ) T: Temperature when the resistance is measured (°C (°F).) Standard Resistance (Check for Short):

|

|

(d) Reconnect the resolver connector.

| OK |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

| NG |

|

|

|

|

![2023 - 2025 MY Corolla HV [09/2022 - ]; HYBRID / BATTERY CONTROL: HYBRID CONTROL SYSTEM (for LITHIUM-ION BATTERY with PA10): PRECAUTION](/t3Portal/stylegraphics/info.gif)