| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM1000000026PZ1 |

| Model Year Start: 2023 | Model: Corolla HV | Prod Date Range: [09/2022 - ] |

| Title: HYBRID / BATTERY CONTROL: HYBRID BATTERY SYSTEM (for LITHIUM-ION BATTERY with PA10): P0ABF28; Hybrid/EV Battery Current Sensor "A" Signal Bias Level Out of Range / Zero Adjustment Failure; 2023 - 2025 MY Corolla HV [09/2022 - ] | ||

|

DTC |

P0ABF28 |

Hybrid/EV Battery Current Sensor "A" Signal Bias Level Out of Range / Zero Adjustment Failure |

DESCRIPTION

Refer to the description for DTC P0ABF11.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Warning Indicate |

Note |

|---|---|---|---|---|---|---|

|

P0ABF28 |

Hybrid/EV Battery Current Sensor "A" Signal Bias Level Out of Range / Zero Adjustment Failure |

The offset value of the battery current sensor is excessively large. (1 trip detection logic) |

|

Comes on |

Master Warning: Comes on |

SAE Code: P0AC0 |

HINT:

- Make sure to perform Current Sensor Offset Learning after replacing a battery current sensor.

- This DTC may be output if Current Sensor Offset Learning has not been completed.

MONITOR DESCRIPTION

If the battery ECU assembly detects a malfunction in a battery current sensor, the battery ECU assembly will illuminate the MIL and store a DTC.

MONITOR STRATEGY

|

Related DTCs |

P0AC0 (INF P0ABF28): Current sensor malfunction |

|

Required sensors/components |

Battery current sensor |

|

Frequency of operation |

Continuous |

|

Duration |

TMC's intellectual property |

|

MIL operation |

1 driving cycle |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

|

The monitor will run whenever the following DTCs are not stored |

TMC's intellectual property |

|

Other conditions belong to TMC's intellectual property |

- |

TYPICAL MALFUNCTION THRESHOLDS

|

TMC's intellectual property |

- |

COMPONENT OPERATING RANGE

|

Battery ECU assembly |

DTC P0AC0 (INF P0ABF28) is not detected |

CONFIRMATION DRIVING PATTERN

HINT:

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON and turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for 2 minutes or more.

- Turn the ignition switch to ON and turn the GTS on.

- Drive the vehicle on urban roads for approximately 10 minutes.[*1]

- Turn the ignition switch off and wait for 2 minutes or more.[*2]

- Turn the ignition switch to ON and turn the GTS on.[*3]

-

With ignition switch ON and wait for 10 seconds or more.[*4]

HINT:

[*1] to [*4]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Enter the following menus: Powertrain / HV Battery / Utility / All Readiness.

-

Check the DTC judgment result.

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE, perform the normal judgment procedure again.

WIRING DIAGRAM

Refer to the wiring diagram for DTC P0ABF11.

CAUTION / NOTICE / HINT

CAUTION:

Refer to the precautions before inspecting high voltage circuit.

NOTICE:

- After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

-

When disconnecting and reconnecting the auxiliary battery

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

PROCEDURE

|

1. |

CHECK DTC OUTPUT (HV BATTERY, HYBRID CONTROL) |

(a) Check for DTCs.

Powertrain > HV Battery > Trouble Codes

Powertrain > Hybrid Control > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

"P0ABF28" only is output, or DTCs except the ones in the table below are also output. |

A |

|

DTCs of hybrid battery system in the table below are output. |

B |

|

DTCs of hybrid control system in the table below are output. |

C |

|

System |

Relevant DTC |

|

|---|---|---|

|

Hybrid battery system |

P060A47 |

Hybrid/EV Battery Energy Control Module Monitoring Processor Watchdog / Safety MCU Failure |

|

P060B49 |

Hybrid/EV Battery Energy Control Module A/D Processing Internal Electronic Failure |

|

|

P060687 |

Hybrid/EV Battery Energy Control Module Processor to Monitoring Processor Missing Message |

|

|

P062F46 |

Hybrid/EV Battery Energy Control Module EEPROM Calibration / Parameter Memory Failure |

|

|

Hybrid control system |

P0A1F94 |

Hybrid/EV Battery Energy Control Module Unexpected Operation |

(b) Turn the ignition switch off.

| B |

|

GO TO DTC CHART (HYBRID BATTERY SYSTEM) |

| C |

|

|

|

2. |

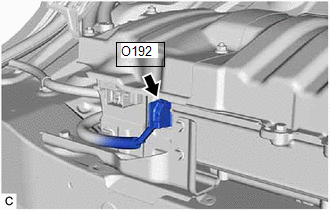

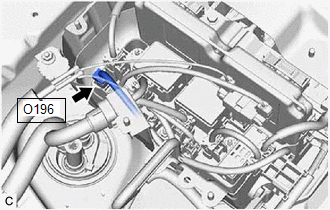

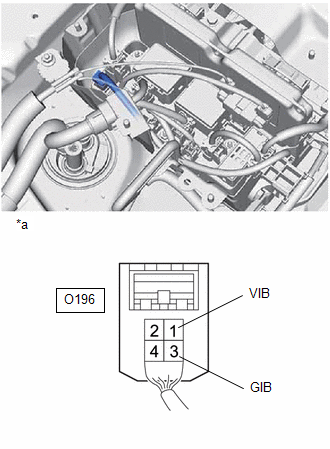

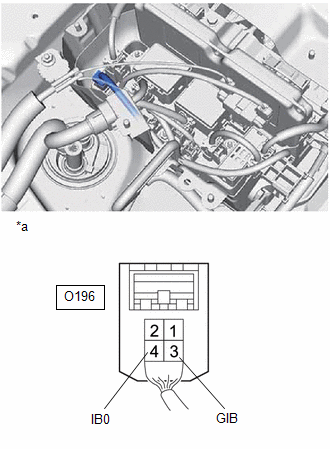

CHECK HARNESS AND CONNECTOR (BATTERY ECU ASSEMBLY - HV BATTERY JUNCTION BLOCK ASSEMBLY) |

CAUTION:

Be sure to wear insulated gloves and protective goggles.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

|

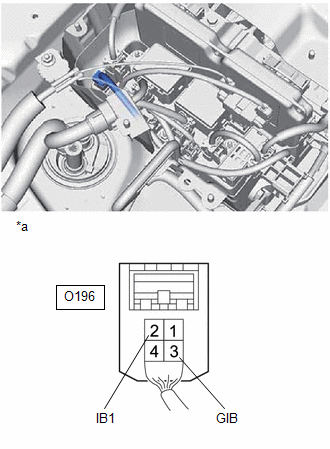

(b) Disconnect the battery ECU assembly connector. NOTICE: Before disconnecting the connector, check that it is not loose or disconnected. |

|

|

(c) Disconnect the battery current sensor connector from the HV battery junction block assembly. NOTICE: Before disconnecting the connector, check that it is not loose or disconnected. |

|

(d) Measure the resistance according to the value(s) in the tables below.

Standard Resistance (Check for Open):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

O192-6 (IB1) - O196-2 (IB1) |

Ignition switch off |

Below 1 Ω |

|

O192-18 (GIB) - O196-3 (GIB) |

Ignition switch off |

Below 1 Ω |

|

O192-5 (IB0) - O196-4 (IB0) |

Ignition switch off |

Below 1 Ω |

|

O192-17 (VIB) - O196-1 (VIB) |

Ignition switch off |

Below 1 Ω |

Standard Resistance (Check for Short):

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

O192-6 (IB1) or O196-2 (IB1) - Body ground and other terminals |

Ignition switch off |

10 kΩ or higher |

|

O192-18 (GIB) or O196-3 (GIB) - Body ground and other terminals |

Ignition switch off |

10 kΩ or higher |

|

O192-5 (IB0) or O196-4 (IB0) - Body ground and other terminals |

Ignition switch off |

10 kΩ or higher |

|

O192-17 (VIB) or O196-1 (VIB) - Body ground and other terminals |

Ignition switch off |

10 kΩ or higher |

(e) Reconnect the battery current sensor connector to the HV battery junction block assembly.

(f) Reconnect the battery ECU assembly connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK HV BATTERY JUNCTION BLOCK ASSEMBLY (BATTERY CURRENT SENSOR (IB0)) |

CAUTION:

Be sure to wear insulated gloves and protective goggles.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Connect the cable to the negative (-) auxiliary battery terminal.

(c) Turn the ignition switch to ON.

|

(d) Using a toyota electrical tester set to 40 V, measure the VIB voltage according to the value(s) in the table below.

NOTICE:

|

|

|

(e) Using a toyota electrical tester set to 4 V, measure the IB0 voltage according to the value(s) in the table below.

NOTICE: Be sure to set the toyota electrical tester to 4 V when performing this test. |

|

(f) Compare the measured values of the IB0 terminal voltage and VIB terminal voltage using the following formula:

|

IB0 voltage - 0.584 X VIB Voltage = less than 0.060 V |

|

IB0 voltage - 0.584 X VIB Voltage = -0.060 V or higher |

|

Result |

Proceed to |

|---|---|

|

Within the specified range above |

A |

|

Other than above |

B |

(g) Turn the ignition switch off.

(h) Disconnect the cable from the negative (-) auxiliary battery terminal.

| B |

|

|

|

4. |

CHECK HV BATTERY JUNCTION BLOCK ASSEMBLY (BATTERY CURRENT SENSOR (IB1)) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Connect the cable to the negative (-) auxiliary battery terminal.

(c) Turn the ignition switch to ON.

|

(d) Using a toyota electrical tester set to 40 V, measure the VIB voltage according to the value(s) in the table below.

NOTICE:

|

|

|

(e) Using a toyota electrical tester set to 4 V, measure the IB1 voltage according to the value(s) in the table below.

NOTICE: Be sure to set the toyota electrical tester to 4 V when performing this test. |

|

(f) Compare the measured values of the IB1 terminal voltage and VIB terminal voltage using the following formula:

|

Condition |

|---|

|

IB1 voltage - 0.416 X VIB Voltage = less than 0.060 V |

|

IB1 voltage - 0.416 X VIB Voltage = -0.060 V or higher |

|

Result |

Proceed to |

|---|---|

|

Within the specified range above. |

A |

|

Other than above |

B |

(g) Turn the ignition switch off.

(h) Disconnect the cable from the negative (-) auxiliary battery terminal.

| B |

|

|

|

5. |

REPLACE BATTERY ECU ASSEMBLY |

|

|

6. |

SIMULATION TEST |

(a) Clear the DTCs and freeze frame data.

Powertrain > HV Battery > Clear DTCs

(b) Drive the vehicle on urban roads for approximately 10 minutes.

(c) Turn the ignition switch off and wait for 2 minutes or more.

(d) Turn the ignition switch to ON and wait for 10 seconds or more.

|

|

7. |

CHECK DTC OUTPUT (HV BATTERY) |

(a) Check for DTCs.

Powertrain > HV Battery > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTCs are not output. |

A |

|

P0ABF28 is also output. |

B |

(b) Turn the ignition switch off.

| A |

|

END |

| B |

|

|

|

|

![2023 - 2025 MY Corolla HV [09/2022 - ]; HYBRID / BATTERY CONTROL: HYBRID BATTERY SYSTEM (for LITHIUM-ION BATTERY with PA10): P0ABF11,...,P1CBB14; Hybrid/EV Battery Current Sensor "A" Circuit Short to Ground+](/t3Portal/stylegraphics/info.gif)