- Communication stop for "Main Body" is indicated on the "Communication Bus Check" screen of the Techstream.

- Communication stop history for "Main Body" is indicated on the "Communication Bus Check (Detail)" screen of the Techstream. (The Lost Communication Time value for "Main Body" is 6 or more.)

- Communication system DTCs (DTCs that start with U) that correspond to "Main Body ECU Communication Stop Mode" in "DTC Combination Table" are output.

| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM1000000026JZZ |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - 11/2022] |

| Title: NETWORKING: CAN COMMUNICATION SYSTEM (for Gasoline Model except TMC Made): Main Body ECU Communication Stop Mode; 2023 MY Corolla Corolla Hatchback GR Corolla [09/2022 - 11/2022] | ||

|

Main Body ECU Communication Stop Mode |

DESCRIPTION

|

Detection Item |

Symptom |

Trouble Area |

|---|---|---|

|

Main Body ECU Communication Stop Mode |

Any of the following conditions are met: |

|

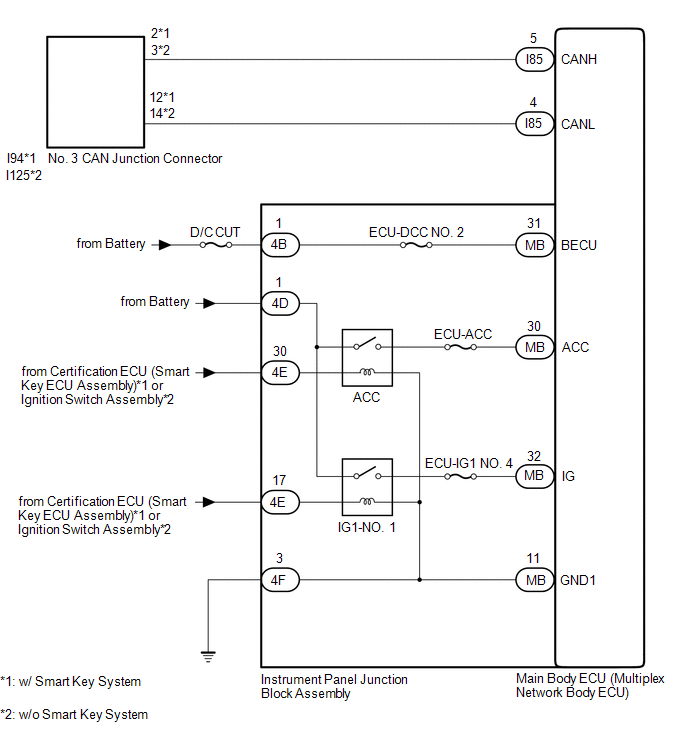

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

NOTICE:

- Because the order of diagnosis is important to allow correct diagnosis, make sure to begin troubleshooting using How to Proceed with Troubleshooting when CAN communication system related DTCs are output.

- Before measuring the resistance of the CAN bus, turn the ignition switch off and leave the vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) battery terminal and leave the vehicle for 10 minutes or more before measuring the resistance.

-

When disconnecting and reconnecting the battery.

HINT:

When disconnecting and reconnecting the battery, there is an automatic learning function that completes learning when the respective system is used.

- Some parts must be initialized and set when replacing or removing and installing parts.

-

After performing repairs, perform the DTC check procedure and confirm that the DTCs are not output again.

DTC check procedure: Turn the ignition switch to ON and wait for 1 minute or more. Then operate the suspected malfunctioning system and drive the vehicle at 60 km/h (37 mph) or more for 5 minutes or more.

- After the repair, perform the CAN bus check and check that all the ECUs and sensors connected to the CAN communication system are displayed as normal.

- Inspect the fuses for circuits related to this system before performing the following procedure.

-

Before replacing the main body ECU (multiplex network body ECU), refer to Registration.*

- *: w/ Smart Key System

HINT:

- Before disconnecting related connectors for inspection, push in on each connector body to check that the connector is not loose or disconnected.

- When a connector is disconnected, check that the terminals and connector body are not cracked, deformed or corroded.

PROCEDURE

|

1. |

CHECK FOR OPEN IN CAN BUS LINES (MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) BRANCH LINE) |

(a) Disconnect the cable from the negative (-) battery terminal.

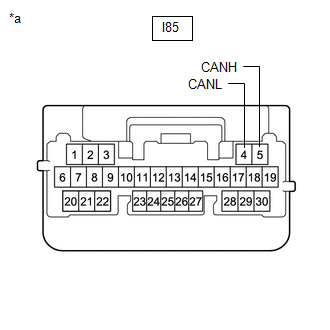

(b) Disconnect the I85 main body ECU (multiplex network body ECU) connector.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |

|

REPAIR OR REPLACE CAN BRANCH LINES OR CONNECTOR (MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)) |

|

|

2. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

(a) Remove the main body ECU (multiplex network body ECU).

|

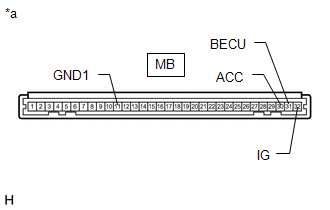

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

NOTICE: Perform this inspection with the wire harness connected to the instrument panel junction block assembly. |

|

(c) Reconnect the cable to the negative (-) battery terminal.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

MB-31 (BECU) - Body ground |

Always |

11 to 14 V |

|

MB-30 (ACC) - Body ground |

Ignition switch ACC |

11 to 14 V |

|

MB-32 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

NOTICE:

Perform this inspection with the wire harness connected to the instrument panel junction block assembly.

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (BECU) |

B |

|

NG (ACC) |

C |

|

NG (IG) |

D |

|

NG (GND1) |

E |

| A |

|

| C |

|

| D |

|

| E |

|

|

|

3. |

CHECK HARNESS AND CONNECTOR (BECU SIGNAL CIRCUIT) |

(a) Disconnect the cable from the negative (-) battery terminal.

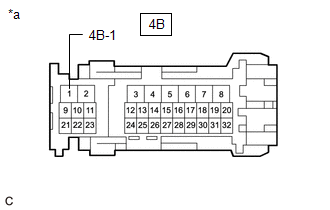

(b) Disconnect the 4B instrument panel junction block assembly connector.

(c) Reconnect the cable to the negative (-) battery terminal.

|

(d) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (BECU SIGNAL CIRCUIT) |

|

4. |

CHECK HARNESS AND CONNECTOR (GROUND CIRCUIT) |

(a) Disconnect the cable from the negative (-) battery terminal.

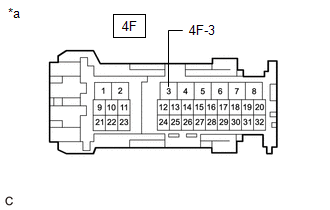

(b) Disconnect the 4F instrument panel junction block assembly connector.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (GROUND CIRCUIT) |

|

|

|

![2023 MY Corolla Corolla Hatchback GR Corolla [09/2022 - 11/2022]; NETWORKING: CAN COMMUNICATION SYSTEM (for Gasoline Model except TMC Made): PROBLEM SYMPTOMS TABLE](/t3Portal/stylegraphics/info.gif)