|

Last Modified: 07-31-2024 |

6.11:8.1.0 |

Doc ID: RM1000000026DZD |

|

Model Year Start: 2023 |

Model: GR Corolla |

Prod Date Range: [09/2022 - 11/2022] |

|

Title: THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function (Gasoline Model, except TMMMS Made)): Power Source Mode does not Change to ON (IG); 2023 MY Corolla Corolla Hatchback GR Corolla [09/2022 - 11/2022] |

|

Power Source Mode does not Change to ON (IG)

|

DESCRIPTION

If the engine switch is pressed with the electrical key transmitter sub-assembly in the cabin, the certification ECU (smart key ECU assembly) receives a signal and changes the power source mode.

Related Data List and Active Test Items

|

Problem Symptom

|

Data List and Active Test

|

|

Power source mode does not change to on (IG) but does change to on (ACC)

|

Power Source Control

-

Power Supply Condition

-

IGP Relay Circuit (Outside) Monitor

-

IGP Relay Circuit (Inside) Monitor

-

IGR Relay Circuit (Outside) Monitor

-

IGR Relay Circuit (Inside) Monitor

|

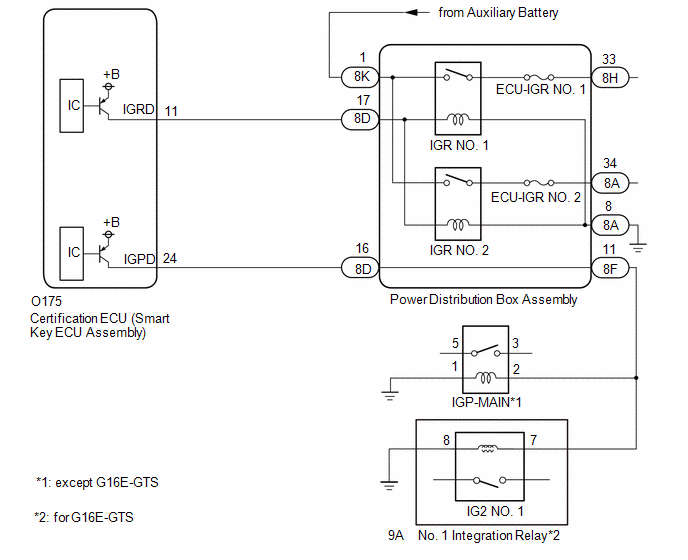

WIRING DIAGRAM

CAUTION / NOTICE / HINT

HINT:

-

If interior verification is unsuccessful, Vehicle Control History may be stored.

-

If Vehicle Control History has been stored, refer to the Vehicle Control History List to determine the detection conditions and narrow down trouble areas.

Body Electrical > Smart Key > Utility

|

Tester Display

|

|

Vehicle Control History (RoB)

|

PROCEDURE

(a) Using the GTS, check for certification ECU (smart key ECU assembly) DTCs.

Body Electrical > Power Source Control > Trouble Codes

Body Electrical > Smart Key > Trouble Codes

|

Result

|

Proceed to

|

|

DTCs are not output

|

A

|

|

Smart Key System (for Start Function) DTCs are output

|

B

|

|

A

|

|

|

|

2.

|

CHECK HARNESS AND CONNECTOR (POWER DISTRIBUTION BOX ASSEMBLY - CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) AND BODY GROUND)

|

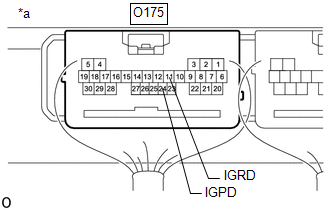

(a) Disconnect the O175 certification ECU (smart key ECU assembly) connector.

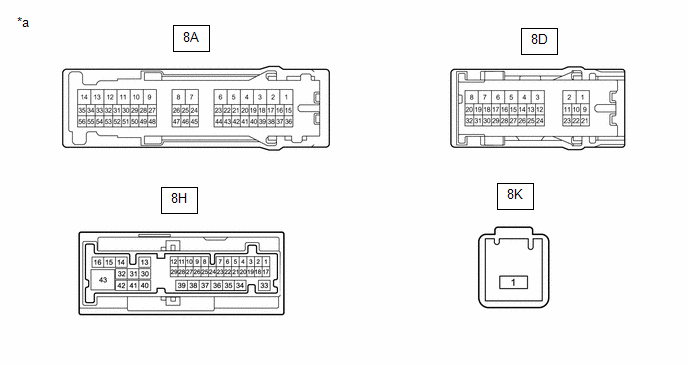

(b) Disconnect the 8A and 8D power distribution box assembly connectors.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

8D-16 - O175-24 (IGPD)

|

Always

|

Below 1 Ω

|

|

8D-17 - O175-11 (IGRD)

|

Always

|

Below 1 Ω

|

|

8A-8 - Body ground

|

Always

|

Below 1 Ω

|

|

8D-16 or O175-24 (IGPD) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

|

8D-17 or O175-11 (IGRD) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|

OK

|

|

|

|

3.

|

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)

|

|

(a) Connect the O175 certification ECU (smart key ECU assembly) connector.

|

|

|

*a

|

Component with harness connected

(Certification ECU (Smart Key ECU Assembly))

|

|

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

O175-11 (IGRD) - Body ground

|

Ignition switch ACC → Ignition switch ON

|

1 V or less → 9 V or higher

|

|

O175-24 (IGPD) - Body ground

|

Ignition switch ACC → Ignition switch ON

|

1 V or less → 9 V or higher

|

|

OK

|

|

|

|

4.

|

CHECK HARNESS AND CONNECTOR (POWER DISTRIBUTION BOX ASSEMBLY - POWER SOURCE)

|

(a) Disconnect the O175 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the 8A, 8D, 8H and 8K, power distribution box assembly connectors.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

8K-1 - Body ground

|

Always

|

11 to 14 V

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|

OK

|

|

|

|

5.

|

CHECK POWER DISTRIBUTION BOX ASSEMBLY

|

(a) Remove the power distribution box assembly.

Click here

![2023 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - 11/2022]; POWER DISTRIBUTION: MAIN BODY ECU: REMOVAL](/t3Portal/stylegraphics/info.gif)

(b) Remove the main body ECU (multiplex network body ECU) from the power distribution box assembly.

|

*a

|

Component without harness connected

(Power Distribution Box Assembly)

|

-

|

-

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

8D-16 - 8F-11

|

Always

|

Below 1 Ω

|

(d) Connect the auxiliary battery terminal (+) to the 8D-17 terminal.

(e) Connect the auxiliary battery terminal (-) to the 8A-8 terminal.

(f) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

8K-1 - 8H-33

|

Auxiliary battery voltage applied between terminals 8D-17 and 8A-8

|

Below 1 Ω

|

|

8K-1 - 8A-34

|

Auxiliary battery voltage applied between terminals 8D-17 and 8A-8

|

Below 1 Ω

|

|

Result

|

Proceed to

|

|

OK (for M20A-FKS)

|

A

|

|

OK (for G16E-GTS)

|

B

|

|

NG

|

C

|

|

A

|

|

|

|

6.

|

CHECK HARNESS AND CONNECTOR (POWER DISTRIBUTION BOX ASSEMBLY - IGP RELAY)

|

(a) Remove the IGP-MAIN relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

8F-11 - No. 1 engine room relay block and No. 1 junction block assembly IGP-MAIN relay terminal 2

|

Always

|

Below 1 Ω

|

|

No. 1 engine room relay block and No. 1 junction block assembly IGP-MAIN relay terminal 1 - Body ground

|

Always

|

Below 1 Ω

|

|

8F-11 or No. 1 engine room relay block and No. 1 junction block assembly IGP-MAIN relay terminal 2 - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|

OK

|

|

|

|

7.

|

INSPECT IGP-MAIN RELAY

|

|

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

3 - 5

|

Auxiliary battery voltage applied between terminals 1 and 2

|

Below 1 Ω

|

|

Auxiliary battery voltage not applied between terminals 1 and 2

|

10 kΩ or higher

|

|

|

| OK |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

| NG |

|

REPLACE IGP-MAIN

|

|

8.

|

CHECK HARNESS AND CONNECTOR (POWER DISTRIBUTION BOX ASSEMBLY - NO. 1 INTEGRATION RELAY)

|

(a) Disconnect the 9A No. 1 integration relay connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

8F-11 - 9A-7

|

Always

|

Below 1 Ω

|

|

9A-8 - Body ground

|

Always

|

Below 1 Ω

|

|

8F-11 or 9A-7 - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|

OK

|

|

|

|

9.

|

INSPECT NO. 1 INTEGRATION RELAY

|

Click here

![2023 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - 11/2022]; POWER DISTRIBUTION: INTEGRATION RELAY: INSPECTION](/t3Portal/stylegraphics/info.gif)

| OK |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|