|

Last Modified: 05-13-2024 |

6.11:8.1.0 |

Doc ID: RM1000000026A6B |

|

Model Year Start: 2023 |

Model: GR Corolla |

Prod Date Range: [09/2022 - 11/2022] |

|

Title: THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function (Gasoline Model, TMMMS Made)): TERMINALS OF ECU; 2023 MY Corolla Corolla Hatchback GR Corolla [09/2022 - 11/2022] |

TERMINALS OF ECU

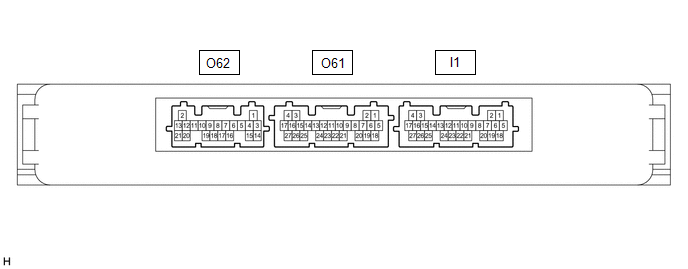

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)

(a) Disconnect the O61, O62 and I1 certification ECU (smart key ECU assembly) connectors.

(b) Measure the voltage and resistance according to the value(s) in the table below.

HINT:

Measure the values on the wire harness side with the connector disconnected.

|

Tester Connection

|

Wiring Color

|

Input / Output

|

Terminal Description

|

Condition

|

Specified Condition

|

Related Data List Item/DTC

|

|

O62-21 (NE) - Body ground

|

L - Body ground

|

Input

|

Engine speed signal

|

Always

|

10 kΩ or higher

|

Engine Condition

|

|

O61-24 (STP1) - Body ground*1

|

BR - Body ground

|

Input

|

Stop light switch signal

|

Brake pedal depressed → Brake pedal released

|

9 V or higher → 1 V or less

|

Stop Light Switch1

|

|

I1-3 (+B) - I1-18 (E)

|

GR - W-B

|

Input

|

Power source

|

Always

|

11 to 14 V

|

-

|

|

I1-22 (P) - I1-18 (E)*1

|

P - W-B

|

Input

|

P position signal

|

Shift lever in P → Shift lever not in P

|

30 kΩ or higher → Below 200 Ω

|

Shift P Signal

|

|

I1-17 (CUTB) - Body ground

|

SB - W-B*3

BR - W-B*4

|

Input

|

Dark current cut pin*2

|

Always

|

11 to 14 V

|

-

|

|

I1-18 (E) - Body ground

|

W-B - Body ground

|

-

|

GND

|

Always

|

Below 1 Ω

|

-

|

|

I1-13 (SSW3) - Body ground

|

P - Body ground

|

Input

|

SSW3 contact signal

|

Engine switch pushed → Engine switch not pushed

|

Below 15 Ω → 10 kΩ or higher

|

Start Switch3

|

|

I1-20 (SSW2) - Body ground

|

L - Body ground

|

Input

|

SSW2 contact signal

|

Engine switch pushed → Engine switch not pushed

|

Below 15 Ω → 10 kΩ or higher

|

Start Switch2

|

|

I1-23 (SSW1) - Body ground

|

V - Body ground

|

Input

|

SSW1 contact signal

|

Engine switch pushed → Engine switch not pushed

|

Below 15 Ω → 10 kΩ or higher

|

Start Switch1

|

|

I1-7 (SPD) - Body ground

|

BR - Body ground

|

Input

|

Vehicle speed signal

|

Always

|

30 kΩ or higher

|

Vehicle Speed Signal

|

-

*1: except Manual Transaxle

-

*2: In order to prevent the vehicle battery from being depleted when the vehicle is shipped long distances, a fuse that cuts unnecessary electrical load while the vehicle is being shipped is installed in the circuit. If the fuse is removed, the circuit becomes open. If the fuse that is between the vehicle battery and terminal CUTB is removed and the circuit is open, the certification ECU (smart key ECU assembly) changes to a certain control mode (example: the transmission of radio waves every 0.25 seconds, which form the detection area, stops).

-

*3: for Sedan

-

*4: except Sedan

(c) Connect the O61, O62 and I1 certification ECU (smart key ECU assembly) connectors.

(d) Measure the voltage and resistance, and check for pulses according to the value(s) in the table below.

|

Tester Connection

|

Wiring Color

|

Input / Output

|

Terminal Description

|

Condition

|

Specified Condition

|

Related Data List Item/DTC

|

|

O62-1 (STA) - I1-18 (E)

|

LG - W-B

|

Input

|

When starting the engine, this monitors the voltage sent from terminal STAR to the starter relay to judge whether the engine is "being started".

|

for Manual Transaxle

-

Engine switch pressed and held with clutch pedal depressed (starter on) → Approximately 1 second after engine switch released (starter off)

except Manual Transaxle

-

Engine switch pressed and held with brake pedal depressed (starter on) → Approximately 1 second after engine switch released (starter off)

|

6 V or higher*3 → 1.0 V or less

|

-

|

|

O62-2 (STAR) - I1-18 (E)

|

W - W-B

|

Input / Output

|

Outputs voltage to the starter relay

-

Outputs voltage (12 V) to the starter relay when starting the engine. (Max. 30 sec. Turns off when an engine speed of 1000 rpm.)

HINT:

When Hi is selected, a start request signal (STAR) will not be output even though a start request signal (STSW) is input.

|

for Manual Transaxle

-

Engine switch pressed and held with clutch pedal depressed (starter on) → Approximately 1 second after engine switch released (starter off)

except Manual Transaxle

-

Engine switch pressed and held with brake pedal depressed (starter on) → Approximately 1 second after engine switch released (starter off)

|

6 V or higher*3 → 1.0 V or less

|

-

|

|

O62-2 (STAR) - I1-18 (E)

|

W - W-B

|

Input / Output

|

for Manual Transaxle

-

Receives clutch start switch signal

-

Monitors whether the clutch start switch is on (clutch pedal depressed) or off(clutch pedal released). Applies voltage via a resistor (large) in the certification ECU (smart key ECU assembly). When the clutch start switch is on, due to the starter relay coil resistance (small) using some of the voltage, the voltage at terminal STAR will be low (2.7 V or less), and when the clutch start switch is off, the voltage will be high (9 V or more).

except Manual Transaxle

-

Receives neutral start switch (P, N position detection) signal

-

Monitors whether the neutral start switch is on (P or N) or off (other than P or N). Applies voltage via a resistor (large) in the certification ECU (smart key ECU assembly). When the neutral start switch is on, due to the starter relay coil resistance (small) using some of the voltage, the voltage at terminal STAR will be low (2.7 V or less), and when the neutral start switch is off, the voltage will be high (9 V or more).

|

|

9 V or higher → 2.7 V or less

|

Neutral SW/ Clutch SW

|

|

O62-21 (NE) - I1-18 (E)

|

L - W-B

|

Input

|

Engine speed signal

|

Idling (engine warmed up)

|

Pulse generation

(See waveform 1)

|

Engine Condition

|

|

O61-24 (STP1) - I1-18 (E)*1

|

BR - W-B

|

Input

|

Stop light switch signal

|

Brake pedal released → Brake pedal depressed

|

1 V or less → 9 V or higher

|

Stop Light Switch1

|

|

I1-12 (SLP) - I1-18 (E)

|

G - W-B

|

Input

|

Steering lock position signal

|

Steering locked → Steering unlocked

|

11 to 14 V → 1.5 V or less

|

Steering Unlock Switch

|

|

I1-25 (SLR+) - I1-18 (E)

|

P - W-B

|

Output

|

Steering lock motor operation command signal

(Steering lock motor operation permission signal sent from the certification ECU (smart key ECU assembly))

|

for Manual Transaxle

-

When a door is opened, the steering lock motor will be operated if all of the following conditions are met:

-

The steering is unlocked.

-

The engine switch is off.

except Manual Transaxle

-

When a door is opened, the steering lock motor will be operated if all of the following conditions are met:

-

The steering is unlocked.

-

The engine switch is off.

-

The shift lever is in P.

|

11 to 14 V → Below 1 V

|

-

|

|

I1-14 (LIN) - I1-18 (E)

|

V - W-B

|

Input / Output

|

LIN communication line

|

Engine switch on (IG)

|

Pulse generation

|

Steering Lock Start Cond

|

|

I1-22 (P) - I1-18 (E)*1

|

P - W-B

|

Input

|

P position signal

|

Shift lever in P → Shift lever not in P

|

9 V or higher → 2.76 V or less

|

Shift P Signal

|

|

I1-13 (SSW3) - I1-18 (E)

|

P - W-B

|

Input

|

SSW3 contact signal

|

Engine switch not pushed → Engine switch pushed

|

9 V or higher → 1 V or less

|

Start Switch3

|

|

I1-20 (SSW2) - I1-18 (E)

|

L - W-B

|

Input

|

SSW2 contact signal

|

Engine switch not pushed → Engine switch pushed

|

9 V or higher → 1 V or less

|

Start Switch2

|

|

I1-23 (SSW1) - I1-18 (E)

|

V - W-B

|

Input

|

SSW1 contact signal

|

Engine switch not pushed → Engine switch pushed

|

9 V or higher → 1 V or less

|

Start Switch1

|

|

I1-16 (ACCD) - I1-18 (E)

|

L - W-B

|

Output

|

ACC signal

|

Engine switch off → Engine switch on (ACC)

|

1 V or less → 8.5 V or higher

|

ACC Relay Monitor

|

|

I1-15 (IG1D) - I1-18 (E)

|

R - W-B

|

Output

|

IG signal

|

Engine switch on (ACC) → Engine switch on (IG)

|

1 V or less → 9 V or higher

|

IG Relay Monitor (Outside)

|

|

I1-7 (SPD) - I1-18 (E)

|

BR - W-B

|

Input

|

Vehicle speed signal

|

Vehicle being driven at approx. 5 km/h (3 mph)

|

Pulse generation

(See waveform 2)

|

Vehicle Speed Signal

|

|

I1-8 (CLG5) - I1-18 (E)

|

G - W-B

|

Output

|

Output to No. 1 indoor electrical key antenna assembly (front floor)

|

Procedure:

-

Engine switch off

-

Electrical key transmitter sub-assembly not inside vehicle

-

Within 30 seconds of closing any door

|

Pulse generation

(See waveform 3)

|

-

|

|

I1-9 (CG5B) - I1-18 (E)

|

R - W-B

|

Output

|

Output to No. 1 indoor electrical key antenna assembly (front floor) (terminal on opposite side of component from CLG5 output terminal)

|

Procedure:

-

Engine switch off

-

Electrical key transmitter sub-assembly not inside vehicle

-

Within 30 seconds of closing any door

|

Pulse generation

(See waveform 3)

|

-

|

|

O61-10 (CLG7) - I1-18 (E)*2

|

G - W-B

|

Output

|

Output to No. 3 indoor electrical key antenna assembly (inside luggage compartment)

|

Procedure:

for Hatchback

-

Engine switch off

-

Electrical key transmitter sub-assembly not inside vehicle

-

Within 30 seconds of closing any door

|

Pulse generation

(See waveform 3)

|

-

|

|

Procedure:

for Sedan

-

Door is closed

-

Engine switch off

-

Electrical key transmitter sub-assembly not inside vehicle

-

Driver door lock sensor touched

|

Pulse generation

(See waveform 4)

|

-

|

|

O61-9 (CG7B) - I1-18 (E)*2

|

W - W-B

|

Output

|

Output to No. 3 indoor electrical key antenna assembly (inside luggage compartment) (terminal on opposite side of component from CLG7 output terminal)

|

Procedure:

for Hatchback

-

Engine switch off

-

Electrical key transmitter sub-assembly not inside vehicle

-

Within 30 seconds of closing any door

|

Pulse generation

(See waveform 3)

|

-

|

|

Procedure:

for Sedan

-

Door is closed

-

Engine switch off

-

Electrical key transmitter sub-assembly not inside vehicle

-

Driver door lock sensor touched

|

Pulse generation

(See waveform 4)

|

-

|

|

I1-11 (AGND) - Body ground

|

W - Body ground

|

-

|

Transponder key amplifier ground

|

Always

|

Below 1 Ω

|

-

BCC Malfunction

-

Abnormal Status

-

Different Encrypt Code

-

Different Serial Number

-

Frame Error

-

Response

|

|

I1-5 (ANT1) - I1-11 (AGND)

|

B - W

|

Input / Output

|

Signal output to transponder key amplifier

(Code sent from certification ECU (smart key ECU assembly) to transponder key amplifier built into engine switch, and then transmitted by transponder key amplifier antenna as radio waves)

|

Engine switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of engine switch pressed

|

Pulse generation

(See waveform 5)

|

-

BCC Malfunction

-

Abnormal Status

-

Different Encrypt Code

-

Different Serial Number

-

Frame Error

-

Response

|

|

I1-6 (ANT2) - I1-11 (AGND)

|

G - W

|

Input / Output

|

Signal input from transponder key amplifier

(Radio waves from transponder key amplifier built into engine switch used to detect key information. Key information then sent to certification ECU (smart key ECU assembly))

|

Engine switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of engine switch pressed

|

Pulse generation

(See waveform 6)

|

|

I1-19 (IND) - I1-18 (E)

|

R - W-B

|

Output

|

Security indicator output

|

Engine switch off → on (IG)

|

Pulse generation → Below 2 V

|

-

|

-

*1: except Manual Transaxle

-

*2: for Hatchback

HINT:

-

*3: While the engine is cranking, the battery voltage may drop to approximately 6 V.

-

The waveform of the steering lock actuator motor stopped can be checked without performing any particular operation.

-

The waveform of the steering lock actuator motor operating can be checked if either of the following operations is performed:

for Manual Transaxle

-

To unlock the steering, bring the electrical key transmitter sub-assembly into the cabin and turn the engine switch on (ACC) or on (IG).

-

To lock the steering, open a door with the engine switch off.

except Manual Transaxle

-

To unlock the steering, bring the electrical key transmitter sub-assembly into the cabin and turn the engine switch on (ACC) or on (IG).

-

To lock the steering, open a door with the engine switch off and the shift lever in P.

(e) Using an oscilloscope, check the waveform of the ECU.

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

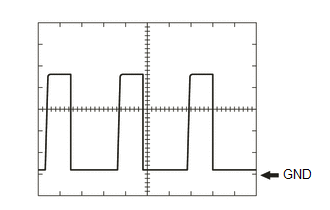

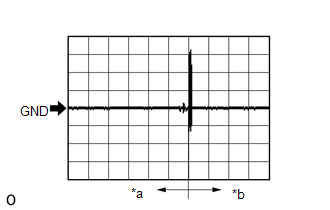

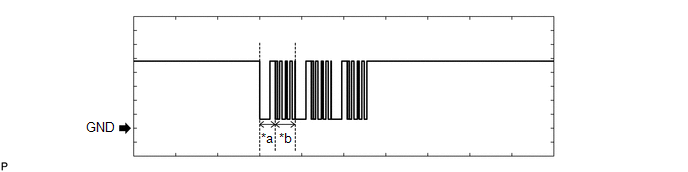

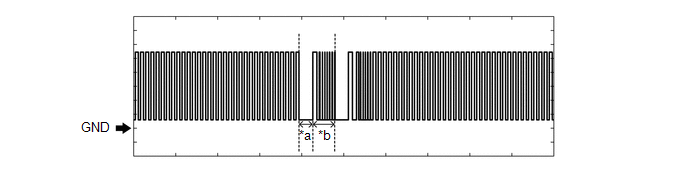

(1) Waveform 1

Measurement Condition

|

Item

|

Content

|

|

Tester Connection

|

O62-21 (NE) - I1-18 (E)

|

|

Tool Setting

|

2 V/DIV., 2 ms./DIV.

|

|

Condition

|

Idling (engine warmed up)

|

HINT:

The wavelength becomes shorter as the engine speed increases.

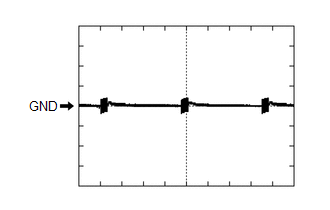

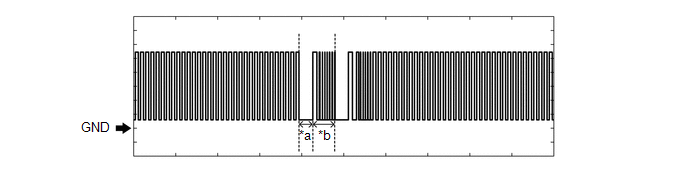

(2) Waveform 2

Measurement Condition

|

Item

|

Content

|

|

Tester Connection

|

I1-7 (SPD) - I1-18 (E)

|

|

Tool Setting

|

5 V/DIV., 20 ms./DIV.

|

|

Condition

|

Vehicle being driven at approx. 5 km/h (3 mph)

|

HINT:

The wavelength becomes shorter as the vehicle speed increases.

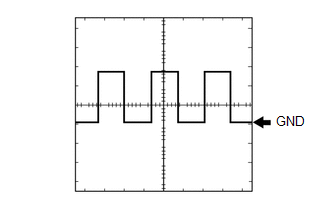

(3) Waveform 3

|

*a

|

For 30 seconds after any door closed

|

|

*b

|

After 30 seconds or more have elapsed since any door closed

|

Measurement Condition

|

Item

|

Content

|

|

Tester Connection

|

I1-8 (CLG5) - I1-18 (E)

I1-9 (CG5B) - I1-18 (E)

O61-10 (CLG7) - I1-18 (E)*

O61-9 (CG7B) - I1-18 (E)*

|

|

Tool Setting

|

2 V/DIV., 500 ms/DIV.

|

|

Condition

|

Procedure:

-

Engine switch off

-

Electrical key transmitter sub-assembly not inside vehicle

-

Within 30 seconds of closing any door

|

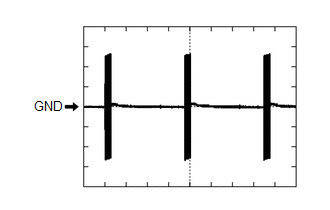

(4) Waveform 4

NOTICE:

The oscilloscope waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

|

*a

|

Driver door lock sensor not touched

|

|

*b

|

Driver door lock sensor touched

|

Measurement Condition

|

Item

|

Content

|

|

Tester Connection

|

O61-10 (CLG7) - I1-18 (E)

O61-9 (CG7B) - I1-18 (E)

|

|

Tool Setting

|

2 V/DIV., 500 ms/DIV.

|

|

Condition

|

Procedure:

-

Door is closed

-

Engine switch off

-

Electrical key transmitter sub-assembly not inside vehicle

-

Driver door lock sensor touched

|

(5) Waveform 5

Measurement Condition

|

Item

|

Content

|

|

Tester Connection

|

I1-5 (ANT1) - I1-11 (AGND)

|

|

Tool Setting

|

20 V/DIV., 200 ms./DIV.

|

|

Condition

|

Engine switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of engine switch pressed

|

(6) Waveform 6

Measurement Condition

|

Item

|

Content

|

|

Tester Connection

|

I1-6 (ANT2) - I1-11 (AGND)

|

|

Tool Setting

|

20 V/DIV., 200 ms./DIV.

|

|

Condition

|

Engine switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of engine switch pressed

|

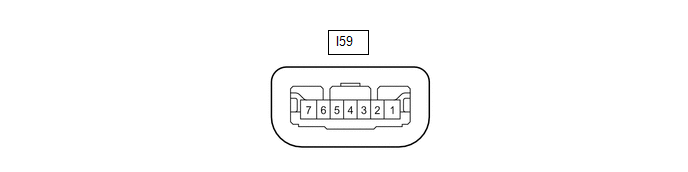

CHECK STEERING LOCK ECU (STEERING LOCK ACTUATOR OR UPPER BRACKET ASSEMBLY)

(a) Disconnect the I59 steering lock ECU (steering lock actuator or upper bracket assembly) connector.

(b) Measure the voltage and resistance according to the value(s) in the table below.

HINT:

Measure the values on the wire harness side with the connector disconnected.

|

Terminal No. (Symbol)

|

Wiring Color

|

Input / Output

|

Terminal Description

|

Condition

|

Specified Condition

|

Related Data List Item/DTC

|

|

I59-1 (GND) - Body ground

|

W-B - Body ground

|

-

|

Ground

|

Always

|

Below 1 Ω

|

-

|

|

I59-6 (IG2) - I59-1 (GND)

|

B - W-B

|

Input

|

IG signal (IG2 power supply input for steering lock motor)

|

Engine switch off

|

Below 1 V

|

-

|

|

Engine switch on (IG)

|

11 to 14 V

|

|

I59-7 (B) - Body ground

|

L - Body ground

|

Input

|

Constant power supply

|

Always

|

11 to 14 V

|

-

|

(c) Connect the I59 steering lock ECU (steering lock actuator or upper bracket assembly) connector.

(d) Measure the voltage, and check for pulses according to the value(s) in the table below.

|

Terminal No. (Symbol)

|

Wiring Color

|

Input / Output

|

Terminal Description

|

Condition

|

Specified Condition

|

Related Data List Item/DTC

|

|

I59-3 (IGE) - I59-1 (GND)

|

P - W-B

|

Input

|

Steering lock motor operation permission signal (motor operation permission signal supplied by certification ECU (smart key ECU assembly))

|

for Manual Transaxle

-

Steering lock motor operating when all conditions met, and then door opened:

-

The steering is unlocked.

-

The engine switch is off.

except Manual Transaxle

-

Steering lock motor operating when all conditions met, and then door opened:

-

The steering is unlocked.

-

The engine switch is off.

-

The shift lever is in P.

|

11 to 14 V → Below 1 V

|

-

Power Supply Short

-

Unlock Request Receive

-

Lock Request Receive

|

|

I59-4 (SLP1) - I59-1 (GND)

|

SB - W-B

|

Output

|

Steering lock bar position signal (signal output from steering unlock sensor)

|

Steering locked → unlocked

|

11 to 14 V → Below 1.5 V

|

Sensor Value

|

|

I59-5 (LIN) - I59-1 (GND)

|

G - W-B

|

Input / Output

|

LIN communication line

|

Engine switch on (IG)

|

Pulse generation

|

Steering Lock Start Cond

|

HINT:

-

There is 1 motor and 2 sensors built into the steering lock actuator or upper bracket assembly.

-

When taking measurements when the lock motor is stopped, it is not necessary to perform any operations.

-

In order to take measurements when the lock motor is operating, perform either of the following operations:

for Manual Transaxle

-

To unlock the steering, carry the key and turn the engine switch on (ACC) or on (IG).

-

To lock the steering, turn the engine switch off, and then open a door.

except Manual Transaxle

-

To unlock the steering, carry the key and turn the engine switch on (ACC) or on (IG).

-

To lock the steering, turn the engine switch off with the shift lever in P, and then open a door.

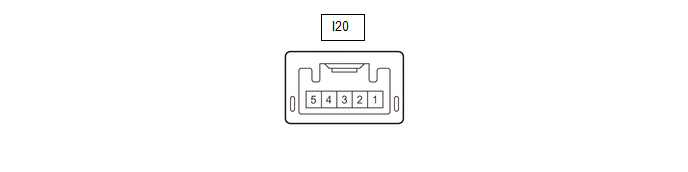

CHECK ID CODE BOX (IMMOBILISER CODE ECU)

(a) Disconnect the I20 ID code box (immobiliser code ECU) connector.

(b) Measure the voltage and resistance according to the value(s) in the table below.

HINT:

Measure the values on the wire harness side with the connector disconnected.

|

Tester Connection

|

Wiring Color

|

Input/Output

|

Terminal Description

|

Condition

|

Specified Condition

|

Related Data List Item

|

|

I20-1 (+B) - Body ground

|

L - Body ground

|

Input

|

Power source

|

Always

|

11 to 14 V

|

-

|

|

I20-5 (GND) - Body ground

|

W-B - Body ground

|

-

|

Ground

|

Always

|

Below 1 Ω

|

(c) Reconnect the I20 ID code box (immobiliser code ECU) connector.

(d) Measure the voltage and check for pulses according to the value(s) in the table below.

|

Tester Connection

|

Wiring Color

|

Input/Output

|

Terminal Description

|

Condition

|

Specified Condition

|

Related Data List Item

|

|

I20-3 (EFII) - I20-5 (GND)

|

B - W-B

|

Input

|

EFI communication input

(Signal input from ECM to ID code box (immobiliser code ECU))

|

Engine switch off

|

11 to 14 V

|

Smart Key

-

EFI Code Receive

-

Engine Start Request

|

|

I20-3 (EFII) - I20-5 (GND)

|

B - W-B

|

Input

|

EFI communication input

(Signal input from ECM to ID code box (immobiliser code ECU))

|

Within 3 seconds of engine start or within 3 seconds of engine switch turned on (IG) after cable disconnected and reconnected to battery

|

Pulse generation

(See waveform 1)

|

|

I20-4 (EFIO) - I20-5 (GND)

|

R - W-B

|

Output

|

EFI communication output

(Signal output from ID code box (immobiliser code ECU) to ECM)

|

Engine switch off

|

Below 1 V

|

|

I20-4 (EFIO) - I20-5 (GND)

|

R - W-B

|

Output

|

EFI communication output

(Signal output from ID code box (immobiliser code ECU) to ECM)

|

Within 3 seconds of engine start or within 3 seconds of engine switch turned on (IG) after cable disconnected and reconnected to battery

|

Pulse generation

(See waveform 2)

|

|

I20-2 (LIN1) - I20-5 (GND)

|

P - W-B

|

Input/Output

|

LIN communication line

|

Engine switch on (IG)

|

Pulse generation

|

Smart Key

|

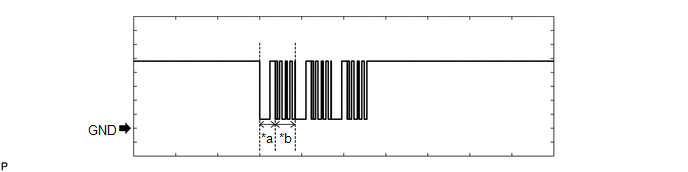

(e) Using an oscilloscope, check the waveform.

NOTICE:

The waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

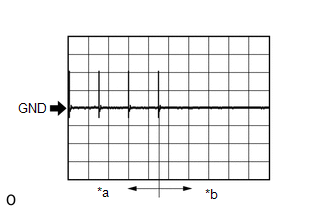

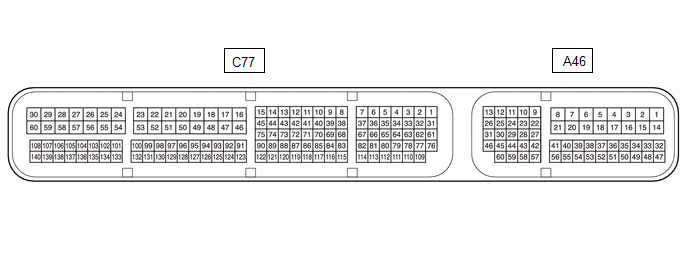

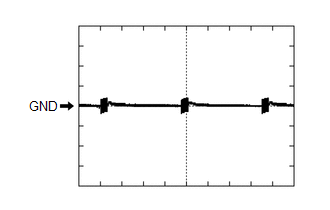

(1) Waveform 1

|

*a

|

Approximately 160 ms

|

*b

|

Approximately 270 ms

|

|

Item

|

Content

|

|

Tester Connection

|

I20-3 (EFII) - I20-5 (GND)

|

|

Tool Setting

|

2 V/DIV., 500 ms./DIV.

|

|

Condition

|

Within 3 seconds of engine start or within 3 seconds of engine switch turned on (IG) after cable disconnected and reconnected to battery

|

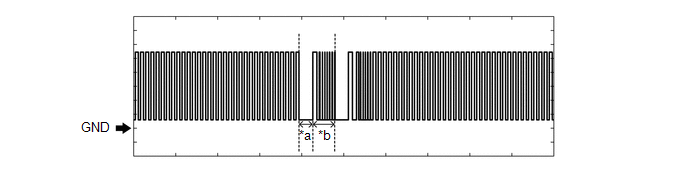

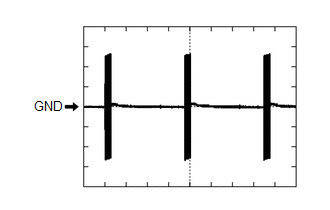

(2) Waveform 2

|

*a

|

Approximately 160 ms

|

*b

|

Approximately 270 ms

|

|

Item

|

Content

|

|

Tester Connection

|

I20-4 (EFIO) - I20-5 (GND)

|

|

Tool Setting

|

2 V/DIV., 500 ms./DIV.

|

|

Condition

|

Within 3 seconds of engine start or within 3 seconds of engine switch turned on (IG) after cable disconnected and reconnected to battery

|

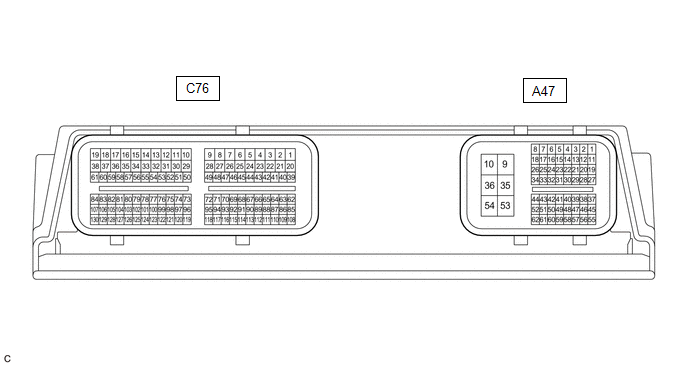

CHECK ECM (for M20A-FKS)

(a) Measure the voltage and resistance, and check for pulses according to the value(s) in the table below.

|

Terminal No. (Symbol)

|

Wiring Color

|

Input / Output

|

Terminal Description

|

Condition

|

Specified Condition

|

Related Data List Item/DTC

|

|

A47-35 (+B2) - A47-10 (E1)

|

LG - W-B

|

Input

|

Ignition power supply

|

Engine switch on (IG)

|

11 to 14 V

|

-

|

|

A47-9 (+B) - A47-10 (E1)

|

BE - W-B

|

Input

|

Ignition power supply

|

Engine switch on (IG)

|

11 to 14 V

|

-

|

|

A47-15 (MREL) - A47-10 (E1)

|

G - W-B

|

Input

|

Ignition power supply

|

Engine switch on (IG)

|

11 to 14 V

|

-

|

|

A47-1 (BATT) - A47-10 (E1)

|

G - W-B

|

Input

|

+B power supply

|

Always

|

11 to 14 V

|

-

|

|

A47-10 (E1) - Body ground

|

W-B - Body ground

|

-

|

Ground

|

Always

|

Below 1 Ω

|

-

|

|

A47-36 (E2) - Body ground

|

W-B - Body ground

|

-

|

Ground

|

Always

|

Below 1 Ω

|

-

|

|

A47-25 (IMO) - A47-10 (E1)

|

B - W-B

|

Output

|

EFI communication input

(Signal input from ECM to ID code box (immobiliser code ECU))

|

Engine switch off

|

11 to 14 V

|

-

|

|

A47-25 (IMO) - A47-10 (E1)

|

B - W-B

|

Output

|

EFI communication input

(Signal input from ECM to ID code box (immobiliser code ECU))

|

Within 3 seconds of engine start or within 3 seconds of engine switch turned on (IG) after cable disconnected and reconnected to battery

|

Pulse generation

(See waveform 1)

|

-

|

|

A47-26 (IMI) - A47-10 (E1)

|

W - W-B

|

Input

|

EFI communication input

(Signal output from ID code box (immobiliser code ECU) to ECM)

|

Engine switch off

|

11 to 14 V → 1 V or less

|

-

|

|

A47-26 (IMI) - A47-10 (E1)

|

W - W-B

|

Input

|

EFI communication input

(Signal output from ID code box (immobiliser code ECU) to ECM)

|

Engine switch turned on (IG) using registered electrical key transmitter sub-assembly

|

Pulse generation

(See waveform 2)

|

-

|

(b) Using an oscilloscope, check the waveform.

NOTICE:

The waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

(1) Waveform 1 (Reference)

|

*a

|

Approximately 160 ms.

|

*b

|

Approximately 270 ms.

|

Measurement Condition

|

Item

|

Content

|

|

Tester Connection

|

A47-25 (IMO) - A47-10 (E1)

|

|

Tool Setting

|

2 V/DIV., 500 ms./DIV.

|

|

Condition

|

Within 3 seconds of engine start or within 3 seconds of engine switch turned on (IG) after cable disconnected and reconnected to battery

|

(2) Waveform 2 (Reference)

|

*a

|

Approximately 160 ms.

|

*b

|

Approximately 270 ms.

|

Measurement Condition

|

Item

|

Content

|

|

Tester Connection

|

A47-26 (IMI) - A47-10 (E1)

|

|

Tool Setting

|

2 V/DIV., 500 ms./DIV.

|

|

Condition

|

Engine switch turned on (IG) using registered electrical key transmitter sub-assembly

|

CHECK ECM (for 2ZR-FAE)

(a) Measure the voltage and resistance, and check for pulses according to the value(s) in the table below.

|

Terminal No. (Symbol)

|

Wiring Color

|

Input / Output

|

Terminal Description

|

Condition

|

Specified Condition

|

Related Data List Item/DTC

|

|

A46-3 (+B2) - C77-59 (E1)

|

B - W-B

|

Input

|

Ignition power supply

|

Engine switch on (IG)

|

11 to 14 V

|

-

|

|

A46-2 (+B) - C77-59 (E1)

|

L - W-B

|

Input

|

Ignition power supply

|

Engine switch on (IG)

|

11 to 14 V

|

-

|

|

A46-46 (MREL) - C77-59 (E1)

|

G - W-B

|

Input

|

Ignition power supply

|

Engine switch on (IG)

|

11 to 14 V

|

-

|

|

A46-1 (BATT) - C77-59 (E1)

|

P - W-B

|

Input

|

+B power supply

|

Always

|

11 to 14 V

|

-

|

|

C77-59 (E1) - Body ground

|

W-B - Body ground

|

-

|

Ground

|

Always

|

Below 1 Ω

|

-

|

|

A46-45 (IMO) - C77-59 (E1)

|

B - W-B

|

Output

|

EFI communication input

(Signal input from ECM to ID code box (immobiliser code ECU))

|

Engine switch off

|

11 to 14 V

|

-

|

|

A46-45 (IMO) - C77-59 (E1)

|

B - W-B

|

Output

|

EFI communication input

(Signal input from ECM to ID code box (immobiliser code ECU))

|

Within 3 seconds of engine start or within 3 seconds of engine switch turned on (IG) after cable disconnected and reconnected to battery

|

Pulse generation

(See waveform 1)

|

-

|

|

A46-28 (IMI) - C77-59 (E1)

|

W - W-B

|

Input

|

EFI communication input

(Signal output from ID code box (immobiliser code ECU) to ECM)

|

Engine switch off

|

11 to 14 V → 1 V or less

|

-

|

|

A46-28 (IMI) - C77-59 (E1)

|

W - W-B

|

Input

|

EFI communication input

(Signal output from ID code box (immobiliser code ECU) to ECM)

|

Engine switch turned on (IG) using registered electrical key transmitter sub-assembly

|

Pulse generation

(See waveform 2)

|

-

|

(b) Using an oscilloscope, check the waveform.

NOTICE:

The waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

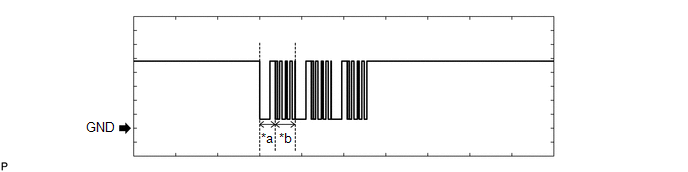

(1) Waveform 1 (Reference)

|

*a

|

Approximately 160 ms.

|

*b

|

Approximately 270 ms.

|

Measurement Condition

|

Item

|

Content

|

|

Tester Connection

|

A46-45 (IMO) - C77-59 (E1)

|

|

Tool Setting

|

2 V/DIV., 500 ms./DIV.

|

|

Condition

|

Within 3 seconds of engine start or within 3 seconds of engine switch turned on (IG) after cable disconnected and reconnected to battery

|

(2) Waveform 2 (Reference)

|

*a

|

Approximately 160 ms.

|

*b

|

Approximately 270 ms.

|

Measurement Condition

|

Item

|

Content

|

|

Tester Connection

|

A46-28 (IMI) - C77-59 (E1)

|

|

Tool Setting

|

2 V/DIV., 500 ms./DIV.

|

|

Condition

|

Engine switch turned on (IG) using registered electrical key transmitter sub-assembly

|

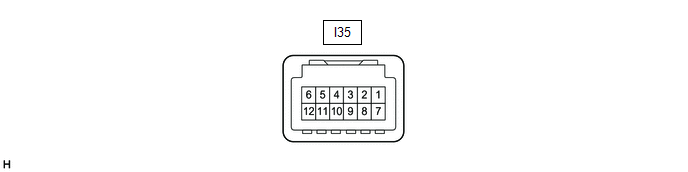

CHECK ENGINE SWITCH

(a) Measure the voltage and resistance according to the value(s) in the table below.

|

Terminal No. (Symbol)

|

Wiring Color

|

Input / Output

|

Terminal Description

|

Condition

|

Specified Condition

|

Related Data List Item/DTC

|

|

I35-3 (GND) - Body ground

|

W - Body ground

|

-

|

Transponder key amplifier ground

|

Always

|

Below 1 Ω

|

-

|

(b) Check for pulses according to the value(s) in the table below.

|

Terminal No. (Symbol)

|

Wiring Color

|

Input / Output

|

Terminal Description

|

Condition

|

Specified Condition

|

Related Data List Item/DTC

|

|

I35-1 (ANT1) - I35-3 (GND)

|

B - W

|

Input / Output

|

Signal input from certification ECU (smart key ECU assembly)

(Code sent from certification ECU (smart key ECU assembly) to transponder key amplifier built into engine switch, and then transmitted by transponder key amplifier antenna as radio waves)

|

Engine switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of engine switch pressed

|

Pulse generation

(See waveform 1)

|

|

|

I35-7 (ANT2) - I35-3 (GND)

|

G - W

|

Input / Output

|

Signal output to certification ECU (smart key ECU assembly)

(Radio waves from transponder key amplifier built into engine switch used to detect key information. Key information then sent to certification ECU (smart key ECU assembly))

|

Engine switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of engine switch pressed

|

Pulse generation

(See waveform 2)

|

(c) Using an oscilloscope, check the waveform.

NOTICE:

The waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

(1) Waveform 1 (Reference)

Measurement Condition

|

Item

|

Content

|

|

Tester Connection

|

I35-1 (ANT1) - I35-3 (GND)

|

|

Tool Setting

|

20 V/DIV., 200 ms./DIV.

|

|

Condition

|

Engine switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of engine switch pressed

|

(2) Waveform 2 (Reference)

Measurement Condition

|

Item

|

Content

|

|

Tester Connection

|

I35-7 (ANT2) - I35-3 (GND)

|

|

Tool Setting

|

20 V/DIV., 200 ms./DIV.

|

|

Condition

|

Engine switch off, electrical key transmitter sub-assembly not in cabin, within 30 seconds of engine switch pressed

|

|