| Last Modified: 01-27-2025 | 6.11:8.1.0 | Doc ID: RM10000000268JD |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - ] |

| Title: G16E-GTS (INTAKE / EXHAUST): TURBOCHARGER: INSPECTION; 2023 - 2025 MY GR Corolla [09/2022 - ] | ||

INSPECTION

PROCEDURE

1. INSPECT TURBOCHARGER SUB-ASSEMBLY

|

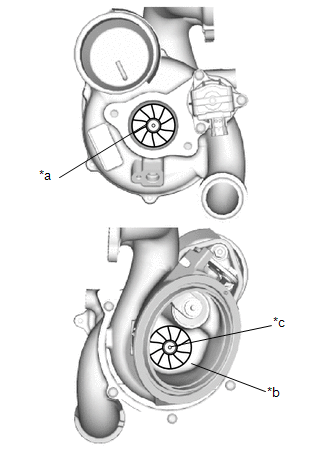

(a) Check if the compressor side impeller and exhaust side turbine are damaged or defective. HINT: Wear on the center of the exhaust side turbine is not a malfunction. |

|

|

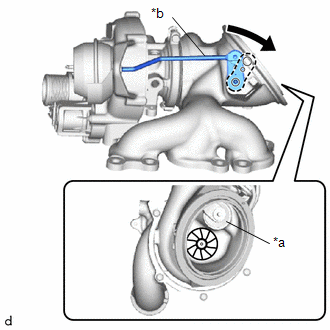

(b) Move the rod by hand and check that the waste gate valve is not stuck. |

|

|

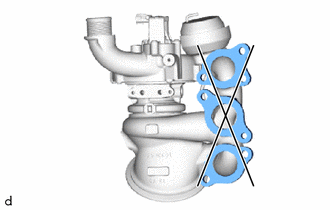

(c) Using a straightedge and feeler gauge, check the turbocharger sub-assembly installation surface for warpage. Standard Warpage: 0.20 mm (0.0079 in.) or less If the result is not as specified, replace the turbocharger sub-assembly. |

|

|

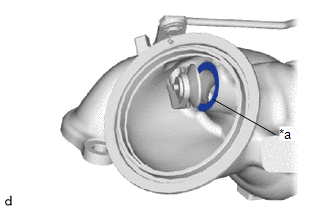

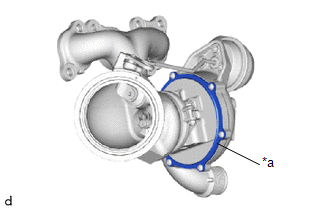

(d) Close the waste gate valve and using a feeler gauge, measure the clearance between the waste gate valve and the contact surface of the valve port of the turbine with valve housing sub-assembly waste gate. Standard Clearance: 0.15 mm (0.00591 in.) or less If the result is not as specified, replace the turbocharger sub-assembly. |

|

|

(e) Check the areas shown in the illustration for oil leakage. OK: There are no oil leaks from the compressor with bearing housing sub-assembly. NOTICE: Oil on the inlet side of the compressor is from oil in the blow-by gas and is not a malfunction. If the result is not as specified, replace the turbocharger sub-assembly. |

|

|

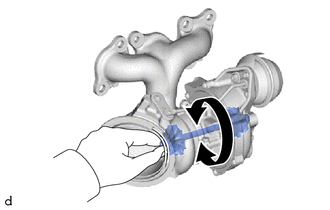

(f) Rotate the compressor wheel by hand as shown in the illustration, and check that the compressor wheel rotates smoothly. OK: Compressor wheel rotates smoothly. HINT: If the compressor wheel does not rotate smoothly, replace the turbocharger sub-assembly. |

|

(g) Check that the turbine shaft rotates smoothly.

|

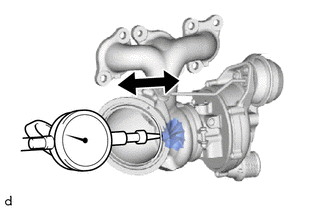

(1) Set a dial indicator to the outlet side of the turbine shaft. |

|

(2) Move the turbine shaft in the axial direction and check for play.

Standard Axial Play:

0.20 mm (0.0079 in.) or less

If the result is not as specified, replace the turbocharger sub-assembly.

2. INSPECT WASTE GATE VALVE ACTUATOR

(a) Check the waste gate valve actuator hose for cracks and damage.

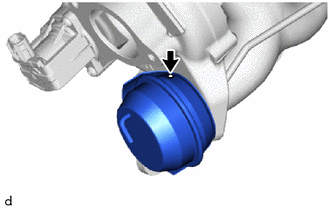

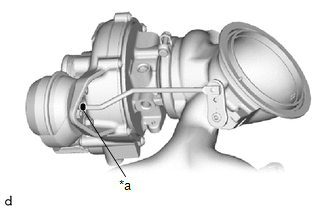

(b) Check the waste gate valve actuator with bracket assembly air hole.

|

(1) Check that the waste gate valve actuator air hole shown in the illustration is not clogged. |

|

(c) Check the waste gate valve actuator with bracket assembly travel.

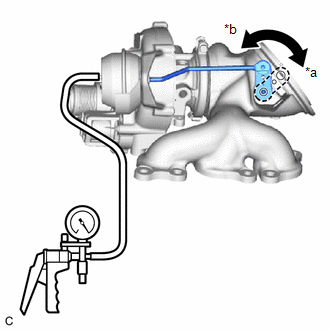

(1) Connect a vacuum pump to the waste gate valve actuator.

|

(2) Using a vacuum pump, apply a vacuum of 30 +/- 4.0 kPa (225 +/- 30 mmHg, 8.8 +/- 1.2 in. Hg) to the diaphragm chamber to operate the waste gate valve actuator. OK: The waste gate valve closes when vacuum is applied. NOTICE: Do not apply a vacuum of 65 kPa (488 mmHg, 19.2 in. Hg) or more to the waste gate valve actuator as doing so may damage the diaphragm. HINT: If the waste gate valve actuator does not operate, replace the turbocharger sub-assembly. |

|

|

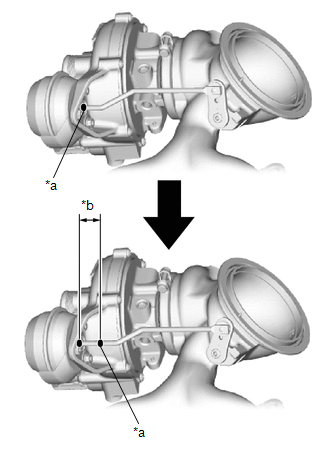

(3) Place a paint mark on the waste gate valve actuator rod from the waste gate valve actuator bracket as shown in the illustration. |

|

(4) Using a vernier caliper, measure the distance from the waste gate valve actuator bracket to the paint mark at a vacuum of 0 kPa (0 mmHg, 0 in. Hg).

|

*a |

Paint Mark |

|

*b |

Travel of Waste Gate Valve Actuator |

|

Vacuum at 0 kPa (0 mmHg, 0 in. Hg) |

Standard:

15 mm (0.591 in.) or more

If the result is not as specified, replace the turbocharger sub-assembly.

NOTICE:

If the result is not as specified when replacing the turbocharger sub-assembly, and check the travel of the waste gate valve actuator again.

(5) Disconnect the vacuum pump from the waste gate valve actuator.

3. INSPECT INTAKE AIR CONTROL VALVE (AIR BY-PASS VALVE ASSEMBLY)

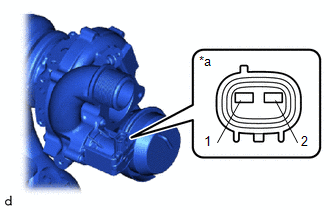

(a) Inspect the resistance.

|

(1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the turbocharger sub-assembly. |

|

|

|

|