|

Last Modified: 05-13-2024 |

6.11:8.1.0 |

Doc ID: RM1000000026649 |

|

Model Year Start: 2023 |

Model: GR Corolla |

Prod Date Range: [09/2022 - 11/2022] |

|

Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: BRAKE ACTUATOR (for Gasoline Model): REMOVAL; 2023 MY Corolla Corolla Hatchback GR Corolla [09/2022 - 11/2022] |

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during brake actuator assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure

|

Necessary Procedure

|

Effect/Inoperative Function when Necessary Procedure not Performed

|

Link

|

|

Skid control ECU (brake actuator assembly)

|

|

Vehicle Control History (RoB) are stored

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - ]; SETUP: WHEN REPLACING OR REMOVING/INSTALLING PARTS: UPDATE ECU SECURITY KEY](/t3Portal/stylegraphics/info.gif)

|

|

|

-

VSC is disabled or malfunctions

-

DTCs are output

-

Slip indicator light illuminates

-

ABS warning light illuminates

|

![2023 MY Corolla Corolla Hatchback GR Corolla [09/2022 - 11/2022]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model with Electric Parking Brake System TMC Made): UTILITY](/t3Portal/stylegraphics/info.gif) w/ Electric Parking Brake System

w/ Electric Parking Brake System

![2023 - 2025 MY Corolla Corolla Hatchback GR Corolla [09/2022 - ]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model without Electric Parking Brake System TMC Made): UTILITY](/t3Portal/stylegraphics/info.gif) w/o Electric Parking Brake System

w/o Electric Parking Brake System

|

for TMMMS Made

-

Perform acceleration sensor zero point calibration and store system information memorization

|

-

VSC is disabled or malfunctions

-

DTCs are output

-

Slip indicator light illuminates

-

ABS warning light illuminates

|

![2023 MY Corolla Corolla Hatchback GR Corolla [09/2022 - 11/2022]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model with Electric Parking Brake System TMMMS Made): UTILITY](/t3Portal/stylegraphics/info.gif) w/ Electric Parking Brake System

w/ Electric Parking Brake System

![2023 MY Corolla Corolla Hatchback GR Corolla [09/2022 - 11/2022]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model without Electric Parking Brake System TMMMS Made): UTILITY](/t3Portal/stylegraphics/info.gif) w/o Electric Parking Brake System

w/o Electric Parking Brake System

|

|

Operate the electric parking brake switch

|

Electric Parking Brake System

|

![2023 - 2025 MY Corolla Corolla Hatchback GR Corolla [09/2022 - ]; PARKING BRAKE: ELECTRIC PARKING BRAKE SYSTEM (for Gasoline Model): PRECAUTION](/t3Portal/stylegraphics/info.gif)

|

|

Tire

|

ECU Data Initialization (When performing tire replacement after RoB code X2104 is output)

|

Active Torque Split AWD System

|

![2023 - 2025 MY Corolla Corolla Hatchback GR Corolla [09/2022 - ]; GF1A (TRANSFER / 4WD / AWD): ACTIVE TORQUE SPLIT AWD SYSTEM: CALIBRATION](/t3Portal/stylegraphics/info.gif)

|

NOTICE:

-

After the ignition switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the ignition switch off, make sure to wait at least 3 minutes before disconnecting the cable from the negative (-) battery terminal.

-

When the cable is disconnected from the negative (-) battery terminal and the security lock setting has been enabled, multi-display operations will be disabled upon next startup unless the password is entered. Be sure to check the security lock setting before disconnecting the cable from the negative (-) battery terminal. (for Audio and Visual System (for Single Knob Type))

HINT:

When the cable is disconnected / reconnected to the battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

Learning completes when vehicle is driven

|

Effect/Inoperative Function when Necessary Procedure not Performed

|

Necessary Procedure

|

Link

|

|

Front Camera System (for TMC Made)

|

-

Drive the vehicle straight ahead at 35 km/h (22 mph) or more for 5 seconds or more.*1

-

Drive the vehicle straight ahead at 15 km/h (10 mph) or more for 1 second or more.*2

|

![2023 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - 11/2022]; ADVANCED DRIVER ASSISTANCE SYSTEM: FRONT CAMERA SYSTEM (for TMC Made): INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Pre-collision System (for TMMMS Made)

|

Drive the vehicle straight ahead at 35 km/h (22 mph) or more for 5 seconds or more.

|

![2023 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - 11/2022]; ADVANCED DRIVER ASSISTANCE SYSTEM: PRE-COLLISION SYSTEM (for TMMMS Made): INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

|

Lane Tracing Assist System (for TMMMS Made)

|

|

Lane Departure Alert System (for TMMMS Made)

|

Learning completes when vehicle is operated normally

|

Effect/Inoperative Function when Necessary Procedure not Performed

|

Effect/Inoperative Function when Necessary Procedure not Performed

|

Link

|

|

Power Door Lock Control System

|

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch.

|

![2023 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - 11/2022]; DOOR LOCK: POWER DOOR LOCK CONTROL SYSTEM (for TMC Made): INITIALIZATION](/t3Portal/stylegraphics/info.gif)

|

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

2. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

for M20A-FKS: Click here

![2023 MY Corolla Corolla Hatchback [09/2022 - 11/2022]; MAINTENANCE: M20A-FKS BATTERY: REMOVAL](/t3Portal/stylegraphics/info.gif)

for 2ZR-FAE: Click here

![2023 MY Corolla [09/2022 - 11/2022]; MAINTENANCE: 2ZR-FAE BATTERY: REMOVAL](/t3Portal/stylegraphics/info.gif)

for G16E-GTS: Click here

![2023 MY GR Corolla [09/2022 - 11/2022]; MAINTENANCE: G16E-GTS BATTERY: REMOVAL](/t3Portal/stylegraphics/info.gif)

3. DRAIN BRAKE FLUID

NOTICE:

If brake fluid leaks onto any painted surface, immediately wash it off.

4. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

Click here

![2023 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - 11/2022]; WIPER / WASHER: FRONT WIPER MOTOR: REMOVAL](/t3Portal/stylegraphics/info.gif)

5. REMOVE NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

except G16E-GTS: Click here

![2023 MY Corolla Corolla Hatchback Corolla HV [09/2022 - 11/2022]; FRONT SUSPENSION: FRONT SHOCK ABSORBER (except G16E-GTS): REMOVAL+](/t3Portal/stylegraphics/info.gif)

for G16E-GTS: Click here

![2023 MY GR Corolla [09/2022 - 11/2022]; FRONT SUSPENSION: FRONT SHOCK ABSORBER (for G16E-GTS): REMOVAL+](/t3Portal/stylegraphics/info.gif)

6. REMOVE OUTER COWL TOP PANEL SUB-ASSEMBLY

except G16E-GTS: Click here

![2023 MY Corolla Corolla Hatchback Corolla HV [09/2022 - 11/2022]; FRONT SUSPENSION: FRONT SHOCK ABSORBER (except G16E-GTS): REMOVAL+](/t3Portal/stylegraphics/info.gif)

for G16E-GTS: Click here

![2023 MY GR Corolla [09/2022 - 11/2022]; FRONT SUSPENSION: FRONT SHOCK ABSORBER (for G16E-GTS): REMOVAL+](/t3Portal/stylegraphics/info.gif)

7. REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY (for M20A-FKS)

Click here

![2023 MY Corolla Corolla Hatchback [09/2022 - 11/2022]; M20A-FKS (ENGINE MECHANICAL): ENGINE ASSEMBLY: REMOVAL+](/t3Portal/stylegraphics/info.gif)

8. REMOVE DASH PANEL HEAT INSULATOR (for M20A-FKS)

|

(b) Remove the 2 nuts and dash panel heat insulator.

|

|

9. REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY (for G16E-GTS)

Click here

![2023 MY GR Corolla [09/2022 - 11/2022]; G16E-GTS (ENGINE MECHANICAL): ENGINE ASSEMBLY: REMOVAL+](/t3Portal/stylegraphics/info.gif)

10. REMOVE DASH PANEL HEAT INSULATOR (for G16E-GTS)

|

(b) Remove the 2 nuts and dash panel heat insulator.

|

|

11. REMOVE BRAKE ACTUATOR WITH BRACKET

(a) except G16E-GTS:

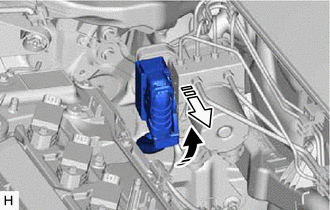

(1) Release the lock lever and disconnect the connector from the brake actuator assembly.

NOTICE:

Be careful not to allow any brake fluid to enter the connector.

|

Release the lock lever

|

|

Disconnect the connector

|

(b) for G16E-GTS:

(1) Release the lock lever and disconnect the connector from the brake actuator assembly.

NOTICE:

Be careful not to allow any brake fluid to enter the connector.

|

Release the lock lever

|

|

Disconnect the connector

|

|

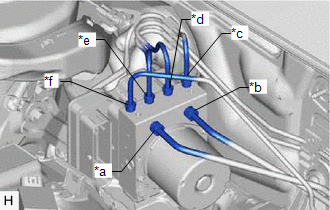

(c) Use tags or make a memo to identify the places to reconnect the brake lines.

|

|

|

*a

|

From 1st Chamber of Brake Master Cylinder Sub-assembly

|

|

*b

|

From 2nd Chamber of Brake Master Cylinder Sub-assembly

|

|

*c

|

To Front Wheel Cylinder Assembly RH

|

|

*d

|

To Rear Wheel Cylinder Assembly LH

|

|

*e

|

To Rear Wheel Cylinder Assembly RH

|

|

*f

|

To Front Wheel Cylinder Assembly LH

|

|

|

|

(d) Using a union nut wrench, disconnect the 6 brake lines from the brake actuator assembly.

NOTICE:

-

Do not kink or damage the brake lines.

-

Do not allow any foreign matter such as dirt or dust to enter the brake lines from the connecting parts.

|

|

|

(e) Disengage the 5 clamps to remove the No. 1 brake tube clamp from the brake lines.

NOTICE:

Do not kink or damage the brake lines.

|

|

|

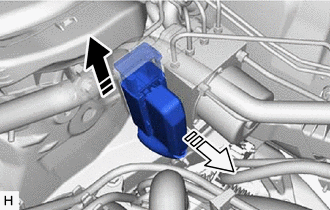

(g) Remove the bolt and brake actuator with bracket.

NOTICE:

-

Do not kink or damage the brake lines.

-

Do not allow any foreign matter such as dirt or dust to enter the brake lines from the connecting parts.

-

Be careful not to allow any brake fluid to enter the connector.

-

Do not hold the brake actuator assembly by the connector.

-

Do not drop the brake actuator with bracket when carrying it.

HINT:

Remove the brake actuator with bracket while avoiding the brake lines.

|

|

12. REMOVE BRAKE ACTUATOR ASSEMBLY (except G16E-GTS)

|

(a) Remove the 3 bolts and brake actuator assembly from the brake actuator bracket assembly.

NOTICE:

-

Do not hold the brake actuator assembly by the connector.

-

Be careful not to allow any brake fluid to enter the connector.

-

Do not drop the brake actuator assembly when carrying it.

|

|

13. REMOVE BRAKE ACTUATOR BRACKET CUSHION (except G16E-GTS)

|

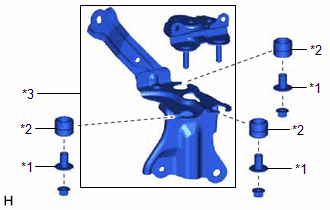

(a) Remove the 3 nuts and separate the brake actuator bracket assembly.

|

|

|

*1

|

No. 1 Brake Actuator Case Collar

|

|

*2

|

Brake Actuator Bracket Cushion

|

|

*3

|

Brake Actuator Bracket Assembly

|

|

|

(b) Remove the 3 No. 1 brake actuator case collars from the brake actuator bracket cushion.

(c) Remove the 3 brake actuator bracket cushions from the brake actuator bracket assembly.

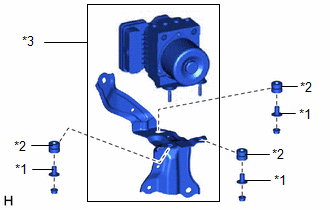

14. REMOVE BRAKE ACTUATOR BRACKET CUSHION (for G16E-GTS)

|

(a) Remove the 3 nuts and separate the brake actuator bracket assembly.

|

|

|

*1

|

No. 1 Brake Actuator Case Collar

|

|

*2

|

Brake Actuator Bracket Cushion

|

|

*3

|

Brake Actuator With Bracket

|

|

|

(b) Remove the 3 No. 1 brake actuator case collars from the brake actuator bracket cushion.

(c) Remove the 3 brake actuator bracket cushions from the brake actuator bracket assembly.

15. REMOVE BRAKE ACTUATOR ASSEMBLY (for G16E-GTS)

|

(a) Remove the 3 bolts and brake actuator assembly from the brake actuator bracket assembly.

NOTICE:

-

Do not hold the brake actuator assembly by the connector.

-

Be careful not to allow any brake fluid to enter the connector.

-

Do not drop the brake actuator assembly when carrying it.

|

|

|