| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM10000000265TF |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - 11/2022] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model without Electric Parking Brake System TMMMS Made): P057113; Brake Switch "A" Circuit Open; 2023 MY Corolla Corolla Hatchback GR Corolla [09/2022 - 11/2022] | ||

|

DTC |

P057113 |

Brake Switch "A" Circuit Open |

DESCRIPTION

The skid control ECU (brake actuator assembly) receives stop light switch assembly signals and uses them to determine whether or not the brakes are applied.

The skid control ECU (brake actuator assembly) has a detection circuit that it uses to detect an open in the stop light input line.

If the skid control ECU (brake actuator assembly) detects an open in this circuit, it will store this DTC.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

P057113 |

Brake Switch "A" Circuit Open |

An open in the stop light switch assembly input line continues for 3 seconds or more. |

|

WIRING DIAGRAM

Refer to DTC P057111.

CAUTION / NOTICE / HINT

NOTICE:

After replacing the skid control ECU (brake actuator assembly), perform acceleration sensor zero point calibration and store system information memorization.

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY OUTPUT CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

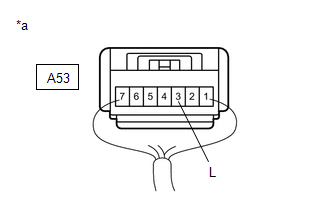

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A53-3 (L) - Body ground |

Brake pedal depressed |

11 to 14 V |

|

A53-3 (L) - Body ground |

Brake pedal released |

Below 1.5 V |

| NG |

|

|

|

2. |

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY INPUT CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

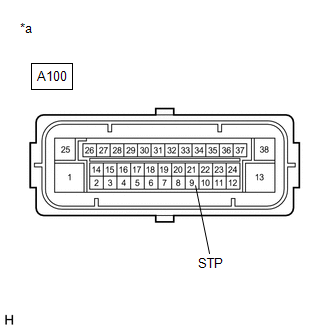

(b) Disconnect the A100 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A100-9 (STP) - Body ground |

Brake pedal depressed |

11 to 14 V |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2023 MY Corolla Corolla Hatchback GR Corolla [09/2022 - 11/2022]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model without Electric Parking Brake System TMMMS Made): P057111; Brake Switch "A" Circuit Short to Ground](/t3Portal/stylegraphics/info.gif)