- Poor idle, etc.

- Engine start function, etc.

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000002651G |

| Model Year Start: 2023 | Model: Corolla Hatchback | Prod Date Range: [09/2022 - ] |

| Title: M20A-FKS (EMISSION CONTROL): CANISTER (w/ Canister Pump Module (for Double Wishbone Type Suspension)): REMOVAL; 2023 - 2025 MY Corolla Corolla Hatchback [09/2022 - ] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during the canister (charcoal canister assembly) removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Gas leaks from exhaust system is repaired |

Inspection after repair |

|

PROCEDURE

1. REMOVE TAIL EXHAUST PIPE ASSEMBLY

2. REMOVE REAR FLOOR SIDE MEMBER COVER LH (w/ Cover)

3. REMOVE REAR FLOOR SIDE MEMBER COVER RH (w/ Cover)

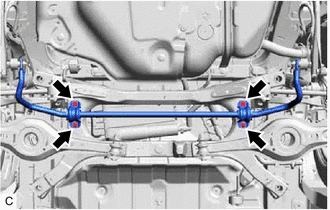

4. SEPARATE REAR STABILIZER BAR SUB-ASSEMBLY

|

(a) Remove the 4 bolts and separate the rear stabilizer bar sub-assembly from the rear suspension member sub-assembly. |

|

5. REMOVE CANISTER (CHARCOAL CANISTER ASSEMBLY)

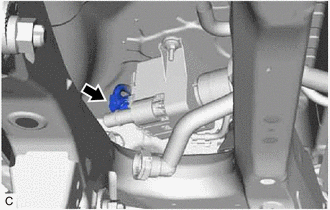

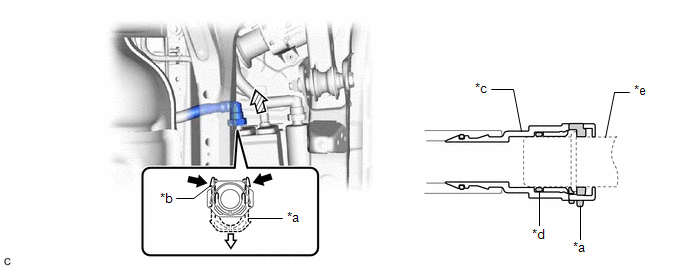

(a) Disconnect the fuel tank vent hose from the canister (charcoal canister assembly).

|

*a |

Retainer |

*b |

Tab |

|

*c |

Tube Connector |

*d |

O-ring |

|

*e |

Pipe (Canister (Charcoal Canister Assembly)) |

- |

- |

|

Pinch |

|

Pull |

|

Pull off |

- |

- |

NOTICE:

- Remove any dirt or foreign matter on the tube connector before performing this work.

- Do not allow any scratches or foreign matter to get on the parts when disconnecting them as the tube connector has an O-ring that seals the pipe (canister (charcoal canister assembly)).

- Perform this work by hand. Do not use any tools.

- Do not forcibly bend, twist or turn the fuel tank vent hose.

- Protect the disconnected parts by covering them with plastic bags after disconnecting the fuel tank vent hose.

- If the tube connector and pipe (canister (charcoal canister assembly)) are stuck, push and pull to release them.

HINT:

Do not remove the retainer.

(1) Pinch the tabs of the retainer to disengage the lock claws and pull it down.

(2) Pull off the fuel tank vent hose.

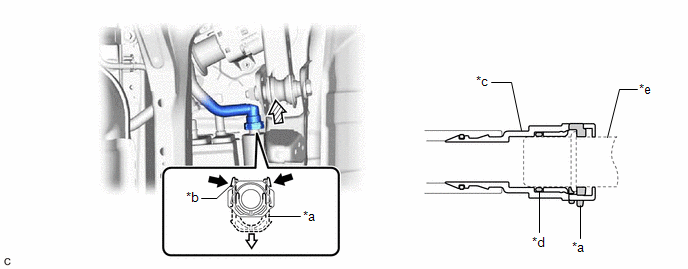

(b) Disconnect the vent line hose from the canister (charcoal canister assembly).

|

*a |

Retainer |

*b |

Tab |

|

*c |

Tube Connector |

*d |

O-ring |

|

*e |

Pipe (Canister (Charcoal Canister Assembly)) |

- |

- |

|

Pinch |

|

Pull |

|

Pull off |

- |

- |

NOTICE:

- Remove any dirt or foreign matter on the tube connector before performing this work.

- Do not allow any scratches or foreign matter to get on the parts when disconnecting them as the tube connector has an O-ring that seals the pipe (canister (charcoal canister assembly)).

- Perform this work by hand. Do not use any tools.

- Do not forcibly bend, twist or turn the vent line hose.

- Protect the disconnected parts by covering them with plastic bags after disconnecting the vent line hose.

- If the tube connector and pipe (canister (charcoal canister assembly)) are stuck, push and pull to release them.

HINT:

Do not remove the retainer.

(1) Pinch the tabs of the retainer to disengage the lock claws and pull it down.

(2) Pull off the vent line hose.

|

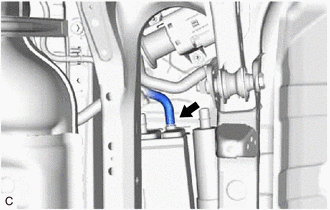

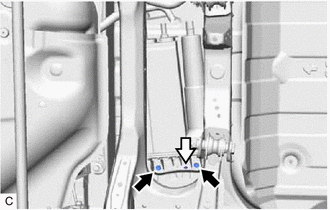

(c) Slide the clip and disconnect the purge line hose from the canister (charcoal canister assembly). |

|

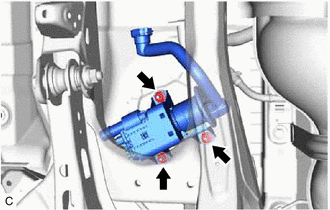

(d) Remove the 2 bolts.

|

Bolt |

|

Clip |

(e) Disengage the clip from the canister (charcoal canister assembly).

|

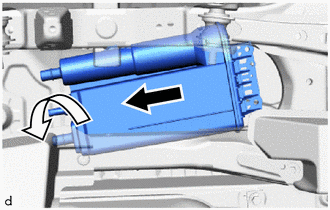

(f) Remove the canister (charcoal canister assembly) from vehicle body as shown in the illustration. |

|

|

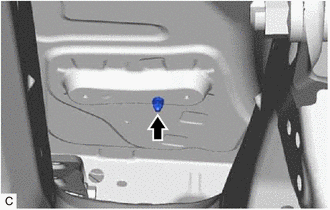

(g) Remove the clip from the vehicle body. |

|

6. REMOVE NO. 2 CHARCOAL CANISTER SUB-ASSEMBLY

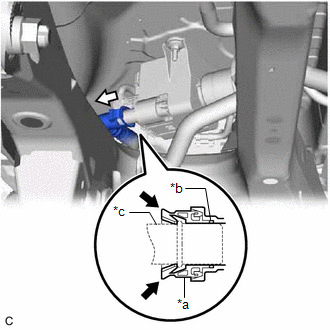

(a) Disconnect the air line tube from the leak detection pump sub-assembly.

|

*a |

Tube Connector |

|

*b |

O-ring |

|

*c |

Pipe (Leak Detection Pump Sub-assembly) |

|

Pinch |

|

Pull off |

NOTICE:

- Remove any dirt or foreign matter on the tube connector before performing this work.

- Perform this work by hand. Do not use any tools.

- Do not forcibly bend, twist or turn the air line tube.

- Protect the disconnected parts by covering them with plastic bags after disconnecting the air line tube.

- If the tube connector and pipe (leak detection pump sub-assembly) are stuck, push and pull to release them.

(1) Push the air line tube firmly toward the leak detection pump sub-assembly.

(2) Pinch the tube connector as shown in the illustration.

(3) Pull off the air line tube from the pipe (leak detection pump sub-assembly).

|

(b) Disconnect the leak detection pump sub-assembly connector. |

|

|

(c) Remove the 3 nuts and No. 2 charcoal canister sub-assembly from the vehicle body. |

|

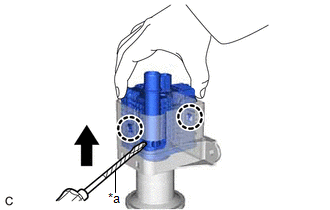

7. REMOVE LEAK DETECTION PUMP SUB-ASSEMBLY

HINT:

Only perform this procedure when replacement of the leak detection pump sub-assembly is necessary.

(a) Before removing the leak detection pump sub-assembly, clean the No. 2 charcoal canister sub-assembly by blowing air into it to ensure that the No. 2 charcoal canister sub-assembly is free of foreign matter.

NOTICE:

- Make sure to clean the No. 2 charcoal canister sub-assembly using air only.

- Do not use gasoline, thinners or solvents.

|

(b) While disengaging the 2 claws as shown in the illustration, push the leak detection pump sub-assembly upwards using a screwdriver with its tip wrapped with protective tape to remove it. |

|

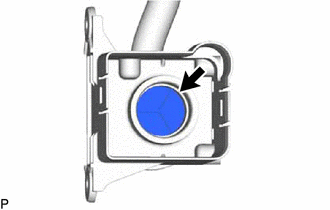

(c) Check if the No. 2 charcoal canister sub-assembly contains foreign matter such as mud or water.

|

(1) Visually check that the inside of the No. 2 charcoal canister sub-assembly is free of foreign matter. |

|

(2) Hold the No. 2 charcoal canister sub-assembly upside down to make sure that it is free of foreign matter.

If the No. 2 charcoal canister sub-assembly contains foreign matter, replace it.

|

|

|

![2021 - 2023 MY Corolla Corolla Hatchback [04/2020 - 11/2022]; M20A-FKS (ENGINE CONTROL): SFI SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)