| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM1000000025YWL |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - ] |

| Title: DRIVE SHAFT / PROPELLER SHAFT: PROPELLER SHAFT ASSEMBLY: INSTALLATION; 2023 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - ] | ||

INSTALLATION

PROCEDURE

1. TEMPORARILY INSTALL PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

(a) Completely remove any oil or the like and clean the contact surfaces of the transfer assembly and propeller with center bearing shaft assembly.

(b) Completely remove any oil or the like and clean the contact surfaces of the rear differential carrier assembly and propeller with center bearing shaft assembly.

|

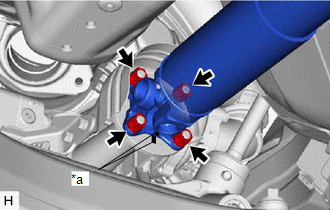

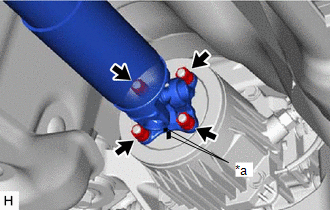

(c) Align the matchmarks of the transfer assembly and propeller with center bearing shaft assembly. NOTICE: Make sure there is no oil on the bolts. If oil is found on any bolt, clean it before installation. |

|

(d) Temporarily install the propeller with center bearing shaft assembly to the transfer assembly with the 4 nuts and 4 washers.

NOTICE:

Do not apply grease to the 4 bolts, 4 nuts or 4 washers.

|

(e) Align the matchmarks of the rear differential carrier assembly and propeller with center bearing shaft assembly. NOTICE: Make sure there is no oil on the bolts. If oil is found on any bolt, clean it before installation. |

|

(f) Temporarily install the propeller with center bearing shaft assembly to the rear differential carrier assembly with the 4 nuts and 4 washers.

NOTICE:

Do not apply grease to the 4 bolts, 4 nuts or 4 washers.

|

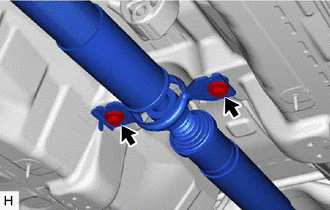

(g) Temporarily install the center support bearing and 2 center No. 2 support bearing washers with the 2 bolts. NOTICE: Make sure there is no oil on the bolts. If oil is found on any bolt, clean it before installation. |

|

2. TIGHTEN PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

(a) Tighten the 4 nuts of the propeller with center bearing shaft assembly and transfer assembly to the torque specification.

Torque:

73.5 N·m {749 kgf·cm, 54 ft·lbf}

(b) Tighten the 4 nuts of the propeller with center bearing shaft assembly and rear differential carrier assembly to the torque specification.

Torque:

73.5 N·m {749 kgf·cm, 54 ft·lbf}

|

(c) Check that the center line of the center support bearing housing is perpendicular to the axis of the propeller shaft. |

|

(d) Tighten the 2 bolts of the center support bearing to the torque specification.

Torque:

36.8 N·m {375 kgf·cm, 27 ft·lbf}

3. INSPECT AND ADJUST JOINT ANGLE

NOTICE:

Perform the measurement with a 4 post lift or pit so that the vehicle is supported by all 4 wheels as if it were on the ground.

(a) Before the angle measurement, stabilize each part by performing procedures like those described below.

(1) Rotate the propeller shaft several times by hand.

(2) Set the jack to the rear differential, and raise and lower the rear differential.

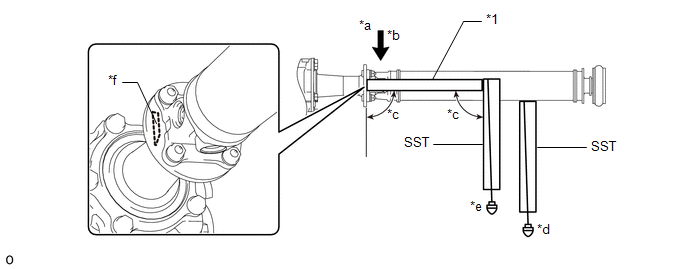

(b) Using SST and a straightedge, measure the angle of the transfer flange (angle D) and the angle of the intermediate shaft (angle A).

|

*1 |

Straightedge |

- |

- |

|

*a |

No. 1 Joint Angle |

*b |

D - A |

|

*c |

90° |

*d |

Angle A |

|

*e |

Angle D |

*f |

Angle D Measurement Position |

SST: 09370-50010

NOTICE:

Make sure the straightedge and SST are at a right angle.

(1) Subtract the measured angle of the intermediate shaft (angle A) from the measured angle of the transfer flange (angle D) to obtain the No. 1 joint angle.

Standard No. 1 Joint Angle:

|

Measurement Position |

Angle |

|---|---|

|

D - A |

-2°18' +/- 1°00' |

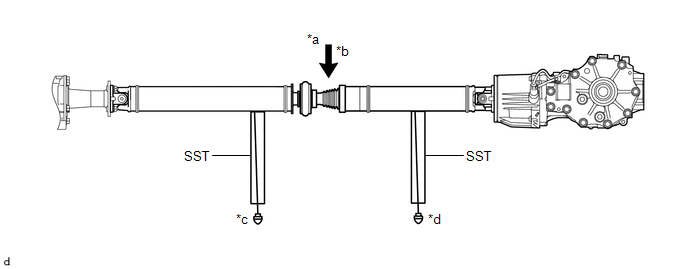

(c) Using SST, measure the angle of the intermediate shaft (angle A) and the angle of the propeller shaft (angle B).

|

*a |

No. 2 Joint Angle |

*b |

A - B |

|

*c |

Angle A |

*d |

Angle B |

SST: 09370-50010

(1) Subtract the measured angle of the propeller shaft (angle B) from the measured angle of the intermediate shaft (angle A) to obtain the No. 2 joint angle.

Standard No. 2 Joint Angle:

|

Measurement Position |

Angle |

|---|---|

|

A - B |

1°07' +/- 1°00' |

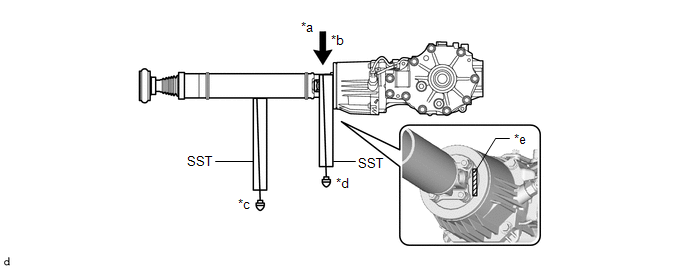

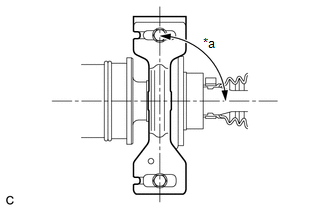

(d) Using SST, measure the angle of the propeller shaft (angle B) and the angle of the rear differential (angle C).

|

*a |

No. 3 Joint Angle |

*b |

B - C |

|

*c |

Angle B |

*d |

Angle C |

|

*e |

Angle C Measurement Position |

- |

- |

SST: 09370-50010

(1) Subtract the measured angle of the rear differential (angle C) from the measured angle of the propeller shaft (angle B) to obtain the No. 3 joint angle.

Standard No. 3 Joint Angle:

|

Measurement Position |

Angle |

|---|---|

|

B - C |

3°05' +/- 1°00' |

(e) If the measured angle of the propeller with center bearing shaft assembly is not within the specified range, or there is vibration or noise, use the following procedure to adjust the propeller with center bearing shaft assembly.

(1) Support the propeller with center bearing shaft assembly with a jack.

(2) Remove the 2 center support bearing mounting bolts.

(3) Slowly lower the jack and separate the center support bearing.

(4) Select an appropriate adjusting washer thickness from the table below, and obtain a washer set.

Adjusting Washer:

|

Part No. |

Thickness |

|---|---|

|

90201-10123 |

2.0 mm (0.0787 in.) |

|

90201-10081 |

4.5 mm (0.177 in.) |

|

90201-10083 |

6.5 mm (0.256 in.) |

|

90201-10084 |

9.0 mm (0.354 in.) |

|

90201-10085 |

11.0 mm (0.433 in.) |

NOTICE:

- Use washers of the same thickness on the left and right sides.

- Do not use 2 or more washers stacked together.

4. INSTALL FRONT NO. 1 FLOOR HEAT INSULATOR SUB-ASSEMBLY

(a) Install the front No. 1 floor heat insulator sub-assembly to the vehicle body with the 2 nuts.

5. INSTALL FRONT EXHAUST PIPE ASSEMBLY

|

|

|

![2023 - 2025 MY GR Corolla [09/2022 - ]; G16E-GTS (INTAKE / EXHAUST): EXHAUST PIPE: INSTALLATION](/t3Portal/stylegraphics/info.gif)