| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM1000000025XZR |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - ] |

| Title: G16E-GTS (ENGINE CONTROL): IGNITION SYSTEM: ON-VEHICLE INSPECTION; 2023 - 2025 MY GR Corolla [09/2022 - ] | ||

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

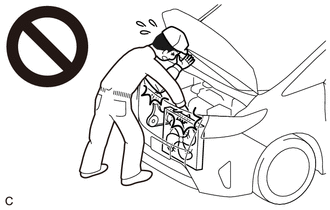

CAUTION:

To prevent injury due to contact with an operating V-ribbed belt or cooling fan, keep your hands and clothing away from the V-ribbed belt and cooling fan when working in the engine compartment with the engine running or the engine switch on (IG).

PROCEDURE

1. PERFORM SPARK TEST

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Trouble Codes.

(e) Check for DTCs.

Powertrain > Engine > Trouble Codes

NOTICE:

If any DTCs are present, perform troubleshooting in accordance with the procedure for each DTC.

(f) Turn the engine switch off.

(g) Remove the 3 ignition coil assemblies and 3 spark plugs.

|

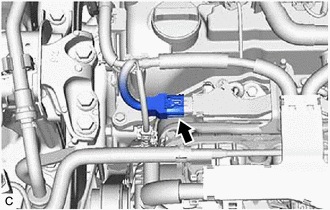

(h) Disconnect the engine wire connector. NOTICE: Perform this step in order to stop fuel injection and prevent damage to the catalyst due to unburned fuel. |

|

|

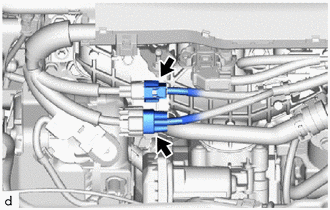

(i) Disconnect the No. 6 engine wire connector. NOTICE: Perform this step in order to stop fuel injection and prevent damage to the catalyst due to unburned fuel. |

|

(j) Install the spark plug to the ignition coil assembly, and then connect the ignition coil assembly connector.

(k) Ground the spark plug.

(l) Check that spark occurs at each spark plug while the engine is being cranked.

NOTICE:

- Be sure to ground the spark plugs when checking them.

- Do not crank the engine for more than 2 seconds.

- If an ignition coil assembly or spark plug has been struck or dropped, replace it.

HINT:

(m) Connect the No. 6 engine wire connector.

(n) Connect the engine wire connector.

(o) Install the 3 ignition coil assemblies and 3 spark plugs.

(p) Turn the engine switch on (IG).

(q) Turn the Techstream on.

(r) Enter the following menus: Powertrain / Engine / Trouble Codes.

(s) Check for DTCs.

Powertrain > Engine > Trouble Codes

(t) Clear the DTCs.

Powertrain > Engine > Clear DTCs

2. INSPECT IGNITION COIL ASSEMBLY AND SPARK TEST

HINT:

Perform "Inspection After Repair" after replacing an ignition coil assembly or spark plug.

(a) Check that the ignition coil assembly connector is securely connected.

|

Result |

Action |

|---|---|

|

NG |

Connect securely |

|

OK |

Go to next step |

(b) Perform a spark test on each ignition coil assembly.

(1) Replace the ignition coil assembly with a known good one.

(2) Perform the spark test again.

|

Result |

Action |

|---|---|

|

NG |

Go to next step |

|

OK |

Replace ignition coil assembly |

(c) Perform a spark test on each spark plug.

(1) Replace the spark plug with a known good one.

(2) Perform the spark test again.

|

Result |

Action |

|---|---|

|

NG |

Inspect ignition system |

|

OK |

Replace spark plug |

NOTICE:

If an ignition coil assembly or spark plug has been struck or dropped, replace it.

(d) Connect the No. 6 engine wire connector.

(e) Install the 3 ignition coil assemblies and 3 spark plugs.

(f) Turn the engine switch on (IG).

(g) Turn the Techstream on.

(h) Enter the following menus: Powertrain / Engine / Trouble Codes.

(i) Check for DTCs.

Powertrain > Engine > Trouble Codes

(j) Clear the DTCs.

Powertrain > Engine > Clear DTCs

3. CHECK SPARK PLUG

NOTICE:

- Do not damage the iridium tip and platinum tip.

- Check the iridium tip visually since the iridium tip may be damaged.

- Never attempt to adjust the electrode gap of a used spark plug.

- Replace with new spark plugs if extremely dirty due to sludge, etc.

- Replace with new spark plugs if damaged at all.

- Replace with a new spark plug if it has been struck or dropped.

- When replacing with a new spark plug, do not remove the cap for protecting the spark plug tip until it is installed to the engine.

HINT:

Perform "Inspection After Repair" after replacing a spark plug.

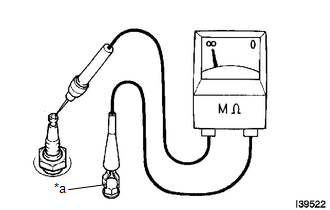

|

(a) Check the electrode. (1) Using a megohmmeter, measure the insulation resistance. Standard Insulation Resistance:

HINT:

|

|

(b) Alternative inspection method.

(1) Start the engine.

NOTICE:

Do not perform this step when any of the following DTCs are output: P030000, P030027, P030085, P030100, P030200, P030300 (Cylinder Misfire Detected).

(2) Quickly accelerate the engine to 4000 rpm 5 times.

NOTICE:

Do not perform this step when any of the following DTCs are output: P030000, P030027, P030085, P030100, P030200, P030300 (Cylinder Misfire Detected).

(3) Remove the spark plug.

(4) Visually check the spark plug.

HINT:

If the electrode is dry, the spark plug is functioning properly. If the electrode is damp, proceed to the next step.

(c) Check the spark plug for any damage to its threads and insulator.

If there is any damage, replace the spark plug.

Recommended Spark Plug:

|

Manufacturer |

Spark Plug Type |

|---|---|

|

NGK |

DILKAR8U7G |

|

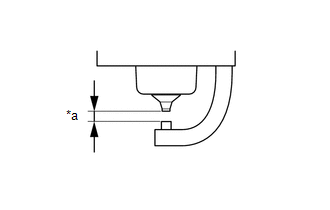

(d) Check the spark plug electrode gap. Maximum Electrode Gap for Used Spark Plug: 0.9 mm (0.0354 in.) NOTICE: Never attempt to adjust the electrode gap of a used spark plug. If the spark plug electrode gap is more than the maximum, replace the spark plug. Standard Electrode Gap for New Spark Plug: 0.6 to 0.7 mm (0.0236 to 0.0276 in.) |

|

(e) Install the spark plug.

4. PERFORM INITIALIZATION

(a) Perform "Inspection After Repair" after replacing an ignition coil assembly or spark plug.

|

|

|

![2023 - 2025 MY GR Corolla [09/2022 - ]; MAINTENANCE: G16E-GTS SPARK PLUG: REMOVAL](/t3Portal/stylegraphics/info.gif)