| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM1000000025V9T |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - ] |

| Title: G16E-GTS (FUEL): FUEL PUMP (for High Pressure): INSTALLATION; 2023 - 2025 MY GR Corolla [09/2022 - ] | ||

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

PROCEDURE

1. TEMPORARILY INSTALL FUEL PUMP ASSEMBLY

NOTICE:

When replacing the fuel pump assembly, it is necessary to replace the No. 1 fuel pipe sub-assembly with a new one.

HINT:

Perform "Inspection After Repair" after replacing the fuel pump assembly.

|

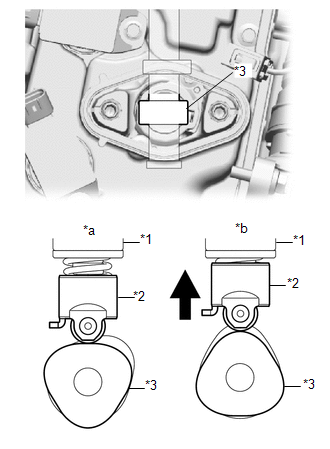

(a) Turn the crankshaft pulley until the flat of the camshaft faces the fuel pump lifter assembly. HINT: This prevents the camshaft nose from pushing up the fuel pump lifter assembly when installing the fuel pump assembly. |

|

|

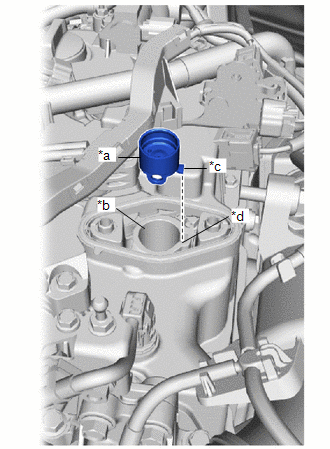

(b) Apply 30 cc (1.8 cu. in.) of engine oil to the pump drive cam. |

|

(c) Apply engine oil to the fuel pump lifter assembly.

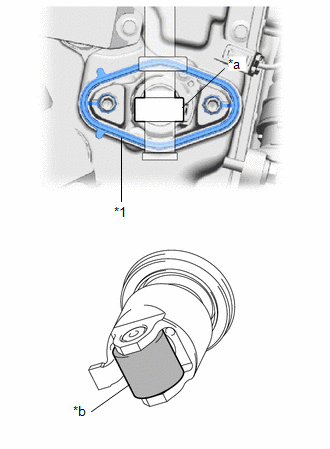

(d) Install a new fuel pump spacer gasket to the cylinder head cover sub-assembly.

|

(e) Apply engine oil to the inside of the fuel pump lifter guide and the outside of the fuel pump lifter assembly. |

|

(f) Set the fuel pump lifter assembly on the fuel pump lifter guide as shown in the illustration.

HINT:

Align the stopper key of the fuel pump lifter assembly with the key groove of the fuel pump lifter guide.

|

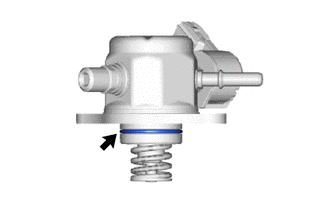

(g) Apply engine oil to a new O-ring and install it to the fuel pump assembly. NOTICE: Do not damage the O-ring. |

|

(h) Set the fuel pump flange and fuel pump assembly on the cylinder head cover sub-assembly.

|

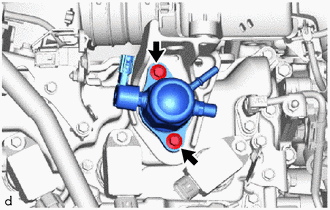

(i) Using an 8 mm socket wrench, temporarily install the fuel pump assembly with the 2 bolts, leaving some allowance for left and right movement. |

|

2. TEMPORARILY INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY

NOTICE:

Do not damage the seals of the union nuts of the No. 1 fuel pipe sub-assembly.

(a) Temporarily install the bolt.

(b) Temporarily install the No. 1 fuel pipe sub-assembly to the fuel delivery pipe sub-assembly and tighten the union nut by hand.

(c) Temporarily install the No. 1 fuel pipe sub-assembly to the fuel pump assembly and tighten the union nut by hand.

3. INSTALL FUEL PUMP ASSEMBLY

(a) Using an 8 mm socket wrench, tighten the 2 bolts.

Torque:

28.5 N·m {291 kgf·cm, 21 ft·lbf}

(b) Connect the fuel pump assembly connector.

4. INSTALL INTAKE AIR RESONATOR

(a) Install the intake air resonator to the fuel pump flange with the bolt.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

5. INSTALL NO. 1 VACUUM TRANSMITTING HOSE

(a) Engage the 2 clamps to connect the No. 1 vacuum transmitting hose to the intake air resonator.

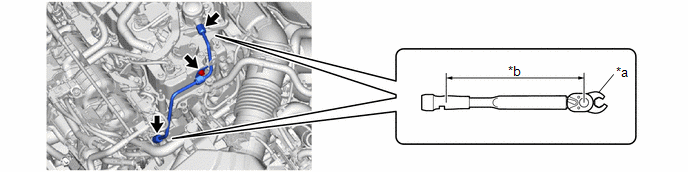

6. INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY

(a) Using a 17 mm union nut wrench, tighten the union nut on the fuel delivery pipe sub-assembly side of the No. 1 fuel pipe sub-assembly.

|

*a |

17 mm Union Nut Wrench |

*b |

Torque Wrench Fulcrum Length |

Torque:

Specified tightening torque :

35 N·m {357 kgf·cm, 26 ft·lbf}

NOTICE:

Do not adjust the torque in the loosening direction.

HINT:

(b) Using a 17 mm union nut wrench, tighten the union nut on the fuel pump assembly side of the No. 1 fuel pipe sub-assembly.

Torque:

Specified tightening torque :

35 N·m {357 kgf·cm, 26 ft·lbf}

NOTICE:

Do not adjust the torque in the loosening direction.

HINT:

(c) Tighten the bolt to the cylinder head cover sub-assembly.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

7. CONNECT ENGINE WIRE

(a) Engage the clamp to connect the engine wire.

(b) Install the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(c) Connect the camshaft position sensor connector.

8. CONNECT NO. 1 WATER BY-PASS HOSE

(a) Connect the No. 1 water by-pass hose and slide the clip to secure it.

9. CONNECT NO. 8 WATER BY-PASS HOSE

(a) Connect the No. 8 water by-pass hose and slide the clip to secure it.

(b) Engage the clamp.

10. INSTALL NO. 2 FUEL TUBE SUB-ASSEMBLY

(a) Connect the No. 2 fuel tube sub-assembly to the fuel pump assembly and fuel delivery pipe assembly.

(b) Install the No. 2 fuel tube sub-assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

11. INSTALL FUEL PIPE CLAMP

(a) Install the fuel pipe clamp to the fuel tube connector.

12. CONNECT NO. 1 FUEL TUBE SUB-ASSEMBLY

(a) Connect the No. 1 fuel tube sub-assembly to the No. 2 fuel tube sub-assembly.

13. CONNECT NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

14. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

15. INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

16. INSTALL NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

17. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

18. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

19. INSTALL SPARE WHEEL CUSHION

20. INSTALL DECK BOARD ASSEMBLY

21. ADD ENGINE COOLANT

22. INSPECT FOR FUEL LEAK

23. INSPECT FOR ENGINE OIL LEAK

24. PERFORM INITIALIZATION

(a) Perform "Inspection After Repair" after replacing the fuel pump assembly.

25. INITIALIZATION AFTER RECONNECTING BATTERY TERMINAL

HINT:

When disconnecting and reconnecting the battery, there is an automatic learning function that completes learning when the respective system is used.

|

|

|

![2019 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [06/2018 - ]; INTRODUCTION: REPAIR INSTRUCTION: PRECAUTION](/t3Portal/stylegraphics/info.gif)