| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM1000000025TVG |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - 11/2022] |

| Title: POWER DISTRIBUTION: MAIN BODY ECU: INSTALLATION; 2023 MY Corolla Corolla Hatchback Corolla HV GR Corolla [09/2022 - 11/2022] | ||

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

-

Before replacing the main body ECU (multiplex network body ECU), refer to Registration. (w/ Smart Key System)

for Gasoline Model except TMMMS Made: Click here

![2023 MY Corolla Corolla Hatchback GR Corolla [09/2022 - 11/2022]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function (Gasoline Model, except TMMMS Made)): REGISTRATION](/t3Portal/stylegraphics/info.gif)

- After the main body ECU (multiplex network body ECU) has been replaced, the automatic light control system will not operate until the engine is started.

PROCEDURE

1. INSTALL MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) (for TMMMS Made)

NOTICE:

- Make sure that the connecting surfaces are free of foreign matter.

- Do not touch the main body ECU (multiplex network body ECU) connector.

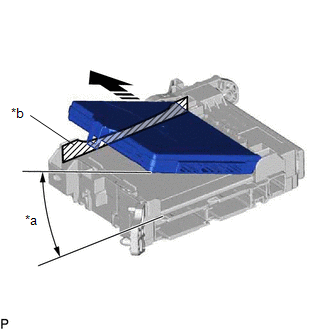

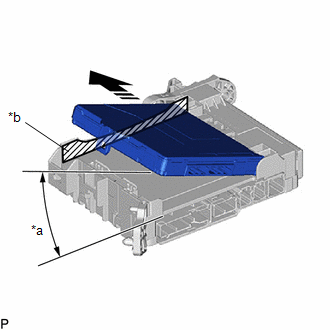

(a) Set the main body ECU (multiplex network body ECU) to the position where the guide of the main body ECU (multiplex network body ECU) contacts the housing sidewall of the instrument panel junction block assembly as shown in the illustration.

|

*a |

20° or more |

|

*b |

Housing Sidewall |

|

Set in this Direction |

HINT:

Make sure to keep the angle at 20° or more as shown in the illustration.

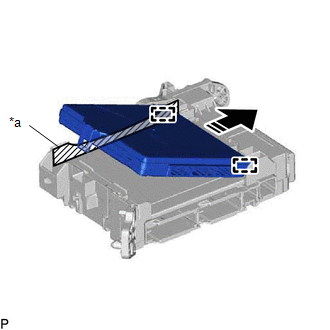

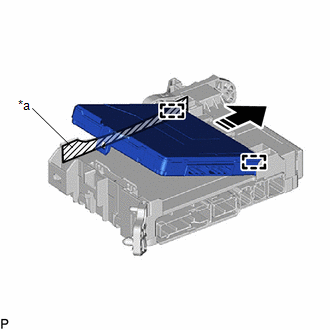

(b) Slide the main body ECU (multiplex network body ECU) along the housing sidewall as shown in the illustration and engage the 2 guides.

|

*a |

Housing Sidewall |

|

Slide in this Direction |

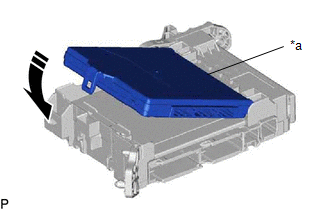

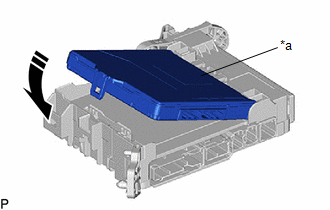

(c) While keeping the main body ECU (multiplex network body ECU) in contact with side A of the instrument panel junction block assembly (axis of rotation), lower it as shown in the illustration.

|

*a |

Side A |

|

Install in this Direction |

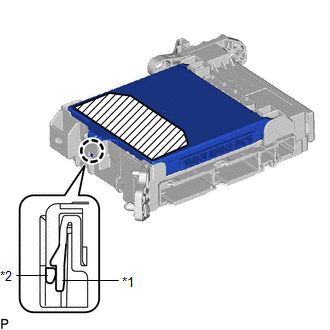

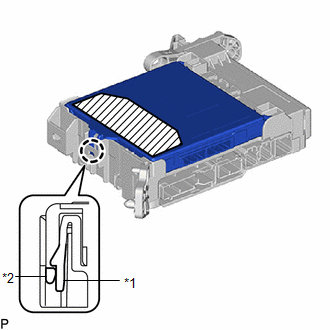

(d) Press the push area until the claw engages to install the main body ECU (multiplex network body ECU).

|

*1 |

Instrument Panel Junction Block Assembly |

|

*2 |

Main Body ECU (Multiplex Network Body ECU) |

|

Push Area |

NOTICE:

- Make sure to press only the push area.

- Confirm the engagement of the main body ECU (multiplex network body ECU) and instrument panel junction block assembly by listening for the click sound of the lock engaging.

HINT:

If a click sound cannot be heard, visually check the engagement of the lock. The engagement can also be confirmed if the main body ECU (multiplex network body ECU) and instrument panel junction block assembly are flush.

2. INSTALL MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) (for TMC Made)

NOTICE:

- Make sure that the connecting surfaces are free of foreign matter.

- Do not touch the main body ECU (multiplex network body ECU) connector.

(a) Set the main body ECU (multiplex network body ECU) to the position where the guide of the main body ECU (multiplex network body ECU) contacts the housing sidewall of the power distribution box assembly as shown in the illustration.

|

*a |

20° or more |

|

*b |

Housing Sidewall |

|

Set in this Direction |

HINT:

Make sure to keep the angle at 20° or more as shown in the illustration.

(b) Slide the main body ECU (multiplex network body ECU) along the housing sidewall as shown in the illustration and engage the 2 guides.

|

*a |

Housing Sidewall |

|

Slide in this Direction |

(c) While keeping the main body ECU (multiplex network body ECU) in contact with side A of the power distribution box assembly (axis of rotation), lower it as shown in the illustration.

|

*a |

Side A |

|

Install in this Direction |

(d) Press the push area until the claw engages to install the main body ECU (multiplex network body ECU).

|

*1 |

Power Distribution Box Assembly |

|

*2 |

Main Body ECU (Multiplex Network Body ECU) |

|

Push Area |

NOTICE:

- Make sure to press only the push area.

- Confirm the engagement of the main body ECU (multiplex network body ECU) and power distribution box assembly by listening for the click sound of the lock engaging.

HINT:

If a click sound cannot be heard, visually check the engagement of the lock. The engagement can also be confirmed if the main body ECU (multiplex network body ECU) and power distribution box assembly are flush.

3. INSTALL NO. 3 WIRING HARNESS CLAMP BRACKET

(a) Engage the guide.

(b) Install the No. 3 wiring harness clamp bracket with the bolt.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

4. INSTALL INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY WITH MAIN BODY ECU (for TMMMS Made)

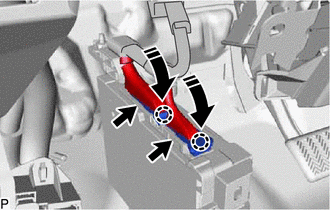

(a) Connect the 2 connectors and pull down the 2 lock levers to engage the 2 claws and lock the connector as shown in the illustration.

NOTICE:

Be sure to connect the connector securely.

|

Install in this Direction |

(b) Engage the clamp.

(c) Engage the clamp.

(d) Engage the clamp.

|

*A |

for CVT |

|

*B |

for Manual Transaxle |

|

Bolt |

|

Nut |

(e) Install the bolt and nut.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

HINT:

Tighten the bolt and nut in the order shown in the illustration.

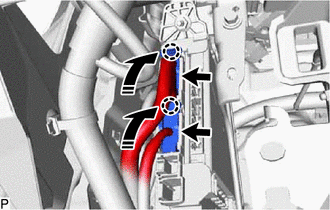

(f) Connect the 2 connectors and raise the 2 lock levers to engage the 2 claws and lock the connector as shown in the illustration.

NOTICE:

Be sure to connect the connector securely.

|

Install in this Direction |

(g) Engage the clamp.

(h) Connect each connector.

5. INSTALL POWER DISTRIBUTION BOX ASSEMBLY WITH MAIN BODY ECU (for TMC Made)

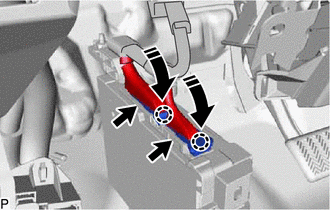

(a) Connect the 2 connectors and pull down the 2 lock levers to engage the 2 claws and lock the connector as shown in the illustration.

NOTICE:

Be sure to connect the connector securely.

|

Install in this Direction |

(b) Engage the clamp.

(c) Engage the clamp.

(d) Engage the clamp.

|

*A |

for CVT |

|

*B |

for Manual Transaxle |

|

Bolt |

|

Nut |

(e) Install the bolt and nut.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

HINT:

Tighten the bolt and nut in the order shown in the illustration.

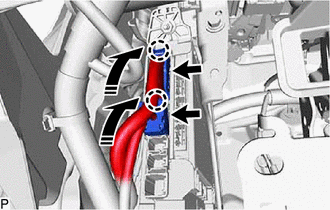

(f) Connect the 2 connectors and raise the 2 lock levers to engage the 2 claws and lock the connector as shown in the illustration.

NOTICE:

Be sure to connect the connector securely.

|

Install in this Direction |

(g) Engage the clamp.

(h) Connect each connector.

6. INSTALL NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY

(a) Install the No. 3 instrument panel to cowl brace sub-assembly with the 2 bolts and nut.

Torque:

Bolt :

10 N·m {102 kgf·cm, 7 ft·lbf}

Nut :

6.0 N·m {61 kgf·cm, 53 in·lbf}

7. INSTALL LOWER INSTRUMENT PANEL FINISH PANEL

8. CONNECT HOOD LOCK CONTROL LEVER SUB-ASSEMBLY

9. INSTALL NO. 1 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

10. INSTALL NO. 1 INSTRUMENT SIDE PANEL

11. CONNECT FRONT DOOR OPENING TRIM WEATHERSTRIP LH

12. INSTALL COWL SIDE TRIM SUB-ASSEMBLY LH

13. INSTALL FRONT DOOR SCUFF PLATE LH

14. CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL

for M20A-FKS:

for 2ZR-FAE:

for 2ZR-FXE:

for G16E-GTS:

15. PERFORM CODE REGISTRATION (for TMC Made)

(a) If the main body ECU (multiplex network body ECU) or the power distribution box assembly has been replaced, perform ECU configuration.

16. PERFORM INITIALIZATION

17. INITIALIZATION AFTER RECONNECTING BATTERY TERMINAL

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

|

|

|