| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM1000000025TDO |

| Model Year Start: 2023 | Model: Corolla Hatchback | Prod Date Range: [09/2022 - ] |

| Title: PA10 (HYBRID TRANSMISSION / TRANSAXLE): HYBRID VEHICLE TRANSAXLE: INSTALLATION; 2023 - 2025 MY Corolla Corolla Hatchback Corolla HV [09/2022 - ] | ||

INSTALLATION

CAUTION / NOTICE / HINT

CAUTION:

The engine assembly with hybrid vehicle transaxle assembly is very heavy. Be sure to follow the procedure described in the repair manual, or the engine lifter may suddenly drop.

PROCEDURE

1. INSTALL TRANSAXLE BREATHER PLUG

HINT:

Perform this procedure only when replacement of the transaxle breather plug is necessary.

(a) Install the transaxle breather plug to the hybrid vehicle transaxle assembly.

Torque:

11.3 N·m {115 kgf·cm, 8 ft·lbf}

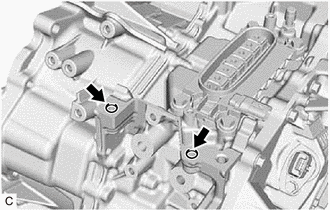

2. INSTALL STUD BOLT

|

(a) Clean and degrease the 2 stud bolts and 2 stud bolt holes. |

|

|

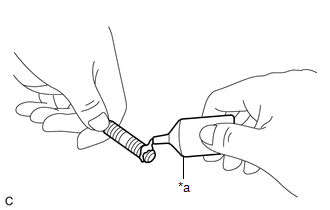

(b) Apply adhesive to 2 or 3 threads on the ends of the 2 stud bolts. Adhesive: Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent NOTICE: Make sure to install the 2 stud bolts immediately after applying adhesive to prevent foreign matter from attaching to them. |

|

(c) Using an E10 "TORX" socket wrench, install the 2 stud bolts to the hybrid vehicle transaxle assembly.

Torque:

30 N·m {306 kgf·cm, 22 ft·lbf}

3. INSTALL TRANSAXLE HOUSING PLUG

(a) Install the transaxle housing plug and a new gasket to the hybrid vehicle transaxle assembly.

Torque:

39.2 N·m {400 kgf·cm, 29 ft·lbf}

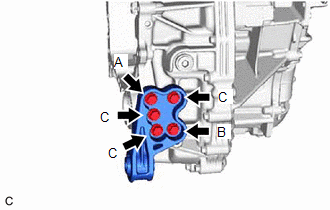

4. INSTALL WIRE HARNESS CLAMP BRACKET

(a) Install the 5 wire harness clamp brackets to the hybrid vehicle transaxle assembly with the 5 bolts.

Torque:

Bolt (A) :

10 N·m {102 kgf·cm, 7 ft·lbf}

Bolt (B) :

20 N·m {204 kgf·cm, 15 ft·lbf}

5. INSTALL NO. 1 TRANSMISSION CONTROL CABLE BRACKET

(a) Install the No. 1 transmission control cable bracket to the hybrid vehicle transaxle assembly with the 2 bolts.

Torque:

12 N·m {122 kgf·cm, 9 ft·lbf}

6. INSTALL MOTOR CABLE

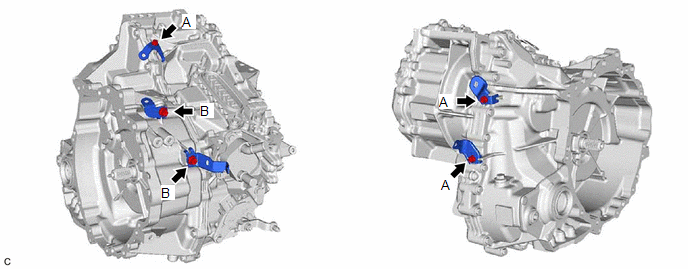

7. INSTALL NO. 2 ENGINE MOVING CONTROL ROD

|

(a) Install the No. 2 engine moving control rod to the hybrid vehicle transaxle assembly with the 5 bolts. Torque: 44 N·m {449 kgf·cm, 32 ft·lbf} NOTICE: Temporarily tighten the bolt (A), and then fully tighten the 5 bolts in the order of (B), (C) and (A). |

|

8. INSTALL FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

(a) Install the front suspension crossmember sub-assembly to the No. 2 engine moving control rod with the bolt.

Torque:

170 N·m {1734 kgf·cm, 125 ft·lbf}

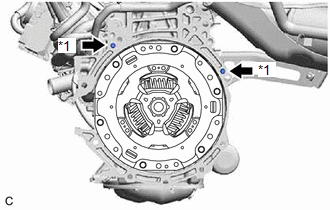

9. INSTALL ENGINE ASSEMBLY

|

(a) Make sure that the knock pins are installed to the engine assembly. |

|

(b) Install the engine assembly to the hybrid vehicle transaxle assembly with the 7 bolts.

Torque:

33 N·m {337 kgf·cm, 24 ft·lbf}

NOTICE:

- When tightening the bolts, be sure that the contact surfaces of the engine assembly and hybrid vehicle transaxle assembly are in close contact with one another.

- Do not apply grease to the inner splines of the transmission input damper assembly or input shaft assembly.

- Make sure that the wire harness or similar items are not pinched between the contact surfaces.

- Do not use excessive force when installing the engine assembly.

- Make sure to align the hybrid vehicle transaxle assembly so that the input shaft assembly of the hybrid vehicle transaxle assembly will be inserted straight into the inner splines of the transmission input damper assembly.

- When inserting the input shaft assembly of the hybrid vehicle transaxle assembly into the inner splines of the transmission input damper assembly, do not shake the engine assembly excessively.

- When installing the engine assembly to the hybrid vehicle transaxle assembly, make sure to securely fit the knock pins into the knock pin holes.

10. INSTALL FLYWHEEL HOUSING SIDE COVER

(a) Install the flywheel housing side cover to the engine assembly.

11. INSTALL STARTER HOLE INSULATOR

(a) Install the starter hole insulator to the engine assembly with 2 new bolts.

Torque:

46 N·m {469 kgf·cm, 34 ft·lbf}

12. CONNECT ENGINE WIRE

(a) Engage the 6 clamps to connect the engine wire.

(b) Install the bolt.

Torque:

13 N·m {133 kgf·cm, 10 ft·lbf}

(c) Connect the motor temperature sensor and generator temperature sensor connector.

(d) Confirm that no foreign matter or water has entered the connector of the shift lever position sensor and connect the connector.

(e) Connect the motor resolver, generator resolver and transmission fluid temperature sensor connector.

13. REMOVE ENGINE HANGERS

14. INSTALL WIRE HARNESS CLAMP BRACKET

15. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

16. PERFORM RESOLVER LEARNING

NOTICE:

If the hybrid vehicle transaxle assembly has been replaced, make sure to perform resolver learning.

|

|

|

![2023 - 2025 MY Corolla Corolla Hatchback Corolla HV [09/2022 - ]; PA10 (HYBRID TRANSMISSION / TRANSAXLE): MOTOR CABLE: INSTALLATION+](/t3Portal/stylegraphics/info.gif)