- Air conditioning amplifier assembly malfunction

- Blower motor with fan sub-assembly malfunction

- Harness or connector

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM1000000025R2H |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - 11/2022] |

| Title: HEATING / AIR CONDITIONING: AIR CONDITIONING SYSTEM (except TMC Made, and Gasoline Model, with Automatic Air Conditioning System): Blower Motor Circuit; 2023 MY Corolla Corolla Hatchback GR Corolla [09/2022 - 11/2022] | ||

|

Blower Motor Circuit |

DESCRIPTION

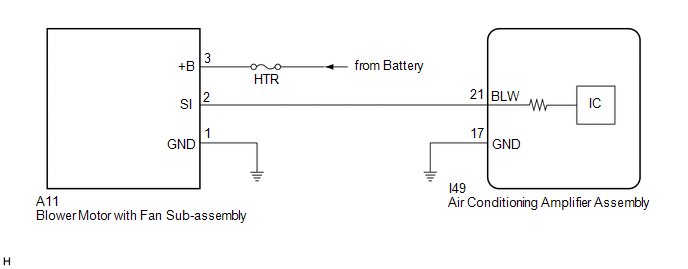

The blower motor with fan sub-assembly is operated by signals from the air conditioning amplifier assembly. Blower motor speed signals are transmitted in accordance with changes in the duty ratio.

If the airflow volume is low or the blower speed cannot be changed, the following factors may be the cause.

|

Symptom |

Factor |

|---|---|

|

Airflow volume cannot be changed |

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Blower Motor |

Blower motor with fan sub-assembly |

Min.: 0 Max.: 31 |

- |

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

|---|

|

Blower Motor |

|

Result |

Proceed to |

|---|---|

|

Blower motor with fan sub-assembly does not operate |

A |

|

Blower motor with fan sub-assembly operates but does not change speed |

B |

| B |

|

|

|

2. |

CHECK HARNESS AND CONNECTOR (BLOWER MOTOR WITH FAN SUB-ASSEMBLY - POWER SOURCE AND BODY GROUND) |

(a) Disconnect the A11 blower motor with fan sub-assembly connector.

(b) Measure the voltage and resistance according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A11-3 (+B) - Body ground |

Always |

11 to 14 V |

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A11-1 (GND) - Body ground |

Always |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK HARNESS AND CONNECTOR (BLOWER MOTOR WITH FAN SUB-ASSEMBLY - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the I49 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A11-2 (SI) - I49-21 (BLW) |

Always |

Below 1 Ω |

|

A11-2 (SI) or I49-21 (BLW) - Other terminals and body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

INSPECT BLOWER MOTOR WITH FAN SUB-ASSEMBLY |

|

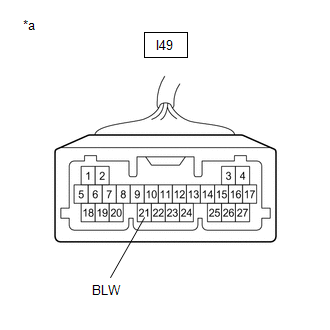

*a |

Front view of wire harness connector (to Air Conditioning Amplifier Assembly) |

(a) Connect the A11 blower motor with fan sub-assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I49-21 (BLW) - Body ground |

Always |

4.75 to 5.25 V |

| NG |

|

|

|

5. |

INSPECT AIR CONDITIONING AMPLIFIER ASSEMBLY |

|

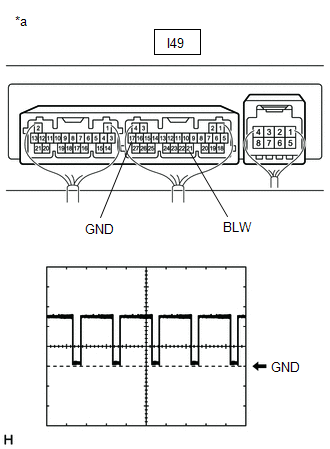

*a |

Component with harness connected (Air Conditioning Amplifier Assembly) |

(a) Connect the I49 air conditioning amplifier assembly connector.

(b) Turn the engine switch on (IG).

(c) Set the blower speed to LO.

(d) Using an oscilloscope, check the waveform.

|

Item |

Content |

|---|---|

|

Terminal No. |

I49-21 (BLW) - I49-17 (GND) |

|

Tool Setting |

2 V/DIV., 1 ms./DIV. |

|

Condition |

|

OK:

Waveform is similar to that shown in the illustration.

HINT:

The waveform varies with the blower speed.

| OK |

|

| NG |

|

|

|

|