- Repair or replacement.

- Turn the ignition switch to ON.

- Drive the vehicle and depress the brake pedal 2 or 3 times to clear the warning lights.

| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM1000000025DUY |

| Model Year Start: 2023 | Model: Corolla | Prod Date Range: [09/2022 - ] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for HV Model): P057112; Brake Switch "A" Circuit Short to Battery; 2023 - 2025 MY Corolla Corolla HV [09/2022 - ] | ||

|

DTC |

P057112 |

Brake Switch "A" Circuit Short to Battery |

DESCRIPTION

The skid control ECU (brake actuator assembly) receives stop light switch assembly signals and uses them to determine whether or not the brakes are applied.

DTCs may be stored if either of the following occurs:

- Stop light switch assembly stuck on malfunction.

- The accelerator and brake pedals are depressed simultaneously.*

HINT:

*: The skid control ECU (brake actuator assembly) may store this DTC upon judging that a stuck on malfunction has occurred when the accelerator pedal and brake pedal are depressed simultaneously. However, this does not indicate a malfunction.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

DTC Output from |

Note |

|---|---|---|---|---|---|---|

|

P057112 |

Brake Switch "A" Circuit Short to Battery |

The vehicle speed is 10 km/h (6 mph) or more, the accelerator pedal is depressed, the master cylinder pressure is 0.5 MPa (5.1 kgf/cm2, 72.5 psi) or less, and the stop light switch assembly is on for 60 seconds or more. |

|

Does not come on |

Brake/EPB |

Output ECU: Skid control ECU (brake actuator assembly) |

- *: w/ Smart Key System

WIRING DIAGRAM

Refer to DTC C117B62.

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

-

DTC precaution

Procedure to clear warning lights (When not clearing DTCs)

Procedure

PROCEDURE

|

1. |

CHECK BRAKE PEDAL OR STOP LIGHT SWITCH ASSEMBLY INSTALLATION |

(a) Check the brake pedal height and stop light switch assembly installation.

OK:

The brake pedal height and stop light switch assembly installation are normal.

| NG |

|

|

|

2. |

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY OUTPUT CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A53-3 (L) - Body ground |

Brake pedal released |

Below 1.5 V |

| OK |

|

|

|

3. |

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

|

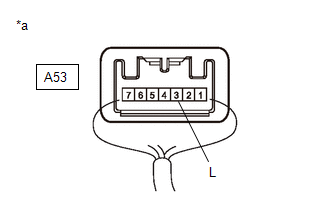

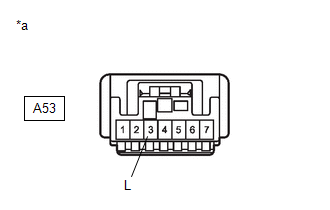

*a |

Front view of wire harness connector (to Stop Light Switch Assembly) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the A53 stop light switch assembly connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A53-3 (L) - Body ground |

Always |

Below 1.5 V |

| OK |

|

|

|

4. |

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - HYBRID VEHICLE CONTROL ECU) |

|

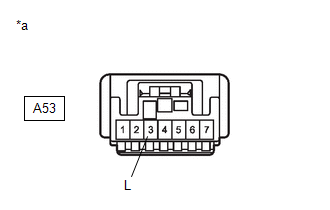

*a |

Front view of wire harness connector (to Stop Light Switch Assembly) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the A53 stop light switch assembly connector.

(d) Disconnect the A161 hybrid vehicle control ECU connector.

(e) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(f) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A53-3 (L) - Body ground |

Always |

Below 1.5 V |

| OK |

|

|

|

5. |

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY) |

|

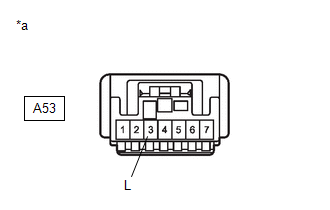

*a |

Front view of wire harness connector (to Stop Light Switch Assembly) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the A53 stop light switch assembly connector.

(d) Disconnect the A161 hybrid vehicle control ECU connector.

(e) Disconnect the A157 electric brake booster (brake booster with master cylinder assembly) connector.

(f) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(g) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A53-3 (L) - Body ground |

Always |

Below 1.5 V |

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (w/o Smart Key System) |

B |

|

NG (w/ Smart Key System) |

C |

| A |

|

| B |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. |

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - SMART KEY ECU ASSEMBLY) |

|

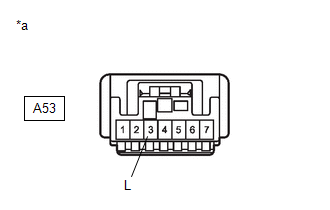

*a |

Front view of wire harness connector (to Stop Light Switch Assembly) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the A53 stop light switch assembly connector.

(d) Disconnect the A161 hybrid vehicle control ECU connector.

(e) Disconnect the A157 electric brake booster (brake booster with master cylinder assembly) connector.

(f) Disconnect the O175 certification ECU (smart key ECU assembly) connector.

(g) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(h) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A53-3 (L) - Body ground |

Always |

Below 1.5 V |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2023 - 2025 MY Corolla Corolla HV [09/2022 - ]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for HV Model): C117B62; Brake Pressure Sensor "A" / Brake Switch "A" Signal Compare Failure](/t3Portal/stylegraphics/info.gif)