| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM1000000025A7Q |

| Model Year Start: 2023 | Model: Corolla Hatchback | Prod Date Range: [09/2022 - 11/2022] |

| Title: M20A-FKS (ENGINE MECHANICAL): ENGINE UNIT: INSTALLATION; 2023 MY Corolla Corolla Hatchback [09/2022 - 11/2022] | ||

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

PROCEDURE

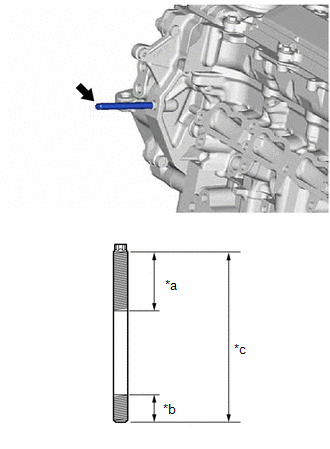

1. INSTALL STUD BOLT

|

(a) Using an E8 "TORX" socket wrench, install the stud bolt to the timing chain cover assembly. Torque: 9.8 N·m {100 kgf·cm, 87 in·lbf} |

|

2. INSTALL WIRE HARNESS CLAMP BRACKET

(a) Using an 8 mm socket wrench, install the wire harness clamp bracket to the camshaft housing sub-assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(b) Using an 8 mm socket wrench, install the wire harness clamp bracket to the No. 1 ventilation case with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

3. INSTALL NO. 2 VENTILATION HOSE

(a) Install the No. 2 ventilation hose to the cylinder head cover sub-assembly and slide the clip to secure it.

4. INSTALL VACUUM SURGE TANK BRACKET

(a) Using an 8 mm socket wrench, install the vacuum surge tank bracket to the camshaft housing sub-assembly with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

5. INSTALL VACUUM SURGE TANK

(a) Install the vacuum surge tank to the vacuum surge tank bracket with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

6. INSTALL PURGE VALVE (PURGE VSV)

7. INSTALL NO. 3 EXHAUST MANIFOLD HEAT INSULATOR

(a) Install the No. 3 exhaust manifold heat insulator to the cylinder block sub-assembly with the 2 bolts.

Torque:

16 N·m {163 kgf·cm, 12 ft·lbf}

8. INSTALL ENGINE WATER PUMP ASSEMBLY (WATER INLET HOUSING)

(a) Install the engine water pump assembly (water inlet housing) and a new gasket to the cylinder block sub-assembly with the 4 bolts.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

9. INSTALL WATER INLET WITH THERMOSTAT SUB-ASSEMBLY

10. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE

(a) Apply a light coat of engine oil to a new O-ring.

(b) Install the O-ring to the engine oil level dipstick guide.

(c) Using an 8 mm socket wrench, install the engine oil level dipstick guide to the cylinder head sub-assembly with the bolt.

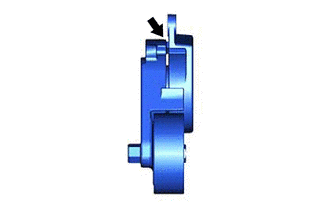

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(d) Install the engine oil level dipstick.

11. INSTALL IGNITION COIL ASSEMBLY

12. INSTALL FUEL INJECTOR SEAL

13. INSTALL DIRECT FUEL INJECTOR ASSEMBLY

14. INSTALL FUEL DELIVERY PIPE

15. INSTALL PORT FUEL INJECTOR ASSEMBLY

16. INSTALL NO. 5 ENGINE WIRE

17. INSTALL INJECTOR VIBRATION INSULATOR

18. INSTALL FUEL DELIVERY SPACER

19. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY

20. INSTALL NO. 6 ENGINE WIRE

(a) Install the No. 6 engine wire to the wire harness clamp bracket with the 2 nuts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(b) Engage the 2 clamps.

(c) Connect the 4 connectors.

21. INSTALL SENSOR WIRE

(a) for TMC Made:

(1) Using an 8 mm socket wrench, install the sensor wire to the water inlet with thermostat sub-assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(2) Engage the 3 clamps.

(3) Connect the 3 connectors.

(b) except TMC Made:

(1) Using an 8 mm socket wrench, install the sensor wire to the water inlet with thermostat sub-assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(2) Engage the 3 clamps.

(3) Connect the 4 connectors.

22. INSTALL NO. 1 WATER BY-PASS HOSE ASSEMBLY

(a) Install the No. 1 water by-pass hose assembly and slide the 2 clips to secure it.

(b) Install the bolt.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

(c) Install the plug to the No. 1 water by-pass hose assembly and slide the clip to secure it.

23. TEMPORARILY INSTALL FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure)

24. TEMPORARILY INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY

25. INSTALL FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure)

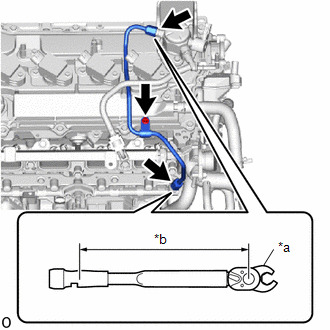

26. INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY

|

(a) Using a 17 mm union nut wrench, tighten the union nut on the fuel delivery pipe side of the No. 1 fuel pipe sub-assembly. Torque: Specified tightening torque : 35 N·m {357 kgf·cm, 26 ft·lbf} NOTICE: Do not adjust the torque in the loosening direction. |

|

(b) Using a 17 mm union nut wrench, tighten the union nut on the fuel pump assembly side of the No. 1 fuel pipe sub-assembly.

Torque:

Specified tightening torque :

35 N·m {357 kgf·cm, 26 ft·lbf}

NOTICE:

Do not adjust the torque in the loosening direction.

HINT:

(c) Using an 8 mm socket wrench, tighten the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

27. CONNECT FUEL TUBE SUB-ASSEMBLY

(a) Connect the fuel tube sub-assembly to the fuel delivery pipe with sensor assembly.

(b) Install the fuel pipe clamp to the fuel tube connector.

(c) Connect the fuel tube sub-assembly to the fuel pump assembly.

28. INSTALL NO. 1 INTAKE MANIFOLD TO HEAD GASKET

29. INSTALL INTAKE MANIFOLD

30. INSTALL INTAKE MANIFOLD STAY

31. INSTALL NO. 3 WATER BY-PASS PIPE

(a) Connect the No. 3 water by-pass pipe to the water outlet and slide the clip to secure it.

(b) Using an 8 mm socket wrench, install the No. 3 water by-pass pipe to the intake manifold with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

32. INSTALL EGR VALVE ASSEMBLY

33. INSTALL NO. 1 EGR PIPE SUB-ASSEMBLY

34. INSTALL EGR COOLER ASSEMBLY

35. INSTALL THROTTLE BODY GASKET

36. INSTALL THROTTLE BODY WITH MOTOR ASSEMBLY

37. INSTALL EXHAUST MANIFOLD (TWC: Front Catalyst)

for Double Wishbone Type Suspension: Click here

![2023 MY Corolla Corolla Hatchback [09/2022 - 11/2022]; M20A-FKS (INTAKE / EXHAUST): EXHAUST MANIFOLD (for Double Wishbone Type Suspension): INSTALLATION+](/t3Portal/stylegraphics/info.gif)

for Torsion Beam Type Suspension: Click here

![2023 - 2025 MY Corolla Corolla Hatchback [09/2022 - ]; M20A-FKS (INTAKE / EXHAUST): EXHAUST MANIFOLD (for Torsion Beam Type Suspension): INSTALLATION+](/t3Portal/stylegraphics/info.gif)

38. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

for Double Wishbone Type Suspension: Click here

![2023 MY Corolla Corolla Hatchback [09/2022 - 11/2022]; M20A-FKS (INTAKE / EXHAUST): EXHAUST MANIFOLD (for Double Wishbone Type Suspension): INSTALLATION+](/t3Portal/stylegraphics/info.gif)

for Torsion Beam Type Suspension: Click here

![2023 - 2025 MY Corolla Corolla Hatchback [09/2022 - ]; M20A-FKS (INTAKE / EXHAUST): EXHAUST MANIFOLD (for Torsion Beam Type Suspension): INSTALLATION+](/t3Portal/stylegraphics/info.gif)

39. INSTALL WATER HOSE CLAMP BRACKET

(a) Install the water hose clamp bracket to the camshaft housing sub-assembly with the 2 bolts.

Torque:

13 N·m {133 kgf·cm, 10 ft·lbf}

(b) Install the water hose clamp bracket to the water hose clamp bracket with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

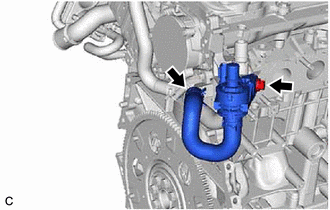

40. INSTALL FLOW SHUTTING VALVE (WATER BY-PASS HOSE ASSEMBLY)

|

(a) Connect the flow shutting valve (water by-pass hose assembly) to the water by-pass outlet sub-assembly and slide the clip to secure it. NOTICE: Make sure to slide the flow shutting valve (water by-pass hose assembly) until it contacts the hose stopper of the water by-pass outlet sub-assembly. |

|

(b) Install the flow shutting valve (water by-pass hose assembly) to the water hose clamp bracket with the bolt.

Torque:

19 N·m {194 kgf·cm, 14 ft·lbf}

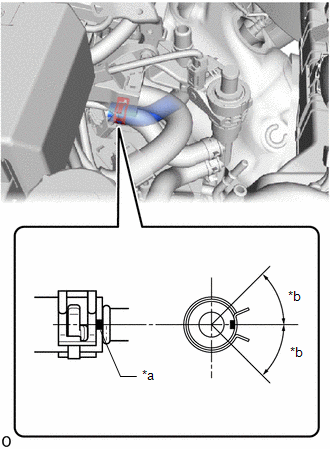

41. INSTALL NO. 2 WATER BY-PASS PIPE SUB-ASSEMBLY

(a) Install the No. 2 water by-pass pipe sub-assembly to the water hose clamp bracket with the bolt.

Torque:

19 N·m {194 kgf·cm, 14 ft·lbf}

|

(b) Connect the No. 2 water by-pass pipe sub-assembly to the water by-pass outlet sub-assembly and slide the clip to secure it. NOTICE:

|

|

42. CONNECT NO. 2 RADIATOR HOSE

(a) Connect the No. 2 radiator hose to the water inlet and slide the clip to secure it.

43. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

NOTICE:

- Do not apply or add any oil or grease to the belt tensioner to prevent abnormal noises from the belt tensioner pulley, belt squealing, etc.

- Do not allow oil or grease to adhere to the moving parts of the belt tensioner, as this may cause malfunctions.

(a) Install the V-ribbed belt tensioner assembly to the No. 2 timing chain cover assembly with the 2 bolts.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

|

|

|