| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM10000000255XK |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - ] |

| Title: G16E-GTS (BATTERY / CHARGING): CHARGING SYSTEM: P058A01; Battery Monitor Module General Electrical Failure; 2023 - 2025 MY GR Corolla [09/2022 - ] | ||

|

DTC |

P058A01 |

Battery Monitor Module General Electrical Failure |

DESCRIPTION

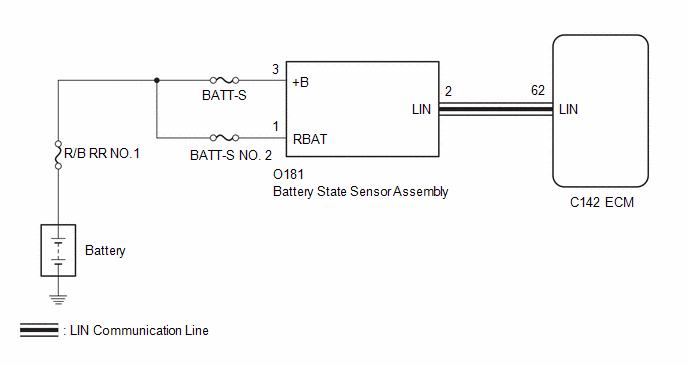

The battery state sensor assembly detects the voltage, current and temperature of the battery. The battery state sensor assembly calculates State of Charge (SOC) based on the voltage and current of the battery and sends it to the ECM. Based on the signals received, the ECM adjusts the charging voltage of the generator assembly.

The battery state sensor assembly calculates the battery temperature based on changes in resistance of a built-in thermistor and sends it to the ECM. The ECM reduces the amount of charging current based on this signal in order to protect the battery.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

Warning Indicate |

Note |

|---|---|---|---|---|---|

|

P058A01 |

Battery Monitor Module General Electrical Failure |

Any of the following conditions is met with the ignition switch ON. (1 trip detection logic):

|

|

Charge warning is not displayed |

SAE Code: P058A |

DTC Detection Conditions

|

Vehicle Condition |

|||||||

|

Pattern 1 |

Pattern 2 |

Pattern 3 |

Pattern 4 |

Pattern 5 |

Pattern 6 |

||

|

Diagnosis Condition |

Ignition switch ON |

○ |

○ |

○ |

○ |

○ |

○ |

|

Malfunction Status |

Current value is 999.939 A or more |

○ |

- |

- |

- |

- |

- |

|

Current value is -1000 A or less |

- |

○ |

- |

- |

- |

- |

|

|

Difference between maximum and minimum current value is 0.0305 A or less |

- |

- |

○ |

- |

- |

- |

|

|

Current detection circuit malfunction signal is received |

- |

- |

- |

○ |

- |

- |

|

|

Battery temperature is 105°C or more |

- |

- |

- |

- |

○ |

- |

|

|

Battery temperature is -40°C or less |

- |

- |

- |

- |

- |

○ |

|

|

Detection Time |

3.2 seconds or more |

3.2 seconds or more |

100 seconds or more |

- |

3.2 seconds or more |

3.2 seconds or more |

|

|

Number of Trips |

1 trip |

1 trip |

1 trip |

1 trip |

1 trip |

1 trip |

|

DTC Detection Conditions

|

Vehicle Condition |

||||||

|

Pattern 7 |

Pattern 8 |

Pattern 9 |

Pattern 10 |

Pattern 11 |

||

|

Diagnosis Condition |

Ignition switch ON |

○ |

○ |

○ |

○ |

○ |

|

Malfunction Status |

Temperature detection circuit malfunction signal is received |

○ |

- |

- |

- |

- |

|

Voltage value remains at 15.98 V or more |

- |

○ |

- |

- |

- |

|

|

Voltage value remains at 6.0 V or less |

- |

- |

○ |

- |

- |

|

|

Voltage detection circuit malfunction signal is received |

- |

- |

- |

○ |

- |

|

|

Writing error occurs in the battery state sensor internal memory (battery identification data) |

- |

- |

- |

- |

○ |

|

|

Detection Time |

- |

3.2 seconds or more |

3.2 seconds or more |

- |

- |

|

|

Number of Trips |

1 trip |

1 trip |

1 trip |

1 trip |

1 trip |

|

HINT:

DTC will be output when conditions for either of the patterns in the table above are met.

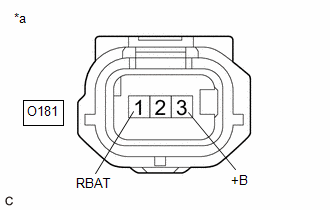

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

- When P162B87 (Lost Communication with Battery Monitor Module Missing Message) is output at the same time, perform the inspection for P162B87 (Lost Communication with Battery Monitor Module Missing Message) first.

PROCEDURE

|

1. |

CHECK BATTERY STATE SENSOR ASSEMBLY INSTALLATION CONDITION |

(a) Check installation condition of the battery state sensor assembly.

| NG |

|

|

|

2. |

CHECK CHARGING SYSTEM |

| NG |

|

REPAIR OR REPLACE CHARGING SYSTEM |

|

|

3. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

(a) Check that the battery state sensor assembly connector is securely connected.

OK:

The connector is securely connected.

(b) Disconnect the battery state sensor assembly connector.

(c) Check the connector case and terminals for deformation or corrosion.

OK:

No deformation or corrosion.

|

(d) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2023 - 2025 MY GR Corolla [09/2022 - ]; G16E-GTS (BATTERY / CHARGING): CHARGING SYSTEM: P162B87; Lost Communication with Battery Monitor Module Missing Message](/t3Portal/stylegraphics/info.gif)