- Purge VSV (Vacuum Switching Valve) stuck closed

- No. 1 check valve stuck closed

- Purge flow

| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM10000000255XA |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - ] |

| Title: G16E-GTS (ENGINE CONTROL): SFI SYSTEM: EVAP System; 2023 - 2025 MY GR Corolla [09/2022 - ] | ||

|

EVAP System |

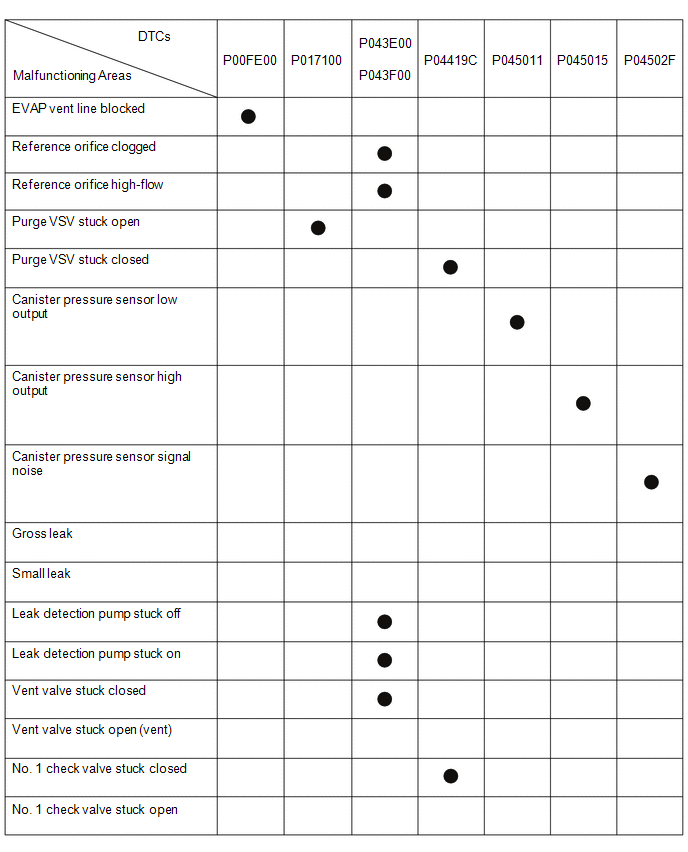

RELATED DTCS

|

DTC No. |

SAE |

Monitoring Item |

Link |

|---|---|---|---|

|

P00FE00 |

P00FE |

EVAP vent line blocked |

|

|

P017100 |

P0171 |

Purge VSV stuck open* |

|

|

P043E00 |

P043E |

Reference orifice clogged (built into canister pump module) |

|

|

P043F00 |

P043F |

Reference orifice high-flow (built into canister pump module) |

|

|

P04419C |

P0441 |

|

|

|

P045011 |

P0452 |

Canister pressure sensor (built into canister pump module) voltage low |

|

|

P045015 |

P0453 |

Canister pressure sensor (built into canister pump module) voltage high |

|

|

P04502F |

P0451 |

Canister pressure sensor (built into canister pump module) signal noise |

|

|

P045500 |

P0455 |

EVAP gross leak |

|

|

P045600 |

P0456 |

EVAP small leak |

|

|

P148D7E |

P148D |

No. 1 check valve stuck open |

|

|

P24007E |

P2402 |

Leak detection pump stuck on (built into canister pump module) |

|

|

P24007F |

P2401 |

Leak detection pump stuck off (built into canister pump module) |

|

|

P24187E |

P2419 |

Vent valve stuck closed (built into canister pump module) |

|

|

P24187F |

P2420 |

Vent valve stuck open (vent) (built into canister pump module) |

|

|

P261029 |

P2610 |

Soak timer (built into ECM) |

|

|

P261093 |

*: If Purge VSV is stuck open, air is sucked in from Purge VSV, and the air fuel ratio becomes Lean and stores P017100.

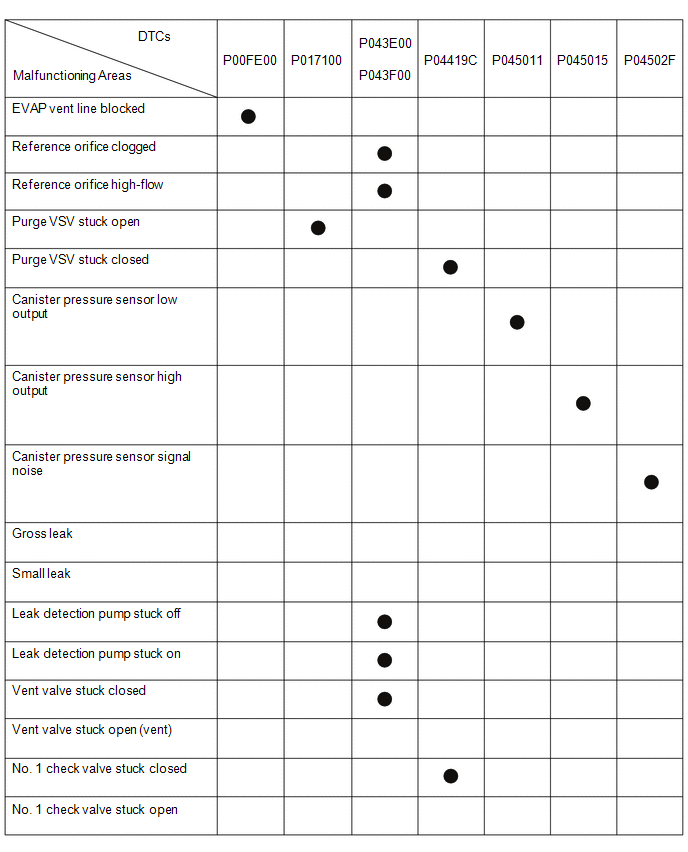

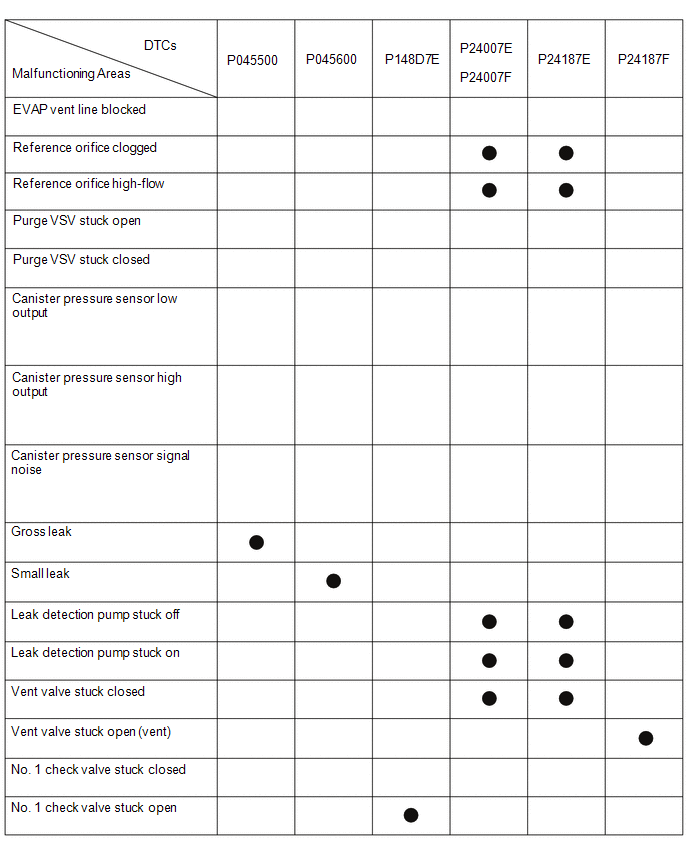

If any EVAP system DTCs are output, the malfunctioning area can be determined using the table below.

NOTICE:

If the reference pressure difference between the first and second checks is more than the specification, all the DTCs relating to the reference pressure (P043E00, P043F00, P24007E, P24007F and P24187E) will all be stored.

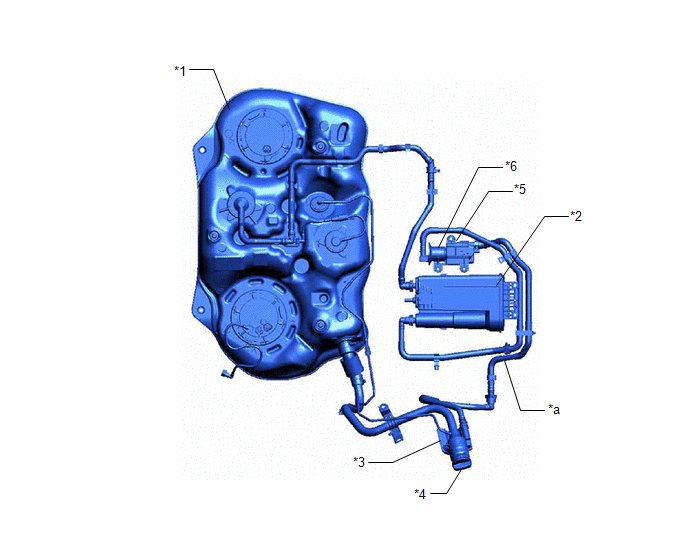

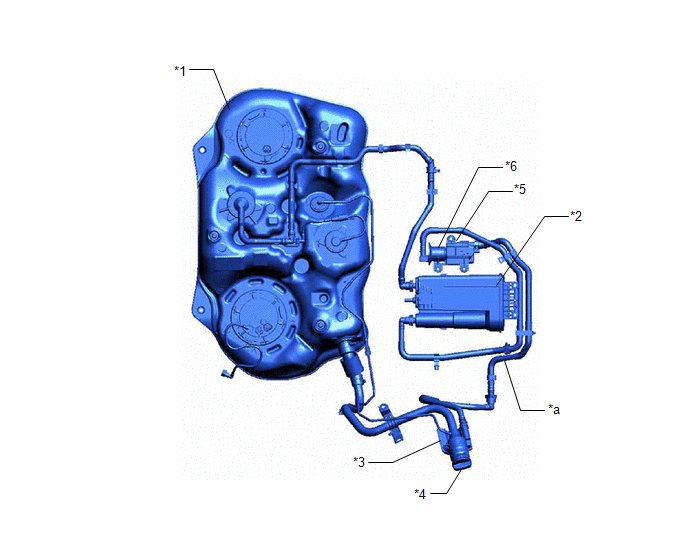

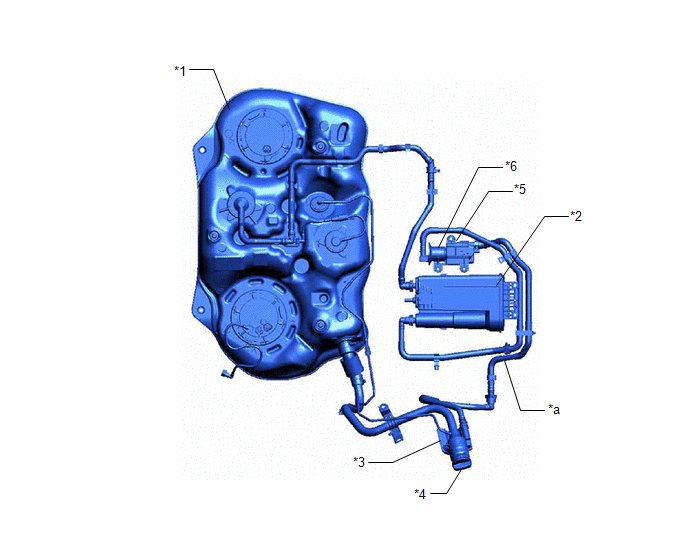

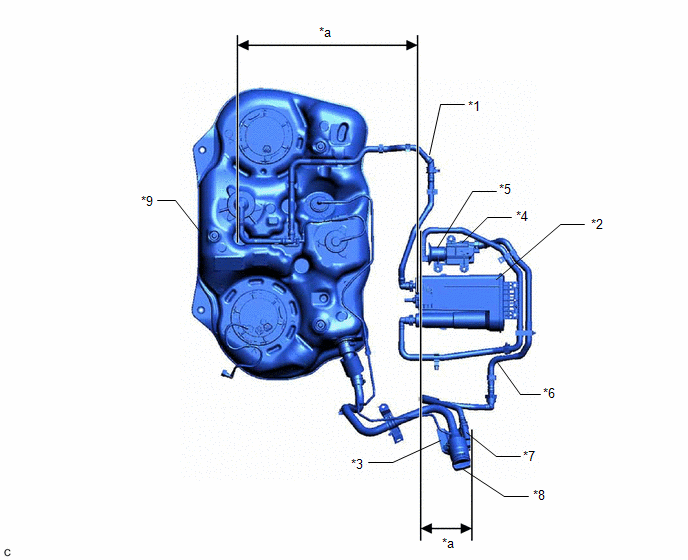

DESCRIPTION

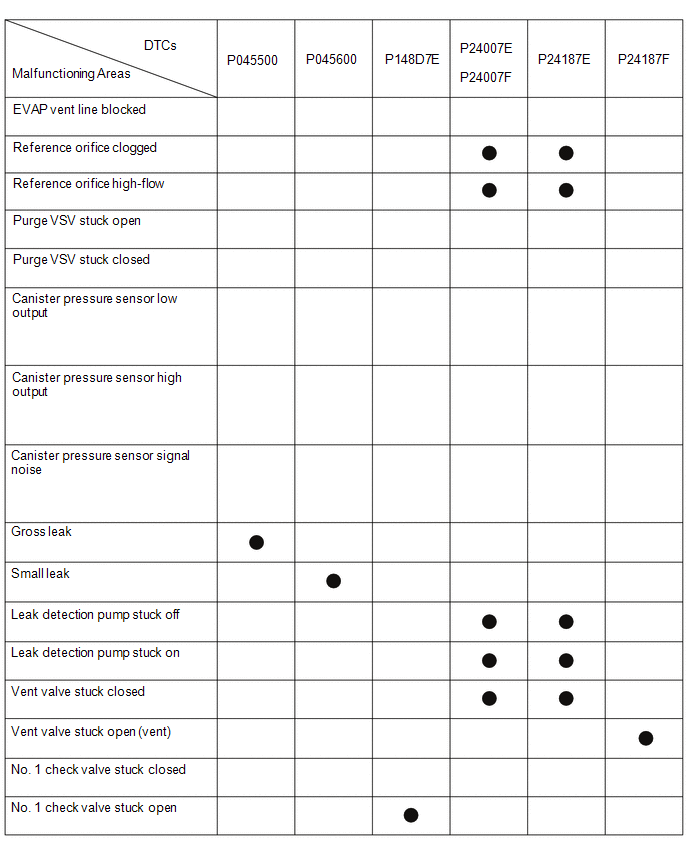

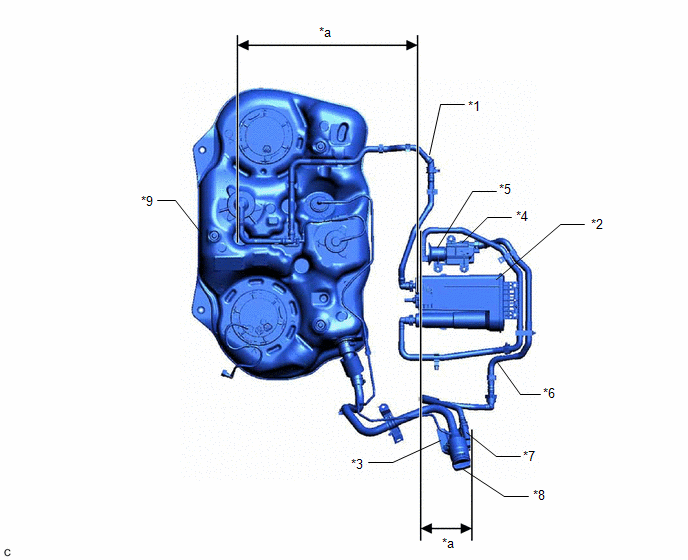

|

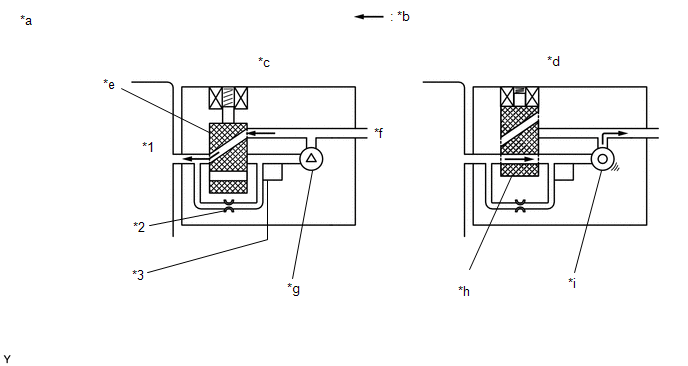

*1 |

Purge VSV |

*2 |

Fuel Vapor Feed Hose (EVAP Hose) (to Intake Manifold) |

|

*3 |

Fuel Vapor Feed Hose (EVAP Hose) (from Canister) |

*4 |

Canister Pump Module - Canister Pressure Sensor - Leak Detection Pump - Vent Valve |

|

*5 |

Canister |

*6 |

No. 2 Charcoal Canister Filter |

|

*7 |

Canister Filter |

*8 |

Air Inlet Port |

|

*9 |

Fuel Tank Cap |

*10 |

Fuel Tank |

|

*11 |

Fuel Tank Vent Hose |

- |

- |

|

*a |

Location of EVAP (Evaporative Emission) System |

*b |

Purge Line |

HINT:

The canister pressure sensor, the leak detection pump and the vent valve are built into the canister pump module.

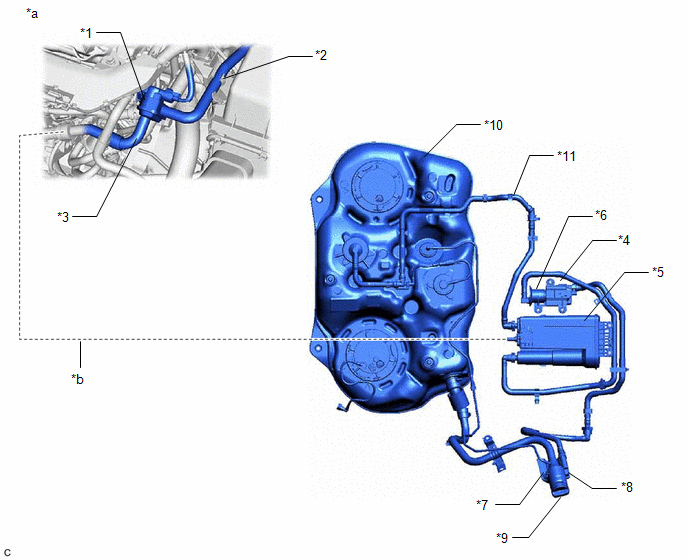

|

*1 |

Canister Pump Module |

*2 |

Intake Manifold |

|

*3 |

Purge VSV |

*4 |

Throttle Valve |

|

*5 |

Canister |

*6 |

No. 2 Charcoal Canister Filter |

|

*7 |

Fuel Tank |

*8 |

Air Cleaner |

|

*9 |

ECM |

*10 |

Canister Filter |

|

*11 |

Soak Timer |

*12 |

Fuel Tank Cap |

|

*13 |

No. 1 Check Valve |

*14 |

Fuel Tank Over Fill Check Valve |

|

*15 |

Fuel Tank Vent Hose |

*16 |

Cut-off Valve |

|

*a |

EVAP System Circuit |

- |

- |

NOTICE:

In the EVAP system of this vehicle, turning on the vent valve does not seal off the EVAP system. To check for leaks in the EVAP system, disconnect the air inlet vent hose and apply pressure from the atmospheric side of the canister.

While the engine is running, if a predetermined condition (closed-loop, etc.) is met, the purge VSV is opened by the ECM and fuel vapors stored in the canister are purged to the intake manifold. The ECM changes the duty cycle ratio of the purge VSV to control purge flow volume.

The purge flow volume is also determined by the intake pressure. Atmospheric pressure is allowed into the canister through the vent valve to ensure that the purge flow is maintained when negative pressure (vacuum) is applied to the canister.

The No. 1 check valve is used between the purge VSV and intake port to prevent intake air from flowing back toward the canister due to the turbo pressure.

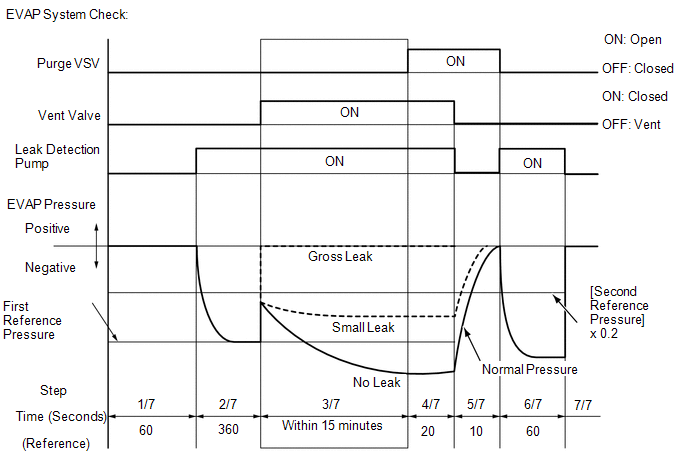

The following two monitors run to confirm appropriate EVAP system operation.

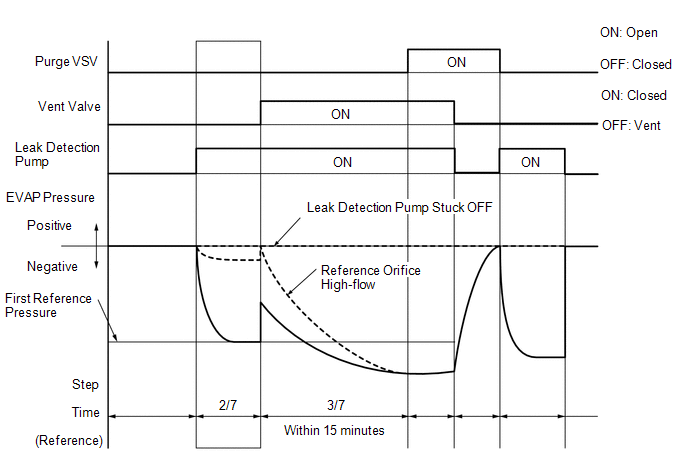

Key-off monitor

This monitor checks for EVAP (evaporative emission) system leaks and canister pump module malfunctions. The monitor starts 5 hours* after the ignition switch is turned off. At least 5 hours are required for the fuel to cool down to stabilize the EVAP pressure, thus making the EVAP system monitor more accurate.

The leak detection pump creates negative pressure (vacuum) in the EVAP system and the pressure is measured. Finally, the ECM monitors for leaks from the EVAP system, and malfunctions in both the canister pump module and purge VSV based on the EVAP pressure.

HINT:

*: If the engine coolant temperature is not less than 35°C (95°F) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not less than 35°C (95°F) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 hours later.

|

Component |

Operation |

|---|---|

|

Canister |

Contains activated charcoal to absorb EVAP (Evaporative Emissions) generated in fuel tank. |

|

Cut-off valve |

Located in fuel tank. Valve floats and closes when fuel tank is 100% full. |

|

Purge VSV (Vacuum Switching Valve) |

Opens or closes line between canister and intake manifold. ECM uses purge VSV to control EVAP purge flow. In order to discharge EVAP absorbed by canister to intake manifold, ECM opens purge VSV. EVAP discharge volume to intake manifold controlled by purge VSV duty cycle (current-carrying time). (Open: on, Close: off) |

|

Fuel Tank Over Fill Check Valve |

|

|

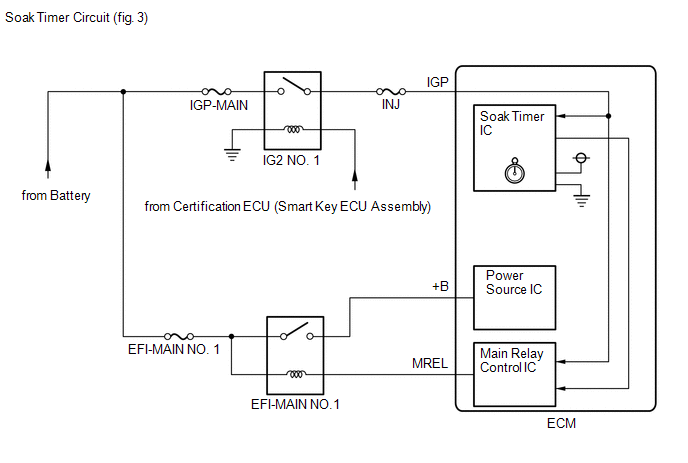

Soak timer |

Built into ECM. To ensure accurate EVAP monitor, measures 5 hours (+/-15 min) after ignition switch is turned off. This allows fuel to cool down, stabilizing EVAP pressure. When approximately 5 hours elapsed, ECM activates (refer to fig. 3). |

|

No. 1 check valve |

Prevents intake air from flowing back toward the canister due to the turbo pressure. |

|

Canister pump module |

Consists of (a) to (d) below. Canister pump module cannot be disassembled. |

|

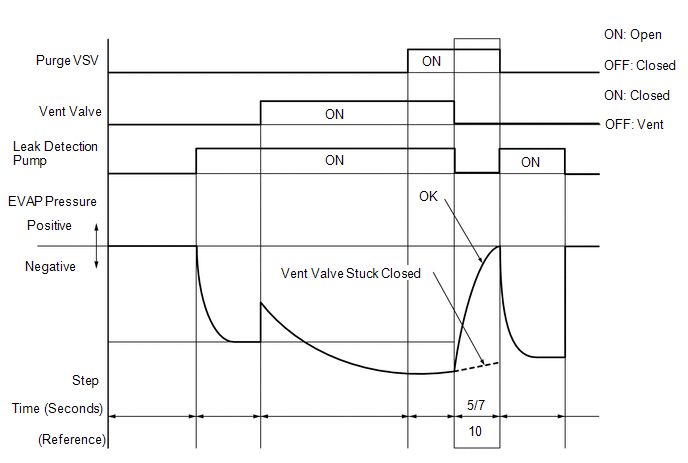

(a) Vent valve* |

Vents and closes EVAP system. When ECM turns valve on, EVAP system is closed. When ECM turns valve off, EVAP system is vented. Negative pressure (vacuum) is created in EVAP system to check for EVAP leaks by closing purge VSV, turning on vent valve (closing it) and operating leak detection pump (refer to fig. 1). |

|

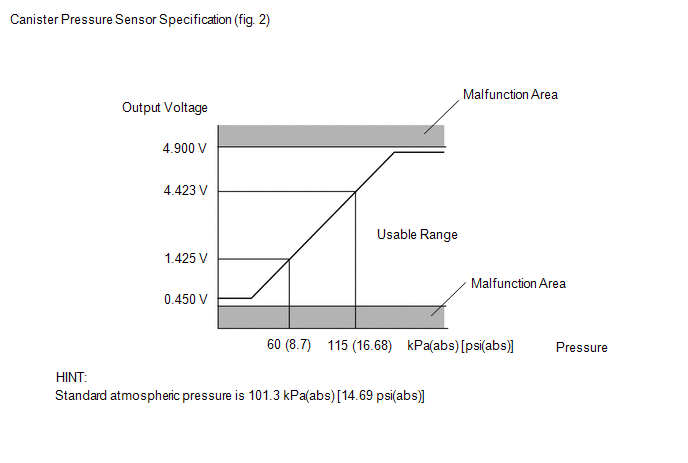

(b) Canister pressure sensor |

Indicates pressure as voltages. ECM supplies regulated 5 V to pressure sensor, and uses feedback from sensor to monitor EVAP system pressure (refer to fig. 2). |

|

(c) Leak detection pump |

Creates negative pressure (vacuum) in EVAP system for leak check. |

|

(d) Reference orifice |

Has opening with 0.02 inch diameter. Vacuum is produced through orifice by closing purge VSV, turning off vent valve and operating leak detection pump, to monitor reference pressure. Reference pressure is used when checking for small EVAP leaks. |

*: Vent Valve Operation

|

Vent Valve |

EVAP System |

|

|---|---|---|

|

Off |

Close |

Vent |

|

On |

Open |

Close |

|

*1 |

Canister |

*2 |

Reference Orifice (0.02 inch) |

|

*3 |

Canister Pressure Sensor |

- |

- |

|

*a |

Canister Pump Module (fig. 1) |

*b |

Airflow |

|

*c |

Condition: Purge Flow |

*d |

Condition: Leak Check |

|

*e |

Vent Valve: off (vent) |

*f |

to Canister Filter (Atmosphere) |

|

*g |

Leak Detection Pump: off |

*h |

Vent Valve: on (closed) |

|

*i |

Leak Detection Pump: on |

- |

- |

WIRING DIAGRAM

Refer to DTC P045011.

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

- The GTS is required to conduct the following diagnostic troubleshooting procedure.

HINT:

- Using the GTS monitor results enables the EVAP (Evaporative Emission) system to be confirmed.

- Read Freeze Frame Data using the GTS. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

CONFIRMATION DRIVING PATTERN

HINT:

After a repair, check Monitor Status by performing the Key-Off Monitor Confirmation described below.

KEY-OFF MONITOR CONFIRMATION

(a) Preconditions

The monitor will not run unless:

- The vehicle has been driven for 10 minutes or more (in a city area or on a freeway).

- The fuel tank is less than 70% full.

- The altitude is less than 2400 m (7872 ft).

- The engine coolant temperature is between 4.4 and 35°C (40 and 95°F).

- The intake air temperature is between 4.4 and 35°C (40 and 95°F).

- The vehicle remains stationary (the vehicle speed is 0 km/h [0 mph]).

(b) Monitor Conditions

- Allow the engine to idle for at least 5 minutes.

-

Turn the ignition switch off and wait for 6 hours (8 or 10.5 hours).

HINT:

Do not start the engine until checking Monitor Status. If the engine is started, the steps described above must be repeated.

(c) Monitor Status

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON.

- Turn the GTS on.

- Enter the following menus: Powertrain / Engine / Monitor / Current Monitor.

-

Check the Monitor Status displayed on the GTS.

HINT:

If Incomplete is displayed, the monitor did not complete. Make sure that the preconditions have been met, and perform the Monitor Conditions again.

MONITOR RESULT

Refer to detailed information in Checking Monitor Status.

P00FE: Evaporative System / TANK VAPOR LINE

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$3D |

$E1 |

Multiply by 0.001 |

kPa |

Test value for tank vapor line restricted / blocked |

P0456: Evaporative System / SMALL LEAK

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$3D |

$C9 |

Multiply by 0.001 |

kPa |

Test value for small leak (P0456) |

P0455: Evaporative System / GROSS LEAK

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$3D |

$CA |

Multiply by 0.001 |

kPa |

Test value for gross leak (P0455) |

P2401: Evaporative System / VACUUM PMP OFF

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$3D |

$CB |

Multiply by 0.001 |

kPa |

Test value for leak detection pump stuck off (P2401) |

P2402: Evaporative System / VACUUM PMP ON

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$3D |

$CD |

Multiply by 0.001 |

kPa |

Test value for leak detection pump stuck on (P2402) |

P2420: Evaporative System / VENT VALVE OFF

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$3D |

$CE |

Multiply by 0.001 |

kPa |

Test value for vent valve stuck off (P2420) |

P2419: Evaporative System / VENT VALVE ON

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$3D |

$CF |

Multiply by 0.001 |

kPa |

Test value for vent valve stuck on (P2419) |

P043E: Evaporative System / ORIFICE CLOGGED

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$3D |

$D0 |

Multiply by 0.001 |

kPa |

Test value for reference orifice low flow (P043E) |

P043F: Evaporative System / ORIFICE HI-FLW

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$3D |

$D1 |

Multiply by 0.001 |

kPa |

Test value for reference orifice high flow (P043F) |

P148D: Evaporative System / PURGE OPEN

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$3D |

$DE |

Multiply by 0.001 |

kPa |

Test value for purge one way valve open stuck (P148D) |

PROCEDURE

|

1. |

CONFIRM DTC |

(a) Turn the ignition switch off and wait for 10 seconds.

(b) Turn the ignition switch to ON.

(c) Turn the ignition switch off and wait for 10 seconds.

(d) Confirm the DTCs and Freeze Frame Data.

If any EVAP system DTCs are stored, the malfunctioning area can be determined using the table below.

Powertrain > Engine > Trouble Codes

NOTICE:

If the reference pressure difference between the first and second checks is greater than the specification, all the DTCs relating to the reference pressure (P043E00, P043F00, P24007E, P24007F and P24187E) are stored.

|

|

2. |

CLEAR DTC |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

|

|

3. |

PERFORM EVAP SYSTEM CHECK (AUTOMATIC MODE) |

NOTICE:

- The Evaporative System Check (Automatic Mode) consists of 7 steps performed automatically by the GTS. It takes a maximum of approximately 24 minutes.

- Do not perform the Evaporative System Check when the fuel tank is more than 70% full because the cut-off valve may be closed, making the fuel tank leak check unavailable.

- Do not run the engine during this operation.

- When the temperature of the fuel is 35°C (95°F) or higher, a large amount of vapor forms and any check results become inaccurate. When performing the Evaporative System Check, keep the temperature less than 35°C (95°F).

(a) Perform the Evaporative System Check using the GTS.

Powertrain > Engine > Utility

|

Tester Display |

|---|

|

Evaporative System Check |

(b) After the Evaporative System Check is completed, check for pending DTCs.

Powertrain > Engine > Trouble Codes

HINT:

If no pending DTCs are displayed, perform the Confirmation Driving Pattern. After this confirmation, check for pending DTCs. If no DTCs are displayed, the EVAP system is normal.

|

|

4. |

CLEAR DTC |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

|

|

5. |

PERFORM EVAP SYSTEM CHECK (MANUAL MODE) |

NOTICE:

- In the Evaporative System Check (Manual Mode), the series of 7 Evaporative System Check steps are performed manually using the GTS.

- Do not perform the Evaporative System Check when the fuel tank is higher than 70% full because the cut-off valve may be closed, making the fuel tank leak check unavailable.

- Do not run the engine in this operation.

- When the temperature of the fuel is 35°C (95°F) or higher, a large amount of vapor forms and any check results become inaccurate. When performing an Evaporative System Check, keep the fuel temperature less than 35°C (95°F).

(a) Perform the Evaporative System Check using the GTS.

Powertrain > Engine > Utility

|

Tester Display |

|---|

|

Evaporative System Check |

|

|

6. |

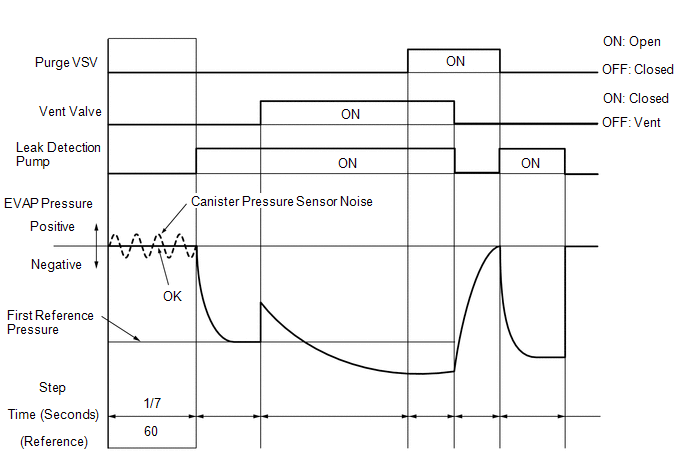

PERFORM EVAP SYSTEM CHECK (STEP 1/7) |

(a) Check the EVAP pressure in step 1/6.

|

DTC*1 |

Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|

|

- |

Virtually no variation in EVAP pressure |

Not yet determined |

A |

|

P04502F |

EVAP pressure fluctuates by +/-0.3 kPa(gauge) [0.044 psi(gauge)] or higher |

Canister pressure sensor signal noise |

B |

|

(P045011 or P045015)*2 |

|

Canister pressure sensor or its circuit has malfunction |

C |

- *1: These DTCs are already present in the ECM when the vehicle arrives and are confirmed in the "Confirm DTC" procedure above.

- *2: If the canister pressure sensor circuit has an open or short, DTC P045011 or P045015 is stored 0.5 seconds after the ignition switch is turned to ON.

HINT:

*3: Canister pressure sensor standard output range is 70 to 110 kPa(abs) [10.15 to 15.95 psi(abs)]. This varies by weather.

| B |

|

| C |

|

|

|

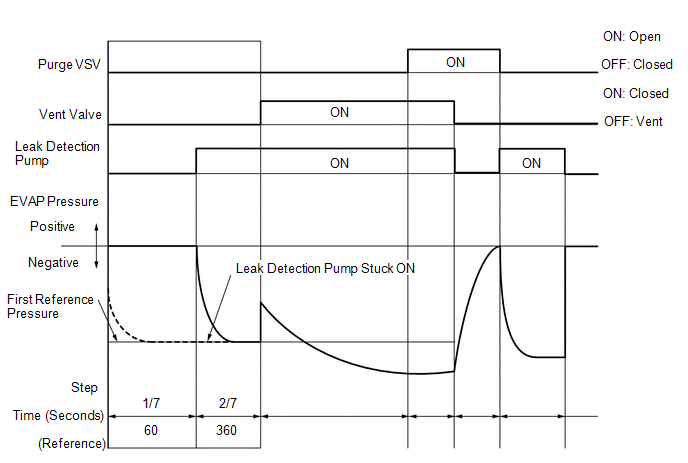

7. |

PERFORM EVAP SYSTEM CHECK (STEP 1/7 TO 2/7) |

(a) Check the EVAP pressure in steps 1/7 and 2/7.

|

DTC* |

Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|

|

- |

Virtually no variation in EVAP pressure during step 1/7. Then decreases to reference pressure |

Not yet determined |

A |

|

P24007E |

Small difference between EVAP pressures during steps 1/7 and 2/7 |

Leak detection pump stuck ON |

B |

- *: These DTCs are already present in the ECM when the vehicle arrives and are confirmed in the "Confirm DTC" procedure above.

HINT:

The first reference pressure is the value determined in step 2/7.

| B |

|

|

|

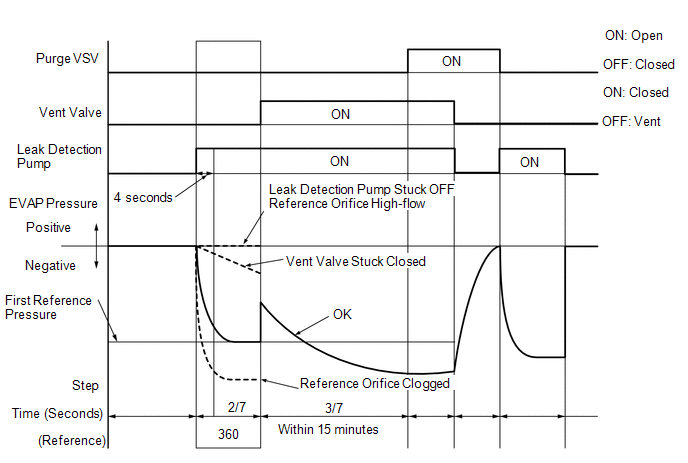

8. |

PERFORM EVAP SYSTEM CHECK (STEP 2/7) |

HINT:

Make a note of the pressures checked in inspection items (A) and (B) below.

(a) Check the EVAP pressure 4 seconds after the leak detection pump is activated*1 (A).

*1: The leak detection pump begins to operate as step 1/7 finishes and step 2/7 starts.

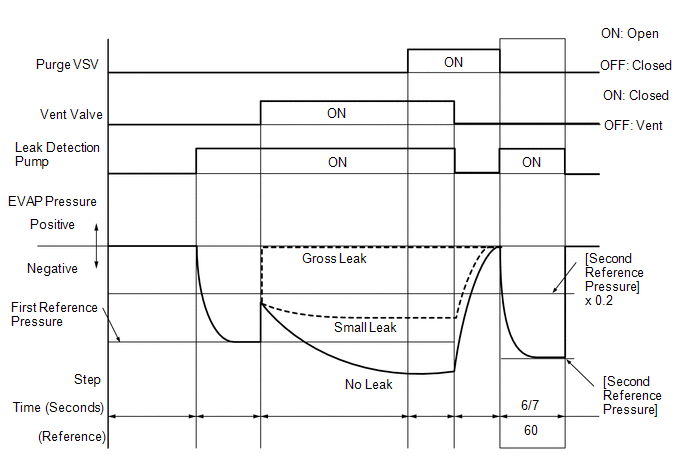

(b) Check the EVAP pressure again when it has stabilized. This pressure is the reference pressure (B).

|

DTC*2 |

Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|

|

- |

EVAP pressure in inspection item (B) is between -4.85 kPa(gauge) and -1.068 kPa(gauge) [-0.703 psi(gauge) and -0.155 psi(gauge)] |

Not yet determined |

A |

|

P043F00 and P24007F |

EVAP pressure in inspection item (B) is -1.068 kPa(gauge) [-0.155 psi(gauge)] or higher |

|

B |

|

P043E00 |

EVAP pressure in inspection item (B) is less than -4.85 kPa(gauge) [-0.703 psi(gauge)] |

Reference orifice clogged |

C |

|

P24187E |

EVAP pressure in inspection item (A) is higher than -0.3 kPa(gauge) [-0.044 psi(gauge)] |

|

D |

- *2: These DTCs are already present in the ECM when the vehicle arrives and are confirmed in the "Confirm DTC" procedure above.

| B |

|

| C |

|

| D |

|

|

|

9. |

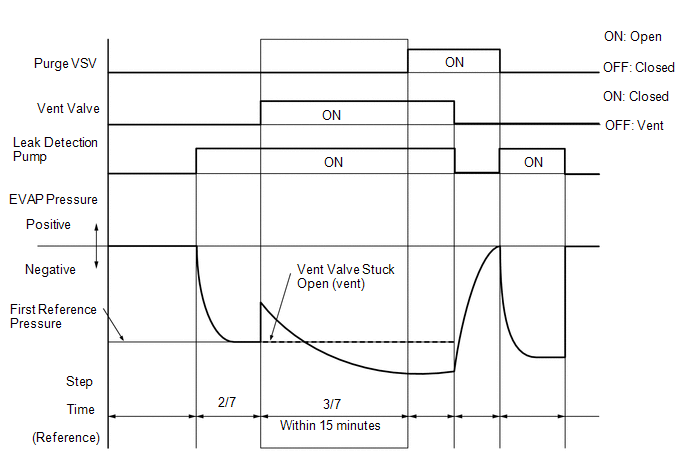

PERFORM EVAP SYSTEM CHECK (STEP 2/7 TO 3/7) |

(a) Check the EVAP pressure in step 3/7.

|

DTC* |

Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|

|

- |

EVAP pressure increases by 0.3 kPa(gauge) [0.044 psi(gauge)] or higher within 10 seconds of proceeding from step 2/7 to step 3/7 |

Not yet determined |

A |

|

P24187F |

No variation in EVAP pressure even after proceeding from step 2/7 to step 3/7 |

|

B |

- *: These DTCs are already present in the ECM when the vehicle arrives and are confirmed in the "Confirm DTC" procedure above.

| B |

|

|

|

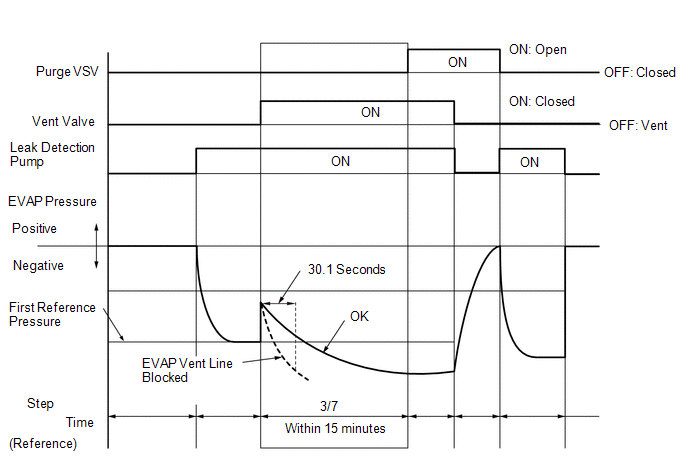

10. |

PERFORM EVAP SYSTEM CHECK (STEP 3/7) |

(a) Check the EVAP pressure in step 3/7.

|

DTC* |

Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|

|

- |

Other than below |

Not yet determined |

A |

|

P00FE00 |

Within 31.1 seconds after step 3/7 begins, the EVAP pressure becomes less than -2.992 kPa(gauge) (-0.434 psi(gauge)) HINT: Vary with first reference pressure. |

|

B |

- *: These DTCs are already present in the ECM when the vehicle arrives and are confirmed in the "Confirm DTC" procedure above.

HINT:

A few minutes are required for the EVAP pressure to become saturated. When there is little fuel in the fuel tank, it takes up to 15 minutes.

| B |

|

|

|

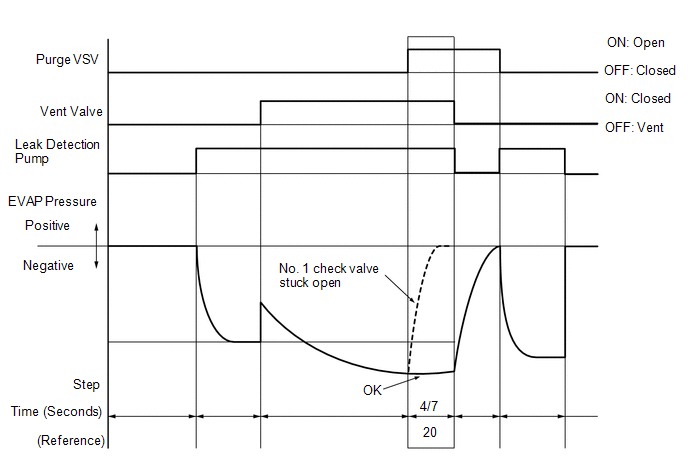

11. |

PERFORM EVAP SYSTEM CHECK (STEP 4/7) |

(a) Check the EVAP pressure in step 4/7.

|

DTC* |

Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|

|

- |

Variation in EVAP pressure is 2.2 kPa(gauge) or less [0.319 psi(gauge)] for 20 seconds, after proceeding from step 3/7 to step 4/7 |

Not yet determined |

A |

|

P148D7E |

EVAP pressure increases by higher than 2.2 kPa(gauge) [0.319 psi(gauge)] within 20 seconds of proceeding from step 3/7 to step 4/7 |

|

B |

*: These DTCs are already present in the ECM when the vehicle arrives and are confirmed in the "Confirm DTC" procedure above.

| B |

|

|

|

12. |

PERFORM EVAP SYSTEM CHECK (STEP 5/7) |

(a) Check the EVAP pressure in step 5/7.

|

DTC* |

Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|

|

- |

EVAP pressure increases by 0.3 kPa(gauge) [0.044 psi(gauge)] or higher within 10 seconds of proceeding from step 4/7 to step 5/7 |

Not yet determined |

A |

|

P24187E |

Variation in EVAP pressure is less than 0.3 kPa(gauge) [0.044 psi(gauge)] for 10 seconds, after proceeding from step 4/7 to step 5/7 |

Vent valve stuck closed |

B |

- *: These DTCs are already present in the ECM when the vehicle arrives and are confirmed in the "Confirm DTC" procedure above.

| B |

|

|

|

13. |

PERFORM EVAP SYSTEM CHECK (STEP 6/7) |

(a) Check the EVAP pressure in step 6/7.

(b) Compare the EVAP pressure in step 3/7 and the second reference pressure (step 6/7).

|

DTC* |

Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|

|

- |

EVAP pressure from step 3/7 lower than second reference pressure (step 6/7) |

Not yet determined (no leakage from EVAP system) |

A |

|

P045500 |

EVAP pressure from step 3/7 higher than [second reference pressure (step 6/7) x 0.2] |

EVAP gross leak |

B |

|

P045600 |

EVAP pressure from step 3/7 higher than second reference pressure (step 6/7) |

EVAP small leak |

*: These DTCs are already present in the ECM when the vehicle arrives and are confirmed in the "Confirm DTC" procedure above.

| B |

|

|

|

14. |

REPAIR OR REPLACE PARTS AND COMPONENTS INDICATED BY OUTPUT DTCS |

(a) Repair the malfunctioning areas indicated by the DTCs that had been confirmed when the vehicle was brought in.

| NEXT |

|

|

15. |

INSPECT EVAP HOSE (PURGE VSV - CANISTER) |

(a) Check for leakages in the EVAP purge line between the purge VSV and canister.

OK:

No leakages in the EVAP purge line between the purge VSV and canister.

| NG |

|

|

|

16. |

CHECK FUEL TANK CAP ASSEMBLY |

(a) Check that the fuel tank cap is correctly installed and confirm that the fuel tank cap meets OEM specifications.

(b) Tighten the fuel tank cap firmly (only one click sound could be heard).

HINT:

If an EVAP tester is available, check the fuel tank cap using the tester.

(1) Remove the fuel tank cap and install it onto a fuel tank cap adapter.

(2) Connect an EVAP tester pump hose to the adapter, and pressurize the cap to 3.2 to 3.7 kPa(gauge) [0.464 to 0.537 psi(gauge)] using an EVAP tester pump.

(3) Seal the adapter and wait for 2 minutes.

(4) Check the pressure. If the pressure is 2 kPa(gauge) [0.29 psi(gauge)] or higher, the fuel tank cap is normal.

|

Test Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|

|

Fuel tank cap correctly installed |

- |

A |

|

Fuel tank cap loose |

|

B |

|

Defective fuel tank cap |

- |

|

|

No fuel tank cap |

- |

C |

| B |

|

| C |

|

|

|

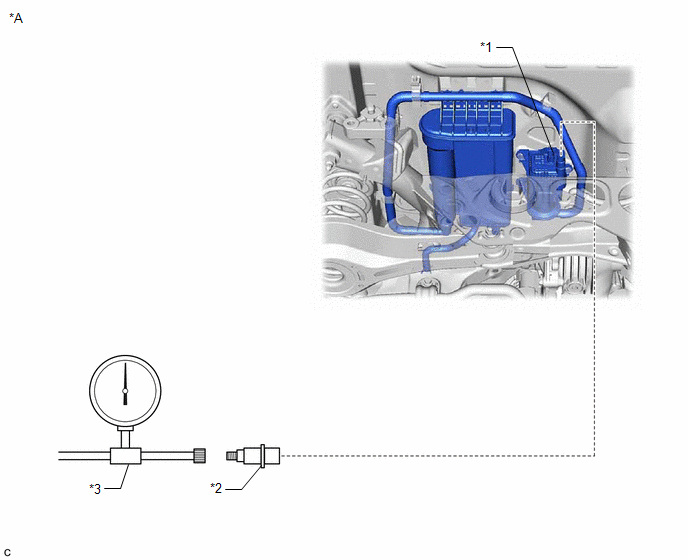

17. |

LOCATE EVAP LEAK PART |

(a) Disconnect the vent hose.

|

*1 |

Fuel Tank |

*2 |

Canister |

|

*3 |

Canister Filter |

*4 |

Fuel Tank Cap |

|

*5 |

Canister Pump Module |

*6 |

No. 2 Charcoal Canister Filter |

|

*a |

Disconnect the vent hose |

- |

- |

(b) Connect the EVAP pressure tester tool to the canister pump module with the adapter.

|

*1 |

Canister Pump Module |

*2 |

Adapter |

|

*3 |

EVAP Pressure Tester Tool |

- |

- |

(c) Pressurize the EVAP system to 3.2 to 3.7 kPa(gauge) [0.464 to 0.537 psi(gauge)].

(d) Apply soapy water to the piping and connecting parts of the EVAP system.

(e) Look for areas where bubbles appear. This indicates the leak point.

(f) Repair or replace the leak point.

HINT:

Disconnect the hose between the canister and fuel tank from the canister. Block the canister side and conduct an inspection. In this way, the fuel tank can be excluded as an area suspected of causing fuel leaks.

| NEXT |

|

|

18. |

CORRECTLY REINSTALL OR REPLACE FUEL TANK CAP ASSEMBLY |

HINT:

- When reinstalling the fuel tank cap, tighten it firmly (only one click sound could be head).

- When replacing the fuel tank cap, use a fuel tank cap that meets OEM specifications, and install it firmly.

| NEXT |

|

|

19. |

REPLACE FUEL TANK CAP ASSEMBLY |

HINT:

When installing the fuel tank cap, tighten it firmly (only one click sound could be head).

| NEXT |

|

|

20. |

REPAIR OR REPLACE EVAP PURGE LINE (PURGE VSV - CANISTER) |

| NEXT |

|

|

21. |

INSPECT NO. 1 CHECK VALVE |

| NG |

|

|

|

22. |

REPAIR OR REPLACE EVAP PURGE LINE (PURGE VSV - NO. 1 CHECK VALVE) |

| NEXT |

|

|

23. |

REPLACE NO. 1 CHECK VALVE |

| NEXT |

|

|

24. |

INSPECT FUEL TANK VENT HOSE |

(a) Check for blockages in the fuel tank vent hose between the fuel tank sub-assembly and canister.

OK:

No blockages in the fuel tank vent hose between the fuel tank sub-assembly and canister

| NG |

|

REPAIR OR REPLACE FUEL TANK VENT HOSE |

|

|

25. |

INSPECT CANISTER (CHARCOAL FILTER INSIDE CANISTER) |

(a) Check for filter blockage in the canister.

OK:

No blockages in the canister.

| NG |

|

|

|

26. |

REPLACE FUEL TANK SUB-ASSEMBLY |

| NEXT |

|

|

27. |

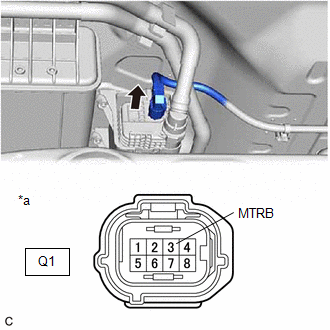

INSPECT CANISTER PUMP MODULE (POWER SOURCE FOR VENT VALVE) |

|

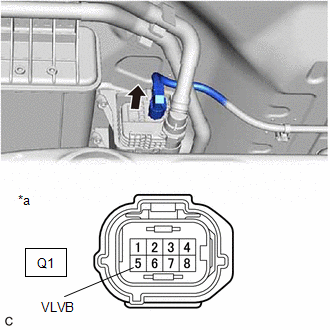

*a |

Front view of wire harness connector (to Canister Pump Module) |

(a) Turn the ignition switch off.

(b) Disconnect the canister pump module connector.

(c) Turn the ignition switch to ON.

(d) Measure the voltage according to the value(s) in the table below.

|

Tester Connection |

Condition |

Specified Condition |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|---|

|

Q1-5 (VLVB) - Body ground |

Ignition switch ON |

11 to 14 V |

|

A |

|

Below 3 V |

|

B |

| B |

|

|

|

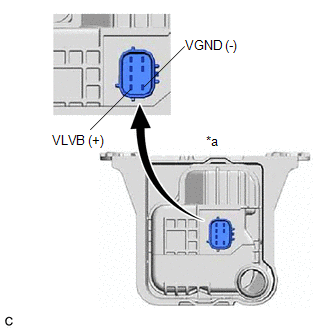

28. |

INSPECT CANISTER PUMP MODULE (VENT VALVE OPERATION) |

|

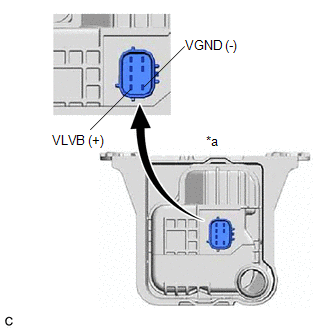

*a |

Component without harness connected (Canister Pump Module) |

(a) Turn the ignition switch off.

(b) Disconnect the canister pump module connector.

(c) Apply the battery voltage to terminals VLVB and VGND of the canister pump module.

(d) Touch the canister pump module to confirm the vent valve operation.

|

Condition |

Tester Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|

|

Apply battery voltage to terminals VLVB and VGND |

Operating |

|

A |

|

Not operating |

|

B |

| B |

|

|

|

29. |

CHECK HARNESS AND CONNECTOR (CANISTER PUMP MODULE - ECM) |

(a) Turn the ignition switch off.

(b) Disconnect the canister pump module connector.

(c) Disconnect the ECM connector.

(d) Measure the resistance according to the value(s) in the table below.

|

Tester Connection |

Condition |

Test Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|---|

|

Q1-1 (VGND) - A139-3 (VPMP) |

Always |

Below 1 Ω |

|

A |

|

10 kΩ or higher |

Wire harness or connector between ECM and canister pump module |

B |

| B |

|

|

|

30. |

INSPECT CANISTER (CHARCOAL FILTER INSIDE CANISTER) |

(a) Check for filter blockage in the canister.

OK:

No blockages in the canister.

| NG |

|

|

|

31. |

INSPECT NO. 2 CHARCOAL CANISTER FILTER (CHARCOAL FILTER INSIDE CANISTER) |

(a) Check for filter blockage in the No. 2 charcoal canister filter.

OK:

No blockages in the No. 2 charcoal canister filter.

| OK |

|

|

|

32. |

REPLACE NO. 2 CHARCOAL CANISTER FILTER |

NOTICE:

- When replacing the No. 2 charcoal canister filter, check the canister interior, canister pump module interior and related pipes for water, fuel and other liquids. If liquids are present, check for disconnections and/or cracks in the following: 1) the pipe from the air inlet port to the canister pump module; 2) the canister filter; and 3) the fuel tank vent hose.

- Check for filter blockage in the canister filter. If the canister filter has blockages, replace the canister filter.

|

*1 |

Fuel Tank |

*2 |

Canister |

|

*3 |

Canister Filter |

*4 |

Fuel Tank Cap |

|

*5 |

Canister Pump Module |

*6 |

No. 2 Charcoal Canister Filter |

|

*a |

Disconnect the vent hose |

- |

- |

| NEXT |

|

|

33. |

REPLACE CANISTER |

NOTICE:

- When replacing the canister, check the canister pump module interior and related pipes for water, fuel and other liquids. If liquids are present, check for disconnections and/or cracks in the following: 1) the pipe from the air inlet port to the canister pump module; 2) the canister filter; and 3) the fuel tank vent hose.

- Check for filter blockage in the canister filter. If the canister filter has blockages, replace the canister filter.

|

*1 |

Fuel Tank |

*2 |

Canister |

|

*3 |

Canister Filter |

*4 |

Fuel Tank Cap |

|

*5 |

Canister Pump Module |

*6 |

No. 2 Charcoal Canister Filter |

|

*a |

Disconnect the vent hose |

- |

- |

| NEXT |

|

|

34. |

PERFORM EVAP SYSTEM CHECK (STEP 3/7) |

(a) Check the EVAP pressure in step 3/7.

|

DTC* |

Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|

|

P043F00 |

EVAP pressure less than [reference pressure] measured in step 2/7 |

Reference orifice high-flow |

A |

|

P24007F |

EVAP pressure almost same as [reference pressure] measured in step 2/7 |

Leak detection pump stuck off |

B |

*: These DTCs are already present in the ECM when the vehicle arrives and are confirmed in the "Confirm DTC" procedure above.

HINT:

The first reference pressure is the value determined in step 2/7.

| A |

|

|

|

35. |

CHECK TERMINAL VOLTAGE (CANISTER PUMP MODULE) |

|

*a |

Front view of wire harness connector (to Canister Pump Module) |

(a) Turn the ignition switch off.

(b) Disconnect the canister pump module connector.

(c) Turn the ignition switch to ON.

(d) Measure the voltage according to the value(s) in the table below.

|

Tester Connection |

Condition |

Test Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|---|

|

Q1-3 (MTRB) - Body ground |

Ignition switch ON |

9 to 14 V |

|

A |

|

Below 3 V |

|

B |

| B |

|

|

|

36. |

CHECK HARNESS AND CONNECTOR (CANISTER PUMP MODULE - BODY GROUND) |

(a) Turn the ignition switch off.

(b) Disconnect the canister pump module connector.

(c) Measure the resistance according to the value(s) in the table below.

|

Tester Connection |

Condition |

Specified Condition |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|---|

|

Q1-4 (MGND) - Body ground |

Always |

Below 1 Ω |

Leak detection pump |

A |

|

10 kΩ or higher |

Wire harness or connector between canister pump module and body ground |

B |

| A |

|

| B |

|

|

37. |

CHECK HARNESS AND CONNECTOR (CANISTER PUMP MODULE - ECM) |

(a) Turn the ignition switch off.

(b) Disconnect the canister pump module connector.

(c) Disconnect the ECM connector.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Q1-3 (MTRB) - A139-5 (MPMP) |

Always |

Below 1 Ω |

|

Q1-3 (MTRB) or A139-5 (MPMP) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|

|

OK |

ECM |

A |

|

NG |

Wire harness or connector between ECM and canister pump module |

B |

| A |

|

| B |

|

|

38. |

INSPECT CANISTER PUMP MODULE (VENT VALVE OPERATION) |

|

*a |

Component without harness connected (Canister Pump Module) |

(a) Turn the ignition switch off.

(b) Disconnect the canister pump module connector.

(c) Apply the battery voltage to terminals VLVB and VGND of the canister pump module.

(d) Touch the canister pump module to confirm the vent valve operation.

|

Condition |

Tester Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|

|

Apply battery voltage to terminals VLVB and VGND |

Operating |

|

A |

|

Not operating |

Vent valve |

B |

| B |

|

|

|

39. |

CHECK HARNESS AND CONNECTOR (CANISTER PUMP MODULE - ECM) |

(a) Turn the ignition switch off.

(b) Disconnect the canister pump module connector.

(c) Disconnect the ECM connector.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Q1-1 (VGND) - A139-3 (VPMP) |

Always |

Below 1 Ω |

|

Q1-1 (VGND) or A139-3 (VPMP) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|

|

OK |

|

A |

|

NG |

Wire harness or connector between ECM and canister pump module |

B |

| B |

|

|

|

40. |

CHECK HARNESS AND CONNECTOR (CANISTER PUMP MODULE - BODY GROUND) |

(a) Turn the ignition switch off.

(b) Disconnect the canister pump module connector.

(c) Measure the resistance according to the value(s) in the table below.

|

Tester Connection |

Condition |

Specified Condition |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|---|

|

Q1-4 (MGND) - Body ground |

Always |

Below 1 Ω |

|

A |

|

10 kΩ or higher |

Wire harness or connector between canister pump module and body ground |

B |

| B |

|

|

|

41. |

CHECK HARNESS AND CONNECTOR (CANISTER PUMP MODULE - ECM) |

(a) Disconnect the canister pump module connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

|

Tester Connection |

Condition |

Specified Condition |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|---|

|

Q1-3 (MTRB) - A139-5 (MPMP) |

Always |

Below 1 Ω |

|

A |

|

10 kΩ or higher |

Wire harness or connector between ECM and canister pump module |

B |

| B |

|

|

|

42. |

REPLACE CANISTER PUMP MODULE |

NOTICE:

- When replacing canister pump module, check the canister pump module interior, canister interior and related pipes for water, fuel and other liquids. If liquids are present, check for disconnections and/or cracks in the following: 1) the pipe from the air inlet port to the canister pump module; 2) the canister filter; and 3) the fuel tank vent hose. If liquids are present in canister interior, replace canister and canister pump module together.

- Check for filter blockage in the canister. If the charcoal filter inside the canister is clogged, replace canister and canister pump module together.

- Check for filter blockage in the canister filter. If the canister filter has blockages, replace the canister filter.

|

*1 |

Fuel Tank Vent Hose |

*2 |

Canister |

|

*3 |

Canister Filter |

*4 |

Canister Pump Module |

|

*5 |

No. 2 Charcoal Canister Filter |

*6 |

Vent Hose |

|

*7 |

Air Inlet Port |

*8 |

Fuel Tank Cap |

|

*9 |

Fuel Tank |

- |

- |

|

*a |

Inspection Area (check for disconnection and/or cracks) |

- |

- |

|

|

43. |

CLEAR DTC |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

|

|

44. |

PERFORM EVAP SYSTEM CHECK (AUTOMATIC MODE) |

NOTICE:

- The Evaporative System Check (Automatic Mode) consists of 7 steps performed automatically by the GTS. It takes a maximum of approximately 24 minutes.

- Do not perform the Evaporative System Check when the fuel tank is higher than 70% full because the cut-off valve may be closed, making the fuel tank leak check unavailable.

- Do not run the engine in this step.

- When the temperature of the fuel is 35°C (95°F) or higher, a large amount of vapor forms and any check results become inaccurate. When performing an Evaporative System Check, keep the fuel temperature less than 35°C (95°F).

(a) Perform the Evaporative System Check using the GTS.

Powertrain > Engine > Utility

|

Tester Display |

|---|

|

Evaporative System Check |

(b) After the Evaporative System Check is completed, check for pending DTCs.

Powertrain > Engine > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

EVAP system DTCs are output |

A |

|

DTC is not output (Pending DTC is not output) |

B |

| B |

|

END |

|

|

45. |

REPLACE ECM |

| NEXT |

|

|

46. |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

| NEXT |

|

|

47. |

REPLACE CANISTER PUMP MODULE |

NOTICE:

- When replacing canister pump module, check the canister pump module interior, canister interior and related pipes for water, fuel and other liquids. If liquids are present, check for disconnections and/or cracks in the following: 1) the pipe from the air inlet port to the canister pump module; 2) the canister filter; and 3) the fuel tank vent hose. If liquids are present in canister interior, replace canister and canister pump module together.

- Check for filter blockage in the canister. If the charcoal filter inside the canister is clogged, replace canister and canister pump module together.

- Check for filter blockage in the canister filter. If the canister filter has blockages, replace the canister filter.

|

*1 |

Fuel Tank Vent Hose |

*2 |

Canister |

|

*3 |

Canister Filter |

*4 |

Canister Pump Module |

|

*5 |

No. 2 Charcoal Canister Filter |

*6 |

Vent Hose |

|

*7 |

Air Inlet Port |

*8 |

Fuel Tank Cap |

|

*9 |

Fuel Tank |

- |

- |

|

*a |

Inspection Area (check for disconnection and/or cracks) |

- |

- |

| NEXT |

|

|

48. |

INSPECT CANISTER PUMP MODULE (CANISTER PRESSURE SENSOR CIRCUIT) |

(a) Check the canister pressure sensor circuit, referring to DTC P045011 canister pressure sensor circuit inspection procedure.

|

|

49. |

CLEAR DTC |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

|

|

50. |

PERFORM EVAP SYSTEM CHECK (AUTOMATIC MODE) |

NOTICE:

- The Evaporative System Check (Automatic Mode) consists of 7 steps performed automatically by the GTS. It takes a maximum of approximately 24 minutes.

- Do not perform the Evaporative System Check when the fuel tank is higher than 70% full because the cut-off valve may be closed, making the fuel tank leak check unavailable.

- Do not run the engine in this operation.

- When the temperature of the fuel is 35°C (95°F) or higher, a large amount of vapor forms and any check results become inaccurate. When performing an Evaporative System Check, keep the fuel temperature less than 35°C (95°F).

(a) Perform the Evaporative System Check using the GTS.

Powertrain > Engine > Utility

|

Tester Display |

|---|

|

Evaporative System Check |

(b) After the Evaporative System Check is completed, check for pending DTCs.

Powertrain > Engine > Trouble Codes

HINT:

If no pending DTCs are found, the repair has been successfully completed.

| NEXT |

|

END |

|

|

|

![2023 - 2025 MY GR Corolla [09/2022 - ]; G16E-GTS (ENGINE CONTROL): SFI SYSTEM: P00FE00; EVAP System Tank Vapor Line Restricted/Blocked](/t3Portal/stylegraphics/info.gif)