- DTC judgment completed

- System normal

| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM10000000255X8 |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - ] |

| Title: G16E-GTS (ENGINE CONTROL): SFI SYSTEM: P2C9000; Crankcase Ventilation System - Hose "A" Disconnected; 2023 - 2025 MY GR Corolla [09/2022 - ] | ||

|

DTC |

P2C9000 |

Crankcase Ventilation System - Hose "A" Disconnected |

DESCRIPTION

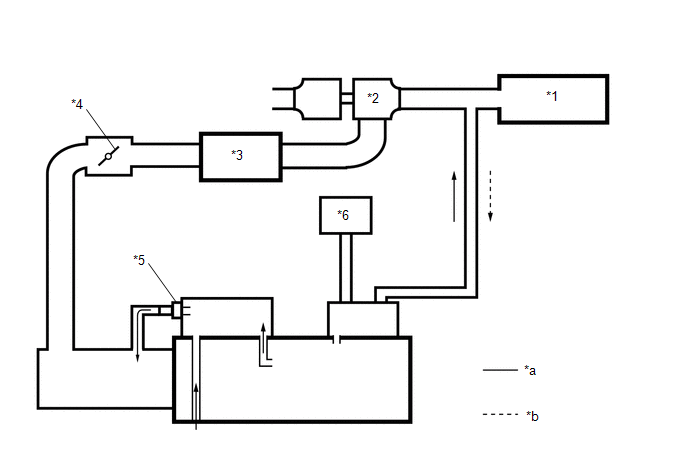

When blowby gas is introduced from the crankcase to the intake system, fresh air is introduced to maintain pressure inside the crankcase.

In order to prevent leaks from the fresh air hose during boosting, the intake air flow and PCV pressure are monitored to detect hose detachment or damage.

|

*1 |

Air Cleaner |

*2 |

Compressor |

|

*3 |

Intercooler |

*4 |

Throttle Valve |

|

*5 |

PCV Valve |

*6 |

Vacuum Sensor Assembly |

|

*a |

Blowby Gas |

*b |

Fresh Air |

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Note |

|---|---|---|---|---|---|

|

P2C9000 |

Crankcase Ventilation System - Hose "A" Disconnected |

The change in PCV pressure is less than the threshold value when the change in intake air flow for each bank is at or above the specified value (2 tripdetection logic). |

|

Comes on |

SAE Code: P2C90 |

MONITOR DESCRIPTION

If the change in PCV pressure does not exceed the threshold value in response to an increase in the intake air flow for each bank, it is determined that the hose is detached or damaged and a DTC is stored.

MONITOR STRATEGY

|

Related DTCs |

P2C90: PCV fresh air hose monitor (bank 1) P2C91: PCV fresh air hose monitor (bank 2) |

|

Required Sensors/Components (Main) |

Vacuum sensor assembly |

|

Required Sensors/Components (Related) |

Mass air flow meter sub-assembly Engine coolant temperature sensor |

|

Frequency of Operation |

Once per driving cycle |

|

Duration |

Within 3 seconds |

|

MIL Operation |

2 driving cycles |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

Atmospheric pressure |

76 kPa(abs) [11 psi(abs)] or higher |

|

Estimated ambient temperature |

-10°C (14°F) or higher |

|

Engine coolant temperature |

75°C (14°F) or higher |

|

Engine speed |

Less than 3800 rpm |

|

Mass air flow meter fail (P0102, P0103, P010F) |

Not detected |

|

Intake air temperature sensor (mass air flow meter sub-assembly) fail (P0112, P0113) |

Not detected |

|

Engine coolant temperature sensor fail (P0117, P0118) |

Not detected |

|

Vacuum sensor assembly fail (P051C, P051D) |

Not detected |

|

Canister pressure sensor - vacuum sensor assembly correlation fail (P109E) |

Not detected |

|

All of the following conditions (a), (b) and (c) are met |

10 times or more |

|

(a) Single calculation term for PCV pressure integral |

0.4 seconds or more |

|

(b) Intake air amount for each bank |

45 gm/sec or higher |

|

(C) Delta intake air amount for each bank |

6 gm/sec or higher |

TYPICAL MALFUNCTION THRESHOLDS

|

Cumulative value of PCV pressure integral |

Below 5 kPa(abs) [0.73 psi(abs)] |

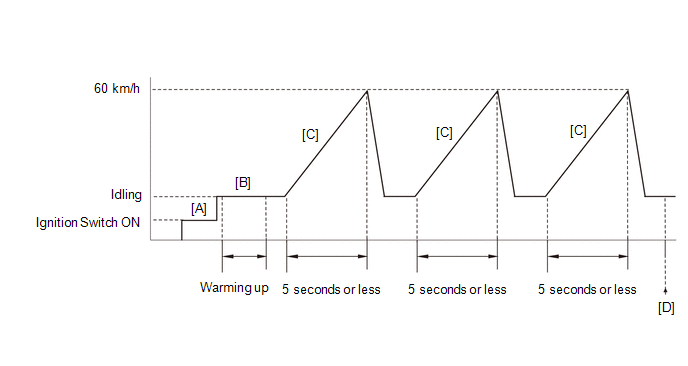

CONFIRMATION DRIVING PATTERN

HINT:

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON.

- Turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON [A].

- Turn the GTS on.

-

Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher [B].

HINT:

The A/C switch and all accessory switches should be off.

-

Accelerate the vehicle to 60 km/h (37 mph) for 5 seconds or less [C].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

- Repeat step [C] above at least 2 times in one driving cycle.

- Enter the following menus: Powertrain / Engine / Trouble Codes [D].

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P2C9000.

-

Check the DTC judgment result.

GTS Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system has a malfunction.

- If the judgment result is INCOMPLETE, perform steps [C] through [D] again.

-

[B] to [D]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- When clearing the permanent DTCs, do not disconnect the cable from the battery terminal or attempt to clear the DTCs during this procedure, as doing so will clear the universal trip and normal judgment histories.

CAUTION / NOTICE / HINT

HINT:

- Read Freeze Frame Data using the GTS. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

-

Bank 1 refers to the bank that includes the No. 1 cylinder*.

*: The No. 1 cylinder is the cylinder which is farthest from the transmission.

-

Bank 2 refers to the bank that does not include the No. 1 cylinder.

DTC

Suspected Area

P2C9000

Bank 1

P2C9100

Bank 2

PROCEDURE

|

1. |

CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P2C9000 AND/OR P2C9100) |

(a) Read the DTCs.

Powertrain > Engine > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

P2C9000 and/or P2C9100 and other DTCs are output |

A |

|

P2C9000 and/or P2C9100 is output |

B |

NOTICE:

If the Freeze Frame Data "Initial Engine Coolant Temperature" is 0°C (0°F) or less, the hose may be temporarily clogged due to freezing

HINT:

If any DTCs other than P2C9000 and/or P2C9100 are output, troubleshoot those DTCs first.

| A |

|

GO TO DTC CHART |

|

|

2. |

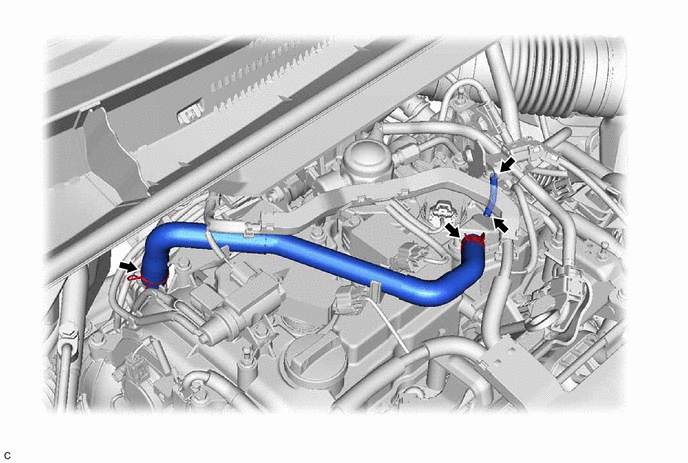

CHECK PCV FRESH AIR LINE (CYLINDER HEAD COVER - AIR INLE DUCT, VACUUM SENSOR ASSEMBLY) |

(a) Check the PCV hose connections.

OK:

PCV hose is connected correctly.

| NG |

|

SECURELY RECONNECTION PCV HOSE |

|

|

3. |

CHECK PCV FRESH AIR LINE (CYLINDER HEAD COVER - AIR INLE DUCT) |

(a) Check the PCV hose clogged and damaged.

OK:

PCV hose is not clogged and damaged.

| NG |

|

CLEAN OR REPLACE PCV HOSE |

|

|

4. |

CHECK PCV FRESH AIR LINE (VACUUM SENSOR ASSEMBLY - CYLINDER HEAD COVER) |

(a) Check the PCV hose clogged and damaged.

OK:

PCV hose is not clogged and damaged.

| NG |

|

CLEAN OR REPLACE PCV HOSE |

|

|

5. |

INSPECT AIR INLET DUCT |

(a) Inspect the air inlet duct.

OK:

PCV fresh air port of the air inlet duct is not clogged and damaged.

| NG |

|

CLEAN OR REPLACE AIR INLET DUCT |

|

|

6. |

INSPECT CYLINDER HEAD COVER |

(a) Inspect the cylinder head cover.

OK:

PCV fresh air port and PCV pressure sensor port of the cylinder head cover is not clogged and damaged.

| OK |

|

| NG |

|

CLEAN OR REPLACE CYLINDER HEAD COVER |

|

|

|

![2023 - 2025 MY GR Corolla [09/2022 - ]; G16E-GTS (ENGINE CONTROL): SFI SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)