- DTC judgment completed

- System normal

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM10000000255X7 |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - ] |

| Title: G16E-GTS (ENGINE CONTROL): SFI SYSTEM: P25B473; Turbocharger/Supercharger Wastegate "A" Actuator Stuck Closed; 2023 - 2025 MY GR Corolla [09/2022 - ] | ||

|

DTC |

P25B473 |

Turbocharger/Supercharger Wastegate "A" Actuator Stuck Closed |

DESCRIPTION

Refer to DTC P024313.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Note |

|---|---|---|---|---|---|

|

P25B473 |

Turbocharger/Supercharger Wastegate "A" Actuator Stuck Closed |

The boost pressure does not drop despite control to open the waste gate valve (2 trip detection logic). |

|

Comes on |

SAE Code: P25B4 |

MONITOR DESCRIPTION

Monitors the turbocharging pressure when the waste gate valve receives an open command. a waste gate valve stuck close malfunction occurs when the turbocharging variation, which results from 2 operation conditions with differing air volumes, becomes equal to, or greater than, the judgment variation. The ECM illuminates the MIL and stores a DTC.

MONITOR STRATEGY

|

Related DTCs |

P25B4: waste gate valve stuck close |

|

Required Sensors/Components (Main) |

No. 2 turbo pressure sensor Mass air flow meter sub-assembly |

|

Required Sensors/Components (Related) |

- |

|

Frequency of Operation |

Once per driving cycle |

|

Duration |

Within 5 seconds |

|

MIL Operation |

2 driving cycles |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

Monitor runs whenever the following DTCs are not stored |

None |

|

All of the following conditions are met |

- |

|

Engine coolant temperature |

75°C (167°F) or higher |

|

Intake air temperature (for mass air flow meter sub-assembly) |

-10°C (14°F) or higher |

|

Battery voltage |

11 V or higher |

|

Atmospheric pressure |

76 kPa(abs) [11 psi(abs)] or higher |

|

Ignition switch |

ON |

|

Time after engine start |

1 second or more |

TYPICAL MALFUNCTION THRESHOLDS

|

Test value of close stuck monitor*1 |

0.5 or more (Intake air amount is 100 g/sec or less) 1.56 or more (Intake air amount is more than 100 g/sec) |

|

*1: Test value is slope of boost pressure to Intake Air Amount*2*3 (Intake Air Amount 1 and Intake Air Amount 2 are Intake Air Amount average of 2 seconds) |

- |

|

*2: Boost pressure 1 and Intake Air Amount 1 |

- |

|

Both of the following conditions are met |

- |

|

Intake air amount average during 2 seconds |

2 to 15 g/sec |

|

Boost pressure 1 and intake air amount 1 |

Not calculated |

|

*3: Boost pressure 2 and Intake Air Amount 2 |

- |

|

Both of the following conditions are met |

- |

|

Intake air amount average during 2 seconds |

20 to 250 g/sec |

|

Boost pressure 2 and intake air amount 2 |

Not calculated |

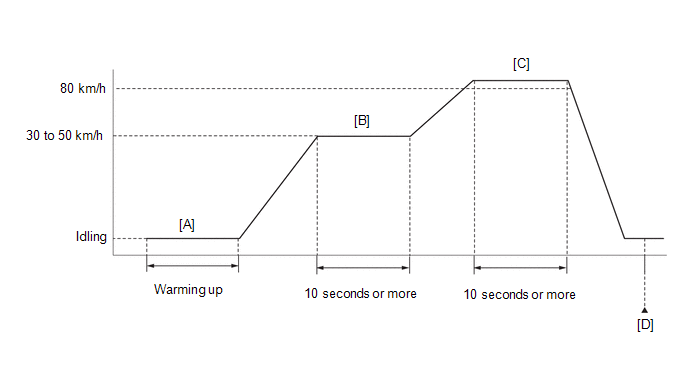

CONFIRMATION DRIVING PATTERN

HINT:

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON and turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON and turn the GTS on.

- Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher [A].

-

Drive the vehicle at 30 to 50 km/h (19 to 31 mph) for 10 seconds or more [B].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

-

Drive the vehicle at 80 km/h (50 mph) or more for 10 seconds or more [C].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

- Enter the following menus: Powertrain / Engine / Trouble Codes [D].

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P25B473.

-

Check the DTC judgment result.

GTS Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE, perform steps [C] and [D] again.

-

[A] to [D]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- When clearing the permanent DTCs, do not disconnect the cable from the battery terminal or attempt to clear the DTCs during this procedure, as doing so will clear the universal trip and normal judgment histories.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

HINT:

Read Freeze Frame Data using the GTS. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

|

1. |

CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P25B473) |

(a) Read the DTCs.

Powertrain > Engine > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC P25B473 is output |

A |

|

DTC P25B473 and other DTCs are output |

B |

HINT:

If any DTCs other than P25B473 are output, troubleshoot those DTCs first.

| B |

|

GO TO DTC CHART |

|

|

2. |

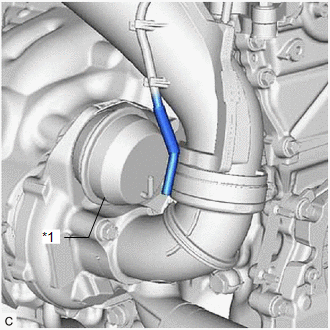

CHECK VACUUM REGULATING VALVE ASSEMBLY |

|

*1 |

Waste Gate Valve Actuator with Bracket Assembly |

(a) Disconnect the vacuum hose of the waste gate valve actuator with bracket assembly.

(b) Start the engine.

(c) Check whether the vacuum hose of the vacuum regulating valve assembly applies no suction your finger.

OK:

Vacuum hose applies no suction to finger.

| NG |

|

|

|

3. |

INSPECT MASS AIR FLOW METER SUB-ASSEMBLY |

(a) Inspect the mass air flow meter sub-assembly, referring to On-vehicle Inspection for Mass Air Flow Meter.

(b) Inspect the mass air flow meter sub-assembly, referring to Inspection for Mass Air Flow Meter.

(c) Inspect the operation of the mass air flow meter sub-assembly.

(1) Start the engine.

(2) Allow the engine to idle until Coolant Temperature reaches 75°C (167°F) or higher.

(3) Read Mass Air Flow Sensor while maintaining an engine speed of 3000 rpm.

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Engine Speed |

|

Mass Air Flow Sensor |

|

Coolant Temperature |

Standard:

|

GTS Display |

Condition |

Specified Condition |

|---|---|---|

|

Mass Air Flow Sensor |

Engine warmed up Shift lever position: P A/C: Off Engine Speed: 3000 rpm |

Between 4.5 and 12 gm/sec |

| NG |

|

|

|

4. |

INSPECT NO. 2 TURBO PRESSURE SENSOR |

| NG |

|

|

|

5. |

REPLACE TURBOCHARGER SUB-ASSEMBLY |

|

|

6. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P25B473) |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

(c) Start the engine and warm it up.

(d) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(e) Check the DTC judgment result.

Powertrain > Engine > Utility

|

Tester Display |

|---|

|

All Readiness |

(f) Input the DTC: P25B473.

|

Result |

Proceed to |

|---|---|

|

NORMAL (DTCs are not output) |

A |

|

ABNORMAL (DTC P25B473 is output) |

B |

| A |

|

|

|

7. |

REPLACE ECM |

| NEXT |

|

|

8. |

CHECK TERMINAL VOLTAGE (POWER SOURCE OF NO. 2 TURBO PRESSURE SENSOR) |

(a) Disconnect the No. 2 turbo pressure sensor connector.

(b) Turn the ignition switch to ON.

|

(c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG |

|

|

|

9. |

REPLACE NO. 2 TURBO PRESSURE SENSOR |

| NEXT |

|

|

10. |

CHECK HARNESS AND CONNECTOR (NO. 2 TURBO PRESSURE SENSOR - ECM) |

(a) Disconnect the No. 2 turbo pressure sensor connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

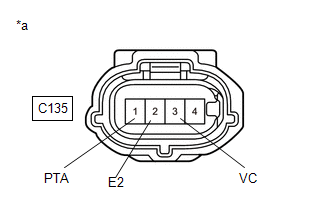

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C135-3 (VC) - C142-80 (VPTA) |

Always |

Below 1 Ω |

|

C135-2 (E2) - C142-79 (EPTA) |

Always |

Below 1 Ω |

|

C135-1 (PTA) - C142-103 (PTA) |

Always |

Below 1 Ω |

|

C135-3 (VC) or C142-80 (VPTA) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C135-1 (PTA) or C142-103 (PTA) - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG |

|

|

|

11. |

REPLACE ECM |

| NEXT |

|

|

12. |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

(a) Repair or replace the wire harness or connector.

| NEXT |

|

|

13. |

CHECK TERMINAL VOLTAGE (POWER SOURCE OF MASS AIR FLOW METER SUB-ASSEMBLY) |

(a) Disconnect the mass air flow meter sub-assembly connector.

(b) Turn the ignition switch to ON.

|

(c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG |

|

|

|

14. |

INSPECT MASS AIR FLOW METER SUB-ASSEMBLY |

| OK |

|

| NG |

|

|

15. |

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY - ECM) |

(a) Disconnect the mass air flow meter sub-assembly connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

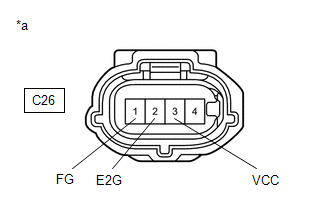

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C26-3 (VCC) - C142-84 (VCVG) |

Always |

Below 1 Ω |

|

C26-1 (FG) - C142-107 (VG) |

Always |

Below 1 Ω |

|

C26-2 (E2G) - C142-83 (E2G) |

Always |

Below 1 Ω |

|

C26-3 (VCC) or C142-84 (VCVG) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C26-1 (FG) or C142-107 (VG) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C26-2 (E2G) or C142-83 (E2G) - Body ground and other terminals |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

16. |

REPLACE VACUUM REGULATING VALVE ASSEMBLY |

|

|

17. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P25B473) |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

(c) Start the engine and warm it up.

(d) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(e) Check the DTC judgment result.

Powertrain > Engine > Utility

|

Tester Display |

|---|

|

All Readiness |

(f) Input the DTC: P25B473.

|

GTS Display |

Description |

|---|---|

|

NORMAL |

|

|

ABNORMAL |

|

|

INCOMPLETE |

|

| NEXT |

|

END |

|

|

|

![2023 - 2025 MY GR Corolla [09/2022 - ]; G16E-GTS (ENGINE CONTROL): SFI SYSTEM: P024313; Turbocharger/Supercharger Wastegate Solenoid "A" Circuit Open+](/t3Portal/stylegraphics/info.gif)