- Purge VSV stuck closed

- No. 1 check valve stuck closed

- Purge flow

| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM10000000255WM |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - ] |

| Title: G16E-GTS (ENGINE CONTROL): SFI SYSTEM: P04419C; Evaporative Emission System Incorrect Purge Flow Low/Insufficient Flow; 2023 - 2025 MY GR Corolla [09/2022 - ] | ||

|

DTC |

P04419C |

Evaporative Emission System Incorrect Purge Flow Low/Insufficient Flow |

DTC SUMMARY

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Note |

|---|---|---|---|---|---|

|

P04419C |

Evaporative Emission System Incorrect Purge Flow Low/Insufficient Flow |

While engine running, following conditions successively met:

|

|

Comes on |

SAE Code: P0441 |

|

DTC No. |

Monitoring Item |

Detection Timing |

Detection Logic |

SAE |

|---|---|---|---|---|

|

P04419C |

|

While engine running |

2 trip |

P0441 |

DESCRIPTION

The description can be found in EVAP (Evaporative Emission) System.

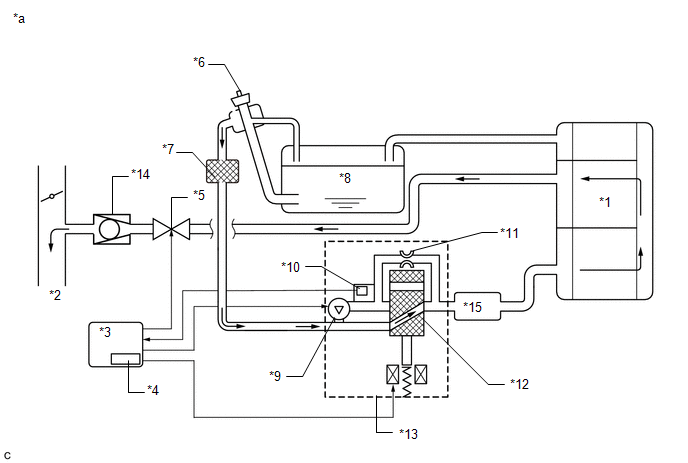

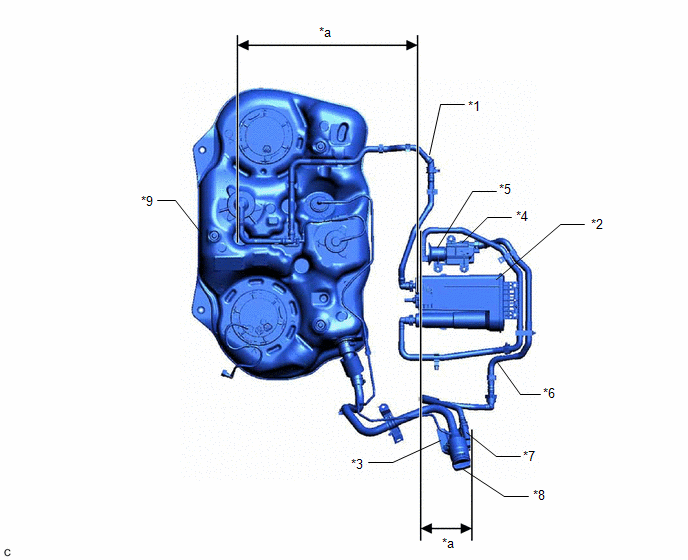

Purge Flow Monitor

The purge flow monitor consists of the 2 monitors. The 1st monitor is conducted every time and the 2nd monitor is activated if necessary.

-

The 1st monitor

While the engine is running and the purge VSV (Vacuum Switching Valve) is on (open), the ECM monitors the purge flow by measuring the EVAP pressure change. If negative pressure is not created, the ECM begins the 2nd monitor.

-

The 2nd monitor

The vent valve is turned on (closed) and the EVAP pressure is then measured. If the variation in the pressure is less than 0.154 kPa(gauge) [0.022 psi(gauge)], the ECM interprets this as the purge VSV or No. 1 check valve being stuck closed, illuminates the MIL and store DTC (2 trip detection logic).

-

Atmospheric pressure check:

- In order to ensure reliable malfunction detection, the variation between the atmospheric pressures, before and after of the purge flow monitor, is measured by the ECM.

|

*1 |

Canister |

*2 |

to Intake Manifold |

|

*3 |

ECM |

*4 |

Soak Timer |

|

*5 |

Purge VSV (On) |

*6 |

Fuel Tank Cap |

|

*7 |

Canister Filter |

*8 |

Fuel Tank |

|

*9 |

Leak Detection Pump (Off) |

*10 |

Canister Pressure Sensor |

|

*11 |

Reference Orifice (0.02 inches) |

*12 |

Vent Valve (Off) |

|

*13 |

Canister Pump Module |

*14 |

No. 1 Check Valve |

|

*15 |

No. 2 Charcoal Canister Filter |

- |

- |

|

*a |

EVAP Purge Flow |

- |

- |

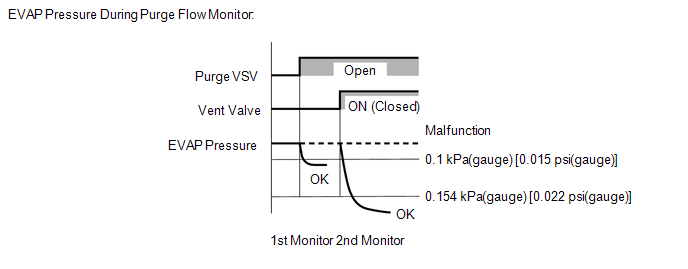

MONITOR DESCRIPTION

PURGE FLOW MONITOR

The purge flow monitor consists of 2 monitors. The 1st monitor is conducted every time and the 2nd monitor is activated if necessary.

-

The 1st monitor

While the engine is running and the purge VSV is on (open), the ECM monitors the purge flow by measuring the EVAP pressure change. If negative pressure is not created, the ECM begins the 2nd monitor.

-

The 2nd monitor

The vent valve is turned on (closed) and the EVAP pressure is then measured. If the variation in the pressure is less than 0.154 kPa(gauge) [0.022 psi(gauge)], the ECM interprets this as the purge VSV or No. 1 check valve being stuck closed, illuminates the MIL and store DTC (2 trip detection logic).

Atmospheric pressure check:

In order to ensure reliable malfunction detection, the variation between the atmospheric pressures, before and after conduction of the purge flow monitor, is measured by the ECM.

MONITOR STRATEGY

|

Required Sensors/Components (Main) |

No. 1 check valve Purge VSV Canister pump module |

|

Required Sensors/Components (Related) |

- |

|

Frequency of Operation |

Once per driving cycle |

|

Duration |

Within 30 seconds |

|

MIL Operation |

2 driving cycles |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

Engine |

Running |

|

Engine coolant temperature |

4.4°C (40°F) or higher |

|

Intake air temperature (for mass air flow meter sub-assembly) |

4.4°C (40°F) or higher |

|

Canister pressure sensor malfunction (P0451, P0452, P0453) |

Not detected |

|

Purge VSV |

Not operated by scan tool |

|

EVAP system check |

Not operated by scan tool |

|

Battery voltage |

10 V or higher |

|

Purge duty-cycle |

8% or more |

|

Engine load |

Less than 80% |

TYPICAL MALFUNCTION THRESHOLDS

|

Both of the following conditions are met: |

Conditions 1 and 2 |

|

1. EVAP pressure change when purge flow is started |

Less than 0.1 kPa(gauge) [0.015 psi(gauge)] |

|

2. EVAP pressure change during purge operation when vent valve on (closed) |

Less than 0.154 kPa(gauge) [0.022 psi(gauge)] |

MONITOR RESULT

Refer to detailed information in Checking Monitor Status.

P0441: Evaporative System / PURGE FLOW

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$3D |

$D7 |

Multiply by 0.001 |

kPa |

Test value for purge flow insufficient |

CONFIRMATION DRIVING PATTERN

HINT:

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON and turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON and turn the GTS on.

- Start the engine and wait 15 minutes or more [A].

- Enter the following menus: Powertrain / Engine / Trouble Codes [B].

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P04419C.

-

Check the DTC judgment result.

GTS Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- You should perform driving pattern after confirming DTC enabling conditions

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system is malfunctioning.

-

[A] to [B]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- When clearing the permanent DTCs, do not disconnect the cable from the battery terminal or attempt to clear the DTCs during this procedure, as doing so will clear the universal trip and normal judgment histories.

WIRING DIAGRAM

Refer to DTC P045011.

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

HINT:

Read Freeze Frame Data using the GTS. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

|

1. |

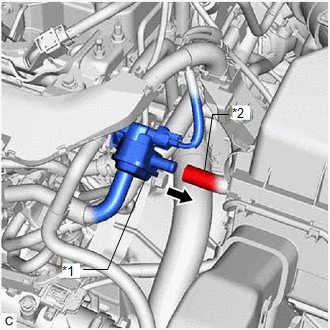

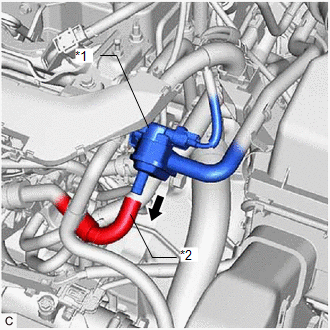

PERFORM ACTIVE TEST USING GTS (ACTIVATE THE EVAP PURGE VSV) |

|

*1 |

Purge VSV |

|

*2 |

Fuel Vapor Feed Hose (to Canister) |

(a) Disconnect the fuel vapor feed hose (connected to the canister) from the purge VSV.

(b) Start the engine.

(c) Using the GTS, turn on the purge VSV (Activate the EVAP Purge VSV: ON).

Powertrain > Engine > Active Test

|

Tester Display |

|---|

|

Activate the EVAP Purge VSV |

(d) Use your finger to confirm that the purge VSV has suction.

|

Test Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|

|

Suction applied |

|

A |

|

No suction |

|

B |

| B |

|

|

|

2. |

INSPECT EVAP HOSE (PURGE VSV - CANISTER) |

(a) Check for blockages in the EVAP purge line between the purge VSV and canister.

OK:

No blockages in the EVAP purge line between the purge VSV and canister.

| NG |

|

|

|

3. |

INSPECT CANISTER (CHARCOAL FILTER INSIDE CANISTER) |

(a) Check for filter blockage in the canister.

OK:

No blockages in the canister.

| NG |

|

|

|

4. |

INSPECT NO. 2 CHARCOAL CANISTER FILTER (CHARCOAL FILTER INSIDE CANISTER) |

(a) Check for filter blockage in the No. 2 Charcoal Canister Filter.

OK:

No blockages in the No. 2 Charcoal Canister Filter.

| NG |

|

|

|

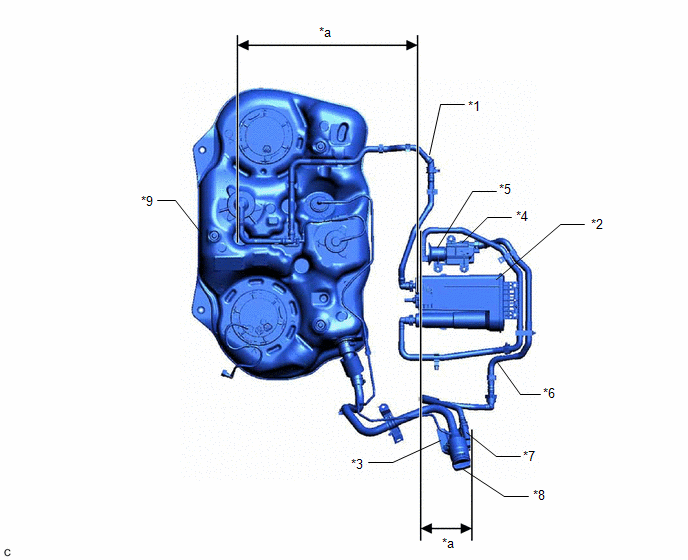

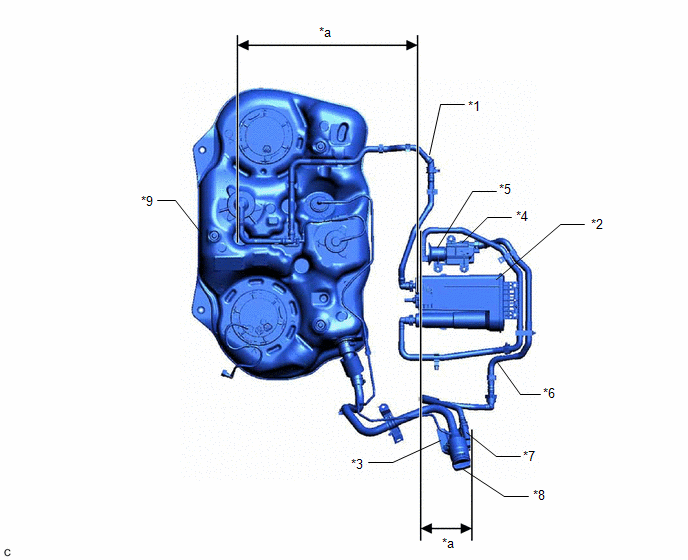

5. |

REPLACE CANISTER PUMP MODULE |

NOTICE:

- When replacing the canister pump module, check the canister pump module interior, canister interior and related pipes for water, fuel and other liquids. If liquids are present, check for disconnections and/or cracks in the following: 1) the pipe from the air inlet port to the canister pump module; 2) the canister filter; and 3) the fuel tank vent hose. If liquids are present in the canister interior, replace the canister and canister pump module together.

- Check for filter blockage in the canister. If the charcoal filter inside the canister is clogged, replace the canister and canister pump module together.

- Check for filter blockage in the canister filter. If the canister filter has blockages, replace the canister filter.

|

*1 |

Fuel Tank Vent Hose |

*2 |

Canister |

|

*3 |

Canister Filter |

*4 |

Canister Pump Module |

|

*5 |

No. 2 Charcoal Canister Filter |

*6 |

Vent Hose |

|

*7 |

Air Inlet Port |

*8 |

Fuel Tank Cap |

|

*9 |

Fuel Tank |

- |

- |

|

*a |

Inspection Area (check for disconnection and/or cracks) |

- |

- |

| NEXT |

|

|

6. |

REPLACE NO. 2 CHARCOAL CANISTER FILTER |

NOTICE:

- When replacing the No. 2 charcoal canister filter, check the canister interior, canister pump module interior and related pipes for water, fuel and other liquids. If liquids are present, check for disconnections and/or cracks in the following: 1) the pipe from the air inlet port to the canister pump module; 2) the canister filter; and 3) the fuel tank vent hose.

- Check for filter blockage in the canister filter. If the canister filter has blockages, replace the canister filter.

|

*1 |

Fuel Tank Vent Hose |

*2 |

Canister |

|

*3 |

Canister Filter |

*4 |

Canister Pump Module |

|

*5 |

No. 2 Charcoal Canister Filter |

*6 |

Vent Hose |

|

*7 |

Air Inlet Port |

*8 |

Fuel Tank Cap |

|

*9 |

Fuel Tank |

- |

- |

|

*a |

Inspection Area (check for disconnection and/or cracks) |

- |

- |

| NEXT |

|

|

7. |

REPLACE CANISTER |

NOTICE:

- When replacing the canister, check the canister pump module interior and related pipes for water, fuel and other liquids. If liquids are present, check for disconnections and/or cracks in the following: 1) the pipe from the air inlet port to the canister pump module; 2) the canister filter; and 3) the fuel tank vent hose.

- Check for filter blockage in the canister filter. If the canister filter has blockages, replace the canister filter.

|

*1 |

Fuel Tank Vent Hose |

*2 |

Canister |

|

*3 |

Canister Filter |

*4 |

Canister Pump Module |

|

*5 |

No. 2 Charcoal Canister Filter |

*6 |

Vent Hose |

|

*7 |

Air Inlet Port |

*8 |

Fuel Tank Cap |

|

*9 |

Fuel Tank |

- |

- |

|

*a |

Inspection Area (check for disconnection and/or cracks) |

- |

- |

| NEXT |

|

|

8. |

REPAIR OR REPLACE EVAP PURGE LINE (PURGE VSV - CANISTER) |

| NEXT |

|

|

9. |

INSPECT EVAP HOSE (PURGE VSV - INTAKE MANIFOLD) |

|

*1 |

Purge VSV |

|

*2 |

Fuel Vapor Feed Hose (to intake manifold) |

(a) Disconnect the fuel vapor feed hose (connected to the intake manifold) from the purge VSV.

(b) Start the engine.

(c) Use your finger to confirm that the fuel vapor feed hose has suction.

|

Test Result |

Suspected Trouble Area |

Proceed to |

|---|---|---|

|

Suction applied |

EVAP hose between purge VSV and intake manifold normal

|

A |

|

No suction |

|

B |

| B |

|

|

|

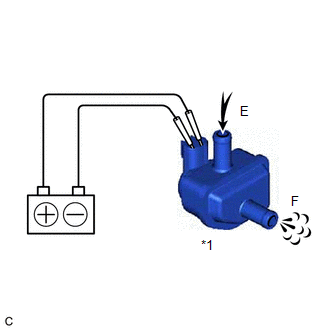

10. |

INSPECT PURGE VSV |

|

*1 |

Purge VSV |

(a) Remove the purge VSV.

(b) Apply battery voltage to the terminals of the purge VSV.

(c) Confirm that air flows from port E to port F.

|

Test Result |

Condition |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|

|

Air flows |

Battery voltage is applied to purge VSV terminals |

Purge VSV normal

|

A |

|

No air flow |

Battery voltage is applied to purge VSV terminals |

Purge VSV |

B |

| B |

|

|

|

11. |

CHECK TERMINAL VOLTAGE (POWER SOURCE OF PURGE VSV) |

(a) Disconnect the purge VSV connector.

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

|

Tester Connection |

Condition |

Specified Condition |

Suspected Trouble Area |

Proceed to |

|---|---|---|---|---|

|

C30-1 (+B) - Body ground |

Ignition switch ON |

11 to 14 V |

Purge VSV power source normal

|

A |

|

Other than result above |

Wire harness or connectors between purge VSV and battery |

B |

| B |

|

|

|

12. |

CHECK HARNESS AND CONNECTOR (PURGE VSV - ECM) |

(a) Disconnect the purge VSV connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C30-2 (EVP1) - C142-45 (PRG) |

Always |

Below 1 Ω |

|

C30-2 (EVP1) or C142-45 (PRG) - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG |

|

|

|

13. |

REPLACE ECM |

| NEXT |

|

|

14. |

INSPECT EFI-MAIN NO. 3 RELAY |

| NG |

|

REPLACE EFI-MAIN NO. 3 RELAY |

|

|

15. |

CHECK TERMINAL VOLTAGE (POWER SOURCE OF EFI-MAIN NO. 3 RELAY) |

(a) Remove the EFI-MAIN NO. 3 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3 (EFI-MAIN NO. 3 relay) - Body ground |

Always |

11 to 14 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - EFI-MAIN NO. 3 RELAY) |

|

|

16. |

CHECK HARNESS AND CONNECTOR (EFI-MAIN NO. 3 RELAY - BODY GROUND) |

(a) Remove the EFI-MAIN NO. 3 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (EFI-MAIN NO. 3 relay) - Body ground |

Always |

Below 1 Ω |

| NG |

|

|

|

17. |

CHECK HARNESS AND CONNECTOR (EFI-MAIN NO. 3 RELAY - PURGE VSV) |

(a) Remove the EFI-MAIN NO. 3 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Disconnect the purge VSV connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

5 (EFI-MAIN NO. 3 relay) - C30-1 (+B) |

Always |

Below 1 Ω |

|

5 (EFI-MAIN NO. 3 relay) or C30-1 (+B) - Body ground and other terminals |

Always |

10 kΩ or higher |

| OK |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (NO. 1 INTEGRATION RELAY - EFI-MAIN NO. 3 RELAY) |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

18. |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

| NEXT |

|

|

19. |

REPLACE PURGE VSV |

| NEXT |

|

|

20. |

INSPECT NO. 1 CHECK VALVE |

| NG |

|

|

|

21. |

INSPECT INTAKE MANIFOLD (EVAP PURGE PORT) |

(a) Stop the engine.

(b) Disconnect the EVAP hose from the intake manifold.

(c) Start the engine.

(d) Use your finger to confirm that the port of the intake manifold has suction.

|

Tester Connection |

Suspected Trouble Area |

Proceed to |

|---|---|---|

|

Suction applied |

EVAP hose between intake manifold and purge VSV |

A |

|

No suction |

Intake manifold (upper intake manifold) |

B |

| B |

|

|

|

22. |

REPAIR OR REPLACE EVAP PURGE LINE (INTAKE MANIFOLD - PURGE VSV) |

| NEXT |

|

|

23. |

INSPECT INTAKE MANIFOLD (EVAP PURGE PORT) |

(a) Check that the EVAP purge port of the intake manifold is not clogged. If necessary, replace the intake manifold.

| NEXT |

|

|

24. |

REPLACE NO. 1 CHECK VALVE |

|

|

25. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P04419C) |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

(c) Start the engine.

(d) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(e) Check the DTC judgment result.

Powertrain > Engine > Utility

|

Tester Display |

|---|

|

All Readiness |

(f) Input the DTC: P04419C.

|

GTS Display |

Description |

|---|---|

|

NORMAL |

|

|

ABNORMAL |

|

|

INCOMPLETE |

|

| NEXT |

|

END |

|

|

|

![2023 - 2025 MY GR Corolla [09/2022 - ]; G16E-GTS (ENGINE CONTROL): SFI SYSTEM: EVAP System+](/t3Portal/stylegraphics/info.gif)