| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM10000000255VV |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - ] |

| Title: G16E-GTS (ENGINE CONTROL): SFI SYSTEM: Lack of Power (Turbocharger System); 2023 - 2025 MY GR Corolla [09/2022 - ] | ||

|

Lack of Power (Turbocharger System) |

CAUTION / NOTICE / HINT

HINT:

- The diagnosis flowchart is for lack of power due to turbocharger factors.

- If symptom-specific diagnosis indicates a turbocharger related problem, check using this flowchart.

PROCEDURE

|

1. |

CHECK TURBOCHARGER SUB-ASSEMBLY |

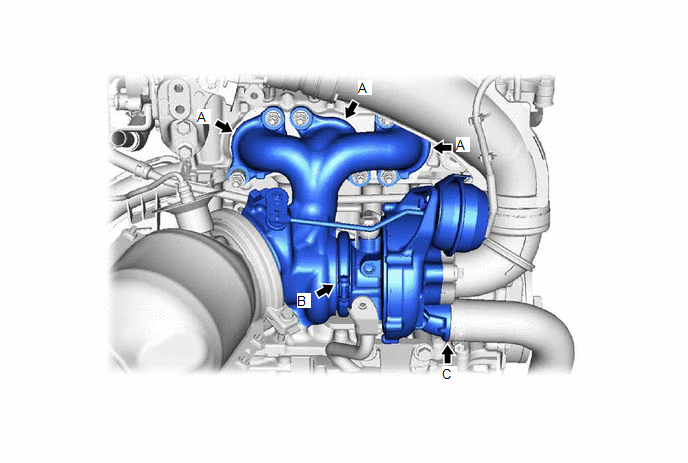

(a) Check for oil leaks and large carbon deposits around the connecting surfaces of the turbocharger sub-assembly.

HINT:

If oil leaks or a large amount of carbon deposits exist, air leaks from the respective sealing surfaces may be causing the lack of boost pressure.

|

Result |

Proceed to |

|---|---|

|

An oil leak or large amount of carbon deposits does not exist. |

A |

|

A large amount of carbon deposits exist around the turbine housing, flange or gaskets in any of the areas (A) shown in the illustration. |

B |

|

A large amount of carbon deposits exist around the waste gate valve link. |

C |

|

Oil is leaking from V-clamp in the area (B) shown in the illustration. |

D |

|

Oil is leaking from the compressor housing in any of the areas (C) shown in the illustration. |

E |

| B |

|

| C |

|

| D |

|

| E |

|

CHECK AND REPAIR AIR TUBE OR HOSE CLAMP |

|

|

2. |

CHECK TURBOCHARGER SUB-ASSEMBLY (INSPECT TURBINE SHAFT) |

(a) Check that the turbine shaft rotates smoothly, without catching.

(b) Check for loose turbine mounting nuts and for axial play in the turbine shaft.

HINT:

If the turbine shaft catches or there is no play, seal failure due to seizure or improper operation due to accumulation of deposits is suspected.

|

Result |

Proceed to |

|---|---|

|

No turbine shaft malfunction |

A |

|

Turbine shaft malfunction |

B |

| B |

|

REPLACE TURBOCHARGER SUB-ASSEMBLY (TURBINE SHAFT MALFUNCTION) |

|

|

3. |

CHECK TURBOCHARGER SUB-ASSEMBLY (INSPECT WASTE GATE VALVE) |

(a) Use a vacuum pump to apply -35 +/-4.0 kPa (-263 +/-35 mmHg) negative pressure to the diaphragm chamber and check that the waste gate valve seats.

NOTICE:

Do not apply a negative pressure of -65 kPa (-488 mmHg) or more to the waste gate valve actuator with bracket assembly, as doing so may damage the diaphragm.

Standard:

Waste gate valve seats without a gap

|

Result |

Proceed to |

|---|---|

|

Seats at less than -35 kPa (-263 mmHg) negative pressure |

A |

|

Seats at -35 kPa (-263 mmHg) or greater negative pressure |

B |

|

Waste gate valve does not move |

C |

| B |

|

REPLACE TURBOCHARGER SUB-ASSEMBLY (WASTE GATE VALVE ACTUATOR MALFUNCTION) |

| C |

|

REPLACE TURBOCHARGER SUB-ASSEMBLY (WASTE GATE VALVE MALFUNCTION) |

|

|

4. |

CHECK TURBOCHARGER SUB-ASSEMBLY (INSPECT WASTE GATE VALVE) |

(a) Check for play in the waste gate valve and waste gate valve link.

Standard:

Play exists

HINT:

Some play is required as the waste gate valve link slides. If no play exists, the valve is determined to be stuck.

(b) Close the waste gate valve and using a feeler gauge, measure the clearance between the waste gate valve and the contact surface of the valve port of the turbine with valve housing sub-assembly waste gate.

Standard:

0.15 mm (0.0059 in.) or less

| NG |

|

REPLACE TURBOCHARGER SUB-ASSEMBLY (WASTE GATE VALVE MALFUNCTION) |

|

|

5. |

CHECK TURBOCHARGER SUB-ASSEMBLY (INSPECT AIR BY-PASS VALVE ASSEMBLY) |

(a) Inspect the air by-pass valve assembly.

| OK |

|

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG |

|

REPLACE TURBOCHARGER SUB-ASSEMBLY (AIR BY-PASS VALVE ASSEMBLY MALFUNCTION) |

|

6. |

CHECK CYLINDER HEAD SUB-ASSEMBLY |

(a) Check for deformation or cracks in the mounting surfaces on the cylinder head sub-assy and the turbocharger sub-assembly.

HINT:

Deformation or cracks on a mounting surface may allow exhaust gas to leak from the damaged position.

Standard:

No deformation or cracks on a mounting surface

|

Result |

Proceed to |

|---|---|

|

No problem with the mounting surface |

A |

|

Deformation or cracks on the cylinder head sub-assy mounting surface |

B |

|

Deformation or cracks on the turbocharger sub-assembly mounting surface |

C |

| B |

|

| C |

|

|

|

7. |

REPLACE GASKET |

(a) Replace the gasket between the cylinder head sub-assy and turbocharger sub-assembly.

|

|

8. |

PERFORM SIMULATION TEST |

(a) Check that the abnormal state has disappeared.

| NEXT |

|

END |

|

9. |

CHECK TURBOCHARGER SUB-ASSEMBLY (INSPECT TURBINE HOUSING) |

(a) Check that the bushing of the turbine housing waste gate valve link is free of cracks.

(b) Close the waste gate valve and using a feeler gauge, measure the clearance between the waste gate valve and the contact surface of the valve port of the turbine with valve housing sub-assembly waste gate.

Standard:

No cracks and play does not exceed 0.15 mm (0.0059 in.)

| OK |

|

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG |

|

REPLACE TURBOCHARGER SUB-ASSEMBLY (TURBINE HOUSING MALFUNCTION) |

|

|

|

![2023 - 2025 MY GR Corolla [09/2022 - ]; G16E-GTS (INTAKE / EXHAUST): TURBOCHARGER: INSPECTION](/t3Portal/stylegraphics/info.gif)