- DTC judgment completed

- System normal

| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM10000000255V1 |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - ] |

| Title: G16E-GTS (ENGINE CONTROL): SFI SYSTEM: P042000; Catalyst System Efficiency Below Threshold Bank 1; 2023 - 2025 MY GR Corolla [09/2022 - ] | ||

|

DTC |

P042000 |

Catalyst System Efficiency Below Threshold Bank 1 |

MONITOR DESCRIPTION

The ECM uses air fuel ratio sensors mounted in front of and behind the Three-Way Catalytic Converter (TWC) to monitor its efficiency.

The first sensor, the air fuel ratio sensor (sensor 1), sends pre-catalyst information to the ECM. The second sensor, the air fuel ratio sensor (sensor 2), sends post-catalyst information to the ECM.

In order to detect any deterioration in the three-way catalytic converter, the ECM calculates the oxygen storage capacity of the three-way catalytic converter. This calculation is based on the output current of the air fuel ratio sensor (sensor 2) while performing active air fuel ratio control.

The oxygen storage capacity value is an indication of the oxygen storage capacity of the three-way catalytic converter. When the vehicle is being driven with a warm engine, active air fuel ratio control is performed for approximately 30 seconds. When it is performed, the ECM deliberately sets the air fuel ratio to lean or rich levels. If the cycle of the waveform for the air fuel ratio sensor (sensor 2) is long, the oxygen storage capacity is great. There is a direct correlation between the air fuel ratio sensor (sensor 2) and the oxygen storage capacity of the three-way catalytic converter.

The ECM uses the oxygen storage capacity value to determine the state of the three-way catalytic converter. If any deterioration has occurred, the ECM will illuminate the MIL and store a DTC.

This system determines the deterioration of the entire catalyst system (including the front and rear catalysts), by using the oxygen storage capacity value of the front catalyst, that is more sensitive than the rear catalyst, as the representative value. Therefore, be sure to replace the front and rear catalysts together when catalyst replacement is necessary.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Note |

|---|---|---|---|---|---|

|

P042000 |

Catalyst System Efficiency Below Threshold Bank 1 |

The oxygen storage capacity value is less than the standard value under active air fuel ratio control (1 trip detection logic). |

|

Comes on |

SAE Code: P0420 |

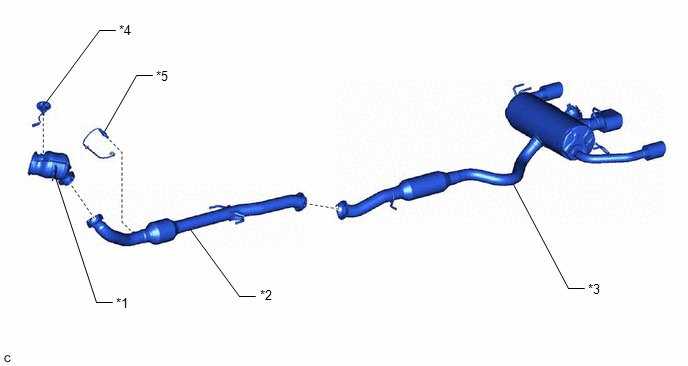

CATALYST LOCATION

|

*1 |

Exhaust Manifold (TWC: Front Catalyst) |

*2 |

Front Exhaust Pipe Assembly (TWC: Rear Catalyst) |

|

*3 |

Tail Exhaust Pipe Assembly |

*4 |

Air Fuel Ratio Sensor (Sensor 1) |

|

*5 |

Air Fuel Ratio Sensor (Sensor 2) |

- |

- |

NOTICE:

When replacing the exhaust manifold (*1) and the front exhaust pipe assembly (*2) in order to replace the three-way catalytic converter, it is not necessary to replace the air fuel ratio sensor (sensor 1) (*4) and the air fuel ratio sensor (sensor 2) (*5).

MONITOR STRATEGY

|

Related DTCs |

P0420: Catalyst deterioration |

|

Required Sensors/Components (Main) |

Air fuel ratio sensor (sensor 1) Air fuel ratio sensor (sensor 2) |

|

Required Sensors/Components (Related) |

Intake air temperature sensor Mass air flow meter sub-assembly Crankshaft position sensor Engine coolant temperature sensor |

|

Frequency of Operation |

Once per driving cycle |

|

Duration |

Approximately 30 seconds |

|

MIL Operation |

Immediate |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

Monitor runs whenever the following DTCs are not stored |

P0010 (VVT oil control solenoid) P0011 (VVT system - advance) P0012 (VVT system - retard) P0013 (Exhaust VVT oil control solenoid) P0014 (Exhaust VVT system - advance) P0015 (Exhaust VVT system - retard) P0016 (VVT system - misalignment) P0017 (Exhaust VVT system - misalignment) P0031, P0032, P101D (Air fuel ratio sensor (sensor 1) heater) P0037, P0038, P102D (Air fuel ratio sensor (sensor 2) heater) P005D, P014C, P014D, P015A, P015B, P2195, P2196, P2237, P2238, P2239, P2252, P2253 (Air fuel ratio sensor (sensor 1)) P0087, P0088, P0191, P0192, P0193 (Fuel pressure sensor (for high pressure side)) P00CF, P0237, P0238 (Turbocharger) P0101, P0102, P0103 (Mass air flow meter) P0106, P0107, P0108 (Manifold absolute pressure) P0111, P0112, P0113 (Intake air temperature sensor) P0116, P0117, P0118 (Engine coolant temperature sensor) P0121, P0122, P0123, P0222, P0223, P2135 (Throttle position sensor) P0125 (Insufficient coolant temperature for closed loop fuel control) P0128 (Thermostat) P0136, P013A, P2270, P2271, P22AB, P22AC, P22AD, P22B3, P22B4 (Air fuel ratio sensor (sensor 2)) P0171, P0172 (Fuel system) P0201, P0202, P0203, P062D, P21CF, P21D0, P21D1 (Fuel injector) P0300 - P0303 (Misfire) P0327, P0328 (Knock control sensor) P0335, P0337, P0338 (Crankshaft position sensor) P0340, P0342, P0343 (Camshaft position sensor) P0365, P0367, P0368 (Exhaust camshaft position sensor) P0500 (Vehicle speed sensor) P0657, P0658, P2102, P2103, P2111, P2112, P2119 (Throttle actuator) P107B, P107C, P107D (Fuel pressure sensor (for low pressure side)) P11EA, P11EC, P11ED, P11EE, P219A, P219C, P219D, P219E (Air-fuel ratio imbalance) P1235 (High pressure fuel pump circuit) P2228, P2229 (Atmospheric pressure sensor) |

|

Response rate during fuel cut from rich condition |

Completed |

|

Battery voltage |

11 V or higher |

|

Intake air temperature |

-10°C (14°F) or higher |

|

Engine coolant temperature |

75°C (167°F) or higher |

|

Atmospheric pressure |

76 kPa(abs) [11 psi(abs)] or higher |

|

Idling |

Off |

|

Engine speed |

Less than 4000 rpm |

|

Sub feedback control |

Executing |

|

Air fuel ratio sensor (sensor 1) status |

Activated |

|

Fuel system status |

Closed loop |

|

Engine load |

10% or higher, and less than 160% |

|

All of the following conditions are met |

1, 2 and 3 |

|

1. Mass air flow |

2.9 gm/sec or more, and less than 60 gm/sec |

|

2. Front catalyst temperature (estimated) |

500°C (932°F) or higher, and below 820°C (1508°F) |

|

3. Rear catalyst temperature (estimated) |

270°C (518°F) or higher, and below 700°C (1292°F) |

|

Shift position |

3rd or higher |

TYPICAL MALFUNCTION THRESHOLDS

|

Oxygen Storage Capacity (OSC) of catalyst (Normalized) |

Less than 1 |

MONITOR RESULT

Refer to detailed information in Checking Monitor Status.

P0420: Catalyst Efficiency / O2 STORAGE B1

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$21 |

$AF |

Multiply by 0.001 |

No dimension |

Oxygen storage capacity of catalyst bank 1 (Normalization) |

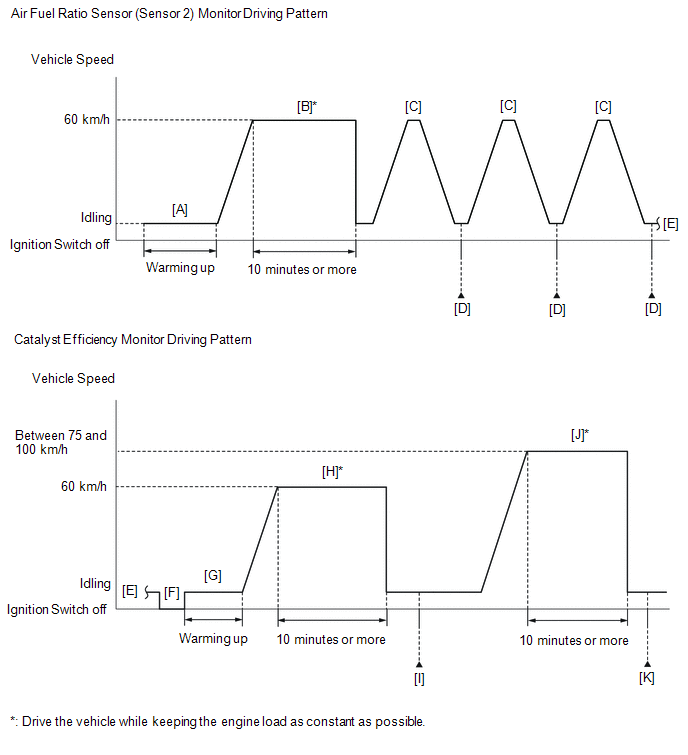

CONFIRMATION DRIVING PATTERN

HINT:

- It is necessary for the response of the air fuel ratio sensor (sensor 2) to be normal in order to confirm DTC P042000. Therefore, perform the confirmation driving pattern for the air fuel ratio sensor (sensor 2) monitor before performing the confirmation driving pattern for the catalyst efficiency monitor.

- Performing this confirmation driving pattern will activate the catalyst efficiency monitor. This is very useful for verifying the completion of a repair.

- After repair has been completed, clear the DTC and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

- When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON.

- Turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON.

- Turn the GTS on.

- Enter the following menus: Powertrain / Engine / Monitor / Current Monitor.

- Check that Catalyst Efficiency / Current is Incomplete.

-

Start the engine and warm it up until the engine coolant temperature is 75°C (167°F) or higher with the shift lever in neutral [A].

HINT:

In order to keep the idle stable, turn the A/C and all other electric loads off and do not perform any shift operations.

-

Drive the vehicle at approximately 60 km/h (37 mph) for 10 minutes or more [B].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

Drive the vehicle while keeping the engine load as constant as possible.

-

With the shift lever in neutral, drive the vehicle at 60 km/h (37 mph), and then decelerate the vehicle by releasing the accelerator pedal for 5 seconds or more to perform the fuel-cut [C].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

- Enter the following menus: Powertrain / Engine / Monitor / Current Monitor / O2 Sensor / Details / SLOW RESPONSE B1S2 [D].

-

Check the Test Value for SLOW RESPONSE B1S2.

HINT:

- If Test Value displays a value larger than 0, perform the following procedure, as the O2 Sensor monitor is finished.

- If Test Value displays 0, perform step [C] until it displays a value larger than 0, as the O2 Sensor monitor is not finished.

- Turn the ignition switch off and wait for at least 30 seconds [F].

- Turn the ignition switch to ON.

- Turn the GTS on.

- Start the engine and warm it up until the engine coolant temperature is 75°C (167°F) or higher [G].

-

Drive the vehicle at approximately 60 km/h (37 mph) for 10 minutes or more [H].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

- Drive the vehicle while keeping the engine load as constant as possible.

- The monitor item will change to Complete as the Catalyst Efficiency monitor operates.

- Enter the following menus: Powertrain / Engine / Trouble Codes [I].

-

Check if any DTCs are stored.

HINT:

- If the monitor item does not change to Complete, and no DTCs are stored, perform the following procedure.

-

[A] to [I]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- When clearing the permanent DTCs, do not disconnect the cable from the battery terminal or attempt to clear the DTCs during this procedure, as doing so will clear the universal trip and normal judgment histories.

-

Drive the vehicle at a speed between 75 and 100 km/h (47 and 62 mph) for 10 minutes or more [J].

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

- Drive the vehicle while keeping the engine load as constant as possible.

- The monitor item will change to Complete as the Catalyst Efficiency monitor operates.

- Enter the following menus: Powertrain / Engine / Trouble Codes [K].

-

Check if any DTCs are stored.

HINT:

If the monitor item does not change to Complete, and no DTCs are stored, extend the driving time.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P042000.

-

Check the DTC judgment result.

GTS Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system has a malfunction.

-

[A] to [K]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- When clearing the permanent DTCs, do not disconnect the cable from the battery terminal or attempt to clear the DTCs during this procedure, as doing so will clear the universal trip and normal judgment histories.

CAUTION / NOTICE / HINT

HINT:

- If a malfunction cannot be found when troubleshooting DTC P042000, a lean or rich abnormality may be the cause. Perform troubleshooting by following the inspection procedure for P017100 (System Too Lean) and P017200 (System Too Rich).

- Sensor 1 refers to the sensor closest to the engine assembly.

- Sensor 2 refers to the sensor farthest away from the engine assembly.

- Read Freeze Frame Data using the GTS. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

|

1. |

CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P042000) |

(a) Read the DTCs.

Powertrain > Engine > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

P042000 and other DTCs are output |

A |

|

P042000 is output |

B |

HINT:

If any DTCs other than P042000 are output, troubleshoot those DTCs first.

| A |

|

GO TO DTC CHART |

|

|

2. |

READ FREEZE FRAME DATA (LONG FT B1S2) |

(a) Using the GTS, read the value displayed in the Freeze Frame Data.

Powertrain > Engine > DTC(P042000) > Freeze Frame Data

|

Tester Display |

|---|

|

Long FT B1S2 |

|

GTS Display |

Result |

Proceed to |

|---|---|---|

|

Long FT B1S2 |

Less than 1.0% |

A |

|

1.0% or higher |

B |

| B |

|

|

|

3. |

PERFORM ACTIVE TEST USING GTS (CONTROL THE INJECTION VOLUME FOR A/F SENSOR) |

(a) Start the engine and warm it up until the engine coolant temperature is 75°C (167°F) or higher.

(b) Warm up the air fuel ratio sensors at an engine speed of 2500 rpm for 90 seconds.

(c) Enter the following menus.

Powertrain > Engine > Active Test

|

Active Test Display |

|---|

|

Control the Injection Volume for A/F Sensor |

|

Data List Display |

|---|

|

Coolant Temperature |

|

Injection Volume |

|

A/F (O2) Sensor Current B1S1 |

|

A/F (O2) Sensor Current B1S2 |

HINT:

- The Active Test "Control the Injection Volume for A/F Sensor" can be used to lower the fuel injection volume by 12.5% or increase the injection volume by 12.5%.

- The air fuel ratio sensor (sensor 1) is displayed as A/F (O2) Sensor Current B1S1, and the air fuel ratio sensor (sensor 2) is displayed as A/F (O2) Sensor Current B1S2 on the GTS.

- The air fuel ratio sensor (sensor 1) has an output delay of a few seconds and the air fuel ratio sensor (sensor 2) has a maximum output delay of approximately 20 seconds.

- If the sensor output current does not change (almost no reaction) while performing the Active Test, the sensor may be malfunctioning.

Standard:

|

GTS Display (Sensor) |

Injection Volume |

Status |

Current |

|---|---|---|---|

|

A/F (O2) Sensor Current B1S1 (Air fuel ratio (sensor 1)) |

12.5% |

Rich |

Below -0.075 mA |

|

-12.5% |

Lean |

Higher than 0.037 mA |

|

|

A/F (O2) Sensor Current B1S2 (Air fuel ratio (sensor 2)) |

12.5% |

Rich |

Below -0.86 mA |

|

-12.5% |

Lean |

Higher than 0.33 mA |

|

Status A/F (O2) Sensor Current B1S1 |

Status A/F (O2) Sensor Current B1S2 |

Actual air fuel ratio, air fuel ratio sensor (sensor 1) and air fuel ratio sensor (sensor 2) condition |

Main Suspected Trouble Area |

Proceed to |

|---|---|---|---|---|

|

Lean/Rich |

Lean/Rich |

Normal |

|

A |

|

Lean |

Lean/Rich |

Air fuel ratio sensor (sensor 1) malfunction |

|

B |

|

Rich |

Lean/Rich |

Air fuel ratio sensor (sensor 1) malfunction |

|

B |

|

Lean/Rich |

Lean |

Air fuel ratio sensor (sensor 2) malfunction |

|

C |

|

Lean/Rich |

Rich |

Air fuel ratio sensor (sensor 2) malfunction |

|

C |

|

Lean |

Lean |

Actual air fuel ratio lean |

|

D |

|

Rich |

Rich |

Actual air fuel ratio rich |

|

D |

- Lean: During the Control the Injection Volume for A/F Sensor Active Test, the air fuel ratio sensor (sensor 1) output current (A/F (O2) Sensor Current B1S1) is consistently higher than 0.037 mA, and the air fuel ratio sensor (sensor 2) output current (A/F (O2) Sensor Current B1S2) is consistently higher than 0.33 mA.

- Rich: During the Control the Injection Volume for A/F Sensor Active Test, the air fuel ratio sensor (sensor 1) output current (A/F (O2) Sensor Current B1S1) is consistently below -0.075 mA, and the air fuel ratio sensor (sensor 2) output current (A/F (O2) Sensor Current B1S2) is consistently below -0.86 mA.

- Lean/Rich: During the Control the Injection Volume for A/F Sensor Active Test, the output current of the air fuel ratio sensor (sensor 1) or air fuel ratio sensor (sensor 2) alternate correctly.

HINT:

Refer to "Data List / Active Test" [A/F (O2) Sensor Current B1S1, A/F (O2) Sensor Current B1S2].

| B |

|

| C |

|

| D |

|

|

|

4. |

CHECK FOR EXHAUST GAS LEAK |

(a) Check for exhaust gas leaks.

OK:

No gas leaks in exhaust system.

| OK |

|

| NG |

|

|

5. |

REPLACE AIR FUEL RATIO SENSOR (SENSOR 1) |

HINT:

Perform "Inspection After Repair" after replacing the air fuel ratio sensor (sensor 1).

| NEXT |

|

|

6. |

CHECK FOR EXHAUST GAS LEAK |

(a) Check for exhaust gas leaks.

OK:

No gas leaks in exhaust system.

| NG |

|

|

|

7. |

REPLACE AIR FUEL RATIO SENSOR (SENSOR 2) |

HINT:

Perform "Inspection After Repair" after replacing the air fuel ratio sensor (sensor 2).

| NEXT |

|

|

8. |

CHECK FOR EXHAUST GAS LEAK |

(a) Check for exhaust gas leaks.

OK:

No gas leaks in exhaust system.

| NG |

|

|

|

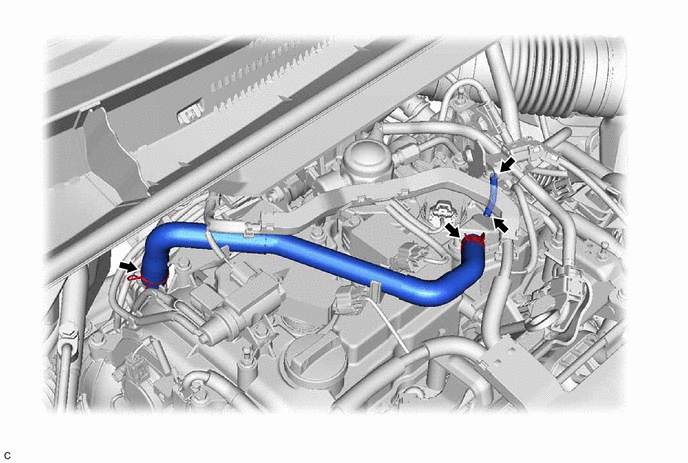

9. |

CHECK PCV VALVE AND HOSE CONNECTIONS |

(a) Check the PCV hose connections.

(b) Check the PCV valve.

OK:

PCV hose and PCV valve are connected correctly and are not damaged.

| NG |

|

REPAIR OR REPLACE PCV VALVE OR HOSE |

|

|

10. |

CHECK INTAKE SYSTEM |

(a) Check the intake system for vacuum leaks.

OK:

No leaks in intake system.

HINT:

Perform "Inspection After Repair" after repairing or replacing the intake system.

| NG |

|

REPAIR OR REPLACE INTAKE SYSTEM |

|

|

11. |

READ VALUE USING GTS (COOLANT TEMPERATURE) |

(a) Read the Data List twice, when the engine is both cold and warmed up.

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Coolant Temperature |

Standard:

|

GTS Display |

Condition |

Specified Condition |

|---|---|---|

|

Coolant Temperature |

Cold engine |

Same as ambient air temperature |

|

Warm engine |

Between 75 and 100°C (167 and 212°F) |

HINT:

Perform "Inspection After Repair" after replacing the engine coolant temperature sensor.

| NG |

|

|

|

12. |

INSPECT MASS AIR FLOW METER SUB-ASSEMBLY |

| NG |

|

|

|

13. |

CHECK FUEL PRESSURE (FOR LOW PRESSURE SIDE) |

| NG |

|

|

|

14. |

CHECK FUEL PRESSURE (FOR HIGH PRESSURE SIDE) |

| NG |

|

|

|

15. |

INSPECT IGNITION SYSTEM |

HINT:

- If the spark plugs or ignition system malfunctions, engine misfire may occur. The misfire count can be read using the GTS. Enter the following menus: Powertrain / Engine / Data List / Misfire Count Cylinder #1 to Misfire Count Cylinder #3.

- Perform "Inspection After Repair" after repairing or replacing the ignition system.

| NG |

|

REPAIR OR REPLACE IGNITION SYSTEM |

|

|

16. |

INSPECT PORT FUEL INJECTOR ASSEMBLY |

(a) Inspect the port fuel injector assembly (whether fuel volume is high or low, and whether injection pattern is poor).

HINT:

Perform "Inspection After Repair" after replacing the port fuel injector assembly.

| NG |

|

|

|

17. |

INSPECT DIRECT FUEL INJECTOR ASSEMBLY |

HINT:

Perform "Inspection After Repair" after replacing the direct fuel injector assembly.

| NG |

|

|

|

18. |

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY CONNECTOR CONNECTION) |

(a) Check the connection and terminal contact pressure of connectors and wire harnesses between the mass air flow meter sub-assembly and ECM.

HINT:

Repair any problems.

|

|

19. |

CLEAR DTC |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

|

|

20. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P042000) |

(a) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(b) Read the DTCs.

Powertrain > Engine > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTCs are not output |

A |

|

P042000 is output |

B |

| A |

|

END |

|

|

21. |

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY - ECM) |

(a) Disconnect the mass air flow meter sub-assembly connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C26-3(VCC) - C142-84(VCVG) |

Always |

Below 1 Ω |

|

C26-1(FG) - C142-107(VG) |

Always |

Below 1 Ω |

|

C26-2(E2G) - C142-83(E2G) |

Always |

Below 1 Ω |

|

C26-3(VCC) or C142-84(VCVG) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C26-1(FG) or C142-107(VG) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C26-2(E2G) or C142-83(E2G) - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

22. |

REPLACE MASS AIR FLOW METER SUB-ASSEMBLY |

HINT:

|

|

23. |

CLEAR DTC |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

|

|

24. |

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

(a) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(b) Read the DTCs.

Powertrain > Engine > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTCs are not output |

A |

|

P042000 is output |

B |

| A |

|

END |

| B |

|

|

25. |

CHECK FUEL LINE |

(a) Check the fuel lines for leaks or blockage.

| OK |

|

| NG |

|

REPAIR OR REPLACE FUEL SYSTEM |

|

26. |

REPAIR OR REPLACE EXHAUST SYSTEM |

HINT:

Perform "Inspection After Repair" after repairing or replacing the exhaust system.

|

|

27. |

CLEAR DTC |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

|

|

28. |

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

(a) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(b) Read the DTCs.

Powertrain > Engine > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTCs are not output |

A |

|

P042000 is output |

B |

| A |

|

END |

|

|

29. |

REPLACE EXHAUST MANIFOLD (TWC: FRONT CATALYST) AND FRONT EXHAUST PIPE ASSEMBLY (TWC: REAR CATALYST) |

NOTICE:

When replacing the exhaust manifold and the front exhaust pipe assembly in order to replace the three-way catalytic converter, it is not necessary to replace the air fuel ratio sensor (sensor 1) and the air fuel ratio sensor (sensor 2).

HINT:

Confirm the replacement parts, referring to the illustration in the Catalyst Location.

(a) Replace the exhaust manifold (TWC: Front catalyst).

(b) Replace the front exhaust pipe assembly (TWC: Rear catalyst).

| NEXT |

|

END |

|

30. |

CHECK FOR EXHAUST GAS LEAK |

OK:

No gas leaks in exhaust system.

HINT:

Perform "Inspection After Repair" after repairing or replacing the exhaust system.

| NG |

|

REPAIR OR REPLACE EXHAUST SYSTEM |

|

|

31. |

REPLACE AIR FUEL RATIO SENSOR (SENSOR 2) |

HINT:

Perform "Inspection After Repair" after replacing the air fuel ratio sensor (sensor 2).

|

|

32. |

CLEAR DTC |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

|

|

33. |

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

(a) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(b) Check for DTCs.

Powertrain > Engine > Trouble Codes

DTCs are not output.

| NEXT |

|

END |

|

|

|

![2023 - 2025 MY GR Corolla [09/2022 - ]; G16E-GTS (ENGINE CONTROL): SFI SYSTEM: CHECKING MONITOR STATUS](/t3Portal/stylegraphics/info.gif)