- When ignition switch ON, total misfire count of all cylinders in last driving cycle is displayed.

- While engine is running, total misfire count of all cylinders in current driving cycle is displayed.

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM10000000255U7 |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [09/2022 - ] |

| Title: G16E-GTS (ENGINE CONTROL): SFI SYSTEM: P030000,P030027,P030085-P030300; Random/Multiple Cylinder Misfire Detected; 2023 - 2025 MY GR Corolla [09/2022 - ] | ||

|

DTC |

P030000 |

Random/Multiple Cylinder Misfire Detected |

|

DTC |

P030027 |

Random/Multiple Cylinder Misfire Detected (Emission) Signal Rate of Change Above Threshold |

|

DTC |

P030085 |

Random / Multiple Cylinder Misfire Detected (Over Temperature) Signal Above Allowable Range |

|

DTC |

P030100 |

Cylinder 1 Misfire Detected |

|

DTC |

P030200 |

Cylinder 2 Misfire Detected |

|

DTC |

P030300 |

Cylinder 3 Misfire Detected |

DESCRIPTION

When the engine misfires, high concentrations of hydrocarbons (HC) enter the exhaust gas. Extremely high hydrocarbon concentration levels can cause an increase in exhaust emission levels. Extremely high concentrations of hydrocarbons can also cause increases in the three-way catalytic converter temperature, which may cause damage to the three-way catalytic converter. To prevent this increase in emissions and to limit the possibility of thermal damage, the ECM monitors the misfire count. When the temperature of the three-way catalytic converter reaches the point of thermal degradation, the ECM blinks the MIL. To monitor misfires, the ECM uses both the camshaft position sensor and the crankshaft position sensor. The camshaft position sensor is used to identify any misfiring cylinders and the crankshaft position sensor is used to measure variations in the crankshaft rotation speed. Misfires are counted when the crankshaft rotation speed variations exceed predetermined thresholds. If the misfire count exceeds the threshold levels, and could cause emission control system performance deterioration, the ECM illuminates the MIL and stores a DTC.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Note |

|---|---|---|---|---|---|

|

P030000 |

Random/Multiple Cylinder Misfire Detected |

Simultaneous misfiring of several cylinders occurs and one of the following conditions is met (2 trip detection logic):

|

|

Comes on/Blinks* *: The MIL flashes when a catalyst-damaging misfire is detected. |

SAE Code: P0300 |

|

P030027 |

Random/Multiple Cylinder Misfire Detected (Emission) Signal Rate of Change Above Threshold |

An emission deterioration misfire occurs (2 trip detection logic). |

|

Comes on |

SAE Code: - |

|

P030085 |

Random / Multiple Cylinder Misfire Detected (Over Temperature) Signal Above Allowable Range |

A misfire occurs that may damage the three-way catalytic converter (2 trip detection logic). |

|

Comes on/Blinks* *: The MIL flashes when a catalyst-damaging misfire is detected. |

SAE Code: - |

|

P030100 |

Cylinder 1 Misfire Detected |

Misfiring of a specific cylinder occurs and one of the following conditions is met (2 trip detection logic):

|

|

Comes on/Blinks* *: The MIL flashes when a catalyst-damaging misfire is detected. |

SAE Code: P0301 |

|

P030200 |

Cylinder 2 Misfire Detected |

Misfiring of a specific cylinder occurs and one of the following conditions is met (2 trip detection logic):

|

|

Comes on/Blinks* *: The MIL flashes when a catalyst-damaging misfire is detected. |

SAE Code: P0302 |

|

P030300 |

Cylinder 3 Misfire Detected |

Misfiring of a specific cylinder occurs and one of the following conditions is met (2 trip detection logic):

|

|

Comes on/Blinks* *: The MIL flashes when a catalyst-damaging misfire is detected. |

SAE Code: P0303 |

When DTCs for misfiring cylinders are randomly stored, but DTC P030000 is not stored, it indicates that misfires have been detected in different cylinders at different times. DTC P030000 is only stored when several misfiring cylinders are detected at the same time.

MONITOR DESCRIPTION

The ECM illuminates the MIL and stores a DTC when either one of the following conditions, which could cause emission deterioration, is detected (2 trip detection logic).

- Within the first 1000 crankshaft revolutions after the engine starts, an excessive number of misfires (approximately 10 to 70 misfires per 1000 crankshaft revolutions) occurs once.

- An excessive number of misfires (approximately 10 to 70 misfires per 1000 crankshaft revolutions) occurs a total of 4 times.

The ECM flashes the MIL (immediate detection logic) and stores a DTC (2 trip detection logic) when either one of the following conditions, which could cause damage to the three-way catalytic converter, is detected.

- At a high engine speed, a sufficient amount of misfires to damage the catalyst occurring within 200 crankshaft revolutions is detected once.

- At a normal engine speed, a sufficient amount of misfires to damage the catalyst occurring within 200 crankshaft revolutions is detected 3 times.

MONITOR STRATEGY

|

Related DTCs |

P0300: Multiple cylinder misfire P0301: Cylinder 1 misfire P0302: Cylinder 2 misfire P0303: Cylinder 3 misfire |

|

Required Sensors/Components (Main) |

Crankshaft position sensor Camshaft position sensor |

|

Required Sensors/Components (Related) |

Engine coolant temperature Intake air temperature sensor (mass air flow meter sub-assembly) Mass air flow meter sub-assembly |

|

Frequency of Operation |

Continuous |

|

Duration |

1000 crankshaft revolutions (soon after engine is started: 1 time, other 4 times) (Emission-related misfire) 200 crankshaft revolutions (1 or 3 times) (Catalyst-damaging misfire) |

|

MIL Operation |

2 driving cycles: Emission-related misfire MIL flashes immediate: Catalyst-damaging misfire |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

Misfire

|

Monitor runs whenever the following DTCs are not stored |

P0016 (VVT system - misalignment) P0017 (Exhaust VVT system - misalignment) P0101, P0102, P0103 (Mass air flow meter) P0107, P0108 (Manifold absolute pressure) P0112, P0113 (Intake air temperature sensor) P0117, P0118 (Engine coolant temperature sensor) P0121, P0122, P0123, P0222, P0223, P2135 (Throttle position sensor) P0125 (Insufficient coolant temperature for closed loop fuel control) P0327, P0328 (Knock control sensor) P0335, P0337, P0338 (Crankshaft position sensor) P0340, P0342, P0343 (Camshaft position sensor) P0365, P0367, P0368 (Exhaust camshaft position sensor) P0500 (Vehicle speed sensor) |

|

Battery voltage |

8 V or higher |

|

VVT system |

Not operated by scan tool |

|

Engine speed |

850 to 7000 rpm |

|

Either of the following conditions is met |

(a) or (b) |

|

(a) Engine coolant temperature at engine start |

Higher than -10°C (14°F) |

|

(b) Engine coolant temperature |

Higher than 20°C (68°F) |

|

Fuel cut |

Off |

Monitor Period of Emission-related Misfire

|

First 1000 revolutions after engine start, or during check mode |

Crankshaft 1000 revolutions |

|

Except above |

Crankshaft 1000 revolutions x 4 |

Monitor Period of Catalyst-damaging Misfire (MIL Blinks)

|

All of the following conditions 1, 2, 3 and 4 are met |

Crankshaft 200 revolutions x 3 |

|

Except above (MIL blinks immediately) |

Crankshaft 200 revolutions |

|

1. Driving cycles |

1st |

|

2. Check mode |

Off |

|

3. Engine speed |

Less than 4963 rpm |

|

4. Engine load |

Less than 157% |

TYPICAL MALFUNCTION THRESHOLDS

Monitor Period of Emission-related Misfire

|

Misfire rate |

2.25% or higher |

Monitor Period of Catalyst-damaging Misfire (MIL Blinks)

|

Number of misfires per 200 revolutions |

81 or more (varies with engine speed and engine load) |

MONITOR RESULT

Refer to detailed information in Checking Monitor Status.

P0300: Misfire / EWMA MISFIRE

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$A1 |

$0B |

Multiply by 1 |

Count |

Total EWMA* misfire count of all cylinders in last ten driving cycles |

P0300: Misfire / MISFIRE RATE

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$A1 |

$0C |

Multiply by 1 |

Count |

|

P0301: Misfire / EWMA MISFIRE1

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$A2 |

$0B |

Multiply by 1 |

Count |

Total EWMA* misfire count of cylinder 1 in last ten driving cycles |

P0301: Misfire / MISFIRE RATE1

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$A2 |

$0C |

Multiply by 1 |

Count |

|

P0302: Misfire / EWMA MISFIRE2

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$A3 |

$0B |

Multiply by 1 |

Count |

Total EWMA* misfire count of cylinder 2 in last ten driving cycles |

P0302: Misfire / MISFIRE RATE2

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$A3 |

$0C |

Multiply by 1 |

Count |

|

P0303: Misfire / EWMA MISFIRE3

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$A4 |

$0B |

Multiply by 1 |

Count |

Total EWMA* misfire count of cylinder 3 in last ten driving cycles |

P0303: Misfire / MISFIRE RATE3

|

Monitor ID |

Test ID |

Scaling |

Unit |

Description |

|---|---|---|---|---|

|

$A4 |

$0C |

Multiply by 1 |

Count |

|

HINT:

*: EWMA (Exponential Weighted Moving Average) misfire counts for last 10 driving cycles (calculated) Calculation: 0.1 x (current counts) + 0.9 x (previous average)

Initial value for (previous average) = 0

CONFIRMATION DRIVING PATTERN

HINT:

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON.

- Turn the GTS on.

- Record the DTC(s) and Freeze Frame Data.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Using the GTS, switch the ECM from normal mode to check mode.

- Start the engine.

- Read the misfire counts of each cylinder, Misfire Count Cylinder #1 to Misfire Count Cylinder #3, with the engine idling. If any misfire count is displayed, skip the following confirmation driving pattern.

-

Drive the vehicle so that the vehicle conditions displayed in Misfire RPM and Misfire Load of the Data List are the same as the Freeze Frame Data. Perform this step several times.

HINT:

In order to store misfire DTCs, it is necessary to operate the vehicle for the period of time shown in the table below, confirm the Misfire RPM and Misfire Load in the Data List.

Engine speed

Duration

Idling

4.5 minutes or more

2000

2.5 minutes or more

3000

1.5 minutes or more

-

Check whether misfires have occurred by checking DTCs and Freeze Frame Data.

HINT:

Do not turn the ignition switch off until the output DTC(s) and Freeze Frame Data have been recorded. When the ECM returns to normal mode (default), the stored DTC(s), Freeze Frame Data and other data are cleared.

- Record the DTC(s), Freeze Frame Data and misfire counts.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

WIRING DIAGRAM

Refer to DTC P010012 for the mass air flow meter sub-assembly circuit.

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

HINT:

-

Check the "Fuel Cut Elapsed Time" in the Data List or the Freeze Frame Data.

If the elapsed time is over 0 seconds, then the engine speed is high (engine speed at which fuel cut occurs + 500 rpm).

When this has happened, there is the possibility that the No. 1 valve rocker arm sub-assembly will become loose and a fire could start, so check that the No. 1 valve rocker arm sub-assembly is properly attached.

- By clearing the DTCs, "Fuel Cut Elapsed Time" will be cleared.

-

In the past, when the primary ignition system (the igniter drive circuit in the ECM, the primary circuit in the ignition coil assembly, the related wire harness, or the connector) was out of order, diagnostic codes from P035113 to P035613 were output. However, these codes are not output in this vehicle.

When a failure in the primary ignition system is suspected, refer to "Catalyst OT Misfire Fuel Cut History", "Catalyst OT Misfire Fuel Cut Cylinder #1 to #3", and "Misfire Count Cylinder #1 to #3" in the Freeze Frame Data, the pending Freeze Frame Data, and the Data List, and confirm in which cylinder the high-frequency misfire was concentrated.

-

Referring to the following contents of the Freeze Frame Data (or the pending Freeze Frame Data) enables an estimation of which cylinder has misfired and to what degree.

- Misfire Count Cylinder #1 to #3: Misfire count according to cylinder.

- Catalyst OT Misfire Fuel Cut Cylinder #1 to #3: This expresses a high-frequency misfire was concentrated in a certain cylinder and that cylinder's fuel injection was stopped.

- If any DTCs other than misfire DTCs are output, troubleshoot those DTCs first.

- If the misfire does not recur when the vehicle is brought to the workshop, reproduce the conditions stored in the ECM as Freeze Frame Data.

-

If the misfire still cannot be reproduced even though the conditions stored in the ECM as Freeze Frame Data have been reproduced, one of the following factors is considered to be a possible cause of the problem:

- There was insufficient fuel in the tank.

- Improper fuel was used.

- The spark plugs have been contaminated.

- The problem requires further diagnosis.

- After finishing repairs, check the misfire counts of the cylinders (Misfire Count Cylinder #1 to Misfire Count Cylinder #3).

- Be sure to confirm that no misfiring cylinder DTCs are stored again by performing the confirmation driving pattern after finishing repairs.

-

For 6 cylinder engine, the ECM intentionally does not set the specific misfiring cylinder DTCs at high engine speed. If misfires occur only in high engine speed areas, only DTC P030000 is set.

In the event of DTC P030000 being present, perform the following operations:

- Clear the DTCs.

- Start the engine and conduct the confirmation driving pattern.

- Read the misfiring counts of each cylinder or DTC(s) using the GTS.

- Repair the cylinder(s) that has a high misfiring rate or is indicated by the DTC.

- After finishing repairs, conduct the confirmation driving pattern again, in order to verify that DTC P030000 is not set.

- When one of Short FT B1S1, Long FT B1S1 in the Freeze Frame Data is outside the range of +/-20%, the air fuel ratio may be rich (-20% or less) or lean (+20% or higher).

- When Coolant Temperature in the Freeze Frame Data is less than 75°C (167°F), the misfires have occurred only while warming up the engine.

- Vehicle body vibration caused by an extremely imbalanced drive wheel may cause misfire DTCs to be stored.

- When a torsional characteristic abnormality has occurred in the flywheel sub-assembly, misfire DTCs may be stored when idling.

- Read Freeze Frame Data using the GTS. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

|

1. |

CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO MISFIRE DTCS) |

(a) Read the DTCs.

Powertrain > Engine > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

P030000, P030027, P030085, P030100, P030200 and/or P030300 are output |

A |

|

P030000, P030027, P030085, P030100, P030200 and/or P030300 and other DTCs are output |

B |

HINT:

If any DTCs other than P030000, P030027, P030085, P030100, P030200 and/or P030300 are output, troubleshoot those DTCs first.

| B |

|

GO TO DTC CHART |

|

|

2. |

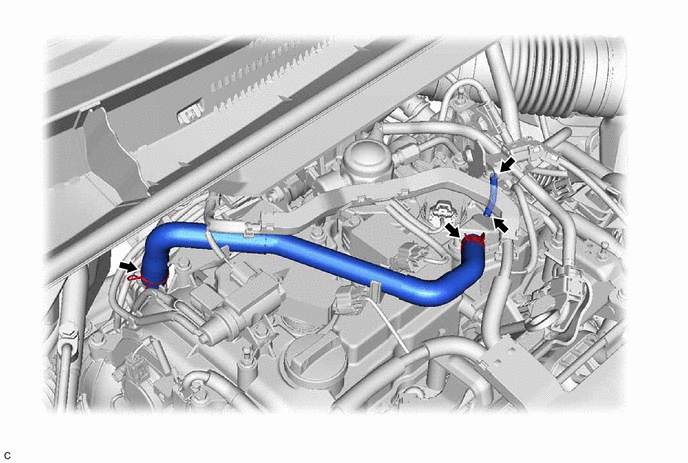

CHECK PCV VALVE AND HOSE CONNECTIONS |

(a) Check the PCV hose connections.

(b) Check the PCV valve.

OK:

PCV hose and PCV valve are connected correctly and are not damaged.

| NG |

|

REPAIR OR REPLACE PCV VALVE OR HOSE |

|

|

3. |

READ VALUE USING GTS (MISFIRE RPM AND MISFIRE LOAD) |

(a) Enter the following menus.

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Misfire RPM |

|

Misfire Load |

(b) Read and note the Misfire RPM and Misfire Load values.

HINT:

The Misfire RPM and Misfire Load values indicate the vehicle conditions under which the misfire occurred.

|

|

4. |

READ VALUE USING GTS (CATALYST OT MISFIRE FUEL CUT) |

(a) Enter the following menus.

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Catalyst OT Misfire Fuel Cut |

(b) Read the value displayed on the GTS.

|

Data List |

Result |

Proceed to |

|---|---|---|

|

Catalyst OT Misfire Fuel Cut |

Avail |

A |

|

Not Avl |

B |

| B |

|

|

|

5. |

READ FREEZE FRAME DATA (CATALYST OT MISFIRE FUEL CUT HISTORY) |

(a) Using the GTS, confirm the vehicle conditions recorded in the Freeze Frame Data which were present when the DTC was stored.

|

Freeze Frame Data Item |

Result |

Proceed to |

|---|---|---|

|

Catalyst OT Misfire Fuel Cut History |

ON |

A |

|

OFF |

B |

| B |

|

|

|

6. |

CHECK MISFIRE COUNT OF PORT INJECTION |

(a) Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher.

(b) Enter the following menus.

Powertrain > Engine > Active Test

|

Active Test Display |

|---|

|

Prohibit the Catalyst OT Misfire Prevent Fuel Cut |

|

Data List Display |

|---|

|

Injection Mode |

|

Misfire Count Cylinder #1 |

|

Misfire Count Cylinder #2 |

|

Misfire Count Cylinder #3 |

(c) Read each value for Misfire Count Cylinder #1 to Misfire Count Cylinder #3 and Injection Mode displayed on the GTS while performing the Active Test.

|

Injection Mode |

Misfire Count |

Proceed to |

|---|---|---|

|

Port |

1 or 2 cylinders have misfire counts |

A |

|

3 cylinders or more have misfire counts |

||

|

There are no misfire counts |

B |

| A |

|

| B |

|

|

7. |

CHECK MISFIRE COUNT OF PORT INJECTION |

(a) Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher.

(b) Enter the following menus.

Powertrain > Engine > Active Test

|

Active Test Display |

|---|

|

Control the Injection Mode |

|

Data List Display |

|---|

|

Injection Mode |

|

Misfire Count Cylinder #1 |

|

Misfire Count Cylinder #2 |

|

Misfire Count Cylinder #3 |

(c) According to the display on the GTS, read the Data List with the Active Test "Control the Injection Mode" set to Port. If no misfire counts occur in any cylinders, perform procedure [A] and [B] and then check the misfire counts again.

(1) Drive the vehicle with the Misfire RPM and Misfire Load noted in the "Read Value Using GTS (Misfire RPM and Misfire Load)" procedures above [A].

(2) Read the Injection Mode and Misfire Count Cylinder #1 to Misfire Count Cylinder #3 or DTCs displayed on the GTS [B].

|

Injection Mode |

Misfire Count |

Proceed to |

|---|---|---|

|

Port |

1 or 2 cylinders have misfire counts |

A |

|

3 cylinders or more have misfire counts |

||

|

There are no misfire counts |

B |

| B |

|

|

|

8. |

CHECK MISFIRE COUNT OF DIRECT INJECTION |

(a) Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher.

(b) Enter the following menus.

Powertrain > Engine > Active Test

|

Active Test Display |

|---|

|

Control the Injection Mode |

|

Data List Display |

|---|

|

Injection Mode |

|

Misfire Count Cylinder #1 |

|

Misfire Count Cylinder #2 |

|

Misfire Count Cylinder #3 |

(c) According to the display on the GTS, read the Data List with the Active Test "Control the Injection Mode" set to Direct. If no misfire counts occur in any cylinders, perform procedure [A] and [B] and then check the misfire counts again.

(1) Drive the vehicle with the Misfire RPM and Misfire Load noted in the "Read Value Using GTS (Misfire RPM and Misfire Load)" procedures above [A].

(2) Read the Injection Mode and Misfire Count Cylinder #1 to Misfire Count Cylinder #3 or DTCs displayed on the GTS [B].

|

Misfire Count |

Proceed to |

|

|---|---|---|

|

Port (Result of step 6 or 7) |

Direct |

|

|

1 or 2 cylinders have misfire counts |

1 or 2 cylinders have misfire counts |

A |

|

3 cylinders or more have misfire counts |

3 cylinders or more have misfire counts |

B |

|

1 or 2 cylinders have misfire counts |

There are no misfire counts |

C |

|

3 cylinders or more have misfire counts |

There are no misfire counts |

D |

HINT:

Perform "Inspection After Repair" after replacing the port fuel injector assembly.

| A |

|

| B |

|

| C |

|

|

|

9. |

CHECK FUEL PRESSURE (FOR LOW PRESSURE SIDE) |

HINT:

Perform "Inspection After Repair" after replacing the port fuel injector assembly.

| OK |

|

|

|

10. |

CHECK FUEL LINE |

(a) Check the fuel lines for leaks or blockage.

HINT:

Perform "Inspection After Repair" after replacing the fuel pump (for low pressure side).

| OK |

|

| NG |

|

REPAIR OR REPLACE FUEL SYSTEM |

|

11. |

CHECK MISFIRE COUNT OF DIRECT INJECTION |

(a) Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher.

(b) Enter the following menus.

Powertrain > Engine > Active Test

|

Active Test Display |

|---|

|

Control the Injection Mode |

|

Data List Display |

|---|

|

Injection Mode |

|

Misfire Count Cylinder #1 |

|

Misfire Count Cylinder #2 |

|

Misfire Count Cylinder #3 |

(c) According to the display on the GTS, read the Data List with the Active Test "Control the Injection Mode" set to Direct. If no misfire counts occur in any cylinders, perform procedure [A] and [B] and then check the misfire counts again.

(1) Drive the vehicle with the Misfire RPM and Misfire Load noted in the "Read Value Using GTS (Misfire RPM and Misfire Load)" procedures above [A].

(2) Read the Injection Mode and Misfire Count Cylinder #1 to Misfire Count Cylinder #3 or DTCs displayed on the GTS [B].

|

Misfire Count |

Proceed to |

|

|---|---|---|

|

Port (Result of step 6 or 7) |

Direct |

|

|

There are no misfire counts |

There are misfire counts |

A |

|

There are no misfire counts |

There are no misfire counts |

B |

HINT:

Perform "Inspection After Repair" after replacing the direct fuel injector assembly.

| A |

|

|

|

12. |

CLEAR DTC |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

|

|

13. |

CHECK MISFIRE COUNT |

(a) Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher.

(b) Enter the following menus.

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Injection Mode |

|

Misfire Count Cylinder #1 |

|

Misfire Count Cylinder #2 |

|

Misfire Count Cylinder #3 |

|

Misfire RPM |

|

Misfire Load |

(c) Drive the vehicle with Misfire RPM and Misfire Load.

(d) Monitor all of the misfire count values and Injection Mode displayed on the GTS.

|

Misfire Count |

Injection Mode |

Proceed to |

|---|---|---|

|

There are no misfire counts |

- |

A |

|

1 or 2 cylinders have misfire counts |

Port or Either |

B |

|

3 cylinders or more have misfire counts |

Port or Either |

C |

|

There are misfire counts |

Direct |

D |

HINT:

Perform "Inspection After Repair" after replacing the direct fuel injector assembly.

| A |

|

| C |

|

| D |

|

|

|

14. |

INSPECT SPARK PLUG |

(a) Inspect the spark plug of the misfiring cylinder.

HINT:

Perform "Inspection After Repair" after replacing the spark plug.

| NG |

|

|

|

15. |

CHECK FOR SPARK (SPARK TEST) |

HINT:

|

|

16. |

CHECK CYLINDER COMPRESSION PRESSURE |

(a) Measure the cylinder compression pressure of the misfiring cylinder.

HINT:

Perform "Inspection After Repair" after repairing or replacing the engine assembly.

| OK |

|

| NG |

|

CHECK ENGINE TO DETERMINE CAUSE OF LOW COMPRESSION |

|

17. |

CHECK INTAKE SYSTEM |

(a) Check the intake system for vacuum leaks.

OK:

No leaks from intake system.

HINT:

Perform "Inspection After Repair" after repairing or replacing the intake system.

| NG |

|

REPAIR OR REPLACE INTAKE SYSTEM |

|

|

18. |

READ VALUE USING GTS (COOLANT TEMPERATURE) |

(a) Enter the following menus.

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Coolant Temperature |

(b) Read the Data List twice, when the engine is both cold and warmed up.

Standard:

|

GTS Display |

Condition |

Specified Condition |

|---|---|---|

|

Coolant Temperature |

Cold engine |

Same as ambient air temperature |

|

After fully warming up |

Between 75 and 105°C (167 and 221°F) |

HINT:

- The engine can be judged as fully warmed up after warming up the engine with the air conditioning off until the electric cooling fan starts to operate.

- Leaving the vehicle overnight allows the engine temperature to be the same as the ambient temperature.

- Perform "Inspection After Repair" after replacing the engine coolant temperature sensor.

| NG |

|

|

|

19. |

INSPECT MASS AIR FLOW METER SUB-ASSEMBLY |

| NG |

|

|

|

20. |

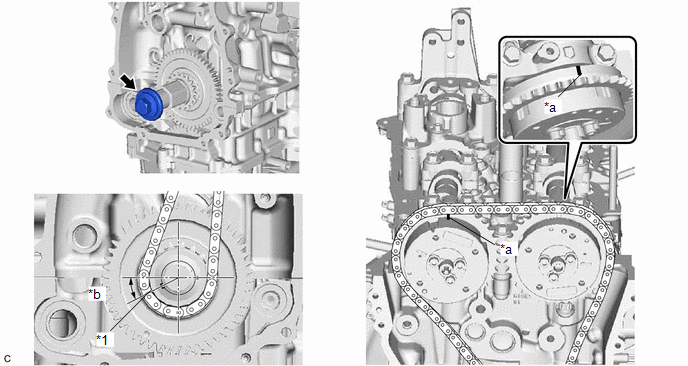

CHECK VALVE TIMING (CHECK FOR LOOSE AND JUMPED TEETH ON TIMING CHAIN) |

|

*1 |

Crankshaft Timing Gear Key |

- |

- |

|

*a |

Timing Mark |

*b |

Approximately 27° |

(a) Remove the cylinder head cover sub-assembly and timing chain cover assembly.

(b) Temporarily install the crankshaft pulley bolt.

(c) Rotate the crankshaft in the correct direction until the timing mark of the camshaft timing gear assembly and camshaft timing exhaust gear assembly are located at the top.

(d) Check that the crankshaft timing gear key as shown in the illustration.

HINT:

If the crankshaft timing gear key moves from the position shown in the illustration, check for mechanical malfunctions that affect the valve timing, such as a jumped tooth or stretching of the timing chain.

(e) Remove the crankshaft pulley bolt.

HINT:

As the exhaust camshaft sub-assembly may rotate counterclockwise strongly when the crankshaft pulley set bolt is removed, use a wrench to hold the hexagonal portion of the exhaust camshaft sub-assembly.

|

|

21. |

CHECK ENGINE MECHANICAL SYSTEM |

(a) Inspect the components that affect the valve timing.

HINT:

Perform the following inspections.

- Chain sub-assembly

- Camshaft timing gear assembly

- Camshaft timing exhaust gear assembly

- Crankshaft timing gear or sprocket

- No. 1 chain tensioner assembly

- Chain tensioner slipper

- No. 1 chain vibration damper

| OK |

|

| NG |

|

REPAIR OR REPLACE MALFUNCTIONING PARTS, COMPONENT AND AREA |

|

22. |

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY CONNECTOR CONNECTION) |

(a) Check the connection and terminal contact pressure of connectors and wire harnesses between the mass air flow meter sub-assembly and ECM.

HINT:

Repair any problems.

|

|

23. |

CLEAR DTC |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

|

|

24. |

CHECK WHETHER DTC OUTPUT RECURS (MISFIRE DTCS) |

(a) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(b) Enter the following menus.

Powertrain > Engine > Utility

|

Tester Display |

|---|

|

All Readiness |

(c) Input the DTC: P030000, P030027, P030085, P030100, P030200 and/or P030300.

(d) Check the DTC judgment result.

|

Result |

Proceed to |

|---|---|

|

NORMAL (DTCs are not output) |

A |

|

ABNORMAL (P030000, P030027, P030085, P030100, P030200 and/or P030300 is output) |

B |

| A |

|

END |

|

|

25. |

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER SUB-ASSEMBLY - ECM) |

(a) Disconnect the mass air flow meter sub-assembly connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C26-3(VCC) - C142-84(VCVG) |

Always |

Below 1 Ω |

|

C26-1(FG) - C142-107(VG) |

Always |

Below 1 Ω |

|

C26-2(E2G) - C142-83(E2G) |

Always |

Below 1 Ω |

|

C26-3(VCC) or C142-84(VCVG) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C26-1(FG) or C142-107(VG) - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

26. |

REPLACE MASS AIR FLOW METER SUB-ASSEMBLY |

HINT:

|

|

27. |

CLEAR DTC |

(a) Clear the DTCs.

Powertrain > Engine > Clear DTCs

(b) Turn the ignition switch off and wait for at least 30 seconds.

|

|

28. |

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

(a) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(b) Enter the following menus.

Powertrain > Engine > Utility

|

Tester Display |

|---|

|

All Readiness |

(c) Input the DTC: P030000, P030027, P030085, P030100, P030200 and/or P030300.

(d) Check the DTC judgment result.

|

Result |

Proceed to |

|---|---|

|

NORMAL (DTCs are not output) |

A |

|

ABNORMAL (P030000, P030027, P030085, P030100, P030200 and/or P030300 is output) |

B |

| A |

|

END |

| B |

|

|

|

|

![2023 - 2025 MY GR Corolla [09/2022 - ]; G16E-GTS (ENGINE CONTROL): SFI SYSTEM: CHECKING MONITOR STATUS](/t3Portal/stylegraphics/info.gif)