- DTC judgment completed

- System normal

| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM100000001NMPG |

| Model Year Start: 2021 | Model: Corolla | Prod Date Range: [04/2020 - 09/2022] |

| Title: 2ZR-FXE (ENGINE CONTROL): SFI SYSTEM: P043E00,P043F00,P24007E,P24007F,P24187E; Evaporative Emission System Leak Detection Reference Orifice Low Flow; 2021 - 2022 MY Corolla Corolla HV [04/2020 - 09/2022] | ||

|

DTC |

P043E00 |

Evaporative Emission System Leak Detection Reference Orifice Low Flow |

|

DTC |

P043F00 |

Evaporative Emission System Leak Detection Reference Orifice High Flow |

|

DTC |

P24007E |

Evaporative Emission System Leak Detection Pump Control Circuit Actuator Stuck On |

|

DTC |

P24007F |

Evaporative Emission System Leak Detection Pump Control Circuit Actuator Stuck Off |

|

DTC |

P24187E |

Evaporative Emission System Switching Valve Control Circuit Actuator Stuck On |

DTC SUMMARY

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Memory |

Note |

|---|---|---|---|---|---|---|

|

P043E00 |

Evaporative Emission System Leak Detection Reference Orifice Low Flow |

Reference orifice detected as clogged during key-off EVAP monitor. |

|

Comes on |

DTC stored |

|

|

P043F00 |

Evaporative Emission System Leak Detection Reference Orifice High Flow |

Reference orifice flow high during key-off EVAP monitor. |

|

Comes on |

DTC stored |

|

|

P24007E |

Evaporative Emission System Leak Detection Pump Control Circuit Actuator Stuck On |

Leak detection pump on malfunction detected during key-off EVAP monitor. |

|

Comes on |

DTC stored |

|

|

P24007F |

Evaporative Emission System Leak Detection Pump Control Circuit Actuator Stuck Off |

Leak detection pump off malfunction detected during key-off EVAP monitor. |

|

Comes on |

DTC stored |

|

|

P24187E |

Evaporative Emission System Switching Valve Control Circuit Actuator Stuck On |

Vent valve on (closed) malfunction detected during key-off EVAP monitor. |

|

Comes on |

DTC stored |

|

HINT:

The reference orifice is located inside the canister pump module.

|

DTC No. |

Monitoring Item |

Detection Timing |

Detection Logic |

SAE Code |

|---|---|---|---|---|

|

P043E00 |

Reference orifice clogged |

EVAP monitoring (Power switch off) |

2 trip |

P043E |

|

P043F00 |

Reference orifice high-flow |

P043F |

||

|

P24007E |

Leak detection pump stuck ON |

P2402 |

||

|

P24007F |

Leak detection pump stuck OFF |

P2401 |

||

|

P24187E |

Vent valve stuck closed |

P2419 |

DESCRIPTION

Refer to EVAP (Evaporative Emission) System.

MONITOR DESCRIPTION

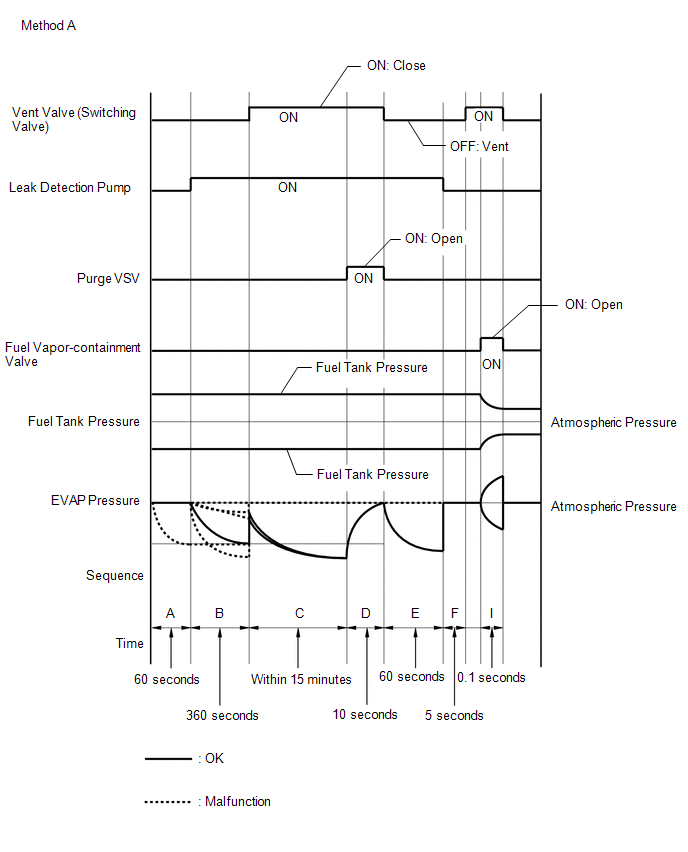

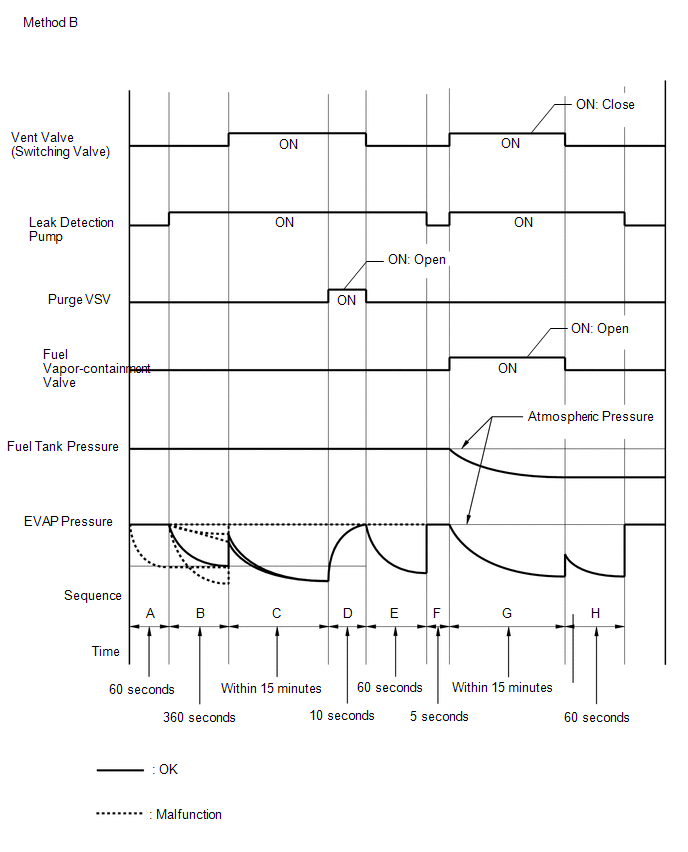

In sequence B and E, the leak detection pump creates negative pressure (vacuum) through the reference orifice. The EVAP system pressure is then measured by the ECM, using the canister pressure sensor, to determine the reference pressure. If the pressure detected meets one of the following conditions, the ECM will illuminated the MIL and store a DTC (2 trip detection logic).

- EVAP pressure is lower than the malfunction criterion.

- EVAP pressure is higher than the malfunction criterion.

- EVAP pressure is not saturated within 60 seconds.

- EVAP pressure difference between sequence B and E is large.

MONITOR STRATEGY

|

Required Sensors/Components (Main) |

Canister pump module |

|

Required Sensors/Components (Related) |

- |

|

Frequency of Operation |

Once per driving cycle |

|

Duration |

Within 7 minutes |

|

MIL Operation |

2 driving cycles |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

Key-off monitor runs when all of the following conditions are met: |

- |

|

Atmospheric pressure |

70 kPa(abs) [10.2 psi(abs)] or higher, and less than 110 kPa(abs) [16 psi(abs)] |

|

Auxiliary battery voltage |

10.5 V or higher |

|

Vehicle speed |

Less than 4 km/h (2.5 mph) |

|

Power switch |

Off |

|

Engine condition |

Not running |

|

Key-OFF duration |

5, 7 or 9.5 hours |

|

Pressure sensor of canister pump module malfunction (P0452 and P0453) |

Not detected |

|

Fuel tank pressure sensor malfunction (P1452 and P1453) |

Not detected |

|

Purge VSV |

Not operated by scan tool |

|

Vent valve |

Not operated by scan tool |

|

Fuel vapor-containment valve |

Not operated by scan tool |

|

Leak detection pump |

Not operated by scan tool |

|

Both of the following conditions (a) and (b) are met before Key-OFF |

- |

|

(a). Duration that vehicle is being driven |

5 minutes or more |

|

(b). Purge flow |

Performed |

|

Engine coolant temperature |

4.4°C (39.9°F) or higher, and less than 35°C (95°F) |

|

Intake air temperature |

4.4°C (39.9°F) or higher, and less than 35°C (95°F) |

TYPICAL MALFUNCTION THRESHOLDS

|

One of following conditions met |

- |

|

EVAP pressure when 1.9 seconds after reference pressure measurement began |

Higher than -0.242 kPa(gauge) [-0.0351 psi(gauge)] |

|

Reference pressure (vary with atmospheric pressure) |

Less than -4.85 kPa(gauge) [-0.7 psi(gauge)] |

|

Reference pressure (vary with atmospheric pressure) |

-1.068 kPa(gauge) [-0.155 psi(gauge)] or higher |

|

Reference pressure (vary with atmospheric pressure) |

Not saturated |

|

Reference pressure difference between the first and second |

0.9 kPa(gauge) [0.1 psi(gauge)] or higher |

MONITOR RESULT

Refer to EVAP System.

CONFIRMATION DRIVING PATTERN

NOTICE:

- The Evaporative System Check (Automatic Mode) consists of 9 steps performed automatically by the Techstream. It takes a maximum of approximately 40 minutes.

- Do not perform the Evaporative System Check when the fuel tank is higher than 90% full because the cut-off valve may be closed, making the fuel tank leak check unavailable.

- Do not start the engine during this operation.

- When the temperature of the fuel is 35°C (95°F) or higher, a large amount of vapor will from and any check result will be inaccurate. When performing the Evaporative System Check, keep the fuel temperature less than 35°C (95°F).

HINT:

- Connect the Techstream to the DLC3.

- Turn the power switch on (IG).

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the power switch off and wait for at least 30 seconds.

- Turn the power switch on (IG) [A].

- Turn the Techstream on.

- Enter the following menus: Powertrain / Engine / Utility / Evaporative System Check / Automatic Mode [B].

- After the "Evaporative System Check" is completed, check for All Readiness by entering the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P043E00, P043F00, P24007E, P24007F or P24187E.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system is malfunctioning.

-

[A] to [B]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- When clearing the permanent DTCs, do not disconnect the cable from the auxiliary battery terminal or attempt to clear the DTCs during this procedure, as doing so will clear the universal trip and normal judgment histories.

CAUTION / NOTICE / HINT

NOTICE:

-

Vehicle Control History may be stored in the hybrid vehicle control ECU if the engine is malfunctioning. Certain vehicle condition information is recorded when Vehicle Control History is stored. Reading the vehicle conditions recorded in both the freeze frame data and Vehicle Control History can be useful for troubleshooting.

- for Nickel Metal Hydride Battery: Click here

![2020 - 2022 MY Corolla Corolla HV [01/2019 - 09/2022]; HYBRID / BATTERY CONTROL: HYBRID CONTROL SYSTEM (for NICKEL METAL HYDRIDE BATTERY): VEHICLE CONTROL HISTORY](/t3Portal/stylegraphics/info.gif)

- for Lithium-ion Battery: Click here

![2021 - 2022 MY Corolla Corolla HV [04/2020 - 09/2022]; HYBRID / BATTERY CONTROL: HYBRID CONTROL SYSTEM (for LITHIUM-ION BATTERY with P610): VEHICLE CONTROL HISTORY](/t3Portal/stylegraphics/info.gif)

(Select Powertrain in Health Check and then check the time stamp data.)

- If any "Engine Malfunction" Vehicle Control History item has been stored in the hybrid vehicle control ECU, make sure to clear it. However, as all Vehicle Control History items are cleared simultaneously, if any Vehicle Control History items other than "Engine Malfunction" are stored, make sure to perform any troubleshooting for them before clearing Vehicle Control History.

PROCEDURE

|

1. |

GO TO EVAP SYSTEM |

(a) Refer to EVAP System.

| NEXT |

|

END |

|

|

|