| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000001N40F |

| Model Year Start: 2021 | Model: Corolla | Prod Date Range: [04/2020 - 09/2022] |

| Title: HYBRID / BATTERY CONTROL: HYBRID CONTROL SYSTEM (for LITHIUM-ION BATTERY with P610): Indicator Circuit; 2021 - 2022 MY Corolla Corolla HV [04/2020 - 09/2022] | ||

|

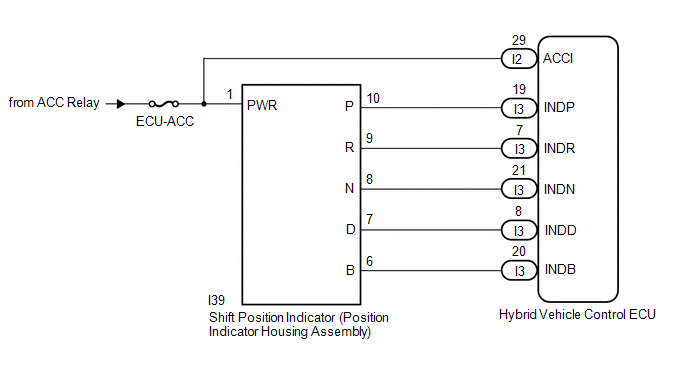

Indicator Circuit |

DESCRIPTION

In accordance with the shift lever position, each shift position indicator light will turn on.

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK POSITION INDICATOR HOUSING ASSEMBLY (SHIFT POSITION INDICATOR) |

(a) Turn the power switch on (ACC).

(b) Check that each shift position indicator light turns on correctly.

|

Result |

Proceed to |

|---|---|

|

All shift position indicator lights turn on simultaneously |

A |

|

Shift position indicator lights other than corresponding one turn on |

B |

|

Corresponding shift position indicator light does not turn on |

C |

|

No shift position indicator lights turn on |

D |

(c) Turn the power switch off.

| A |

|

| C |

|

| D |

|

|

|

2. |

CHECK HARNESS AND CONNECTOR (CHECK FOR SHORT TO GND) |

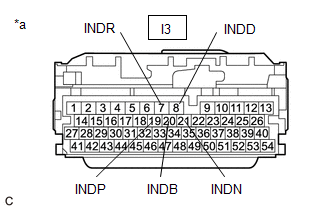

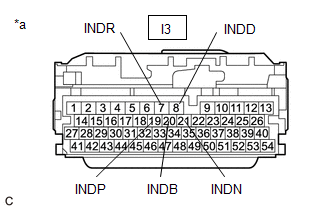

(a) Disconnect the I3 hybrid vehicle control ECU connector.

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(c) Reconnect the I3 hybrid vehicle control ECU connector.

| OK |

|

|

|

3. |

CHECK HARNESS AND CONNECTOR (HYBRID VEHICLE CONTROL ECU - SHIFT POSITION INDICATOR (POSITION INDICATOR HOUSING ASSEMBLY)) |

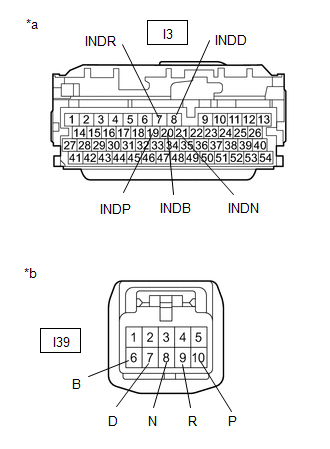

(a) Disconnect the I3 hybrid vehicle control ECU connector.

(b) Disconnect the I39 shift position indicator (position indicator housing assembly) connector.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(d) Reconnect the I39 shift position indicator (position indicator housing assembly) connector.

(e) Reconnect the I3 hybrid vehicle control ECU connector.

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

4. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

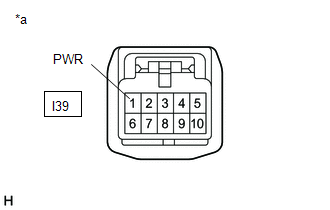

(a) Disconnect the I39 shift position indicator connector.

(b) Turn the power switch on (ACC).

|

(c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

(d) Turn the power switch off.

(e) Reconnect the I39 shift position indicator connector.

| NG |

|

REPAIR OR REPLACE POWER SOURCE CIRCUIT |

|

|

5. |

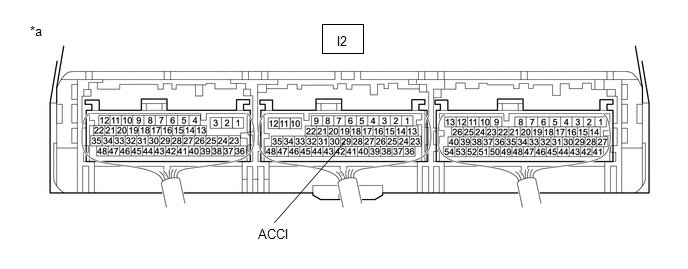

CHECK HARNESS AND CONNECTOR (POWER SOURCE TERMINAL ACCI) |

(a) Turn the power switch on (ACC).

(b) Measure the voltage according to the value(s) in the table below.

|

*a |

Component with harness connected (Hybrid Vehicle Control ECU) |

- |

- |

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I2-29 (ACCI) - Body ground |

Power switch on (ACC) |

11 to 14 V |

(c) Turn the power switch off.

| NG |

|

REPAIR OR REPLACE POWER SOURCE CIRCUIT |

|

|

6. |

CHECK HARNESS AND CONNECTOR (CHECK FOR OPEN) |

(a) Disconnect the I3 hybrid vehicle control ECU connector.

(b) Turn the power switch on (ACC).

|

(c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

(d) Turn the power switch off.

(e) Reconnect the I3 hybrid vehicle control ECU connector.

| OK |

|

|

|

7. |

CHECK HARNESS AND CONNECTOR (HYBRID VEHICLE CONTROL ECU - SHIFT POSITION INDICATOR (POSITION INDICATOR HOUSING ASSEMBLY)) |

(a) Disconnect the I3 hybrid vehicle control ECU connector.

(b) Disconnect the I39 shift position indicator connector.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(d) Reconnect the I39 shift position indicator connector.

(e) Reconnect the I3 hybrid vehicle control ECU connector.

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|