- Wireless Door Lock Control System (for Gasoline Model with Smart Key System)

- Smart Key System (for Gasoline Model, Entry Function)

- Smart Key System (for Gasoline Model, Start Function)

- Steering lock function

| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM100000001HZ8W |

| Model Year Start: 2020 | Model: Corolla Hatchback | Prod Date Range: [03/2019 - 09/2022] |

| Title: M20A-FKS (ENGINE MECHANICAL): REAR CRANKSHAFT OIL SEAL: REMOVAL; 2020 - 2022 MY Corolla Corolla Hatchback [03/2019 - 09/2022] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during engine assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

*1: for Hatchback

*2: w/o Smart Key System *3: w/ Smart Key System |

|||

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Control System (for Gasoline Model) |

|

|

Pre-collision System (for Gasoline Model) |

|||

|

Lighting System (w/ AFS)(EXT) |

|||

|

Initialize back door lock*1 |

Power Door Lock Control System (for Hatchback, Gasoline Model) |

||

|

Replacement of ECM |

Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

||

|

Replacement of ECM*3 |

Code registration (Smart Key System (for Gasoline Model, Start Function)) |

|

|

|

Replacement of ECM*2 |

Code registration (Immobiliser system) |

Engine start |

|

|

Inspection After Repair |

|

|

|

Replacement of continuously variable transaxle assembly |

|

|

|

|

Replacement of ECM |

|

||

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Perform headlight ECU sub-assembly LH initialization |

Lighting system (w/ AFS)(EXT) |

|

|

Front wheel alignment adjustment |

|

|

|

|

CVT fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly |

|

NOTICE:

After the ignition switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the ignition switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Navigation System and Audio and Visual System (for Gasoline Model))

PROCEDURE

1. REMOVE CONTINUOUSLY VARIABLE TRANSAXLE ASSEMBLY (for CVT)

2. REMOVE CLUTCH DISC ASSEMBLY (for Manual Transaxle)

3. REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY (for CVT)

(a) Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat level surface.

NOTICE:

- Using height adjustment attachments and plate lift attachments, keep the engine assembly level.

- To prevent the oil pan sub-assembly from deforming, do not place any attachments under the oil pan sub-assembly of the engine assembly.

- Using an engine sling device and engine lift, secure the engine assembly before servicing.

|

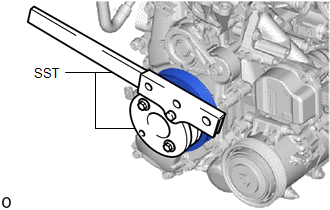

(b) Using SST, hold the crankshaft pulley assembly. SST: 09213-54015 SST: 09330-00021 |

|

|

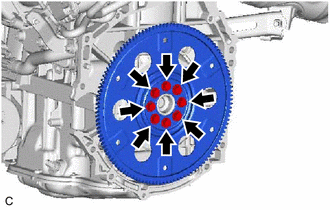

(c) Remove the 8 bolts, rear drive plate spacer, drive plate and ring gear sub-assembly. |

|

4. REMOVE FLYWHEEL SUB-ASSEMBLY (for Manual Transaxle)

|

(a) Using SST, hold the crankshaft pulley assembly. SST: 09213-54015 SST: 09330-00021 |

|

|

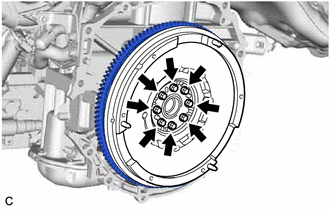

(b) Using a 10 mm hexagon wrench, remove the 8 bolts and flywheel sub-assembly. |

|

5. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE

|

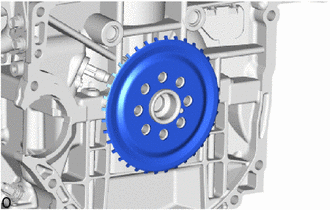

(a) Remove the No. 1 crankshaft position sensor plate. |

|

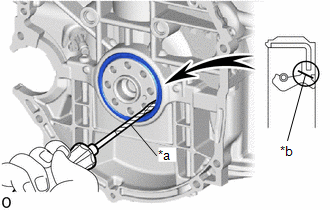

6. REMOVE REAR ENGINE OIL SEAL

|

(a) Using a knife, cut off the lip of the rear engine oil seal. |

|

(b) Using a screwdriver, pry out the rear engine oil seal.

NOTICE:

Do not damage the surface of the rear engine oil seal press fit hole or the crankshaft.

HINT:

Tape the screwdriver tip before use.

|

|

|

![2019 - 2022 MY Corolla Corolla Hatchback GR Corolla [06/2018 - 09/2022]; PRE-COLLISION: PRE-COLLISION SYSTEM (for Gasoline Model): INITIALIZATION](/t3Portal/stylegraphics/info.gif)