| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000001HSCJ |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [03/2019 - 11/2022] |

| Title: 2ZR-FAE (ENGINE MECHANICAL): ENGINE UNIT: DISASSEMBLY; 2020 - 2023 MY Corolla [03/2019 - 11/2022] | ||

DISASSEMBLY

PROCEDURE

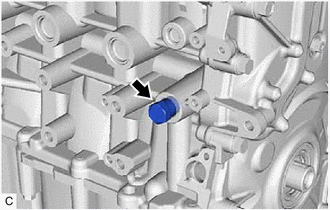

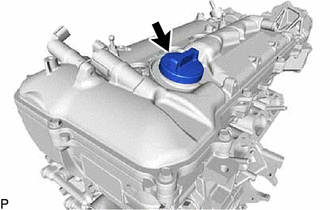

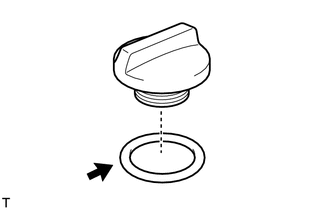

1. REMOVE OIL FILLER CAP SUB-ASSEMBLY

|

(a) Remove the oil filler cap sub-assembly from the cylinder head cover sub-assembly. |

|

2. REMOVE OIL FILLER CAP GASKET

|

(a) Remove the oil filler cap gasket from the oil filler cap sub-assembly. |

|

3. REMOVE SPARK PLUG

4. REMOVE VALVEMATIC SHAFT SENSOR (CAM POSITION SENSOR) (w/ Canister Pump Module)

5. REMOVE CAMSHAFT POSITION SENSOR

6. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

7. REMOVE CRANKSHAFT POSITION SENSOR

8. REMOVE ENGINE OIL PRESSURE SWITCH ASSEMBLY

9. REMOVE KNOCK CONTROL SENSOR

10. REMOVE ENGINE COOLANT TEMPERATURE SENSOR

11. REMOVE CYLINDER HEAD COVER SCREEN (w/o Canister Pump Module)

|

(a) Remove the bolt and cylinder head cover screen from the cylinder head cover sub-assembly. |

|

12. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

|

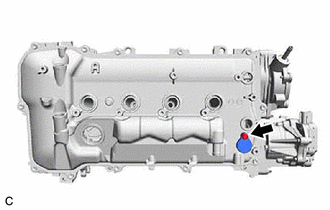

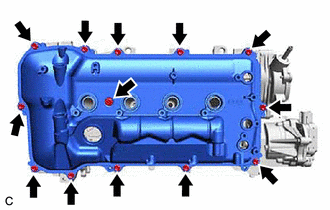

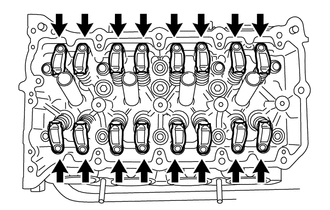

(a) Remove the 13 bolts, seal washer and cylinder head cover sub-assembly. |

|

|

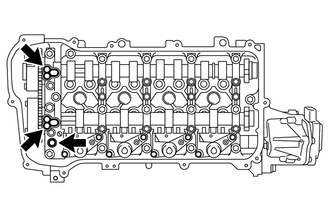

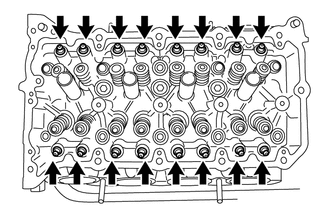

(b) Remove the 3 gaskets from the camshaft bearing cap. NOTICE: As gaskets may stick to the cylinder head cover sub-assembly, be careful not to drop any of the gaskets into the engine when removing the cylinder head cover sub-assembly. |

|

13. REMOVE CYLINDER HEAD COVER GASKET

|

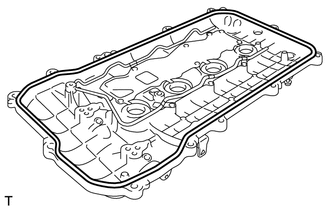

(a) Remove the cylinder head cover gasket. |

|

14. REMOVE SPARK PLUG TUBE GASKET

|

(a) Pry up the 4 claws of the ventilation baffle plate. NOTICE: Do not deform the claws of the ventilation baffle plate more than necessary. |

|

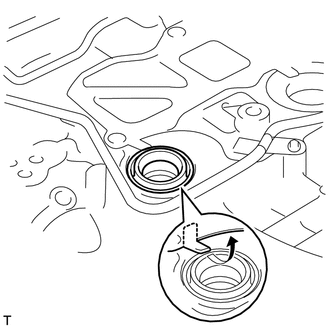

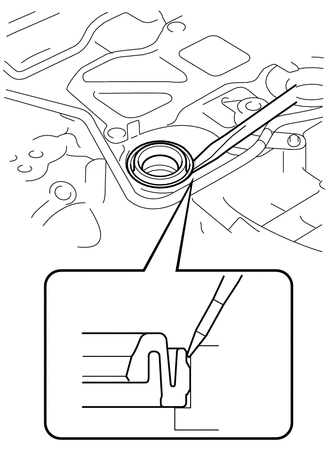

(b) Using a screwdriver as shown in the illustration, deform each spark plug tube gasket inwards and remove the 4 spark plug tube gaskets from the cylinder head cover sub-assembly.

NOTICE:

-

As much as possible prevent the spark plug tube gaskets from being deformed.

The removed spark plug tube gaskets will be used when reinstalling the new spark plug tube gaskets.

- Do not damage the cylinder head cover sub-assembly.

- Make sure not to damage the spark plug tube gasket and cylinder head cover sub-assembly when inserting the screwdriver in the joint area.

HINT:

- If the cylinder head cover sub-assembly is damaged, smooth the surface with 400-grit sandpaper.

- Prevent the spark plug tube gaskets from being deformed as much as possible. The removed spark plug tube gaskets will be used when installing new spark plug tube gaskets.

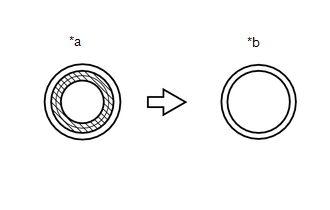

(1) Using a cutter, cut off the sealing part of the removed plug tube gasket.

|

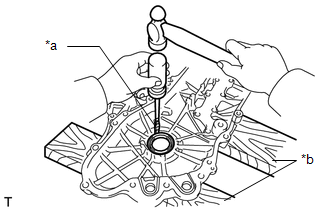

*a |

Before cutting off |

|

*b |

After cutting off |

|

Area to be cut off |

15. REMOVE OIL FILTER SUB-ASSEMBLY

16. REMOVE OIL FILTER UNION

|

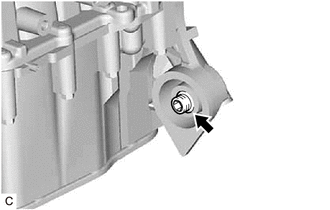

(a) Using a 12 mm hexagon socket wrench, remove the oil filter union from the oil filter bracket. |

|

17. SET NO. 1 CYLINDER TO TDC/COMPRESSION

|

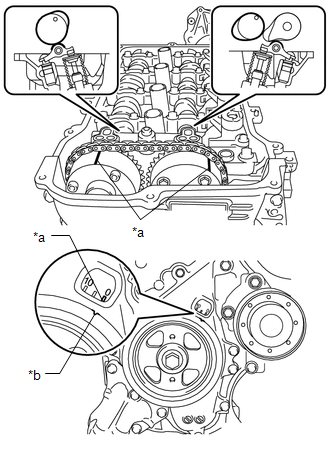

(a) Turn the crankshaft pulley until its timing notch and timing mark "0" of the timing chain cover sub-assembly are aligned. |

|

(b) Check that timing marks on both the camshaft timing exhaust gear assembly and camshaft timing gear assembly are facing upward as shown in the illustration.

HINT:

If not, turn the crankshaft 1 complete revolution (360°) and align the marks as above.

18. REMOVE CRANKSHAFT PULLEY

19. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

|

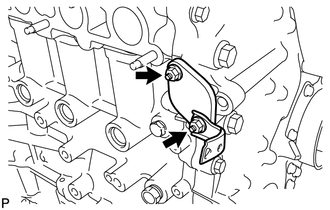

(a) Remove the 2 nuts, bracket, No. 1 chain tensioner assembly and gasket from the timing chain cover sub-assembly. NOTICE: Do not turn the crankshaft without the No. 1 chain tensioner assembly installed. |

|

20. REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

|

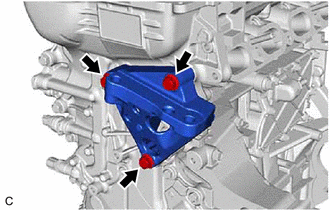

(a) Remove the 3 bolts and engine mounting bracket RH from the timing chain cover sub-assembly. |

|

|

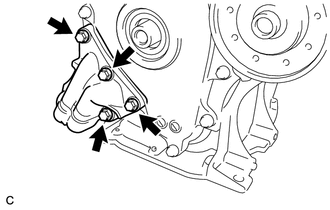

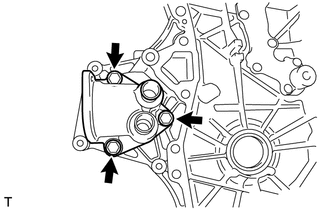

(b) Remove the 4 bolts and oil filter bracket from the timing chain cover sub-assembly. |

|

|

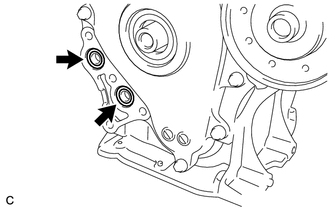

(c) Remove the 2 O-rings from the timing chain cover sub-assembly. |

|

|

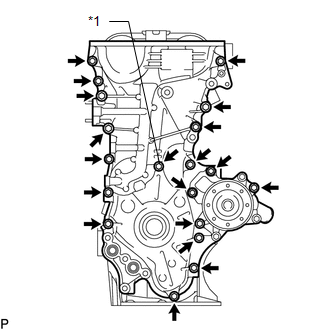

(d) Remove the 19 bolts and seal washer. |

|

|

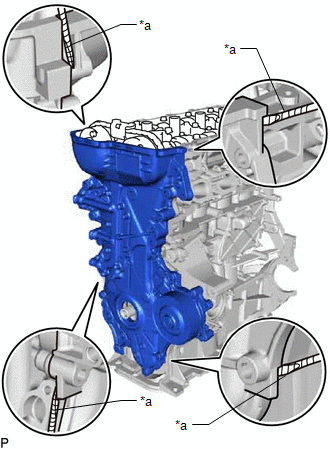

(e) Remove the timing chain cover sub-assembly by prying between the timing chain cover sub-assembly and cylinder head sub-assembly, camshaft housing sub-assembly, cylinder block sub-assembly and stiffening crankcase assembly with a screwdriver as shown in the illustration. NOTICE: Be careful not to damage the contact surfaces of the cylinder head sub-assembly, camshaft housing sub-assembly, cylinder block sub-assembly, stiffening crankcase assembly and timing chain cover sub-assembly. HINT: Tape the screwdriver tip before use. |

|

|

(f) Remove the O-ring from the cylinder block sub-assembly. |

|

(g) Remove the 2 O-rings from the cylinder head sub-assembly.

|

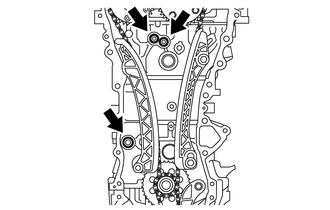

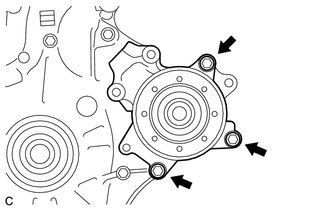

(h) Remove the 3 bolts and engine water pump assembly from the timing chain cover sub-assembly. |

|

|

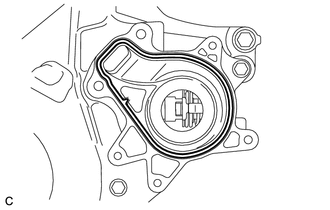

(i) Remove the gasket from the timing chain cover sub-assembly. |

|

21. REMOVE TIMING CHAIN COVER OIL SEAL

|

(a) Using a screwdriver and hammer, remove the timing chain cover oil seal. NOTICE: Be careful not to damage the timing chain cover sub-assembly. HINT: Tape the screwdriver tip before use. |

|

22. REMOVE WATER INLET HOUSING STUD BOLT

NOTICE:

If a water inlet housing stud bolt is deformed or its threads are damaged, replace it.

(a) Using an E5 "TORX" socket wrench, remove the 2 water inlet housing stud bolts.

23. REMOVE WATER INLET HOUSING

|

(a) Remove the 3 bolts, gasket and water inlet housing from the timing chain cover sub-assembly. |

|

24. REMOVE NO. 1 GENERATOR BRACKET

|

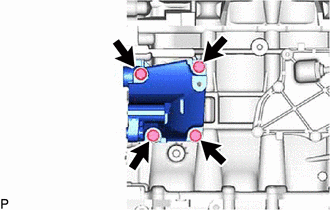

(a) Remove the 4 bolts and No. 1 generator bracket from the cylinder block sub-assembly. |

|

25. REMOVE CHAIN TENSIONER SLIPPER

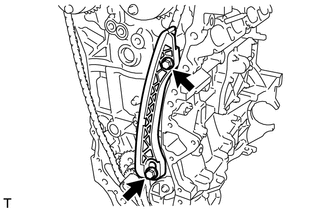

|

(a) Remove the chain tensioner slipper from the cylinder block sub-assembly. |

|

26. REMOVE NO. 1 CHAIN VIBRATION DAMPER

|

(a) Remove the 2 bolts and No. 1 chain vibration damper. |

|

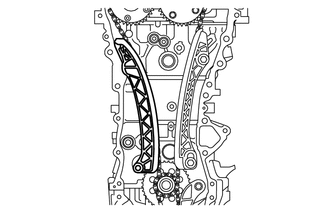

27. REMOVE CHAIN SUB-ASSEMBLY

|

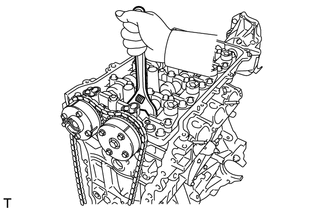

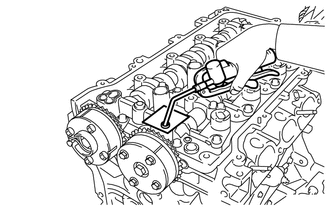

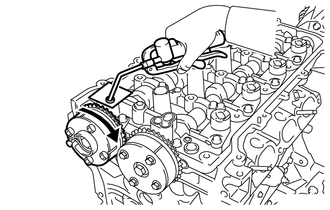

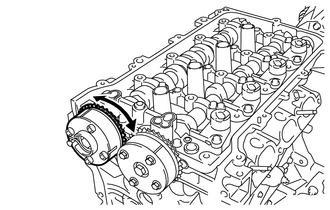

(a) Hold the hexagonal portion of the camshaft with a wrench and turn the camshaft timing gear assembly counterclockwise to loosen the chain sub-assembly between the camshaft timing exhaust gear assembly and camshaft timing gear assembly. |

|

(b) With the chain sub-assembly loosened, release the chain sub-assembly from the camshaft timing gear assembly and place it on the camshaft timing gear assembly.

HINT:

Be sure to release the chain sub-assembly from the sprocket completely.

(c) Turn the camshaft clockwise to return it to the original position and remove the chain sub-assembly.

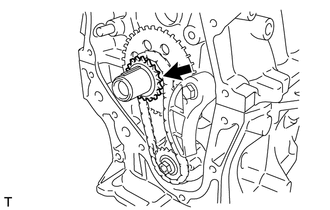

28. REMOVE CRANKSHAFT TIMING SPROCKET

|

(a) Remove the crankshaft timing sprocket from the crankshaft. |

|

29. REMOVE NO. 2 CHAIN SUB-ASSEMBLY

|

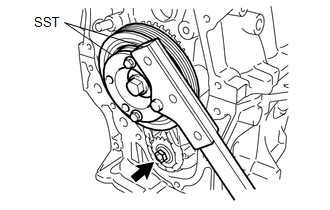

(a) Temporarily install the crankshaft pulley with the crankshaft pulley bolt. |

|

(b) Using SST, hold the crankshaft pulley. Then remove the oil pump drive shaft gear nut.

SST: 09213-54015

91551-00850

SST: 09330-00021

(c) Remove SST, the crankshaft pulley bolt and crankshaft pulley.

|

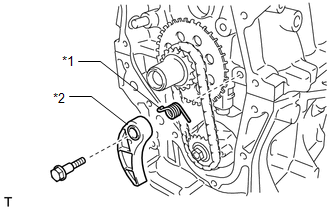

(d) Remove the bolt, chain tensioner plate and chain damper spring. |

|

|

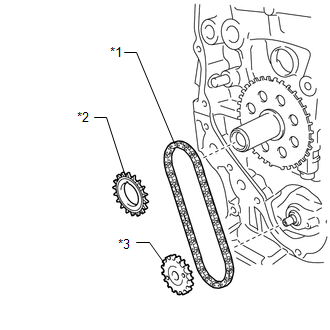

(e) Remove the oil pump drive gear, oil pump drive shaft gear and No. 2 chain sub-assembly. |

|

30. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE

|

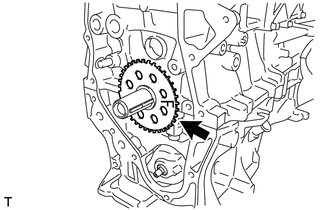

(a) Remove the No. 1 crankshaft position sensor plate. |

|

31. REMOVE CRANKSHAFT TIMING GEAR KEY

|

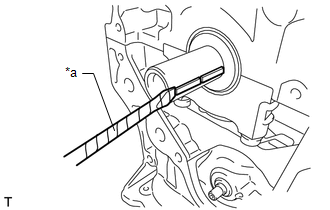

(a) Using a screwdriver with its tip wrapped with protective tape, remove the 2 crankshaft timing gear keys from the crankshaft. |

|

32. INSPECT CAMSHAFT TIMING GEAR ASSEMBLY

(a) Inspect the lock of the camshaft timing gear assembly.

|

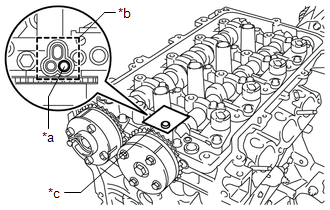

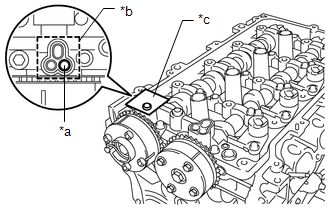

(b) After cleaning the VVT oil hole in the intake side of the No. 1 camshaft bearing cap, completely seal the oil hole with adhesive tape or equivalent as shown in the illustration to prevent air from leaking. NOTICE: Be sure to cover the oil hole completely because air leaks due to insufficient sealing will prevent the lock pin from being released. |

|

(c) Prick a hole in the tape covering the oil hole as shown in the illustration. (Procedure A)

|

(d) Apply approximately 150 kPa (1.5 kgf/cm2, 22 psi) of air pressure to the hole pricked in procedure A to release the lock pin. NOTICE:

|

|

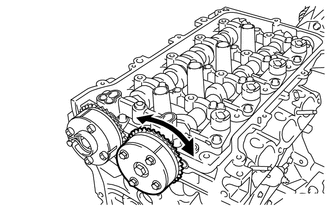

(e) Forcibly turn the camshaft timing gear assembly in the advance direction (counterclockwise).

HINT:

Depending on the air pressure applied, the camshaft timing gear assembly may turn in the advance direction without assistance.

|

(f) Turn the camshaft timing gear assembly within its movable range (26.5 to 28.5°) 2 or 3 times without turning it to the most retarded position. Make sure that the camshaft timing gear assembly turns smoothly. |

|

(g) Remove the adhesive tape from the No. 1 camshaft bearing cap.

33. INSPECT CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY

(a) Check the lock of the camshaft timing exhaust gear assembly.

|

(b) After cleaning the VVT oil hole in the exhaust side of the No. 1 camshaft bearing cap, completely seal the oil hole with adhesive tape or equivalent as shown in the illustration to prevent air from leaking. NOTICE: Be sure to cover the oil hole completely because air leaks due to insufficient sealing will prevent the lock pin from being released. |

|

(c) Prick a hole in the tape covering the oil hole as shown in the illustration. (Procedure A)

|

(d) Apply approximately 200 kPa (2.0 kgf/cm2, 29 psi) of air pressure to the hole pricked in procedure A to release the lock pin. NOTICE:

|

|

(e) Using a screwdriver with its tip wrapped with protective tape, forcibly turn the camshaft timing exhaust gear assembly in the retard direction (clockwise).

NOTICE:

- Be sure to keep the camshaft timing exhaust gear assembly in the retard direction using a screwdriver. If the gear is released, it will return to the most advanced position automatically due to the force from the spring.

- Do not damage the camshaft timing exhaust gear assembly.

|

(f) Using a screwdriver with its tip wrapped with protective tape, turn the camshaft timing exhaust gear assembly within its movable range (19 to 21°) 2 or 3 times without turning it to the most advanced position. Make sure that the camshaft timing exhaust gear assembly turns smoothly. |

|

(g) Remove the adhesive tape from the No. 1 camshaft bearing cap.

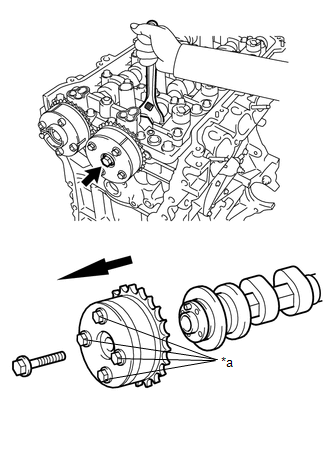

34. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY

|

(a) Remove the bolt while holding the hexagonal portion of the camshaft, and then remove the camshaft timing gear assembly. NOTICE:

|

|

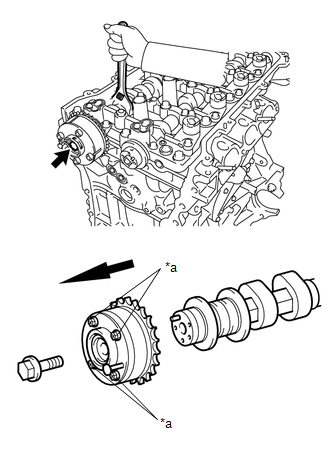

35. REMOVE CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY

|

(a) Remove the bolt while holding the hexagonal portion of the No. 2 camshaft, and then remove the camshaft timing exhaust gear assembly. NOTICE:

|

|

36. REMOVE VALVE ROCKER ARM LOST MOTION DAMPER SUB-ASSEMBLY

37. INSTALL VALVE ROCKER ARM LOST MOTION DAMPER SUB-ASSEMBLY

38. REMOVE CAMSHAFT HOUSING SUB-ASSEMBLY

39. REMOVE CONTINUOUSLY VARIABLE VALVE LIFT CONTROLLER ASSEMBLY

40. REMOVE NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

|

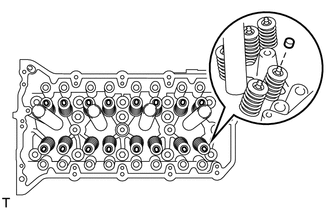

(a) Remove the 16 No. 1 valve rocker arm sub-assemblies from the cylinder head sub-assembly. HINT: Arrange the removed parts in such a way that they can be reinstalled to their original locations. |

|

41. REMOVE VALVE LASH ADJUSTER ASSEMBLY

|

(a) Remove the 16 valve lash adjuster assemblies from the cylinder head sub-assembly. HINT: Arrange the removed parts in such a way that they can be reinstalled to their original locations. |

|

42. REMOVE VALVE STEM CAP

|

(a) Remove the 16 valve stem caps. HINT: Arrange the removed parts in the correct order. |

|

43. REMOVE CYLINDER HEAD SUB-ASSEMBLY

44. REMOVE CYLINDER HEAD GASKET

45. REMOVE PCV VALVE (VENTILATION VALVE SUB-ASSEMBLY)

46. REMOVE OIL PAN DRAIN PLUG

|

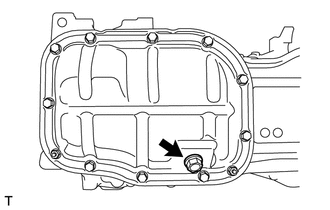

(a) Remove the oil pan drain plug and gasket from the No. 2 oil pan sub-assembly. |

|

47. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY

|

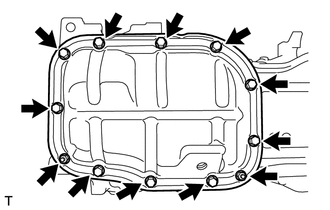

(a) Remove the 10 bolts and 2 nuts from the No. 2 oil pan sub-assembly. |

|

|

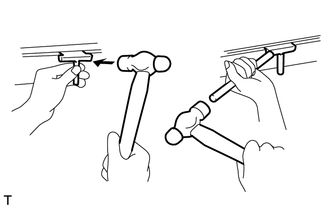

(b) Insert the blade of an oil pan seal cutter between the stiffening crankcase assembly and No. 2 oil pan sub-assembly. Cut through the applied sealer and remove the No. 2 oil pan sub-assembly. NOTICE:

|

|

48. REMOVE OIL PUMP ASSEMBLY

49. REMOVE STIFFENING CRANKCASE ASSEMBLY

|

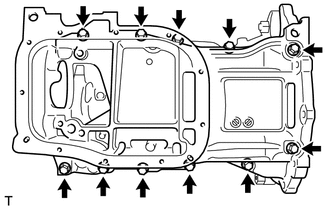

(a) Uniformly loosen and remove the 11 bolts from the stiffening crankcase assembly. |

|

|

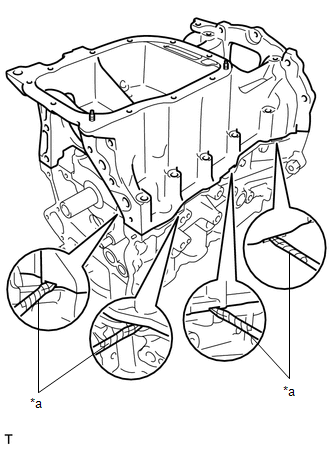

(b) Remove the stiffening crankcase assembly by prying between the stiffening crankcase assembly and cylinder block sub-assembly with a screwdriver with its tip wrapped with protective tape. NOTICE: Be careful not to damage the contact surfaces of the stiffening crankcase assembly and cylinder block sub-assembly. |

|

50. REMOVE NO. 1 TAPER SCREW PLUG

|

(a) Remove the No. 1 taper screw plug. |

|

51. REMOVE CAMSHAFT HOUSING STRAIGHT PIN

NOTICE:

It is not necessary to remove a camshaft housing straight pin unless it is being replaced.

52. REMOVE STIFFENING CRANKCASE RING PIN

NOTICE:

It is not necessary to remove a stiffening crankcase ring pin unless it is being replaced.

53. REMOVE STUD BOLT

NOTICE:

If a stud bolt is deformed or its threads are damaged, replace it.

54. REMOVE REAR ENGINE OIL SEAL

|

|

|

![2020 - 2023 MY Corolla [01/2019 - 11/2022]; MAINTENANCE: 2ZR-FAE SPARK PLUG: REMOVAL+](/t3Portal/stylegraphics/info.gif)